These fasteners are characterized by a series of rings around their shank, providing significantly enhanced holding power compared to smooth-shanked counterparts. Commonly employed in woodworking and construction, they are particularly effective when securing materials that are prone to movement or separation. For example, their use in subflooring or siding applications ensures a robust and lasting connection, minimizing the risk of loosening over time.

The enhanced grip these fasteners offer stems from the way the wood fibers interlock with the rings as the nail is driven. This mechanical bond resists withdrawal forces far more effectively than friction alone. This feature is especially valuable in applications subject to vibration, temperature fluctuations, or moisture changes, where a secure and durable hold is paramount. Their history is rooted in the need for stronger, more reliable fastening solutions in demanding environments, leading to their widespread adoption across diverse industries.

Understanding the properties and applications of these specialized fasteners is essential for achieving optimal results in various projects. Subsequent sections will delve into their specific types, suitable applications, proper installation techniques, and factors to consider when selecting the appropriate size and material for a given task. These detailed insights will provide a comprehensive guide to leveraging their benefits effectively.

Practical Considerations for Utilizing Specialized Fasteners

The following points offer guidance on selecting and employing fasteners with enhanced holding capabilities, ensuring optimal performance and longevity in various applications.

Tip 1: Material Selection: Choose fasteners crafted from materials compatible with the surrounding environment and the materials being joined. Corrosion-resistant options, such as stainless steel, are recommended for outdoor or moisture-prone applications to prevent degradation and maintain structural integrity.

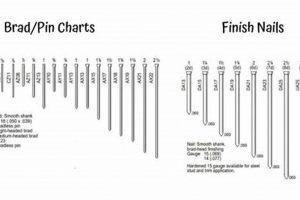

Tip 2: Shank Length Calculation: Accurately determine the appropriate fastener length to ensure sufficient penetration into the receiving material. A general rule is to penetrate at least two-thirds of the total fastener length into the substrate for a secure hold. Inadequate length compromises holding power.

Tip 3: Pre-Drilling Techniques: In dense hardwoods or when working near edges, pre-drilling pilot holes is advisable. This minimizes the risk of splitting the wood and facilitates easier, more accurate fastener insertion.

Tip 4: Proper Driving Technique: Employ consistent and controlled driving force to avoid bending or damaging the fastener. Overdriving can crush the surrounding material, reducing its ability to grip the shank effectively. Consistent depth setting on nail guns is essential.

Tip 5: Avoid Over-Spacing: Correct spacing between fasteners is crucial for distributing load and preventing concentrated stress points. Consult relevant building codes or engineering guidelines to determine appropriate spacing based on the application and materials involved.

Tip 6: Inspect for Damage: Prior to installation, meticulously inspect each fastener for defects, such as bent shanks or damaged heads. Defective fasteners should be discarded, as they can compromise the integrity of the connection.

Tip 7: Consider Withdrawal Resistance Needs: If the application is subjected to significant pull-out forces, select fasteners with deeper or more aggressive ring profiles. This will maximize resistance to withdrawal and ensure a durable, long-lasting connection.

Proper fastener selection and installation techniques are essential for maximizing the benefits of these specialized fasteners. Adhering to these guidelines will contribute to increased structural integrity and reduced maintenance requirements.

The following sections will address frequently asked questions regarding these fasteners, providing further clarity on their specific attributes and applications.

1. Enhanced Holding Power

The defining characteristic of ring shank finish nails is their superior holding power, directly attributable to the series of rings encircling the shank. This design facilitates a mechanical interlock with the wood fibers, creating a significantly stronger bond compared to smooth-shanked nails that rely solely on friction. The rings effectively resist withdrawal forces, preventing the nail from loosening over time. The cause of this increased retention is the deformation of wood fibers into the annular grooves as the nail is driven. The effect is a joint that can withstand greater stress and strain.

Enhanced holding power is an essential component of ring shank finish nails because it addresses the common problem of nail pull-out, particularly in applications subject to vibration, temperature fluctuations, or cyclical loading. For example, when attaching trim to drywall, the drywall’s composition offers limited resistance to smooth nails. Ring shank finish nails, however, grip the drywall more effectively, providing a more secure and lasting hold. Similarly, in flooring applications, ring shank nails help to prevent squeaking by minimizing movement between the subfloor and finished floor. This is especially important when the subfloor is subjected to moisture, which could cause the board to buckle and lift the fastener.

In summary, the enhanced holding power provided by ring shank finish nails is not merely a design feature; it is a functional requirement for many construction and woodworking applications. By understanding the mechanism behind this increased retention and applying the nails appropriately, professionals and DIY enthusiasts can ensure more durable, reliable, and aesthetically pleasing results. While challenges exist in ensuring consistent ring quality and proper driving techniques, the benefits of enhanced holding power make these fasteners a valuable choice for projects where long-term performance is critical. The broader theme connects to the selection of the correct fastener for the intended application, which can have a significant impact on the integrity and lifespan of the structure.

2. Reduced Wood Splitting

The occurrence of wood splitting during fastening processes can compromise the structural integrity and aesthetic appeal of finished projects. The design and application of ring shank finish nails offer a mitigation strategy to this common issue, warranting a detailed examination of the contributing factors and preventative measures.

- Fine Shank Diameter

The relatively slender shank diameter of finish nails, including those with ring shanks, minimizes the displacement of wood fibers during insertion. This reduced displacement translates to a lower risk of radial cracking, particularly in delicate trim work or near the edges of wooden boards. A smaller diameter necessitates less force for penetration, thereby reducing the outward pressure on the wood.

- Blunt Tip Geometry

While a sharp tip is often associated with easier penetration, it can also act as a wedge, exacerbating splitting. Finish nails generally feature a slightly blunted tip, which compresses rather than cleaves the wood fibers. This compressive action, in conjunction with the ring shank’s holding power, contributes to a more secure and less destructive fastening method.

- Precise Driving Depth Control

Overdriving any nail, regardless of shank type, increases the likelihood of splitting. The use of pneumatic nailers with adjustable depth settings allows for consistent and controlled nail placement, preventing excessive force that could lead to cracking. Careful depth adjustment ensures the nail head sits flush with the surface without damaging the surrounding wood.

- Wood Species Considerations

Different wood species exhibit varying degrees of susceptibility to splitting. Hardwoods with tight grain patterns are generally more resistant, while softwoods and brittle species require greater care. When working with prone-to-splitting materials, pre-drilling pilot holes is a recommended practice, regardless of the nail type being used. This preemptive measure creates a pathway for the nail shank, minimizing fiber disruption.

The combined effect of a fine shank, blunt tip, controlled driving depth, and consideration for wood species contributes to the reduced splitting characteristics associated with ring shank finish nails. While not a complete elimination of the risk, these factors provide a significant advantage over alternative fastening methods, particularly in applications demanding precision and a high-quality finish. Proper technique and an understanding of the material properties are paramount to achieving optimal results.

3. Versatile Applications

The adaptability of ring shank finish nails across diverse applications stems from their balanced properties of secure holding power and minimal visual impact. This combination renders them suitable for projects ranging from delicate interior trim work to more demanding exterior applications. The enhanced grip provided by the ringed shank ensures a lasting connection, while the relatively small head size allows for a seamless finish, often concealed with paint or filler. For example, these fasteners are frequently employed in the installation of baseboards, crown molding, and door casings, where a strong and inconspicuous hold is paramount. This capacity to blend functionality with aesthetics is a primary driver of their widespread usage. The practical significance lies in the ability to achieve robust and visually pleasing results across numerous project types.

Beyond interior trim, ring shank finish nails find application in exterior projects such as siding and fencing. While larger, more specialized fasteners are available for these tasks, the finish nail variant offers a viable option when a less obtrusive appearance is desired. Their use in siding installation, for instance, allows for a secure attachment of the material to the framing while minimizing the visual distraction caused by larger nail heads. Similarly, in fence construction, these fasteners can be used to attach decorative elements or secure smaller components, providing a reliable hold without compromising the overall aesthetic. Furthermore, the availability of corrosion-resistant coatings expands their applicability to moisture-prone environments, ensuring longevity and preventing premature failure. These are useful in many construction areas.

In conclusion, the versatility of ring shank finish nails is a direct consequence of their design, balancing secure holding with a refined appearance. This attribute facilitates their adoption across a spectrum of applications, from interior trim and cabinetry to exterior siding and fencing. While not always the optimal choice for every project, their adaptability makes them a valuable addition to any toolbox. Understanding the strengths and limitations of these fasteners allows for informed decision-making and the achievement of desirable results in a variety of woodworking and construction endeavors.

4. Material Compatibility

The selection of ring shank finish nails necessitates careful consideration of material compatibility to ensure both structural integrity and aesthetic preservation of the fastened materials. The adverse effects of galvanic corrosion, resulting from the interaction of dissimilar metals in the presence of an electrolyte (such as moisture), can compromise the longevity of the connection. The failure to account for material compatibility introduces the potential for premature degradation of the nail, the surrounding wood, or both. For instance, using uncoated steel nails in conjunction with redwood or cedar, which contain natural acids, will accelerate corrosion of the steel, leading to staining and eventual weakening of the joint. This phenomenon underscores the importance of matching the fastener material to the chemical properties of the materials being joined.

Practical applications of material compatibility principles involve choosing appropriate coatings or alloys for ring shank finish nails. Stainless steel nails offer superior corrosion resistance and are suitable for use with treated lumber, coastal environments, and outdoor projects. Hot-dipped galvanized nails provide a cost-effective alternative for many exterior applications, offering a protective zinc coating that inhibits rust formation. Copper nails, while more expensive, are often preferred for aesthetic reasons and compatibility with certain wood types, such as mahogany. The proper selection mitigates the risk of staining, wood discoloration, and structural failure, ensuring a lasting and visually appealing finish. The practical example is selecting stainless steel ring shank nails for installing siding made from a composite material that may contain corrosive additives. The material compatibility is important to maintain a beautiful building.

In conclusion, material compatibility is a critical component of successful ring shank finish nail usage. The interplay between fastener material, wood type, and environmental conditions dictates the long-term performance of the connection. Challenges arise in accurately assessing potential corrosive interactions, particularly with newer composite materials or treated lumber. However, adherence to established guidelines and consultation with material suppliers can minimize the risks. Understanding these principles enables informed decision-making, contributing to the durability and visual quality of finished projects. The broader theme encompasses the responsible and sustainable use of construction materials, emphasizing the importance of considering the entire lifecycle of a project.

5. Proper Installation

The efficacy of ring shank finish nails is inextricably linked to adherence to proper installation techniques. The design, incorporating annular rings along the shank, provides enhanced holding power, but this advantage is contingent upon correct application. Improper installation, such as overdriving or underdriving, negates the intended benefits and can lead to project failure. Overdriving, for example, can crush the surrounding wood fibers, diminishing the nail’s grip and potentially causing surface damage. Conversely, underdriving leaves the nail head protruding, compromising aesthetics and presenting a safety hazard. The intended function of these fasteners, therefore, is fundamentally dependent on precise and deliberate installation procedures. A practical example is the installation of fine trim; a nail driven at an angle or at incorrect depth will disrupt the alignment and necessitate rework, wasting time and resources.

Further compounding the significance of proper installation is the material being fastened. Hardwoods require a different approach than softwoods. Pre-drilling pilot holes, for instance, is often necessary when working with dense hardwoods to prevent bending the nail or splitting the wood. The absence of this step can result in a compromised connection and a reduction in the overall structural integrity of the assembly. In exterior applications, ensuring the nail is driven straight and flush with the surface is critical for preventing water intrusion, which can lead to corrosion and premature failure. Similarly, using a nail gun with an adjustable depth setting and understanding the substrate materials are crucial for consistent and reliable results. A nail’s performance characteristics are fully realized only when paired with appropriate and precise installation methods.

In summary, the potential benefits of ring shank finish nails are contingent upon meticulous installation practices. Challenges arise from variations in wood density, the complexity of fastener selection, and the requirement for specialized tools like nail guns. However, understanding these challenges and implementing best practices such as pre-drilling, using appropriate depth settings, and selecting the correct nail length are essential for achieving optimal performance and longevity. Ignoring these factors renders the inherent advantages of ring shank finish nails moot. The broader theme underscores the importance of craftsmanship and precision in construction and woodworking, where attention to detail significantly impacts the overall quality and durability of the finished product.

6. Longevity

The extended lifespan of structures and components fastened with ring shank finish nails is a direct consequence of their enhanced holding power and resistance to withdrawal. The annular rings, by mechanically interlocking with wood fibers, provide a bond that withstands cyclical loading, vibration, and environmental fluctuations more effectively than smooth shank nails. This inherent resistance to loosening translates directly into reduced maintenance requirements and prolonged structural integrity. For example, exterior trim fastened with these nails is less likely to detach due to wind or temperature changes, thereby mitigating the need for frequent repairs or replacements. The selection of these fasteners inherently reflects a commitment to long-term performance and value.

The practical significance of this longevity extends beyond simple cost savings. Consider the implications for safety in elevated structures, such as decks or balconies. A compromised railing system, due to nail failure, poses a significant risk. Utilizing ring shank finish nails in these critical connections provides an added margin of safety by ensuring a more robust and durable attachment. Furthermore, the reduced need for repairs minimizes disruption and inconvenience for occupants. The initial investment in these specialized fasteners yields long-term benefits in terms of safety, reduced maintenance costs, and enhanced structural reliability. As an example, the preservation of historical buildings often relies on these nails to ensure minimal damage of its precious construction.

In conclusion, the relationship between ring shank finish nails and longevity is a critical consideration for any project where long-term performance is paramount. While challenges exist in quantifying the precise lifespan extension offered by these fasteners, the underlying principles of enhanced holding power and resistance to withdrawal provide a clear indication of their superior durability. The choice to employ ring shank finish nails underscores a commitment to quality and sustainability, reducing the need for frequent replacements and minimizing the environmental impact associated with construction and maintenance activities. The broader theme reflects a growing emphasis on durability and life-cycle assessment in the construction industry.

Frequently Asked Questions About Ring Shank Finish Nails

This section addresses common inquiries and misconceptions surrounding the application and performance of ring shank finish nails, providing concise and authoritative answers.

Question 1: Are ring shank finish nails suitable for all types of wood?

Ring shank finish nails exhibit broad compatibility with various wood species. However, the density and splitting characteristics of the wood necessitate careful consideration. Hardwoods may require pre-drilling to prevent bending or splitting. Softwoods generally accept these nails without pre-drilling, provided proper driving techniques are employed.

Question 2: Do ring shank finish nails leave visible marks on the surface?

Finish nails, by design, possess relatively small heads, minimizing their visibility. When properly installed, the nail head can be set flush with or slightly below the surface and concealed with wood filler or paint. The visibility is further reduced when selecting coated or colored nails that match the surrounding material.

Question 3: Can ring shank finish nails be used in exterior applications?

The suitability of ring shank finish nails for exterior applications hinges on material selection. Standard steel nails are prone to corrosion and are not recommended for prolonged exposure to moisture. Stainless steel or hot-dipped galvanized nails provide superior corrosion resistance and are appropriate for exterior use, particularly in coastal or high-humidity environments.

Question 4: What is the difference between ring shank and spiral shank nails?

Ring shank nails feature a series of annular rings along the shank, providing enhanced holding power through mechanical interlock. Spiral shank nails, conversely, possess a twisted shank that creates a screw-like action upon insertion. While both offer improved grip compared to smooth shank nails, ring shank nails are generally preferred for applications where withdrawal resistance is paramount, while spiral shanks are suitable for materials prone to movement.

Question 5: Are ring shank finish nails more difficult to remove than smooth shank nails?

The enhanced holding power of ring shank finish nails inherently makes them more resistant to removal. Attempting to extract these nails without proper tools or techniques can damage the surrounding material. Specialized nail pullers or nippers are recommended for minimizing damage during removal.

Question 6: Do ring shank finish nails require specialized tools for installation?

While manual installation is possible, the use of pneumatic nail guns is highly recommended for consistent depth control and efficient installation. The selection of a nail gun with adjustable depth settings is crucial for preventing overdriving or underdriving, ensuring optimal performance and minimizing surface damage.

In summary, ring shank finish nails offer a reliable fastening solution when properly selected and installed. Understanding their specific attributes and limitations is essential for achieving durable and aesthetically pleasing results.

The subsequent section will explore alternative fastening methods and their respective advantages and disadvantages.

Ring Shank Finish Nails

This exposition has illuminated the characteristics, advantages, and practical considerations surrounding ring shank finish nails. The enhanced holding power, arising from the annular rings, provides a superior grip compared to traditional smooth shank nails, mitigating the risk of loosening over time. Reduced wood splitting, versatile applications, and the critical importance of material compatibility have been examined, alongside the necessity for proper installation techniques to maximize fastener efficacy. The discussion has further addressed common inquiries, seeking to dispel misconceptions and foster informed decision-making in fastener selection.

The informed application of ring shank finish nails ensures more robust and durable connections across a spectrum of woodworking and construction endeavors. Future advancements may focus on enhanced corrosion resistance, optimized shank designs, and improved installation technologies. A continued commitment to understanding and applying best practices will enable professionals and DIY enthusiasts to leverage these fasteners effectively, contributing to projects that stand the test of time.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)