This power tool is a cordless fastening device utilized in woodworking and construction. It is designed for driving finish nails into various materials, typically used for detailed work such as trim, molding, and cabinetry. An example of its application includes securing baseboards to walls without the need for a compressor or hoses.

The significance of this tool lies in its portability and convenience. Its cordless operation eliminates the restrictions of traditional pneumatic nailers, improving maneuverability on job sites. Historically, pneumatic nailers were the standard, requiring bulky compressors. This model represents a shift toward increased user independence and efficiency, benefiting contractors and DIY enthusiasts alike by reducing setup time and increasing project completion speed.

The following sections will delve into specific aspects, including its features, performance characteristics, and practical applications in different scenarios.

Operation and Maintenance Tips

The following guidelines are designed to optimize the performance and extend the lifespan of the tool.

Tip 1: Battery Maintenance: Ensure batteries are fully charged before use. Regular charging cycles prevent diminished capacity and prolong battery life. Store batteries in a cool, dry place when not in use to avoid degradation.

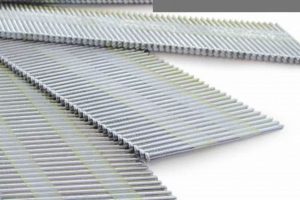

Tip 2: Nail Selection: Utilize the correct gauge and length of finish nails specified for the tool. Incorrect nail selection can cause jams, misfires, or damage to the tool itself.

Tip 3: Depth Adjustment: Adjust the depth of drive according to the material’s density. Test the nailer on a scrap piece to prevent overdriving or underdriving nails. A flush finish indicates proper depth setting.

Tip 4: Regular Cleaning: Periodically clean the nailer’s nose and magazine. Remove any debris, such as nail fragments or sawdust, to ensure smooth operation and prevent jams.

Tip 5: Proper Storage: Store the nailer in its case or a dry environment when not in use. This protects it from dust, moisture, and physical damage, extending its operational life.

Tip 6: Contact Actuation Mode Awareness: Understand the difference between sequential and contact actuation modes. Sequential mode enhances precision, while contact actuation increases speed for repetitive tasks. Choosing the correct mode optimizes performance for specific applications.

Tip 7: Inspect Contact Tip: Regularly inspect the contact tip for wear or damage. A worn or damaged contact tip can affect nail placement and potentially damage the work surface. Replace as needed.

Adhering to these recommendations promotes efficient operation, minimizes downtime, and contributes to the long-term reliability of the nailer.

The subsequent section will address troubleshooting common issues that may arise during usage.

1. Cordless Operation

Cordless operation is a defining characteristic of the Ridgid 18V finish nailer, fundamentally altering its usability and application scope compared to traditional pneumatic models. The absence of air hoses and compressors directly translates to enhanced portability. This intrinsic mobility permits operation in locations where access to compressed air is either unavailable or impractical. Construction sites with limited power access, remote renovation projects, and tasks requiring frequent relocation benefit significantly from this design. The effect of cordless operation is a streamlined workflow, minimizing setup time and eliminating the physical constraints imposed by tethered systems.

The importance of cordless operation extends beyond mere convenience. It contributes to increased safety on job sites by reducing tripping hazards associated with air hoses. It also simplifies transportation and storage. An example of its practical significance is its use in punch-list work where the need to drive only a few nails doesn’t warrant the setup of a full pneumatic system. Cabinet installers find the cordless design particularly useful for on-site adjustments and securing trim without the bulk and noise of a compressor.

In conclusion, the implementation of cordless technology in the Ridgid 18V finish nailer is not merely a feature, but a core design principle that fundamentally enhances its practicality and utility. While battery life and charging time present potential limitations, the benefits of increased mobility and reduced setup time significantly outweigh these challenges in many application scenarios. This cordless design represents a crucial step towards more efficient and versatile power tool technology, aligning with the demands of modern construction and woodworking projects.

2. Nail Capacity

Nail capacity, referring to the maximum number of nails the magazine of the device can hold, is a critical specification directly influencing the operational efficiency of the Ridgid 18V finish nailer. It affects workflow continuity and the frequency with which the user must interrupt work to reload.

- Magazine Size and Workflow

The magazine’s capacity directly dictates how often the operator must pause to reload nails. A larger magazine minimizes interruptions, particularly in applications involving extensive trim work or repetitive fastening tasks. Conversely, a smaller capacity may necessitate more frequent reloading, potentially reducing overall productivity on larger projects.

- Nail Strip Configuration

The configuration of nail strips within the magazine also impacts capacity. Some magazines accommodate longer strips, while others are limited to shorter segments. The ability to use longer strips translates to fewer reloading cycles. Additionally, the ease with which nail strips can be loaded influences downtime. A user-friendly design can expedite the reloading process, mitigating the impact of capacity limitations.

- Gauge and Nail Length Considerations

The gauge and length of the nails used also play a role in determining the effective nail capacity. While the magazine might have a fixed volume, the number of nails it can hold varies depending on the size of each individual nail. Shorter, smaller-gauge nails will allow for a higher nail count compared to longer, larger-gauge fasteners. The specific application dictates the appropriate nail size and, consequently, the achievable magazine capacity in practice.

- Material and Build Quality

The magazine’s construction directly influences its reliability and longevity. A robust design, resistant to bending or deformation, ensures consistent nail feeding and prevents jams. High-quality materials contribute to the overall durability of the tool, including its ability to withstand the repetitive stress of loading and firing nails over an extended period.

Therefore, nail capacity is not merely a numerical specification; it represents a key factor influencing the practical usability and efficiency of the Ridgid 18V finish nailer in various applications. Understanding the interplay between magazine size, nail configuration, gauge, and material quality allows users to optimize their workflow and choose the most appropriate tool for a given task.

3. Depth Adjustment

Depth adjustment is a critical feature integrated into the Ridgid 18V finish nailer, influencing the precision and quality of fastening. The ability to control the depth to which a nail is driven is paramount for achieving consistent, professional results in various materials and applications. Without a reliable depth adjustment mechanism, nails may be overdriven, damaging the surface, or underdriven, failing to provide adequate holding power. The depth adjustment feature typically consists of a dial or knob that allows the user to modify the driving force of the tool, accommodating materials of varying density and thickness.

The practical significance of depth adjustment is evident in applications such as installing delicate trim or working with softwoods. Overdriving nails into soft materials can leave unsightly marks and compromise the structural integrity of the wood. Conversely, when working with hardwoods or denser materials, insufficient driving force can leave nails protruding, requiring manual setting or resulting in weak joints. A well-calibrated depth adjustment system enables the user to achieve a flush, secure finish, enhancing both the aesthetics and the functionality of the work. For instance, when installing crown molding, the depth must be precisely set to avoid penetrating too deeply into the drywall or furring strips, which could cause damage or splitting. Similarly, when attaching thin veneers or decorative panels, careful depth adjustment prevents the nails from marring the surface.

In summary, the depth adjustment feature on the Ridgid 18V finish nailer is not a mere convenience but a necessity for achieving optimal fastening results across a range of materials and applications. It directly impacts the quality, durability, and aesthetic appeal of the finished product. Understanding how to properly adjust and utilize this feature is essential for maximizing the tool’s potential and ensuring professional-grade workmanship. Failure to properly adjust the depth can lead to rework, material waste, and compromised structural integrity, underscoring the importance of this seemingly simple, yet vital, component.

4. Brushless Motor

The integration of a brushless motor into the Ridgid 18V finish nailer represents a significant technological advancement directly impacting tool performance and longevity. Unlike traditional brushed motors, a brushless motor eliminates the friction-generating carbon brushes, leading to several key advantages. One primary effect is increased motor efficiency. With reduced internal friction, the motor converts a higher percentage of electrical energy into mechanical energy, resulting in extended battery runtime per charge. This becomes particularly crucial during prolonged use on job sites where access to charging facilities may be limited.

The elimination of brushes also mitigates the need for periodic maintenance and replacement, a common requirement with brushed motors. The absence of brush wear significantly extends the motor’s lifespan, contributing to the overall durability and reliability of the nailer. For example, a contractor relying on the nailer for daily tasks can expect a more consistent and uninterrupted operation over time, reducing downtime and associated costs. Furthermore, brushless motors typically generate less heat during operation, decreasing the risk of overheating and further enhancing long-term reliability. In practical applications, this translates to a more robust tool capable of withstanding demanding work conditions and providing a consistent level of performance.

In conclusion, the incorporation of a brushless motor in the Ridgid 18V finish nailer offers clear benefits in terms of efficiency, durability, and reduced maintenance. This design choice directly contributes to enhanced productivity and cost-effectiveness for users, making it a key factor to consider when evaluating the overall value and performance of the tool. While the initial cost of a brushless motor may be slightly higher, the long-term advantages in operational efficiency and reduced maintenance often outweigh the initial investment. The trend towards brushless motor technology reflects an industry-wide focus on providing more durable, efficient, and user-friendly power tools.

5. AirStrike Technology

AirStrike Technology represents a pneumatic innovation integrated into the Ridgid 18V finish nailer, designed to eliminate the necessity of external compressors and air hoses. This integration fundamentally alters the tool’s portability and operational convenience, aligning with the demands of modern job sites.

- Self-Contained Pneumatic System

AirStrike Technology employs a self-contained, compressed air cylinder within the tool body. Upon activation, this cylinder releases a burst of compressed air to drive the nail. This eliminates the need for external air sources, enhancing mobility and reducing setup time. For instance, a trim carpenter can efficiently move between rooms without dragging hoses or needing to reposition a compressor.

- Reduced Noise and Vibration

Compared to traditional pneumatic systems, AirStrike Technology generally produces less noise and vibration. The contained nature of the air release minimizes the sharp, percussive sounds associated with compressor-driven tools. This contributes to a more comfortable working environment, particularly during extended use. This also reduces the amount of vibration felt by the user, allowing greater precision for detailed projects.

- Power and Performance Considerations

While providing cordless convenience, AirStrike Technology must balance power output with battery life. The tool is engineered to deliver sufficient driving force for finish nails across various materials, but continuous operation at maximum power may impact battery duration. The engineering balances efficiency with power for each cycle, so a quality battery is a must.

- Maintenance and Reliability

The complexity of the AirStrike system necessitates adherence to recommended maintenance procedures. Regular cleaning and inspection of the internal components are crucial for ensuring consistent performance and preventing malfunctions. Furthermore, understanding the tool’s limitations and avoiding excessive strain can contribute to its longevity. The cylinders of the system also must be inspected regularly for optimal performance.

AirStrike Technology represents a deliberate design choice within the Ridgid 18V finish nailer framework, prioritizing portability and ease of use. Its integration requires a careful balance of power, efficiency, and maintenance considerations, reflecting the evolving demands of the power tool industry.

6. Sequential/Contact Modes

Sequential and contact actuation modes represent distinct operational settings on the Ridgid 18V finish nailer, each influencing the speed and precision of nail deployment. Sequential mode mandates that the contact tip is depressed against the work surface before the trigger is pulled. This operational sequence enforces a deliberate, single-nail firing action. In contrast, contact actuation, also known as bump-fire, allows the nailer to fire a nail each time the contact tip is depressed against the work surface while the trigger is continuously held. The choice between these modes directly impacts the efficiency and safety of the task at hand. For example, installing intricate trim work, where precision and careful placement are paramount, benefits from sequential mode’s controlled firing action. The user can accurately position the nailer and ensure proper alignment before firing, minimizing the risk of misfires or damage to delicate materials.

Contact actuation, conversely, is advantageous for rapid, repetitive fastening tasks, such as sheathing or fencing. The continuous firing capability significantly accelerates the process, allowing for quick coverage of large areas. However, this increased speed comes with a greater risk of accidental firing if the user is not experienced or attentive. The selection of the appropriate mode hinges on a careful assessment of the project requirements, user skill level, and safety considerations. Incorrect mode selection can lead to reduced efficiency, compromised quality, and increased potential for injury. A practical example is framing, where a high volume of nails must be driven quickly. Here, contact actuation is a time-saver, but requires strict adherence to safety protocols to prevent unintended nail discharge.

In summary, the sequential and contact actuation modes are integral components of the Ridgid 18V finish nailer, offering versatility and adaptability to diverse fastening applications. The choice between these modes requires a thorough understanding of their operational characteristics and the specific demands of the task at hand. Mastering this selection process is crucial for maximizing productivity, ensuring quality workmanship, and maintaining a safe working environment. Improper usage not only reduces efficiency but also increases the probability of workplace accidents, highlighting the critical significance of comprehending these actuation modes.

7. 15 Gauge

The term “15 Gauge” specifies the diameter of the nails compatible with the Ridgid 18V finish nailer, directly influencing its application range and the resulting finish quality. Understanding the implications of this gauge is crucial for optimizing tool performance and achieving desired outcomes in various woodworking and construction projects.

- Nail Size and Holding Power

A 15-gauge nail represents a balance between holding strength and minimal visibility. Its diameter provides sufficient grip for securing trim, molding, and cabinetry while leaving a relatively small hole. This contrasts with larger gauges, which offer greater holding power but create more noticeable entry points, and smaller gauges, which are less visible but may lack the necessary strength for certain applications. The Ridgid 18V finish nailer, designed for 15-gauge nails, is therefore suited for tasks where a balance between secure fastening and aesthetic considerations is essential. An example is securing baseboards, where a strong hold is needed, but a large nail hole would be undesirable.

- Application Versatility

The 15-gauge specification dictates the types of projects for which the Ridgid 18V finish nailer is best suited. It excels in applications requiring a finer finish compared to heavier-duty framing nailers. This includes installing door and window casings, assembling furniture, and attaching decorative elements. While not ideal for structural applications demanding maximum holding strength, the 15-gauge nailer offers versatility within the realm of finish work. A practical scenario would be attaching crown molding to walls, where precise placement and minimal surface damage are priorities.

- Nail Availability and Cost

The prevalence of 15-gauge nails influences their availability and cost. Due to their common usage in finish carpentry, 15-gauge nails are readily available at most hardware stores and lumberyards. This widespread availability contributes to competitive pricing, making them a cost-effective choice for many projects. The Ridgid 18V finish nailer’s compatibility with this widely available nail gauge simplifies supply acquisition and reduces project expenses. The cost of 15-gauge nails is generally less than that of specialized fasteners, contributing to the overall economy of using the tool.

- Tool Design Considerations

The 15-gauge nail specification informs the design and functionality of the Ridgid 18V finish nailer. The magazine, firing mechanism, and depth adjustment system are all calibrated to accommodate 15-gauge nails. This integration ensures consistent nail feeding, reliable firing, and precise depth control, all essential for achieving professional-quality results. The nailer is engineered to handle the specific dimensions and characteristics of 15-gauge nails, maximizing its performance and minimizing the risk of jams or misfires. The compatibility is such that only 15-gauge nails will work effectively on the product.

In summary, the “15 Gauge” designation is not merely a specification but a defining characteristic that shapes the application, performance, and overall value of the Ridgid 18V finish nailer. Its implications extend from holding power and versatility to nail availability and tool design, underscoring its importance in achieving desired results in a variety of woodworking and construction projects. The choice to use this gauge is a conscious decision aligning with specific project requirements and aesthetic considerations, making it a key element in the tool’s overall utility.

Frequently Asked Questions Regarding the Ridgid 18V Finish Nailer

This section addresses common inquiries pertaining to the operation, maintenance, and capabilities of the Ridgid 18V finish nailer. The following information is intended to provide clarity and guidance for users.

Question 1: What is the appropriate air pressure setting for optimal performance of the Ridgid 18V finish nailer?

The Ridgid 18V finish nailer does not require an external air compressor, as it utilizes AirStrike technology. Therefore, there is no need to adjust or monitor air pressure settings.

Question 2: What is the recommended procedure for clearing a jammed nail from the Ridgid 18V finish nailer?

First, disconnect the battery. Then, using the tool’s jam release mechanism (typically a lever or latch), carefully open the nail magazine and remove any fragmented or misaligned nails. Ensure the nail path is clear before reassembling the magazine and reconnecting the battery.

Question 3: What type of nails are compatible with the Ridgid 18V finish nailer?

The Ridgid 18V finish nailer is designed to accept 15-gauge finish nails within a specific length range, typically from 1-1/4 inches to 2-1/2 inches. Refer to the tool’s manual for precise specifications.

Question 4: How does the depth adjustment feature function, and how does it impact the finished result?

The depth adjustment mechanism, usually a dial or knob located on the tool, regulates the driving force of the nailer. Adjusting this setting allows the user to control the depth to which the nail is driven into the material, preventing overdriving or underdriving, and ensuring a flush finish.

Question 5: What is the expected battery life of the Ridgid 18V finish nailer under typical operating conditions?

Battery life is contingent upon factors such as the type of battery used, the material being fastened, and the frequency of use. However, a fully charged Ridgid 18V battery should typically allow for driving several hundred nails before requiring a recharge. Exact figures are best obtained from the battery specifications.

Question 6: What maintenance procedures are recommended to ensure the longevity and optimal performance of the Ridgid 18V finish nailer?

Regularly clean the nailer’s nose and magazine to remove debris. Inspect the contact tip for wear or damage. Store the tool in a dry environment when not in use. Refer to the owner’s manual for detailed maintenance guidelines.

These FAQs provide a foundation for understanding key aspects of the Ridgid 18V finish nailer. Users should consult the owner’s manual for more comprehensive information and safety guidelines.

The next section will address common troubleshooting scenarios encountered while operating the tool.

Concluding Remarks on the Ridgid 18V Finish Nailer

This exploration has covered various facets of the ridgid 18v finish nailer, from its operational characteristics and maintenance considerations to its technological features like AirStrike and the brushless motor. Each element contributes to the tool’s overall utility and performance within the realm of finish carpentry. Key factors such as nail capacity, depth adjustment, and actuation modes directly influence the quality and efficiency of fastening tasks.

Understanding the nuanced interplay of these components is crucial for maximizing the potential of the ridgid 18v finish nailer. Continued adherence to recommended operating procedures and maintenance practices will ensure its long-term reliability and contribute to professional-grade workmanship. The tool represents an investment in efficiency and precision; responsible utilization will yield commensurate returns in project quality and completion speed.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)