A specialized pneumatic tool designed to drive fasteners into wood trim, this device is frequently employed in the installation of skirting boards. It utilizes compressed air to propel thin, headless nails that leave minimal surface damage, allowing for a clean and professional appearance. For instance, a carpenter might use it to affix decorative molding along the bottom edge of a wall, concealing the joint between the wall and the flooring.

The adoption of such tools significantly enhances efficiency and precision in woodworking projects. Compared to manual nailing, it offers faster application, reduced risk of splitting the material, and a more consistent depth of drive. Its history traces back to the broader development of pneumatic tools, born from the need for increased productivity in construction and manufacturing industries.

The subsequent sections will explore the different types available, factors to consider when selecting a suitable model, proper usage techniques, and essential safety precautions to ensure optimal performance and user well-being.

Essential Tips for Using a Finish Nailer for Baseboard Installation

Effective utilization of a pneumatic fastening tool in skirting board applications demands adherence to specific techniques and considerations. The following guidelines aim to optimize performance and minimize potential complications during installation.

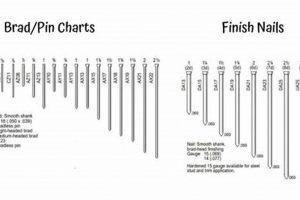

Tip 1: Select the Appropriate Nail Gauge: Employing the correct nail gauge is crucial to prevent splitting or damage to the skirting board. Typically, 15- or 16-gauge nails are recommended for most applications. Softer woods may require a smaller gauge to minimize visible entry points.

Tip 2: Adjust Depth Setting: Precise adjustment of the depth setting ensures nails are driven flush with the surface without penetrating too deeply or remaining proud. Test the setting on a scrap piece of the material before initiating the main installation.

Tip 3: Consistent Nail Spacing: Maintain uniform nail spacing along the length of the skirting board to ensure even distribution of holding force. A spacing of 12 to 16 inches is generally adequate, but closer spacing may be necessary for curved or uneven surfaces.

Tip 4: Angle the Nailer Correctly: When fastening to wall studs, angling the device slightly upwards or downwards provides enhanced holding power. Avoid angling the nailer excessively, as this can cause the nail to exit the side of the material.

Tip 5: Use Adhesive in Conjunction: Applying construction adhesive to the back of the skirting board before fastening adds significant strength and reduces the likelihood of movement over time. Ensure the adhesive is compatible with the wall surface and the material.

Tip 6: Locate Studs Accurately: Precisely identifying and fastening to wall studs provides the most secure attachment. Employ a stud finder to locate studs behind the drywall, marking their positions clearly before beginning installation.

Tip 7: Handle Mitered Corners with Care: Mitered corners require precise alignment and secure fastening to prevent gaps or separation. Consider using corner clamps or specialized miter supports to maintain accuracy during installation.

Adherence to these guidelines contributes to a professional-looking and structurally sound skirting board installation. Proper technique not only enhances the aesthetic appeal but also ensures the long-term stability of the trim.

The subsequent discussion will focus on troubleshooting common issues and providing solutions to ensure seamless implementation.

1. Gauge

The gauge of a nail directly correlates to its diameter, and selecting the appropriate gauge for a finish nailer used on skirting boards is paramount. A higher gauge number indicates a thinner nail. Utilizing an incorrect gauge can cause several problems. For example, if a too-thick (lower gauge) nail is used on delicate skirting board, the material could split, resulting in visual imperfections and structural weakness. Conversely, if the nail is too thin (high gauge), it may lack sufficient holding power, leading to the baseboard detaching over time.

As a component of the overall tool system, the nailer must be compatible with the chosen gauge of nail. A finish nailer designed for 15-gauge nails, for instance, will not function correctly with 18-gauge nails, and attempting to force the issue can damage the tool. Consider a scenario where a contractor attempts to use an 18-gauge brad nailer (designed for very fine finishing) on solid oak baseboard. The brads might buckle or fail to penetrate fully, rendering them ineffective.

Therefore, understanding the relationship between gauge and material is essential for successful skirting board installation. The choice of gauge should be based on the density of the baseboard material, the desired level of concealment, and the holding power required. Employing the wrong gauge results in compromised aesthetics and durability. Selecting and using the correct guage is key to ensure optimal and robust attachment of baseboards, preventing aesthetic issues or structural failure.

2. Air Pressure

Operational efficiency and effectiveness of a pneumatic fastening tool, specifically when affixing skirting boards, are directly contingent on the consistent regulation of compressed air. Insufficient pressure results in incomplete nail penetration, leaving fasteners protruding from the material surface. This outcome necessitates manual correction, increasing labor time and potentially marring the finish. Conversely, excessive pressure risks overdriving the nails, causing them to sink too deeply, damaging the surrounding wood and diminishing holding strength. The consequence is often visible surface imperfections and a compromised structural bond. For instance, in colder climates, fluctuations in ambient temperature can affect air compressor output, leading to inconsistencies in nail depth if the pressure is not meticulously monitored and adjusted accordingly.

Maintaining optimal pressure levels, as specified by the tool manufacturer, ensures consistent and predictable performance. This typically involves setting the compressor’s regulator to a pressure range between 70 and 100 pounds per square inch (PSI), depending on the density of the skirting board material and the desired depth of drive. The use of an in-line pressure gauge is recommended to provide a real-time visual representation of the pressure being delivered to the nailer, enabling immediate adjustments as needed. As an example, a professional carpenter installing solid maple skirting boards might begin with a pressure setting of 85 PSI and then fine-tune it based on the initial test drives into scrap material to achieve the perfect nail set.

In summary, proper management of air pressure is integral to achieving professional-grade skirting board installations using a pneumatic fastening system. Failure to do so can lead to both aesthetic and structural deficiencies. Consistent monitoring, coupled with precise adjustments, ensures that each fastener is driven to the correct depth, resulting in a secure, visually appealing, and durable finished product. Addressing fluctuations in environmental conditions that may impact the tool’s performance is critical for maintaining consistent fastening quality.

3. Depth Adjustment

In the context of securing skirting boards, the precise setting of fastener depth is critical. This adjustment feature, present on most finishing nailers, directly impacts the final aesthetic and structural integrity of the installation. Improper depth can lead to cosmetic flaws and compromised holding power, underscoring the importance of understanding and correctly utilizing this tool feature.

- Flush Setting for Aesthetic Appeal

The ability to set nails flush with the surface of the skirting board ensures a clean, professional appearance. A nail driven too deeply creates an undesirable indentation, while a nail left protruding is equally unsightly. Accurate depth adjustment allows the installer to consistently achieve a smooth, even surface ready for finishing, such as painting or filling. For instance, consider a scenario where a high-gloss paint is applied to skirting boards: any imperfections in nail depth become highly noticeable under the sheen, detracting from the overall finish.

- Preventing Damage to Material

Excessive driving depth can damage the skirting board material, particularly softer woods like pine. Overdriven nails can crush the wood fibers, leaving a visible crater and weakening the surrounding area. This damage not only affects the appearance but also reduces the holding strength of the fastener. Conversely, insufficient depth leaves the nail head exposed, posing a potential hazard and preventing a secure fit. Depth adjustment allows for the careful balancing of fastener depth to prevent material damage while ensuring adequate holding force.

- Adapting to Material Density

Skirting boards are manufactured from a variety of materials, ranging from softwoods to hardwoods and composites. Each material possesses different density characteristics, requiring variations in nail driving depth. Depth adjustment mechanisms allow the user to compensate for these differences. A harder material, such as oak, may require a greater depth setting than a softer material, such as MDF, to achieve a flush finish. Failure to adjust the depth appropriately can result in inconsistent results and compromised aesthetics.

- Ensuring Secure Attachment

Proper nail depth is essential for achieving a secure and lasting attachment of skirting boards to the wall. A nail driven too deeply may not engage the wall framing adequately, while a nail left protruding provides minimal holding power. By carefully adjusting the driving depth, the user can ensure that the nail penetrates the wall sufficiently to provide a strong, reliable connection. This is particularly important in areas subject to impact or stress, such as hallways or doorways, where skirting boards are more likely to be bumped or kicked.

These facets illustrate the profound influence of depth adjustment on the successful installation of skirting boards. The ability to precisely control fastener depth ensures not only a visually appealing result but also a structurally sound and durable attachment. Neglecting this crucial setting can lead to cosmetic flaws, material damage, and a compromised installation, thereby underscoring the importance of mastering depth adjustment when working with a finishing nailer and skirting boards.

4. Nail Length

The selection of appropriate fastener length is a critical determinant in the successful application of finish nailers for securing skirting boards. The length must be meticulously considered to ensure adequate penetration without compromising the integrity of underlying structures or the aesthetics of the finished trim.

- Penetration Depth and Holding Power

The primary function of a nail is to provide a secure mechanical bond between the skirting board and the wall. Insufficient nail length results in inadequate penetration into the wall framing, reducing holding power and potentially leading to the skirting board detaching over time. Conversely, excessive nail length may penetrate too deeply, potentially damaging electrical wiring, plumbing, or other concealed utilities within the wall cavity. For example, using 2-inch nails on half-inch drywall backed by metal studs will likely result in poor engagement and a loose baseboard.

- Skirting Board Thickness and Material

The thickness and material composition of the skirting board itself directly influence the required nail length. Thicker boards necessitate longer nails to ensure sufficient engagement with the underlying wall structure. Similarly, denser materials such as solid hardwood require longer and potentially thicker nails than softer materials like MDF or finger-jointed pine. A scenario involving the installation of 3/4-inch oak skirting board onto drywall over wooden studs would necessitate nails long enough to pass through the board and penetrate at least one inch into the stud.

- Wall Construction and Stud Spacing

The type of wall construction and the spacing of studs behind the finished wall surface significantly impact nail length selection. Walls with thicker drywall or plaster require longer nails to reach the underlying studs. Furthermore, if studs are spaced further apart, a slightly longer nail may be beneficial to increase the chances of hitting a stud when fastening. However, the installer must exercise caution to avoid over-penetration. Consider a situation where the contractor knows the stud spacing to be 24″ OC. Extra care needs to be taken to ensure the fasteners are going into a stud.

- Avoiding “Nail Pop”

Using nails that are too long can increase the risk of “nail pop,” a phenomenon where the nail head pushes through the surface of the drywall due to seasonal movement of the framing lumber. This creates unsightly bumps and cracks in the wall finish. To mitigate this risk, select a nail length that provides adequate holding power without excessive penetration into the framing members. For instance, using a 1 1/4″ nail is generally preferable to a 2″ nail when attaching thin baseboard to drywall over adequately spaced studs.

Proper selection of nail length is thus a balancing act between achieving secure attachment, avoiding damage to concealed utilities, and preventing cosmetic imperfections. A thorough understanding of wall construction, skirting board material, and fastener characteristics is essential for successful skirting board installation using a finish nailer. Failure to appropriately account for these factors can lead to compromised aesthetics and structural integrity of the trim work. Always consult local building codes and best practices to determine the optimal nail length for specific applications.

5. Safety Features

The integration of specific protective mechanisms into pneumatic fastening tools is crucial, particularly when installing skirting boards. These features mitigate the inherent risks associated with high-pressure systems and rapid fastener deployment, safeguarding both the user and the surrounding environment.

- Contact-Trip Mechanisms

A contact-trip mechanism, also known as a sequential-trip or dual-action trigger, prevents unintentional firing. The tool requires both the nose piece to be compressed against the work surface and the trigger to be activated before a fastener is discharged. This reduces the likelihood of accidental nail discharge if the trigger is inadvertently squeezed while the tool is not properly positioned. For instance, if a user drops the tool, the contact-trip mechanism prevents it from firing upon impact with the ground.

- Directional Exhaust Ports

Pneumatic tools exhaust compressed air, which can dislodge debris and create a potentially hazardous environment. Directional exhaust ports allow the user to redirect the airflow away from their face and the work area, preventing eye irritation and the spread of dust or particles. This feature is especially relevant in confined spaces where proper ventilation may be limited. Directing exhaust down and away from the face protects from flying debris, improving workplace safety.

- Adjustable Depth Control

While primarily intended for achieving a flush finish, adjustable depth control contributes to safety by reducing the risk of overdriving fasteners. Overdriving can cause the nail to exit the backside of the skirting board or damage concealed wiring or plumbing within the wall. Precise depth control ensures that nails are driven to the optimal depth for secure fastening without creating hazards behind the work surface. A user might initially set the depth too high and adjust it down when installing a thin baseboard over a wall known to have utilities.

- Safety Glasses/Eye Protection

Although not an integrated component of the tool itself, the consistent use of appropriate eye protection is paramount. Skirting board installation can generate splinters, dust, and ricocheting fasteners. Safety glasses or goggles protect the eyes from these hazards, preventing potential injuries. Many manufacturers recommend the use of safety glasses with side shields when operating power fastening tools, regardless of the presence of other safety features.

These protective elements, either integrated into the tool or employed as supplementary personal protective equipment, are indispensable for safe skirting board installation utilizing a pneumatic fastener. Prioritizing these safety measures minimizes the potential for workplace accidents and contributes to a secure and productive work environment. Regularly inspecting and maintaining all safety features further enhances user protection.

6. Weight

The mass of a finish nailer significantly impacts its usability and efficiency, particularly during prolonged skirting board installation. The tool’s weight influences user fatigue, maneuverability, and precision, ultimately affecting the quality and speed of the finished trim work.

- Operator Fatigue and Endurance

Heavier tools contribute to increased fatigue, especially during extended periods of use. Installing skirting boards typically involves repetitive movements and holding the tool in various positions, often overhead or at awkward angles. A lighter nailer reduces strain on the user’s arm, shoulder, and back muscles, improving endurance and minimizing the risk of repetitive strain injuries. A carpenter installing baseboard in a large room would likely experience less fatigue with a lightweight nailer compared to a heavier model.

- Maneuverability and Accessibility

A lighter nailer is easier to maneuver in tight spaces and difficult-to-reach areas. Skirting board installation often requires working in corners, around doorways, and under cabinets, where space is limited. A lighter, more compact tool allows for greater precision and control in these challenging situations. A lighter nailer might be necessary when installing baseboard in an area with many sharp turns and corners.

- Precision and Control

Excessive tool weight can compromise the user’s ability to maintain a steady hand and achieve accurate nail placement. A lighter nailer allows for better control and reduces the likelihood of errors, such as misaligned nails or damage to the skirting board. This is particularly important when working with delicate or expensive materials. The precision enabled by a lighter nailer improves the quality of the finished product.

- Portability and Storage

Lighter nailers are easier to transport and store. Contractors who move frequently between job sites benefit from the reduced weight and bulk of lighter tools. Reduced weight also simplifies storage and organization of tools in a workshop or vehicle. Easy transport and storage ensure the tool is always accessible and available for use.

The weight of a finish nailer is a critical factor influencing user comfort, precision, and efficiency during skirting board installation. Lighter tools generally offer advantages in terms of reduced fatigue, improved maneuverability, and enhanced control, contributing to a more productive and higher-quality end result. Balancing weight considerations with other factors like power and features is key to selecting the most appropriate nailer for specific applications.

7. Power Source

The operative mechanism of a finish nailer, specifically when employed for skirting board installation, is fundamentally determined by its power source. Two primary power source options exist: pneumatic (compressed air) and cordless (battery). The choice between these two configurations profoundly affects the tool’s portability, power output, operational cost, and overall suitability for specific applications. For instance, a pneumatic model necessitates an air compressor, limiting mobility but often providing consistent and higher power. Conversely, a cordless model offers untethered movement but may exhibit reduced power or require frequent battery changes.

Pneumatic finish nailers, connected to an air compressor via a hose, deliver consistent driving force, which is particularly advantageous when working with dense materials or long fastener lengths. This configuration typically results in lower operational costs, as there is no reliance on consumable batteries. However, the need for an air compressor restricts portability and necessitates proximity to a power outlet. A contractor installing skirting boards in a remote location without access to electricity would find a pneumatic model impractical. Cordless finish nailers, powered by rechargeable batteries, offer enhanced maneuverability and eliminate the constraints of air hoses and power cords. This makes them ideal for jobsites with limited access or where mobility is paramount. The initial investment in a cordless model is often higher, and the ongoing cost of batteries must be considered. A homeowner installing skirting boards in a finished basement might prefer the convenience of a cordless model to avoid the hassle of setting up an air compressor.

Ultimately, the selection of an appropriate power source for a finish nailer used in skirting board installation requires a careful assessment of job site conditions, material properties, and budgetary considerations. Pneumatic models excel in situations demanding consistent power and lower operational costs, while cordless models prioritize portability and convenience. Understanding these trade-offs enables informed decision-making and ensures optimal performance. Despite its advantages, a cordless model also poses the challenge of battery management and ensuring sufficient charge for completing the project. Considering all factors ensures successful and efficient baseboard installations.

Frequently Asked Questions

The following section addresses common inquiries regarding the utilization of pneumatic fastening tools for securing skirting boards. These questions aim to clarify best practices and resolve potential challenges encountered during installation.

Question 1: What nail gauge is recommended for securing baseboard to drywall over wood studs?

Typically, a 15- or 16-gauge nail provides adequate holding power without excessive visibility. Softer wood baseboards may benefit from 18-gauge fasteners to minimize splitting.

Question 2: How does air pressure impact the performance of a finish nailer during baseboard installation?

Insufficient pressure results in protruding nails, while excessive pressure can overdrive fasteners, damaging the baseboard. Optimal pressure settings, as specified by the tool manufacturer, are crucial for consistent results.

Question 3: What is the purpose of depth adjustment on a finish nailer when installing baseboard?

Depth adjustment ensures nails are driven flush with the surface, preventing both unsightly protrusions and damage to the baseboard material. It allows for adaptation to varying material densities.

Question 4: How does nail length affect the security and aesthetics of baseboard installation?

Nails must be long enough to penetrate the wall framing adequately for secure attachment, but not so long as to damage concealed utilities or cause “nail pop.” Proper length is dependent on baseboard thickness and wall construction.

Question 5: What safety precautions are essential when operating a finish nailer for baseboard installation?

The use of safety glasses is mandatory. Ensure the tool has a functional contact-trip mechanism, and direct the exhaust port away from the face. Understanding depth adjustment also reduces hazards.

Question 6: How does the weight of a finish nailer influence the installation of baseboard, especially in large rooms?

Lighter tools reduce operator fatigue, improving maneuverability and precision. This is particularly important during prolonged use in large rooms or when working in confined spaces.

Proper application of these techniques significantly contributes to a professional-looking and structurally sound baseboard installation.

The next section will cover common errors made when performing this type of project and provide advice for avoiding them.

Conclusion

This exposition has detailed various aspects of utilizing a finish nailer for baseboard installations. Key considerations include appropriate nail gauge, precise air pressure regulation, accurate depth adjustment, selection of suitable nail length, and adherence to essential safety protocols. Furthermore, the impact of tool weight and power source on user experience and project outcomes has been thoroughly examined.

Mastering the proper application of a finish nailer is paramount for achieving professional-grade results in baseboard installation. Consistent adherence to these guidelines will ensure a secure, aesthetically pleasing, and durable finished product. Further research and practical experience are encouraged to refine technique and optimize performance in diverse installation scenarios.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)