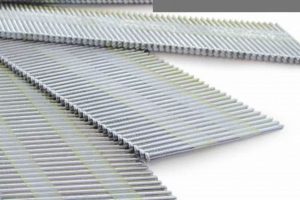

These fasteners, designed for pneumatic nail guns, possess a specific angled collation to facilitate access into corners and tight spaces during trim and finish carpentry. Often employed with a specialized tool from a particular manufacturer, these fasteners enable efficient and secure attachment of molding, baseboards, and other decorative elements. The angled design allows for a greater degree of maneuverability and precision when working in restrictive environments.

The use of these angled fasteners offers advantages in terms of speed, accuracy, and reduced material splitting compared to traditional hand-nailing methods. Historically, finish carpenters relied on manual techniques that were labor-intensive and prone to errors. The advent of pneumatic nailers and collated fasteners significantly improved productivity and the overall quality of finish work. This technology allows for faster project completion, more consistent results, and a reduction in the physical strain on the installer.

The subsequent sections will elaborate on specific types of these fasteners, compatible tools, recommended applications, and best practices for achieving optimal results in various woodworking and construction projects. Understanding the nuances of gauge, length, and collation angle is critical for selecting the appropriate fastener for a given task.

Usage Guidance

The following guidelines will enhance the efficacy of angled collation fasteners and ensure optimal performance in finish carpentry applications.

Tip 1: Consistent Tool Maintenance: Regularly inspect and maintain the pneumatic nailer designed for angled fasteners. Ensure proper air pressure and lubrication to prevent misfires and ensure consistent nail depth. Clogged or dirty tools will likely damage the workpiece or the fasteners.

Tip 2: Selection of Appropriate Fastener Length: Choose the length of the fastener based on the combined thickness of the materials being joined. Insufficient length will result in weak joints; excessive length can protrude through the back of the workpiece, compromising aesthetics and structural integrity.

Tip 3: Proper Angle of Application: Maintain the correct angle during nail placement to ensure optimal holding power. Inconsistent angles can lead to fastener deflection, reduced holding strength, and potential damage to the surrounding wood fibers.

Tip 4: Use of Appropriate Safety Equipment: Always wear appropriate safety glasses or a face shield to protect eyes from flying debris. The high-velocity discharge of these fasteners poses a risk of injury if proper precautions are neglected.

Tip 5: Material Compatibility: Verify compatibility between the fastener material (e.g., galvanized, stainless steel) and the type of wood being used. Incompatible materials can lead to corrosion or discoloration, compromising the longevity and appearance of the finish.

Tip 6: Test Before Final Application: Test fire a few fasteners into a piece of scrap material to ensure that the nailer is properly adjusted and the fastener is setting correctly. This step helps prevent damage to the finished project.

Tip 7: Check Collation Integrity: Regularly inspect the collation strip for damage or deformation. Damaged collation strips can cause the nailer to jam or misfire.

Adherence to these guidelines will enhance the performance and longevity of finish carpentry projects by ensuring proper fastener selection, application, and tool maintenance.

Subsequent sections will focus on specific applications and advanced techniques.

1. Gauge Consistency

Gauge consistency in angled finish fasteners directly affects the reliable operation of pneumatic nailers. These fasteners are manufactured to a specific diameter, or gauge, that corresponds to the internal mechanisms of the tool designed to drive them. Variations in gauge, even minor ones, can disrupt the smooth feeding of fasteners through the nailer’s magazine and firing chamber. This, in turn, leads to misfires, jams, and potential damage to the tool’s internal components. Such malfunctions increase project completion time, requiring frequent stops to clear jams and potentially necessitating costly repairs or replacements of equipment.

For example, if a batch of 16-gauge angled finish nails exhibits inconsistencies where some nails are slightly thicker than the specified diameter, these thicker nails may become lodged in the nailer’s firing mechanism. Conversely, nails that are thinner than the standard gauge may not be properly gripped by the driver, resulting in incomplete or inconsistent nail penetration. The manufacturer’s specifications for the nailer typically include a recommended gauge range for compatible fasteners. Deviating from this range will almost certainly result in performance issues. Real-world scenarios involve trim carpenters experiencing inconsistent nail depth and repeated jams when using fasteners from less reputable suppliers that lack strict quality control processes.

In summary, gauge consistency represents a critical factor in the reliable and efficient deployment of angled finish fasteners. Variations in gauge lead to tool malfunctions, increased labor costs, and compromised project quality. Therefore, selecting fasteners from reputable manufacturers known for rigorous quality control and adherence to established standards is paramount to ensuring consistent and trouble-free operation. Investing in high-quality fasteners mitigates the risk of equipment damage and contributes to the overall efficiency and success of finish carpentry projects.

2. Collation Angle

The collation angle represents a critical design parameter for angled finish nails. This angle dictates the orientation of the fasteners within the strip or magazine, determining the accessibility and ease of use within specific pneumatic nail guns. A precise collation angle ensures the tool can consistently feed and drive the fasteners into the workpiece at the intended inclination. Deviations from the specified angle can lead to jamming, misfires, and inconsistent nail placement, ultimately affecting the quality and structural integrity of the finished work. For instance, if the collation angle is too steep, the nail gun may struggle to properly position the fastener against the workpiece, resulting in angled or protruding nails. Conversely, a shallower angle might cause the fasteners to bind within the magazine, impeding the tool’s operation.

The specific manufacturer often dictates the collation angle standard; therefore, compatibility between nail gun and nail type is essential. Using fasteners with an incorrect collation angle can damage the tool, void warranties, and lead to unsafe operating conditions. Field reports from construction sites often detail instances where incorrect fastener selection resulted in tool malfunctions and project delays. Furthermore, the collation material and its adhesive properties significantly influence the smooth feeding of the fasteners. Inferior collation materials can degrade over time or in response to environmental factors, causing the fasteners to detach and further disrupt the nail gun’s operation. Therefore, the integrity of the collation and the precision of the angle are paramount to ensuring consistent and reliable performance.

In summary, the collation angle is an intrinsic component of angled finish nails, directly impacting their compatibility and performance within pneumatic nail guns. Understanding this relationship is crucial for selecting the appropriate fasteners for a given tool and application. Choosing fasteners with the correct collation angle and ensuring the integrity of the collation material minimize tool malfunctions, enhance project efficiency, and contribute to the overall quality and safety of finish carpentry work. Compromising on these specifications can result in costly repairs, project delays, and potentially hazardous operating conditions.

3. Fastener Length

Fastener length is a primary determinant of the structural integrity and aesthetic outcome when using Paslode angled finish nails. Incorrect fastener length directly correlates with compromised joint strength or undesirable visual results. A fastener that is too short fails to penetrate sufficiently into the substrate, resulting in a weak connection prone to failure under stress. Conversely, an excessively long fastener protrudes through the back of the workpiece, detracting from the finished appearance and potentially posing a safety hazard. The proper selection of fastener length, therefore, is not merely a procedural step, but a critical decision impacting the longevity and visual appeal of the finished product. Real-world examples illustrate the importance of this consideration: Baseboards secured with fasteners of inadequate length may detach from the wall over time, requiring costly repairs. Similarly, molding attached with excessively long fasteners presents an unprofessional appearance due to visible nail protrusions.

The optimal fastener length is determined by the combined thickness of the materials being joined and the density of the substrate. Softer woods, such as pine, require longer fasteners for adequate holding power compared to denser hardwoods like oak. Additionally, the intended application plays a significant role in fastener length selection. Securing delicate trim requires shorter fasteners to prevent splitting, while attaching heavier components necessitates longer fasteners for increased stability. Specialized charts and guidelines are available from fastener manufacturers and industry associations, providing recommendations for various materials and applications. These resources serve as invaluable tools for ensuring that the appropriate fastener length is chosen for each project. Overlooking these guidelines can lead to structural weaknesses, aesthetic defects, and increased project costs due to rework and material replacement.

In summary, the connection between fastener length and Paslode angled finish nails underscores the importance of meticulous planning and informed decision-making in finish carpentry. Proper selection of fastener length directly influences joint strength, aesthetic quality, and project longevity. Challenges associated with this selection process include variations in material density and the complexity of certain applications. However, by adhering to established guidelines and considering the specific requirements of each project, professionals can ensure that fastener length contributes to the overall success and durability of the finished product. This understanding highlights fastener length as a critical, non-negotiable component within the framework of quality finish carpentry.

4. Coating Type

The coating type applied to angled finish nails is a crucial factor in determining their resistance to corrosion and their suitability for various environmental conditions. Paslode angled finish nails, often used in interior and exterior trim applications, are vulnerable to degradation from moisture, chemicals, and atmospheric pollutants. The coating acts as a protective barrier, preventing the underlying steel from oxidizing and corroding. Different coating types offer varying levels of protection, with options ranging from basic zinc coatings to more durable finishes like stainless steel or specialized polymer coatings. The selection of an appropriate coating directly influences the lifespan and performance of the finished carpentry work. Failure to consider the environmental factors and select an adequate coating can lead to premature fastener failure, resulting in weakened joints and aesthetic degradation. For example, using uncoated or minimally coated nails in damp environments, such as bathrooms or outdoor decks, will inevitably lead to rust and eventual structural compromise. The resulting discoloration can also stain the surrounding wood, necessitating costly repairs or replacements.

The practical implications of coating selection extend beyond mere corrosion resistance. Certain coatings, such as those containing lubricants, can reduce friction during nail insertion, minimizing wood splitting and improving driving efficiency. This is particularly important when working with hardwoods or delicate trim pieces where splitting is a concern. Furthermore, specific coatings are designed to enhance the bonding between the fastener and the wood fibers, improving holding power and overall joint strength. Considerations regarding compatibility with specific types of wood are also relevant. Some coatings may react negatively with certain wood preservatives or extractives, leading to discoloration or accelerated corrosion. Therefore, careful consideration of the coating’s chemical properties and potential interactions with the surrounding materials is crucial for ensuring long-term performance and aesthetic integrity. In coastal regions, where exposure to saltwater is prevalent, stainless steel nails or those with specialized marine-grade coatings are essential for preventing rapid corrosion and maintaining structural integrity.

In summary, the coating type of Paslode angled finish nails constitutes a pivotal component influencing their durability, performance, and suitability for diverse applications. Selection should be guided by a thorough assessment of environmental conditions, material compatibility, and desired aesthetic outcomes. Challenges associated with coating selection include the wide array of available options and the potential for misinterpreting manufacturer specifications. However, by prioritizing coating type as a key performance parameter, professionals can mitigate the risk of premature fastener failure, enhance the longevity of their finished carpentry work, and ensure customer satisfaction. A proactive approach to understanding and selecting appropriate coatings is, therefore, an essential aspect of responsible and high-quality craftsmanship.

5. Tool Compatibility

The performance and reliability of angled finish nails are intrinsically linked to the compatibility of the tool used to drive them. Proper tool compatibility ensures consistent nail placement, reduces the risk of malfunctions, and contributes to the overall quality and efficiency of finish carpentry work. Disregard for compatibility can lead to damage to both the tool and the materials being fastened, resulting in increased costs and project delays.

- Collation Angle Matching

The collation angle of the angled finish nails must precisely match the magazine and driving mechanism of the nail gun. Mismatched angles can cause feeding problems, resulting in jams and misfires. For instance, a nail gun designed for 34-degree angled nails will not function correctly with 21-degree nails, as the nails will not align properly with the driver. This incompatibility leads to inconsistent nail depth and potential damage to the tool’s internal components.

- Gauge and Length Specifications

Nail guns are designed to accommodate a specific range of nail gauges and lengths. Using nails outside of these specifications can cause the tool to malfunction or fail to drive the nails properly. Attempting to use nails that are too thick can overload the driver, leading to premature wear or breakage. Conversely, nails that are too thin may not be properly gripped, resulting in incomplete or inconsistent nail penetration.

- Air Pressure Requirements

Pneumatic nail guns require a specific range of air pressure to operate effectively. Supplying insufficient air pressure can result in weak or incomplete nail driving, while excessive pressure can damage the tool or cause the nails to penetrate too deeply. Maintaining the recommended air pressure ensures consistent performance and prolongs the lifespan of the tool.

- Maintenance and Calibration

Regular maintenance and calibration are essential for ensuring proper tool compatibility. Worn or damaged components can affect the tool’s ability to drive nails accurately and reliably. Periodic cleaning, lubrication, and adjustment of the tool’s settings can prevent malfunctions and maintain optimal performance. Neglecting maintenance can lead to inconsistent nail placement and increased wear on both the tool and the fasteners.

The interaction between the tool and the fastener is a system. Each component needs to fit and function together, in order for the project to be successful and the tool to remain uninjured. Tool choice matters.

6. Joint Strength

Joint strength, in the context of finish carpentry utilizing Paslode angled finish nails, signifies the capacity of a connection between two or more workpieces to withstand tensile, shear, and compressive forces without failure. It is a critical performance parameter directly influenced by several factors related to the fastener and its application.

- Fastener Material and Design

The material composition and structural design of the angled finish nail play a foundational role in determining joint strength. Nails manufactured from high-tensile steel offer greater resistance to bending and deformation under load. Furthermore, features such as barbed shanks or specialized coatings enhance frictional resistance within the wood fibers, increasing pull-out strength. For example, galvanized nails provide enhanced corrosion resistance while maintaining adequate tensile strength for interior applications, whereas stainless steel nails are preferable in exterior settings requiring superior resistance to environmental degradation.

- Nail Penetration Depth and Angle

Adequate nail penetration depth into the substrate is paramount for achieving optimal joint strength. Insufficient penetration reduces the surface area of contact between the nail and the wood, weakening the connection. Similarly, the angle at which the nail is driven into the wood influences the distribution of forces within the joint. A consistent and appropriate driving angle ensures that the nail shank engages the wood fibers effectively, maximizing holding power. Real-world scenarios highlight the importance of proper technique: driving nails at too shallow an angle can cause them to bend or deflect, compromising the joint’s integrity.

- Wood Species and Density

The species and density of the wood being joined exert a significant influence on joint strength. Softer woods, such as pine, offer less resistance to nail pull-out compared to denser hardwoods like oak or maple. The inherent structural properties of the wood, including its grain pattern and fiber alignment, affect the nail’s ability to grip and maintain a secure connection. Therefore, selecting the appropriate nail length and gauge for the specific wood species is crucial for achieving desired joint strength. For example, using excessively long or thick nails in delicate trim made from softwoods can cause splitting, weakening the joint.

- Fastener Spacing and Pattern

The spacing and pattern of angled finish nails within a joint directly impact its overall strength and stability. Closely spaced nails distribute the load more evenly across the joint, reducing stress concentrations and minimizing the risk of failure. A well-designed nailing pattern, such as staggering the nails or using a triangular configuration, can further enhance joint strength by providing increased resistance to racking and twisting forces. Practical applications of this principle are evident in the construction of cabinets and furniture, where carefully planned nail patterns contribute to the structural integrity of the finished product.

These aspects, when carefully considered and implemented, ensure that Paslode angled finish nails contribute effectively to robust and reliable joints in a wide range of finish carpentry applications. A comprehensive understanding of these interconnected variables allows professionals to achieve optimal results and deliver durable, high-quality workmanship.

7. Material Quality

The integrity and performance of Paslode angled finish nails are significantly dependent on the quality of the materials used in their construction. The composition and treatment of these materials directly affect the fastener’s strength, durability, and resistance to corrosion, thereby impacting the overall quality and longevity of finish carpentry projects.

- Steel Composition and Hardness

The specific grade of steel used in manufacturing the nails directly influences their tensile strength and shear resistance. Higher-quality steel alloys exhibit greater hardness, reducing the likelihood of bending or breaking during installation. The steel must also be sufficiently ductile to allow for clinching or bending without fracturing. Lower-grade steel may lack the necessary strength to penetrate dense materials or withstand significant loads, leading to joint failure. Proper quality control measures during the steel production phase are essential to ensure consistent material properties across the entire batch of nails.

- Coating Integrity and Adhesion

The coating applied to the nails, whether zinc, galvanized, or stainless steel, provides crucial protection against corrosion. The effectiveness of the coating hinges on its uniform application and strong adhesion to the underlying steel substrate. Inadequate surface preparation or inconsistent coating thickness can create weak points where corrosion can initiate and spread. Furthermore, the coating material itself must be resistant to the specific environmental conditions encountered in the intended application. Using nails with compromised coating integrity can lead to unsightly rust stains, weakened joints, and premature failure of the finished product. Proper testing and quality assurance protocols are necessary to verify the coating’s adherence and resistance to environmental factors.

- Collation Material Strength and Flexibility

The material used to collate the nails into strips or coils is equally important for ensuring proper tool performance. The collation material must be strong enough to hold the nails securely together during handling and loading into the nail gun. It also needs to be flexible enough to allow for smooth feeding through the tool’s magazine and driving mechanism. Brittle or weak collation material can break apart, causing jams and misfires. The collation material’s resistance to temperature changes and moisture is another important consideration, as extreme conditions can affect its integrity. Consistent collation quality across the entire production batch is essential for minimizing tool malfunctions and ensuring efficient nail driving.

These interrelated aspects of material quality collectively determine the reliability and longevity of Paslode angled finish nails. Compromises in any of these areas can have detrimental effects on the performance of the fasteners and the overall quality of the finished carpentry work. Selecting nails from reputable manufacturers with rigorous quality control standards is, therefore, paramount to ensuring consistent performance and minimizing the risk of project failures.

Frequently Asked Questions

This section addresses common inquiries concerning the application, selection, and performance characteristics of these specialized fasteners.

Question 1: What differentiates angled finish nails from straight finish nails?

Angled finish nails are collated at a specific angle to facilitate access into corners and tight spaces, a feature not present in straight finish nails. This design allows for greater maneuverability when installing trim and molding.

Question 2: Can generic angled finish nails be used in a Paslode nailer?

While some generic brands may appear compatible, utilizing non-Paslode fasteners can void the tool’s warranty and potentially damage the firing mechanism. Paslode nails are designed to meet specific tolerances for optimal performance.

Question 3: What gauge and length of angled finish nail is appropriate for installing baseboards?

The appropriate gauge and length depend on the baseboard thickness and the substrate material. Generally, 15- or 16-gauge nails ranging from 1-1/4 to 2 inches are suitable for typical baseboard installations. Consult manufacturer guidelines for specific recommendations.

Question 4: How should angled finish nails be stored to prevent corrosion?

Store fasteners in a dry environment, away from moisture and extreme temperature fluctuations. Original packaging, or airtight containers, are recommended to minimize exposure to corrosive elements.

Question 5: What safety precautions should be observed when using a pneumatic nailer with angled finish nails?

Always wear appropriate eye protection to guard against flying debris. Ensure the nailer is properly maintained and operated within the recommended air pressure range. Never point the tool at oneself or others.

Question 6: How can nail “blowout” or splitting of the wood be prevented when using these fasteners?

Select a fastener length appropriate for the material thickness. Consider using a finer gauge nail, pre-drilling pilot holes in dense hardwoods, or adjusting the nailer’s depth setting to prevent over-driving.

Proper selection and application techniques are paramount for achieving professional results with Paslode angled finish nails. Adherence to manufacturer guidelines and safety protocols is essential.

The subsequent section will delve into troubleshooting common issues encountered during finish carpentry projects.

Conclusion

This exploration has underscored the multifaceted nature of Paslode angled finish nails, extending beyond a simple fastening solution. Material composition, collation angle, tool compatibility, and application-specific considerations have been detailed, emphasizing the integrated system these fasteners represent within the context of professional finish carpentry. Understanding these elements contributes directly to project success and mitigates potential performance deficiencies.

A comprehensive understanding of these fasteners is essential for construction professionals. Continued adherence to best practices and mindful application of the knowledge presented herein will ensure optimal results and uphold the highest standards of craftsmanship within the industry. Further research and experimentation with varying materials and techniques are encouraged to advance the collective understanding of Paslode angled finish nails and their contribution to the built environment.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)