Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

This pneumatic tool is designed for driving 16-gauge finish nails into wood surfaces. These nails are characterized by their relatively small diameter, resulting in minimal visibility when driven. This makes them ideal for applications where aesthetic appeal is paramount, such as trim work, molding installation, and cabinet construction. The tool operates by utilizing compressed air to rapidly propel the nails, ensuring consistent and efficient fastening.

The use of such a device enhances efficiency and precision in woodworking projects. Compared to manual nailing, it offers significant time savings and reduces the risk of surface damage. Historically, finish nailers have evolved from simple, manually operated devices to sophisticated pneumatic and cordless models, driven by the need for increased productivity and improved finish quality in both professional and DIY settings. The development of these tools reflects an ongoing pursuit of superior craftsmanship and streamlined workflows within the woodworking industry.

The subsequent sections will delve into specific features, operational guidelines, maintenance procedures, and safety considerations associated with using these tools. A comparative analysis with similar devices, troubleshooting common issues, and best practices for optimal performance will also be addressed.

Essential Usage Considerations

The following guidelines are designed to optimize the performance and longevity of the driving tool while ensuring user safety and project quality.

Tip 1: Regulate Air Pressure: Maintain the compressor output within the manufacturer’s specified range. Excessive pressure can damage the tool and lead to nail penetration issues. Insufficient pressure may result in incomplete nail driving.

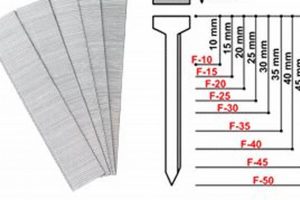

Tip 2: Select Appropriate Nail Length: Use nail lengths appropriate for the material thickness being fastened. Nails that are too short will not provide adequate holding power. Nails that are too long can protrude through the backside of the workpiece, creating an undesirable aesthetic and potential hazard.

Tip 3: Ensure Proper Nail Loading: Load nails correctly into the magazine, following the manufacturer’s instructions. Improper loading can cause jams and misfires, reducing efficiency and potentially damaging the tool.

Tip 4: Maintain a Firm and Consistent Grip: Hold the tool firmly against the workpiece to ensure consistent nail depth and prevent recoil. A loose grip can lead to inaccurate nail placement and increased risk of injury.

Tip 5: Apply Lubrication Regularly: Use the recommended air tool oil to lubricate the tool’s internal components regularly. This helps reduce friction, prolongs the tool’s life, and ensures smooth operation.

Tip 6: Inspect Before Each Use: Before each use, inspect the tool for any signs of damage, loose connections, or leaks. Address any issues promptly to prevent malfunctions and ensure safe operation.

These guidelines are designed to promote safe, efficient, and high-quality operation of the tool, ultimately contributing to the success of woodworking projects.

The subsequent sections will focus on troubleshooting common issues and advanced techniques for using the pneumatic tool.

1. Pneumatic Power

Pneumatic power is the operational foundation of this specific finishing tool. The device leverages compressed air to deliver the necessary force to drive 16-gauge finish nails into various materials. The consistent and controlled application of pneumatic energy is directly responsible for the tool’s ability to perform repetitive tasks with speed and precision. Without a reliable source of compressed air, the device cannot function as intended. For instance, a decrease in air pressure will invariably lead to incomplete nail penetration, rendering the tool ineffective. Real-world applications such as installing intricate trim work in residential construction underscore the practical dependence on a robust pneumatic system.

The efficiency of the driving tool is directly proportional to the stability and consistency of the compressed air supply. Fluctuations in air pressure can lead to inconsistent nail depth and potentially damage the workpiece. Therefore, proper regulation and maintenance of the air compressor are crucial for optimal performance. In a professional setting, such as a cabinet-making workshop, a well-maintained pneumatic system ensures consistent results and reduces the need for rework, ultimately increasing productivity. Another aspect is the reduction of user fatigue, pneumatic operation decreases the physical exertion that would be required from a manual tool.

In summary, the relationship between pneumatic power and this type of nailer is one of essential dependency. The consistent and controlled application of compressed air is fundamental to the tool’s operation, efficiency, and ability to deliver precise results. Challenges in maintaining a stable air supply can directly impact the quality of work and overall productivity. Understanding this relationship is critical for maximizing the tool’s potential and ensuring successful project outcomes.

2. Gauge Precision

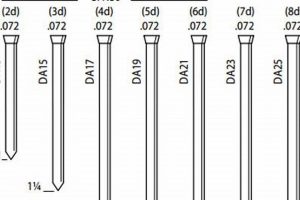

Gauge precision, referring to the nail diameter, is a crucial characteristic of this tool. The 16-gauge specification indicates the diameter of the nails the tool is designed to drive. This parameter directly influences the tool’s application and the resulting finish. A higher gauge number signifies a smaller nail diameter, resulting in less visible nail holes and minimizing the need for extensive filling and sanding. Consequently, applications requiring a fine finish, such as installing delicate trim or molding, benefit directly from the precise gauge specification. The tool’s design is specifically calibrated to accommodate and drive 16-gauge nails consistently and accurately.

The impact of gauge precision extends to the structural integrity of the fastened materials. While smaller gauge nails offer aesthetic advantages, they also provide less holding power compared to larger gauge nails. Therefore, selecting the appropriate gauge is a critical consideration. For instance, when securing thin pieces of wood, the 16-gauge specification is ideal because it reduces the risk of splitting the material while providing adequate fastening strength. In contrast, using a larger gauge nail could cause damage and detract from the overall appearance. The tool’s inherent design complements this need, ensuring consistent and reliable nail driving without compromising the integrity of the workpiece.

In summary, gauge precision is an integral component of a pneumatic finish nailer’s functionality and application. The 16-gauge specification facilitates fine finishing and minimizes surface damage, while the tool’s design ensures accurate and consistent nail driving. Understanding the relationship between gauge precision, material selection, and desired finish is essential for achieving professional results and maximizing the tool’s effectiveness. Improper gauge selection or inconsistencies in driving can undermine the entire project outcome.

3. Finish Quality

Finish quality is a paramount consideration in woodworking and trim applications. A pneumatic tool designed for driving 16-gauge finish nails plays a critical role in achieving a desirable finish. The inherent design and functionality of the tool directly influence the final appearance of the workpiece. The selection and proper usage of such a tool are integral to achieving a professional and aesthetically pleasing result.

- Nail Depth Consistency

The capacity to consistently drive nails to a uniform depth is crucial. Overdriving nails can mar the surface, necessitating filling and sanding, while underdriving leaves nails protruding, posing both aesthetic and functional issues. This tool, when properly calibrated, ensures nails are set at the ideal depth, minimizing post-installation touch-ups.

- Minimized Surface Damage

Driving nails manually or with less precise tools can lead to surface marring and dents. The tool, equipped with features such as a no-mar tip, reduces the likelihood of damaging the surrounding material. This is particularly important when working with delicate or pre-finished surfaces, where repairs can be challenging and time-consuming.

- Accurate Nail Placement

Precision nail placement is essential for achieving a clean and professional look. This tool allows for accurate targeting, ensuring that nails are driven exactly where they are needed. This is crucial when attaching trim or molding, where misalignment can be highly visible and detract from the overall finish.

- Nail Hole Size and Concealment

Using a 16-gauge nail inherently produces a smaller entry hole compared to larger gauge fasteners. This characteristic aids in minimizing the visibility of nail holes. When combined with appropriate filling techniques, the resulting finish is smoother and more aesthetically pleasing. This attribute becomes particularly important in projects where a seamless appearance is highly desired.

These characteristics collectively contribute to the overall finish quality achievable with the driving tool. Proper utilization and maintenance are essential to realize the tool’s full potential. Furthermore, the selection of appropriate nails and workpiece preparation are crucial components in achieving professional results. The integration of these factors ensures the resulting finish meets the desired aesthetic and functional requirements.

4. Depth Adjustment

The depth adjustment feature on a 16-gauge finish nailer is integral to achieving consistent and professional results. This setting regulates the force with which the tool drives the nail, dictating the extent of nail penetration into the workpiece. Improper depth adjustment leads to either overdriven nails, which mar the surface and require filling, or underdriven nails, which protrude and present a functional and aesthetic flaw. The presence of a reliable depth adjustment mechanism allows the user to fine-tune the tool’s performance to match the density and thickness of the material being fastened. For example, when working with softwoods like pine, a shallower setting prevents overdriving, while hardwoods like oak require a deeper setting to ensure adequate nail penetration.

The mechanism by which depth adjustment is achieved varies across models, but typically involves a dial or knob that controls the air pressure or the striking force of the tool’s internal hammer. The ability to easily and accurately adjust the depth on a 16-gauge finish nailer translates directly into time savings and reduced material waste. Consider the scenario of installing decorative molding: a precise depth setting minimizes the need for touch-ups and corrections, allowing for faster and more efficient installation. Furthermore, proper depth adjustment prevents the splitting of delicate trim pieces, thereby minimizing material loss and ensuring a high-quality finish.

In conclusion, depth adjustment is not merely an ancillary feature but a fundamental component of a 16-gauge finish nailer’s overall utility. Its precise management influences the quality of the finished product, minimizing imperfections and maximizing efficiency. While the specific implementation of the depth adjustment mechanism may differ across brands and models, its core function remains consistent: to enable users to tailor the tool’s performance to the demands of the task at hand, ensuring consistently superior results. Ignoring or mismanaging this feature negates many of the advantages offered by the tool.

5. Sequential/Contact Actuation

Actuation mode represents a critical consideration when operating a pneumatic finish nailer. The choice between sequential and contact actuation directly impacts both the speed and safety of operation. This section will explore the operational differences and relevant implications within the context of driving tools.

- Sequential Actuation: Controlled Precision

Sequential actuation necessitates the operator to depress the safety contact tip against the workpiece before pulling the trigger. This two-step process reduces the risk of accidental nail discharge. It prioritizes precision and controlled nail placement, making it suitable for tasks requiring high accuracy, such as installing intricate trim work or delicate moldings. An example includes applications where precise corner joints are crucial, ensuring each nail is placed exactly as intended.

- Contact Actuation: Rapid Application

Contact actuation, conversely, allows the operator to fire nails rapidly by keeping the trigger depressed and bumping the safety contact tip against the workpiece. This mode prioritizes speed, making it advantageous for high-volume applications like framing or subflooring, where nail placement is less critical. This is applicable in construction where efficiency is paramount, even if it means a slight compromise in absolute precision.

- Safety Implications and Risk Mitigation

The selection of actuation mode directly impacts user safety. Contact actuation, while faster, inherently carries a higher risk of accidental nail discharge due to the potential for unintentional trigger activation. Sequential actuation mitigates this risk by requiring a deliberate sequence of actions. Therefore, operators must carefully assess the task at hand and prioritize safety by selecting the appropriate actuation mode and adhering to recommended safety protocols.

- Tool Customization and Operational Flexibility

Some pneumatic finish nailer models offer the flexibility to switch between sequential and contact actuation modes, providing operators with adaptability to different project requirements. This feature enhances the tool’s versatility, allowing users to optimize performance based on the specific demands of the task. Consider a scenario where a carpenter needs to switch between installing trim and framing; a dual-mode nailer streamlines the workflow.

In conclusion, actuation mode represents a significant factor influencing both the speed and safety of operating a pneumatic finish nailer. Selecting the appropriate mode requires careful consideration of the task requirements and a commitment to adhering to recommended safety protocols. Versatile tools equipped with both sequential and contact actuation provide operators with enhanced operational flexibility, enabling them to optimize performance based on the unique demands of each project.

Frequently Asked Questions

The following addresses common inquiries regarding the operation, maintenance, and application of the specified pneumatic tool. Understanding these aspects contributes to safe and efficient usage.

Question 1: What is the appropriate air pressure for optimal operation?

The recommended air pressure typically ranges between 70 and 120 PSI. Consult the manufacturer’s specifications for precise figures. Excessive pressure risks damage to both the tool and the workpiece, while insufficient pressure results in incomplete nail driving.

Question 2: What type of lubricant should be used?

Use a dedicated air tool oil specifically formulated for pneumatic tools. Avoid using substitutes such as WD-40 or general-purpose lubricants, as these can damage internal components.

Question 3: How frequently should the tool be cleaned and maintained?

Regular cleaning and maintenance are essential. Ideally, clean the tool after each use and lubricate it daily, especially with frequent operation. Periodically inspect the air filter and replace it as needed.

Question 4: What are the common causes of nail jams, and how can they be resolved?

Nail jams often result from using incorrect nail sizes, damaged nails, or a dirty magazine. Ensure the correct nail size is used, inspect for damage, and clean the magazine regularly. Refer to the user manual for specific troubleshooting steps.

Question 5: Is eye protection necessary when operating this type of tool?

Eye protection is mandatory. Wear safety glasses or goggles to shield against flying debris and potential nail ricochet. Failure to do so carries significant risk of eye injury.

Question 6: What is the difference between sequential and contact actuation?

Sequential actuation requires the safety contact tip to be depressed before the trigger is pulled, prioritizing safety. Contact actuation allows nails to be fired rapidly by bumping the contact tip against the workpiece while the trigger is depressed, prioritizing speed. Choose the appropriate mode based on the task and safety considerations.

Proper understanding and adherence to these guidelines will contribute to the safe, efficient, and reliable operation of the pneumatic tool.

The subsequent section will delve into advanced usage techniques and troubleshooting strategies.

Conclusion

The preceding discussion has illuminated critical facets of the dewalt 16 gauge finish nailer, encompassing its operational characteristics, usage considerations, and common challenges. The tool’s pneumatic power, gauge precision, depth adjustment capabilities, and actuation modes are key determinants of its performance and suitability for various woodworking applications. The emphasis on safety protocols, regular maintenance, and appropriate selection of materials directly correlates to the longevity and effectiveness of the device.

The informed and responsible utilization of the dewalt 16 gauge finish nailer is paramount for achieving professional-grade results and ensuring user safety. Continued adherence to recommended practices and a thorough understanding of the tool’s capabilities will maximize its value and contribute to the successful completion of diverse projects.