Two common types of fasteners employed in woodworking and construction differ significantly in their intended application and structural properties. One is designed for delicate work, prioritizing aesthetics and minimizing visibility. The other is engineered for robust connections, emphasizing strength and shear resistance in structural elements. For example, the former is often used to attach trim or molding, while the latter is crucial for assembling the skeletal framework of a building.

The selection of the appropriate fastener is critical for the longevity and stability of any project. Utilizing the incorrect type can lead to cosmetic imperfections, structural weaknesses, or even catastrophic failure. Historically, variations in fastener design were limited, but advancements in manufacturing have yielded specialized options tailored to increasingly specific needs, improving both efficiency and the quality of finished projects.

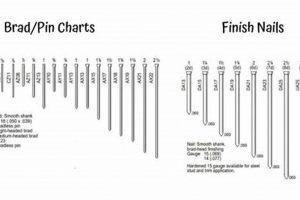

The following sections will detail the key characteristics of each type, including their respective sizes, gauges, head styles, and applications, allowing for an informed decision-making process when selecting the optimal fastener for a given task. A discussion of the tools used for driving each type, and factors influencing fastener selection will also be presented.

Selection and Usage Tips

Proper selection and utilization of fasteners are paramount for both structural integrity and aesthetic appeal. Awareness of their respective strengths and limitations is crucial for a successful project.

Tip 1: Distinguish between requirements. Assess if strength or appearance is the primary concern. Structural elements demand robust fasteners, while finishing work benefits from concealed applications.

Tip 2: Gauge the appropriate length. Fastener length should penetrate sufficiently into the substrate to ensure secure fastening, but avoid excessive length that protrudes or compromises the material.

Tip 3: Consider material compatibility. Employ fasteners composed of materials compatible with the materials being joined. Dissimilar metals can cause galvanic corrosion and weaken the connection over time.

Tip 4: Mind the angle of entry. Drive fasteners perpendicular to the surface whenever possible. Angled entry reduces holding power and increases the likelihood of bending or misalignment.

Tip 5: Pre-drilling pilot holes. When working with hardwoods or near edges, pre-drilling pilot holes prevents splitting and ensures accurate placement.

Tip 6: Adjust driving pressure. Regulate air pressure on pneumatic tools to avoid overdriving or underdriving fasteners. Consistent depth is essential for both strength and appearance.

Tip 7: Select the correct tool. Employ the appropriate tool designed for the specific fastener type. Using an incorrect tool can damage the fastener or compromise the connection.

Adhering to these guidelines will enhance the quality and durability of any woodworking or construction project, minimizing the risk of failure and maximizing aesthetic value.

The subsequent section will provide a comparative analysis of the specific tools required for each fastener type, further elucidating the differences in their application.

1. Gauge

Gauge, a numerical measurement of nail diameter, is a defining characteristic that differentiates these types. A higher gauge number indicates a thinner nail. This difference has direct implications for the nail’s strength, holding power, and the potential for splitting the wood into which it is driven. The selection of gauge directly influences the suitability of a nail for a specific task; for example, employing a low-gauge nail in delicate trim work is more likely to cause visible damage or splitting, rendering it unsuitable. Conversely, a high-gauge nail lacks the necessary strength for structural framing, where secure connections are paramount.

Consider a scenario where crown molding is being installed. A high-gauge nail, like an 18-gauge, is preferable due to its slim profile. This minimizes the risk of splitting the molding and leaves a small, easily concealed hole. In contrast, consider the construction of a stud wall. Here, a low-gauge nail, such as an 8-gauge, is essential. Its larger diameter provides the necessary shear strength to withstand the forces acting on the wall, ensuring structural integrity. The incorrect gauge selection in either scenario would compromise the project’s quality.

Understanding the relationship between gauge and nail type is crucial for successful project outcomes. Recognizing that gauge directly affects holding power, splitting potential, and aesthetic impact enables informed decision-making. This understanding not only contributes to the longevity and stability of the project but also minimizes material waste and rework, saving time and resources.

2. Head Type

The design of a nail’s head is a critical factor in differentiating between these two fastener types, influencing both functionality and aesthetics. Variations in head shape and size dictate the manner in which the nail interacts with the surface material, impacting holding power, visibility, and the potential for countersinking. This feature dictates whether a fastener is appropriate for applications where concealment is paramount or where robust fastening is the primary concern. The head’s design directly influences its intended application and the resultant finish of the work.

Consider the round head, commonly found on those intended for framing. Its large surface area provides substantial holding power, crucial for structural applications where joints must withstand significant stress. Conversely, those designed for finishing often feature a brad or small, nearly headless design. This minimizes visibility and allows for easy concealment with wood filler or paint, essential for trim work and other applications where a clean, unobtrusive appearance is desired. The choice of head type is not arbitrary; it is directly linked to the intended purpose and the desired outcome of the fastening process.

In summary, head type is a key determinant in the selection process. Understanding the relationship between head design and application requirements is essential for achieving optimal results. Selecting the appropriate head type ensures not only secure fastening but also contributes significantly to the overall aesthetic quality of the finished product. Ignoring this critical aspect can compromise both the structural integrity and the visual appeal of any woodworking or construction endeavor.

3. Shank Design

Shank design is a critical differentiating factor between these fastener categories, directly affecting holding power and application suitability. Variations in shank configuration determine the degree of friction and mechanical interlock achieved within the substrate material. This characteristic is crucial for understanding the appropriate use case for each type.

- Smooth Shank

Smooth shanks, common in those designed for finishing, offer minimal resistance during insertion. This reduces the likelihood of splitting delicate wood, making them ideal for trim and molding. However, smooth shanks provide lower holding power compared to other designs, necessitating alternative methods like adhesives for long-term stability in certain applications.

- Ring Shank

Ring shanks feature a series of annular rings along the shaft. These rings provide increased withdrawal resistance as the wood fibers interlock with the grooves. Framing often utilizes ring-shank nails to withstand shear forces and maintain structural integrity in framing applications. The increased holding power makes them less prone to loosening over time, contributing to a more durable structure.

- Spiral Shank

Spiral shanks, characterized by a twisted or helical form, are designed to rotate during insertion. This twisting action creates a tighter grip within the wood fibers, enhancing holding power and reducing the potential for nail popping. They are frequently employed in applications requiring high withdrawal resistance, such as subflooring or decking. The spiral design effectively transforms driving force into rotational force, optimizing the connection.

- Barbed Shank

Barbed shanks incorporate small, backward-facing barbs along the shaft. These barbs act as one-way anchors, resisting withdrawal once the nail is driven. While offering significant holding power, barbed shanks can be more difficult to drive and may increase the risk of splitting the wood. Their use is typically limited to specialized applications where exceptional pullout resistance is paramount, such as securing roofing materials.

In summary, shank design directly correlates with the intended application and performance characteristics of a fastener. While smooth shanks prioritize aesthetics and ease of use, ring, spiral, and barbed shanks emphasize holding power and long-term durability. The selection of an appropriate shank design is essential for ensuring both the structural integrity and aesthetic quality of any construction or woodworking project, underscoring the significance of understanding these nuanced differences.

4. Application

The intended application dictates the appropriate selection between these two fastener types. This is a critical factor, as each is engineered for specific tasks. Improper application can lead to structural instability or aesthetic deficiencies. Framing, involving the assembly of structural elements like walls and roofs, requires fasteners capable of withstanding significant loads. In contrast, finish work, which includes installing trim, molding, and cabinetry, demands fasteners that minimize visibility and prevent damage to delicate materials.

An example of this distinction lies in the construction of a stud wall. Framing is essential here to connect studs, top plates, and bottom plates securely. Fasteners with high shear strength, such as those with ring shanks and larger diameters, are used. Employing smaller, less robust options in this scenario would compromise the structural integrity of the wall, potentially leading to collapse under stress. Conversely, installing crown molding necessitates using fasteners that leave minimal visible holes. Employing larger diameter in this scenario would result in unsightly blemishes, detracting from the finished appearance.

In summary, understanding the intended application is paramount when choosing between these fastener options. Failure to recognize the specific demands of each task can lead to suboptimal results, ranging from structural weakness to cosmetic flaws. Careful consideration of the application is crucial for ensuring both the longevity and aesthetic appeal of any construction or woodworking project.

5. Holding Power

Holding power, the capacity of a fastener to resist withdrawal from a substrate, is a critical performance metric that distinguishes options available. This attribute is not merely a measure of resistance but a determinant of structural integrity and long-term durability. The selection between these options hinges significantly on the required holding power for a given application.

- Shank Design and Friction

Shank design directly influences holding power through friction. Framing fasteners often feature ring or spiral shanks, increasing surface area and mechanical interlock with the wood fibers. This enhanced friction provides substantial resistance to pullout, essential in structural applications. Finish fasteners typically possess smooth shanks, prioritizing ease of insertion and minimizing the risk of splitting delicate materials. The lower friction of smooth shanks, however, results in reduced holding power, suitable for applications where aesthetic considerations outweigh structural demands. For example, fastening heavy trim with those designed for finishing, which may have smooth shanks, could lead to separation over time due to insufficient friction.

- Head Size and Pull-Through Resistance

Head size is another factor contributing to holding power. Framing fasteners generally have larger heads, providing a greater surface area to resist pull-through. This is particularly important in applications where the fastened material is subjected to significant tensile forces. The small or nearly headless nature of those designed for finishing minimizes visibility but also reduces pull-through resistance. In applications like attaching thin paneling, the risk of the fastener head pulling through the material is higher if the head size is not adequately matched to the applied load.

- Material Density and Nail Embedment

The density of the substrate material significantly affects holding power. Denser materials, such as hardwoods, offer greater resistance to withdrawal compared to softer materials like pine. The depth of nail embedment also plays a crucial role. Deeper penetration into the substrate increases the surface area in contact with the fastener, enhancing holding power. Framing applications typically involve fastening into dense lumber, maximizing the benefits of robust shank designs and ample embedment depths. When fastening into less dense materials with those for finishing, careful consideration of nail length and pre-drilling may be necessary to prevent splitting and ensure adequate holding power.

- Corrosion Resistance and Longevity

Corrosion can significantly reduce the holding power of fasteners over time. Corrosion weakens the fastener and diminishes its ability to grip the surrounding material. Fasteners intended for exterior applications or environments with high humidity require corrosion-resistant coatings or materials, such as galvanized steel or stainless steel. The reduced size and application contexts typically associated with those for finishing may lead to less emphasis on corrosion resistance compared to framing. However, for applications in damp or humid environments, corrosion resistance remains a crucial factor in maintaining long-term holding power and preventing joint failure.

These multifaceted considerations underscore the crucial role of holding power in differentiating these two categories. Understanding the interplay between shank design, head size, material density, and corrosion resistance is essential for selecting the appropriate fastener and ensuring the long-term structural integrity and aesthetic quality of any construction project. The required holding power must align with the anticipated stresses and environmental conditions to guarantee a secure and durable connection.

Frequently Asked Questions

This section addresses common inquiries regarding the selection and application of these two distinct fastener types. The information presented aims to clarify misconceptions and provide practical guidance for optimal project outcomes.

Question 1: Is it acceptable to substitute one for the other in a pinch?

Substitution is generally discouraged. Framing nails are engineered for structural applications, possessing greater shear strength and holding power. Finish nails prioritize aesthetics and are not designed to withstand significant loads. Using a finish nail in place of a framing nail compromises structural integrity. Conversely, using a framing nail for finish work often results in visible damage and detracts from the desired aesthetic.

Question 2: What factors determine the appropriate length?

Length selection depends primarily on the thickness of the materials being joined. A general rule dictates that the nail should penetrate at least two-thirds of its length into the receiving material. However, factors such as wood density and the presence of adhesives can influence this requirement. Overly long nails can protrude and pose a safety hazard, while insufficient length compromises holding power.

Question 3: Are there specific safety precautions to observe?

Eye protection is crucial when using any type of nail gun or hammer. Misdirected fasteners can cause serious injury. Hand protection, such as gloves, is also recommended to prevent injuries from handling materials and tools. Furthermore, users should be thoroughly familiar with the operation and safety features of the tools employed.

Question 4: How does wood type influence fastener selection?

Wood density significantly affects holding power and splitting potential. Hardwoods, such as oak and maple, offer greater resistance to withdrawal but are also more prone to splitting. Softwoods, like pine and fir, are less prone to splitting but provide lower holding power. Pre-drilling pilot holes is often necessary when working with hardwoods to prevent splitting, regardless of fastener type.

Question 5: Can these be used in exterior applications?

Standard nails are susceptible to corrosion in exterior environments. For outdoor projects, galvanized or stainless steel fasteners are recommended. These materials offer superior resistance to rust and corrosion, ensuring long-term structural integrity. The specific alloy and coating should be selected based on the severity of the environmental conditions.

Question 6: What is the best method for concealing those designed for finishing?

The small hole left by those designed for finishing can be effectively concealed using wood filler. The filler should be matched to the color of the surrounding wood. After the filler dries, it should be sanded smooth to blend seamlessly with the surface. Alternatively, paintable caulk can be used for painted surfaces.

In summary, informed decision-making regarding fastener selection is crucial for ensuring project success. Understanding the unique characteristics of each type, along with the specific demands of the application, is essential for achieving optimal results.

The following section will explore the tools used to drive each type of nail, further highlighting their differences and application techniques.

Conclusion

This exploration has detailed the fundamental differences and specific applications of these two distinct categories of fasteners. Gauge, head type, shank design, application, and holding power are critical differentiating factors that dictate appropriate usage. Understanding these attributes is paramount for ensuring both structural integrity and aesthetic quality in construction and woodworking projects.

The careful selection of the correct fastener, based on a thorough assessment of project requirements, remains essential. Continued adherence to best practices in fastener selection and application will contribute to improved project outcomes and enhanced safety within the construction and woodworking trades.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)