A portable fastening tool, powered by batteries, is designed for driving small-gauge nails into wood for trim work, cabinetry, and other delicate applications. This type of tool eliminates the need for hoses or cords, offering enhanced mobility and convenience on job sites.

The freedom from restrictive power sources is a significant advantage, improving efficiency and reducing tripping hazards. The rise of this battery-operated technology has revolutionized woodworking and construction projects by enabling users to perform tasks more easily in various locations. Prior to this innovation, pneumatic or corded models were the standard, limiting movement and requiring access to compressed air or electrical outlets.

The following sections will examine factors to consider when selecting this type of tool, maintenance tips for optimal performance, and a comparison with traditional methods of fastening.

Operating and Maintaining a Cordless Finish Nailer

Proper operation and regular maintenance are critical for maximizing the lifespan and performance of battery-powered finish nailers. Adhering to these guidelines ensures reliable and consistent results.

Tip 1: Battery Management: Employ a consistent charging schedule. Avoid allowing batteries to fully deplete, as this can shorten their lifespan. Utilize compatible chargers designed for the specific battery type.

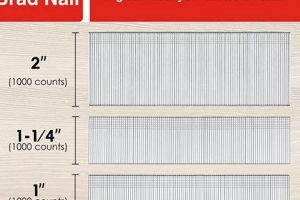

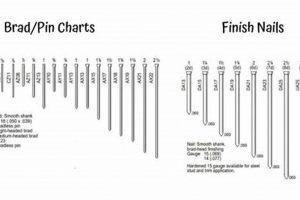

Tip 2: Nail Selection: Employ the correct nail length and gauge recommended by the manufacturer for the specific application. Using incorrect nails may lead to jamming or damage to the tool.

Tip 3: Depth Adjustment: Adjust the depth-of-drive setting to ensure nails are consistently set flush with the work surface without damaging the surrounding material. Test the setting on scrap material before proceeding with the final workpiece.

Tip 4: Regular Cleaning: Periodically clean the nailer’s nosepiece and magazine to remove debris and prevent jams. A small brush or compressed air can be used for this purpose.

Tip 5: Lubrication: Consult the manufacturer’s instructions regarding lubrication. Some models require occasional lubrication of internal components to maintain smooth operation.

Tip 6: Storage: Store the nailer in a clean, dry environment to protect it from corrosion and damage. Remove the battery when storing the tool for extended periods.

Tip 7: Safety Precautions: Always wear appropriate safety glasses to protect eyes from flying debris. Never point the nailer at oneself or others. Disconnect the battery before performing any maintenance or adjustments.

By following these maintenance recommendations, operators can extend the lifespan of the cordless finish nailer and ensure consistently precise and reliable performance.

The subsequent section will address common troubleshooting issues and their potential solutions.

1. Battery Voltage

Battery voltage directly influences the performance characteristics of a portable, battery-powered fastening tool. A higher voltage typically equates to increased power output, enabling the tool to drive nails more consistently and effectively, particularly into harder materials. Conversely, a lower voltage may result in reduced driving force, potentially leading to incomplete nail sets or jamming. For example, a professional cabinet maker working with hardwoods such as maple or oak will likely require a tool with a higher voltage rating to ensure proper nail penetration. The selection of an appropriate voltage is therefore crucial for achieving desired results and preventing rework.

The relationship between battery voltage and runtime is also significant. While higher voltage systems may provide greater power, they do not necessarily guarantee longer runtimes. Battery capacity, measured in amp-hours (Ah), plays a critical role in determining how long a tool can operate on a single charge. A lower voltage tool with a higher Ah battery may, in some instances, offer a longer runtime than a higher voltage tool with a lower Ah battery. This interplay between voltage and capacity must be considered when evaluating portable fastening tools for specific project requirements.

In summary, battery voltage is a primary determinant of the power and driving force provided by portable fastening tools, affecting their ability to handle various materials and applications. While higher voltage often translates to increased power, considerations of battery capacity and the specific demands of the task at hand are essential for selecting the optimal tool. Understanding this connection enables informed decisions, leading to improved efficiency and project outcomes.

2. Nail Capacity

Nail capacity, referring to the number of nails a portable, battery-powered fastening tool can hold in its magazine, significantly influences workflow efficiency. A higher nail capacity reduces the frequency of reloading, thereby minimizing interruptions and maximizing productivity, especially in large-scale projects. For example, a trim carpenter installing baseboards throughout a house will benefit from a tool with a greater capacity, allowing for uninterrupted runs along walls and decreasing the overall time spent on the task.

The practical consequences of limited nail capacity extend beyond mere inconvenience. Repeatedly reloading a tool can disrupt the rhythm of work, leading to inconsistencies in the quality of finish. Moreover, the time spent reloading accumulates over the course of a project, potentially impacting project timelines and increasing labor costs. Consequently, professionals often prioritize models with ample capacity, trading off slight increases in weight or size for the enhanced efficiency they provide. In contrast, DIY enthusiasts undertaking smaller, less demanding projects might find lower-capacity models sufficient, as the frequency of reloading is less critical.

Ultimately, the optimal nail capacity for a portable, battery-operated fastening tool is contingent upon the specific application and the user’s needs. High-volume tasks demand higher capacities to maintain efficiency and minimize downtime. Understanding this relationship allows informed selection, contributing to increased productivity and improved project outcomes. Challenges can arise when tool manufacturers compromise magazine durability to achieve higher capacity, creating the need to balance nail holding quantity with overall build quality.

3. Depth Adjustment

Depth adjustment is a critical feature in a cordless finish nailer. This functionality allows the user to control the depth to which the nail is driven into the material. The consequence of improper depth setting is either a nail that protrudes above the surface or one that is driven too deep, damaging the surrounding material. Precise depth adjustment ensures a flush, professional finish, eliminating the need for manual setting and patching. For instance, when fastening delicate trim to a cabinet, a shallow setting prevents splitting the wood; conversely, when attaching thicker molding to a wall stud, a deeper setting is necessary for secure fastening. Therefore, depth adjustment is integral to the versatility and effectiveness of a cordless finish nailer.

The mechanism for depth adjustment varies across models, ranging from tool-free dials to adjustable nose pieces. Tool-free adjustments offer convenience and speed, enabling quick changes between different materials. The ability to fine-tune the depth is particularly important when working with varying densities of wood. Softwoods like pine require less driving force than hardwoods like oak, and an adjustable setting accommodates these differences. Moreover, consistency in depth setting is vital for aesthetic uniformity, especially in visible applications such as crown molding or baseboard installation. An inconsistent depth setting can result in an uneven, unprofessional appearance, detracting from the overall quality of the finished product.

In summary, depth adjustment is an indispensable attribute of a cordless finish nailer. It ensures that nails are driven to the appropriate depth, safeguarding the material and yielding a professional-quality finish. The capacity to adjust this setting quickly and accurately enhances the tool’s versatility and contributes significantly to the overall efficiency of woodworking and finishing projects. Understanding the implications of depth setting and properly utilizing the adjustment feature are essential skills for any user of a cordless finish nailer.

4. Weight Distribution

Weight distribution is a paramount consideration in the design and utilization of portable, battery-powered fastening tools. The balance of weight directly impacts user fatigue, precision, and overall control during operation. An improperly balanced tool can lead to strain, reduced accuracy, and potential safety hazards.

- Ergonomic Impact on User Fatigue

Uneven weight distribution requires the user to exert more effort to maintain a stable grip and accurate nail placement. This increased exertion accelerates fatigue, particularly during prolonged use. For instance, a tool with a significant weight bias towards the front may cause wrist and forearm strain, leading to decreased productivity and increased risk of musculoskeletal injuries. A well-balanced tool minimizes these effects by distributing the weight evenly across the user’s hand, reducing the required effort for control and stability.

- Influence on Precision and Accuracy

A balanced weight distribution contributes significantly to improved accuracy and precision in nail placement. When a tool is poorly balanced, the user must compensate for the imbalance, introducing potential for unintended movement and imprecise nail positioning. This is especially crucial when working on delicate trim or intricate woodworking projects where accurate nail placement is paramount. Tools with a balanced design allow for smoother, more controlled operation, resulting in cleaner, more professional results.

- Relationship to Tool Maneuverability

Weight distribution affects the tool’s maneuverability in confined spaces or awkward positions. A tool that is top-heavy or excessively weighted to one side can be difficult to control in tight corners or when working overhead. This reduced maneuverability can limit the user’s ability to reach certain areas and compromise the quality of the work. A well-balanced tool offers greater flexibility and ease of use, allowing the user to navigate difficult workspaces with greater confidence and control.

- Connection to Long-Term User Health

The effects of poor weight distribution accumulate over time, potentially leading to chronic musculoskeletal issues. The strain and repetitive movements required to control an unbalanced tool can contribute to conditions such as carpal tunnel syndrome, tendonitis, and other repetitive strain injuries. Choosing a tool with optimized weight distribution can mitigate these risks, promoting long-term user health and well-being. Prioritizing ergonomics and balanced design is essential for safeguarding the health of professional users who rely on these tools daily.

The interplay of these facets underscores the importance of weight distribution in the selection and use of portable, battery-powered fastening tools. A well-balanced tool not only enhances immediate performance and accuracy but also contributes to long-term user comfort and safety. Manufacturers who prioritize ergonomic design and balanced weight distribution create tools that are more efficient, user-friendly, and conducive to sustainable work practices.

5. Trigger Mechanism

The trigger mechanism in a portable, battery-powered fastening tool is a critical interface between the operator and the tool’s functionality. This mechanism controls the actuation of the nail-driving process, directly influencing precision, speed, and safety. A well-designed trigger allows for consistent nail placement and efficient operation, whereas a poorly designed trigger can lead to inaccurate nail delivery, user fatigue, and increased risk of accidental firing. For example, a sensitive trigger with minimal travel may increase the risk of unintentional nail discharge, while a trigger requiring excessive force can cause hand strain and reduce productivity during extended use.

Two primary types of trigger mechanisms are commonly found in battery-powered finish nailers: sequential actuation and contact actuation. Sequential actuation requires the user to press the safety contact tip against the workpiece before pulling the trigger, preventing unintentional firing. This mode is often preferred for precision work where accurate nail placement is paramount. Contact actuation, conversely, allows the user to keep the trigger depressed and drive nails by simply bumping the safety contact tip against the work surface. This mode is typically used for high-speed applications where nail placement accuracy is less critical. The choice between these modes depends on the specific task and the user’s preference, influencing both efficiency and safety.

In summary, the trigger mechanism is an essential component of the portable, battery-powered fastening tool, directly impacting performance, safety, and user experience. The type of trigger mechanism, its sensitivity, and its ergonomic design all contribute to the overall effectiveness of the tool. Understanding the nuances of different trigger mechanisms allows users to make informed decisions based on their specific needs and applications. Challenges in trigger mechanism design include balancing sensitivity with safety and minimizing user fatigue during prolonged operation. The ongoing development of more sophisticated and ergonomic trigger mechanisms reflects the industry’s commitment to improving the performance and safety of these tools.

6. Brushless Motor

The integration of brushless motors represents a significant advancement in portable, battery-powered fastening tools. Brushless motors operate with greater efficiency and longevity compared to their brushed counterparts. This is primarily attributable to the elimination of physical brushes, which are prone to wear and generate friction and heat. In the context of a cordless finish nailer, the utilization of a brushless motor translates directly to extended runtime per battery charge, increased power output for driving nails into denser materials, and a prolonged overall tool lifespan. For instance, a professional carpenter using a brushless nailer for all-day trim work will experience fewer battery changes and consistent performance, thereby enhancing productivity.

The absence of brushes in the motor design also reduces the need for regular maintenance. Brushed motors require periodic brush replacement, whereas brushless motors are virtually maintenance-free. This reduction in maintenance translates to lower operating costs and less downtime for the user. Moreover, the enhanced efficiency of brushless motors allows for more compact tool designs, which can improve maneuverability in confined spaces. An example of this is a smaller, lighter cordless finish nailer that can more easily access tight corners or overhead locations. The reduced heat generation of brushless motors also contributes to increased tool reliability and reduces the risk of overheating during continuous use.

In summary, the adoption of brushless motor technology has substantially improved the performance, durability, and efficiency of cordless finish nailers. The benefits of extended runtime, reduced maintenance, and increased power output make brushless models a compelling choice for both professional and DIY users. Understanding the advantages of brushless motors allows for informed purchasing decisions, leading to improved productivity and a lower total cost of ownership over the tool’s lifespan. Potential challenges include the higher initial cost of brushless models, which may be offset by their long-term benefits. Future developments in motor technology are likely to further enhance the capabilities of cordless finish nailers, solidifying their position as essential tools for a wide range of applications.

7. Jam Clearance

Jam clearance is a critical operational aspect of any fastening tool, particularly for cordless finish nailers. The frequency and ease with which a nail jam can be resolved directly impacts productivity, downtime, and overall user satisfaction. A robust jam clearance mechanism is therefore an essential feature to consider when evaluating this type of equipment.

- Mechanism Design and Accessibility

The design of the jam clearance mechanism dictates the ease with which a user can remove a lodged nail. Accessible designs, often involving tool-free latches or levers, allow for quick and efficient removal of jams without requiring additional tools. A finish carpenter using a cordless nailer on a time-sensitive project benefits significantly from a readily accessible jam clearance system, minimizing disruptions and maintaining workflow.

- Tool-Free vs. Tool-Required Clearance

Tool-free jam clearance mechanisms are generally preferred due to their convenience. Requiring a separate tool to clear a jam introduces additional steps and potential delays, particularly on a job site where tools may not be readily accessible. The distinction between tool-free and tool-required clearance directly influences the time spent resolving a jam and the overall efficiency of the work process.

- Jam Prevention Features

While effective jam clearance is crucial, preventative measures are equally important. Some cordless finish nailers incorporate features designed to minimize the occurrence of jams, such as optimized nail magazine designs, precise nail feeding mechanisms, and sensors that detect and prevent misfires. These features reduce the need for jam clearance interventions, contributing to a more seamless and productive workflow.

- Impact on Tool Longevity

The design and implementation of the jam clearance system can also affect the long-term durability of the cordless finish nailer. A poorly designed mechanism that requires excessive force or manipulation can potentially damage internal components over time. A robust and well-engineered system, on the other hand, contributes to the overall longevity and reliability of the tool.

In summation, the jam clearance capabilities of a cordless finish nailer are integral to its performance and usability. Factors such as mechanism design, accessibility, and the presence of preventative features all contribute to the overall efficiency and reliability of the tool. A comprehensive understanding of these facets enables informed purchasing decisions and optimized utilization in various woodworking and construction applications.

Frequently Asked Questions

This section addresses common inquiries and clarifies key aspects related to cordless finish nailers, providing information for informed decision-making.

Question 1: What distinguishes a cordless finish nailer from other types of nailers?

A cordless finish nailer is specifically designed for driving 15- or 16-gauge finish nails. These nails are smaller than those used in framing or roofing nailers, making them suitable for delicate trim work, cabinetry, and other applications where a less conspicuous fastener is desired. The cordless designation indicates that the tool is battery-powered, eliminating the need for an air compressor or electrical cord.

Question 2: What is the expected battery life of a cordless finish nailer?

Battery life varies depending on the voltage and amp-hour rating of the battery, as well as the material being fastened. Higher voltage and amp-hour ratings generally provide longer runtimes. Harder materials will require more energy to drive nails, reducing the overall battery life. Refer to the manufacturer’s specifications for estimated nail counts per charge.

Question 3: Is a cordless finish nailer as powerful as a pneumatic model?

Modern cordless finish nailers are capable of delivering comparable power to pneumatic models for most applications. However, pneumatic nailers may offer a slight advantage in driving nails into exceptionally dense hardwoods. The convenience and portability of cordless models often outweigh this marginal difference in power for many users.

Question 4: What safety precautions should be observed when operating a cordless finish nailer?

Always wear appropriate eye protection to guard against flying debris. Keep hands and body parts clear of the nail discharge area. Disconnect the battery before performing any maintenance or adjustments. Avoid operating the tool in explosive environments. Consult the manufacturer’s safety guidelines for comprehensive instructions.

Question 5: What is the typical maintenance required for a cordless finish nailer?

Maintenance primarily involves keeping the tool clean and free of debris. Regularly inspect the nail magazine and nosepiece for obstructions. Lubricate moving parts as recommended by the manufacturer. Store the tool in a dry environment when not in use. Replace batteries as needed.

Question 6: Are all cordless finish nailers compatible with all brands of finish nails?

Compatibility depends on the gauge and length of the nails, as well as the design of the nail magazine. Consult the tool’s specifications to ensure that the intended nails are compatible. Using incorrect nails may lead to jamming or damage to the tool.

These FAQs provide a fundamental understanding of cordless finish nailers, enabling users to make informed choices and operate the tools safely and effectively.

The subsequent section will delve into comparative analyses of various cordless finish nailer models currently available on the market.

Conclusion

The preceding analysis has explored the attributes, operation, and maintenance of the finish nailer cordless. Key aspects such as battery voltage, nail capacity, depth adjustment, weight distribution, trigger mechanism, motor type, and jam clearance have been examined in detail. A thorough understanding of these elements is essential for making informed purchasing and usage decisions.

Continued advancements in battery technology and motor design will likely lead to further improvements in the performance and efficiency of cordless finish nailers. The information presented herein serves as a foundation for evaluating current models and anticipating future innovations in this vital tool category. Responsible use and adherence to safety guidelines remain paramount.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)