This power tool, manufactured by Makita, is designed for driving finish nails into wood surfaces. It operates without a cord, relying on battery power for portability and convenience. An example of its use is attaching trim, molding, or cabinetry in woodworking projects.

The device’s significance lies in its freedom from air compressors and hoses, enabling efficient operation in various locations, including those with limited access to power. This design improves job site mobility, reduces setup time, and contributes to increased productivity. Historically, pneumatic versions were the standard, but cordless models offer enhanced user experience.

The subsequent sections will delve into the specific features, performance characteristics, maintenance requirements, and ideal applications of this battery-operated fastening system. A comparison with other similar products and advice on selecting the appropriate model will also be included.

Operational Tips for Cordless Finish Nailers

Employing a cordless finish nailer effectively necessitates understanding optimal practices for performance and longevity.

Tip 1: Battery Management: Prioritize consistent battery charging. Full depletion negatively impacts overall battery lifespan. Maintain a regular charging schedule even during periods of infrequent use.

Tip 2: Depth Adjustment Calibration: Before initiating work on a finished surface, test the depth adjustment on a piece of scrap material. This ensures nails are driven flush without damaging the surrounding wood.

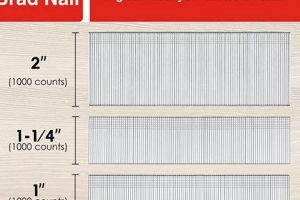

Tip 3: Consistent Nail Selection: Use only specified nail types and sizes as indicated in the manufacturers documentation. Deviations can cause tool malfunction or unreliable fastening.

Tip 4: Proper Tool Maintenance: Regularly clean the nailer’s nose and magazine. Accumulated debris impairs nail feeding and driving mechanisms, potentially leading to jams.

Tip 5: Secure Workpiece Stabilization: Ensure the material being fastened is properly secured. Movement during nail driving can result in inaccurate placement and potential injury.

Tip 6: Consider Environmental Factors: Extreme temperatures can affect battery performance. Storing the nailer and batteries in a climate-controlled environment optimizes operational efficiency.

Implementing these practices enhances operational efficiency, extends the life of the nailer, and contributes to consistently professional results.

The following section will summarize key considerations for choosing the appropriate model for specific applications.

1. Power Source

The power source is a critical determinant of performance and practicality in cordless finish nailers. It dictates runtime, portability, and the overall user experience. The following facets explore the various aspects of power sources in relation to these tools.

- Battery Voltage and Ampere-Hour (Ah) Rating

Voltage provides the necessary force to drive nails, and the Ah rating reflects the battery’s capacity to deliver power over time. Tools typically utilize 18V batteries, with higher Ah ratings (e.g., 5.0Ah) providing extended use between charges. This is essential for larger projects or job sites where frequent recharging is impractical.

- Battery Technology (Lithium-Ion)

Lithium-ion batteries are the standard for these nailers due to their high energy density, low self-discharge rate, and lack of memory effect. This technology ensures consistent power delivery and allows for convenient partial charging without reducing battery lifespan.

- Charging System

The charging system impacts the nailer’s overall usability. Rapid chargers can significantly reduce downtime, while some models offer compatibility with vehicle charging systems, expanding operational flexibility. Indicator lights provide feedback on charging status and battery health.

- Battery Interchangeability and Ecosystem

Makita often uses the same battery platform across its range of cordless tools. This interoperability allows users to share batteries between different tools, reducing overall equipment costs and simplifying power management on job sites. This feature adds significant value to professional users who already own other Makita cordless tools.

These aspects of the power source directly influence the practical application of cordless finish nailers. An adequate voltage ensures reliable nail driving, while sufficient battery capacity minimizes interruptions. Furthermore, battery technology and the charging system contribute to the convenience and efficiency of operation, making power source a core consideration when choosing this equipment.

2. Nail Capacity

Nail capacity, the number of nails the magazine holds, is a significant determinant of operational efficiency in a Makita cordless finish nailer. A larger capacity directly reduces the frequency of reloading, thus minimizing interruptions during continuous operation. The impact of this is particularly evident on extensive projects involving substantial lengths of trim or molding. For example, a model with a 100-nail capacity requires reloading less often than one holding only 50 nails, resulting in tangible time savings and enhanced productivity.

The design of the magazine also influences the ease of reloading. A magazine that opens and closes smoothly, with a clear mechanism for nail insertion, further contributes to efficient operation. In contrast, a poorly designed magazine might cause nail jams or require more time to reload, negating some of the benefits of a cordless system. Professional carpenters often consider the nail capacity and magazine design when selecting a cordless finish nailer to maximize their on-site output. A poorly chosen capacity can also lead to incomplete tasks and reduced profitability.

Consequently, nail capacity serves as a practical metric for evaluating the suitability of a given Makita cordless finish nailer for specific applications. Understanding this connection allows users to select a tool that optimally balances convenience, runtime, and the demands of the task at hand. Failure to consider nail capacity can lead to inefficiencies and increased labor costs, underscoring its importance in the overall performance equation.

3. Depth Adjustment

Depth adjustment is a critical feature on a Makita cordless finish nailer, directly impacting the quality and precision of fastening. It governs the extent to which nails are driven into the work surface, ensuring consistent results across varied materials and applications. The ability to fine-tune this parameter is essential for achieving professional finishes and preventing damage to the workpiece.

- Mechanism Type and Precision

Depth adjustment mechanisms on these nailers vary, ranging from tool-free dials to more complex systems involving shims or specialized tools. The precision of the adjustment directly influences the user’s ability to consistently set nails flush with the surface or countersink them to a specific depth. A high-quality mechanism provides incremental control, allowing for subtle adjustments to accommodate differing wood densities and nail types.

- Material Compatibility

Different materials require varying nail depths. Softwoods like pine necessitate shallower settings to prevent nails from passing through, while hardwoods such as oak require deeper settings to ensure secure fastening. The depth adjustment feature enables the nailer to adapt to these differing requirements, preventing splitting or protruding nails. For example, installing trim on a drywall surface requires a precise, shallow setting to avoid damaging the underlying wallboard.

- Nail Type and Size Considerations

The length and gauge of the finish nails being used also influence the required depth setting. Longer nails naturally require a deeper setting to be fully embedded, while smaller gauge nails may require a shallower setting to prevent over-driving. The depth adjustment feature allows the user to compensate for these variations, ensuring optimal performance across a range of nail types and sizes.

- Impact on Finish Quality

Improper depth adjustment directly affects the final appearance of the finished product. Nails driven too deeply leave unsightly depressions, while nails not driven far enough protrude from the surface. Correctly utilizing the depth adjustment feature ensures a clean, professional finish, where nails are either flush with the surface or consistently countersunk to a uniform depth, depending on the desired aesthetic. For instance, a precise depth setting is crucial when installing crown molding to achieve a seamless transition between the molding and the wall.

In summary, the depth adjustment feature is integral to the versatility and performance of a Makita cordless finish nailer. It allows the tool to adapt to a wide range of materials, nail types, and applications, ultimately determining the quality and appearance of the finished product. Without precise depth adjustment, consistent, professional results are difficult to achieve, highlighting its importance as a key feature for users seeking optimal performance.

4. Ergonomic Design

Ergonomic design constitutes a fundamental component of a Makita cordless finish nailer, directly influencing user comfort, reducing fatigue, and enhancing overall productivity. The physical demands associated with prolonged tool usage necessitate careful consideration of weight distribution, grip design, and balance. A nailer with poor ergonomics can lead to operator strain, decreased accuracy, and potential long-term musculoskeletal issues. Conversely, a well-designed nailer promotes a natural grip, minimizes vibration transfer to the user’s hand, and reduces the force required to operate the tool. For instance, a handle with a non-slip coating and contoured shape allows for secure handling, even with gloved hands or in damp conditions. The placement of controls, such as the depth adjustment dial and power switch, should also be intuitive and easily accessible to minimize unnecessary hand movements and disruptions to the workflow.

The balance of the nailer is equally critical. A front-heavy design requires the user to exert more force to maintain control, leading to fatigue and reduced precision. Optimal weight distribution ensures that the tool feels balanced in the hand, requiring minimal effort to keep it aligned with the workpiece. This is particularly important when working overhead or in confined spaces where maneuverability is limited. Vibration dampening features, such as rubberized grips and internal dampening mechanisms, also contribute to user comfort by reducing the transmission of vibrations generated during nail driving. Excessive vibration can cause numbness, tingling, and long-term nerve damage.

In summary, ergonomic design is not merely an aesthetic consideration but a practical necessity for a Makita cordless finish nailer. It directly impacts user comfort, reduces the risk of injury, and enhances overall productivity. A well-designed nailer minimizes strain, promotes natural hand positioning, and optimizes weight distribution, enabling users to work comfortably and efficiently for extended periods. Investing in a nailer with superior ergonomics is a worthwhile consideration for any professional or serious DIY enthusiast who values long-term health and performance. Conversely, neglecting ergonomic design can result in decreased productivity, increased risk of injury, and ultimately, reduced job quality.

5. Application Range

The application range of a Makita cordless finish nailer directly correlates to its utility and versatility on a job site. The tool’s capabilities determine the types of projects it can effectively undertake. This range extends beyond simply driving finish nails; it encompasses material compatibility, nail size accommodation, and the precision required for different tasks. For instance, a nailer designed for heavy-duty trim work might lack the finesse needed for delicate molding applications, leading to material damage. The specific application dictates the required power, nail capacity, and depth adjustment capabilities of the nailer. A broad application range translates to a more adaptable and valuable tool, while a limited range restricts its use to specific scenarios. Real-life examples of typical applications include installing baseboards, crown molding, door and window casings, cabinet assembly, and decorative trim. Understanding the application range is essential for selecting the appropriate nailer for a given set of tasks.

The interplay between the intended application and the nailer’s specifications highlights the practical significance of this consideration. A contractor focusing on residential trim work will prioritize a lightweight, versatile model with adjustable depth settings. Conversely, a cabinet maker may require a nailer with greater power and nail capacity for assembling larger units. Overlooking the application range can result in inefficient operation, compromised finish quality, or even tool damage. The chosen nailer must be capable of handling the required nail sizes and material densities without sacrificing precision or reliability. Moreover, the tool’s ergonomic design should support the tasks at hand, minimizing user fatigue during extended use.

In conclusion, the application range serves as a critical parameter in evaluating a Makita cordless finish nailer. Matching the tool’s capabilities to the intended uses ensures optimal performance, efficient operation, and high-quality results. The application range is a primary driver of tool selection and a key determinant of its long-term value. Failure to adequately assess this factor can lead to suboptimal performance and ultimately, increased project costs. The suitability of the device for its intended application should be carefully considered.

6. Maintenance Needs

Maintenance needs are intrinsically linked to the performance and longevity of a Makita cordless finish nailer. Neglecting routine maintenance leads to diminished operational efficiency and an increased probability of malfunctions. Accumulated debris within the nail chamber, for instance, directly impedes the nail feeding mechanism, causing jams and inconsistent fastening. Battery maintenance is equally critical. Improper charging or storage can degrade battery performance, resulting in reduced runtime and diminished power output. A lack of lubrication on moving parts accelerates wear and tear, shortening the tool’s lifespan. Real-world examples include contractors experiencing premature tool failure due to neglecting regular cleaning and lubrication, and DIY enthusiasts facing battery issues stemming from improper storage practices. Understanding these maintenance needs is not merely a matter of convenience but a prerequisite for maximizing the investment in a Makita cordless finish nailer.

Practical applications of this understanding translate into tangible benefits. Implementing a routine maintenance schedule, which includes cleaning the nail chamber, lubricating moving parts, and properly storing batteries, extends the tool’s operational life and reduces the likelihood of costly repairs. Periodic inspection of the tool for worn or damaged components allows for timely replacement, preventing minor issues from escalating into major problems. Furthermore, adhering to the manufacturer’s recommendations for nail type and size minimizes the risk of internal damage caused by incompatible fasteners. The cost of replacement parts and labor for repairs can often exceed the cost of preventative maintenance, underscoring the economic advantages of a proactive approach.

In summary, the maintenance needs of a Makita cordless finish nailer constitute an integral aspect of its overall performance and value. While challenges such as time constraints and a lack of awareness may impede consistent maintenance practices, the long-term benefits of adherence significantly outweigh the perceived inconveniences. Addressing these needs ensures consistent operation, extends the tool’s lifespan, and ultimately contributes to a more efficient and cost-effective workflow. The connection between maintenance and performance is undeniable, making proactive maintenance a necessity, not an option, for owners of these devices.

Frequently Asked Questions

The following addresses common inquiries regarding the operation, maintenance, and selection of Makita cordless finish nailers. The information is intended to provide clarity and ensure optimal tool performance.

Question 1: What is the expected lifespan of the battery for a Makita cordless finish nailer?

Battery lifespan is contingent upon usage frequency, charging habits, and storage conditions. Generally, a well-maintained lithium-ion battery can provide several years of service. Consistent charging practices and storage in a climate-controlled environment prolong battery life.

Question 2: How often should a Makita cordless finish nailer be serviced?

Professional users should consider annual servicing, while infrequent users may extend this interval to every two years. Regular cleaning and lubrication remain essential regardless of service frequency. Adherence to the manufacturer’s recommendations optimizes tool performance.

Question 3: What types of finish nails are compatible with a Makita cordless finish nailer?

Compatibility varies depending on the specific model. It is imperative to consult the tool’s manual for the approved nail gauge, length, and collation type. Using incompatible nails can result in tool malfunction and void the warranty.

Question 4: What safety precautions are necessary when operating a Makita cordless finish nailer?

Eye protection is mandatory. Hearing protection is recommended in noisy environments. Ensure the workpiece is securely fastened before driving nails. Disconnect the battery during maintenance or nail changes. Never point the nailer at oneself or others.

Question 5: Can a Makita cordless finish nailer be used in wet or damp conditions?

These tools are not designed for use in wet or damp environments. Exposure to moisture can damage the electrical components and create a safety hazard. Operating the nailer in dry conditions is essential.

Question 6: What is the best method for storing a Makita cordless finish nailer when not in use?

Store the nailer in a dry, climate-controlled environment. Remove the battery to prevent self-discharge and potential damage. A hard-sided case provides protection from physical impacts and environmental factors.

Consistent maintenance, adherence to safety protocols, and informed usage contribute to the optimal performance and longevity of the device. The information above highlights key concerns and provides a foundation for proper tool operation.

The concluding section will summarize the key considerations outlined throughout this article, providing a comprehensive overview for prospective buyers and current owners.

Conclusion

This exploration of the Makita cordless finish nailer has detailed critical aspects, from power source and nail capacity to ergonomic design and maintenance needs. A thorough understanding of these elements allows for informed decision-making when selecting a tool suited to specific project requirements. Neglecting these considerations can lead to inefficiencies, compromised results, and potential equipment damage. The benefits of cordless operation, combined with Makita’s reputation for quality, make this type of nailer a valuable asset in various construction and woodworking applications.

The continued innovation in battery technology and tool design will further enhance the performance and versatility of cordless finish nailers. Professionals and serious hobbyists are encouraged to remain informed about advancements in this technology to optimize their tool selection and maintenance practices. A well-chosen and properly maintained device can significantly contribute to project efficiency and the delivery of consistently high-quality results.