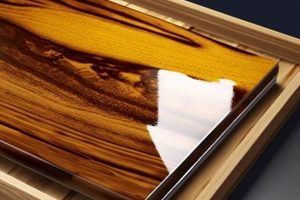

A surface application applied to wooden kitchen worktops, it serves to protect and enhance the material’s natural aesthetic. For instance, a clear coat of polyurethane can provide a durable, water-resistant layer to a butcher block countertop, showcasing the wood grain while safeguarding against spills and scratches.

The application is paramount for longevity and ease of maintenance. It safeguards against moisture penetration, preventing warping, staining, and bacterial growth. Historically, natural oils were used; however, modern formulations offer improved durability, resistance to chemicals, and varying degrees of sheen, contributing to both the functionality and visual appeal of the kitchen.

The subsequent discussion will delve into the types of protectants available, application techniques, and considerations for selection based on wood species and desired aesthetic outcomes.

Essential Considerations for Wooden Kitchen Worktop Protection

Proper application and maintenance are crucial for preserving the integrity and appearance of wood surfaces in the kitchen. The following recommendations outline key steps for optimal results.

Tip 1: Selection of Appropriate Product: Identify the specific needs of the wood. Oil-based formulations offer enhanced penetration and a natural look, while water-based options provide greater durability and lower VOC emissions.

Tip 2: Surface Preparation is Paramount: Prior to application, ensure the wood surface is thoroughly cleaned, sanded smooth, and free of any existing coatings or contaminants. This promotes proper adhesion and a uniform finish.

Tip 3: Application Techniques: Apply thin, even coats using a high-quality brush, roller, or spray gun. Avoid excessive build-up, which can lead to runs or an uneven appearance. Allow each coat to dry completely before applying the next.

Tip 4: Multiple Coats for Durability: Typically, a minimum of three coats is recommended for adequate protection. Additional coats may be necessary in high-use areas or for increased water resistance.

Tip 5: Proper Curing Time: Adhere strictly to the manufacturer’s recommended curing time. This allows the protectant to fully harden and develop its protective properties.

Tip 6: Regular Maintenance: Implement a routine cleaning schedule using appropriate cleaning products formulated for wood. Avoid harsh chemicals or abrasive cleaners, which can damage the finish.

Tip 7: Immediate Spill Cleanup: Promptly address spills to prevent staining and moisture penetration. Wipe up liquids immediately with a clean, absorbent cloth.

Adhering to these guidelines ensures the longevity and beauty of wooden kitchen surfaces, protecting against wear, tear, and environmental factors.

The subsequent section will address common problems and troubleshooting techniques related to wooden worktop maintenance.

1. Protection

The safeguarding of wooden worktops against environmental factors and daily use is a primary consideration in kitchen design. Appropriate measures mitigate damage and extend the lifespan of the material.

- Moisture Resistance

Water penetration leads to warping, swelling, and eventual decay. A protective coat, such as polyurethane or varnish, creates a barrier against liquids, preventing water damage and preserving the structural integrity of the wood.

- Scratch and Impact Resistance

Daily use involves sharp objects and heavy items, increasing the risk of scratches and dents. A durable protectant offers a resilient surface that withstands wear and tear, maintaining the aesthetic appearance of the counter.

- Stain Prevention

Food spills and cleaning agents can cause discoloration and permanent staining. The application of a quality sealant prevents liquids from penetrating the wood pores, simplifying cleanup and preserving the color of the wood.

- UV Protection

Prolonged exposure to sunlight can fade and degrade wood surfaces. Some protectants contain UV inhibitors, reducing the harmful effects of sunlight and maintaining the color and luster of the worktop.

These protective facets are integral to the longevity and visual appeal of wooden kitchen worktops. Selecting and applying a protectant tailored to the specific wood species and usage patterns ensures lasting performance and satisfaction.

2. Aesthetics

The visual appeal of wooden worktops is intrinsically linked to its protection and enhancement. The choice of sealant or coating directly influences the wood’s color, sheen, and overall aesthetic character. For example, a matte sealant preserves a natural, rustic appearance, while a gloss sealant amplifies the wood’s grain and creates a more reflective surface. Incorrect selection diminishes the visual effect, impacting the perceived quality and value of the kitchen space. Consider a cherry wood surface: an oil-based finish enhances its rich, warm tones, whereas a water-based finish might appear dull in comparison.

Furthermore, the application technique significantly impacts the end result. Uneven application, brush strokes, or air bubbles compromise the surface’s smoothness and visual appeal. Proper preparation, including sanding and cleaning, is crucial to ensure uniform absorption and a flawless presentation. Consider the effect of a professionally applied, multi-layered lacquer on a maple countertop versus a single coat of poorly applied varnish; the former exhibits depth and clarity, enhancing the wood’s natural beauty, while the latter appears cheap and unfinished.

Ultimately, successful integration of wooden surfaces relies on balancing protective needs with aesthetic goals. The selection of appropriate sealant and application techniques ensures the longevity of the wood while enhancing the kitchen’s overall design and visual appeal.

3. Durability

Durability, as it pertains to wooden kitchen worktops, is directly dependent on the selected protector and its effective application. The inherent vulnerability of wood to moisture, impact, and abrasion necessitates the use of a protective barrier. A compromised protector quickly results in damage, such as water rings, scratches from utensils, and staining from food spills, thus diminishing the structural integrity and visual appeal. For example, a butcher block surface subjected to heavy use without adequate protection becomes easily scored and unsanitary due to bacterial accumulation within the crevices.

The choice of protector affects the long-term performance. Polyurethane offers high resistance to scratches and moisture but may yellow over time. Penetrating oil protectants offer a natural look and are easy to repair, but less resistant to water damage. Regular maintenance, including reapplication of the protector as needed, is essential. A worktop treated with tung oil requires frequent reapplication compared to one coated with a catalyzed varnish. The correct balance between aesthetic preference and durability is paramount for optimizing the lifespan of the surface.

Therefore, the long-term viability of wooden kitchen worktops is reliant on durable surfaces. Selection of a protector appropriate to the anticipated use, combined with adherence to a regular maintenance schedule, will safeguard from wear, tear, and external environmental factors. This proactive approach guarantees both the longevity and aesthetic value of wood surfaces in the kitchen.

4. Maintenance

Consistent upkeep is crucial to preserving the integrity and aesthetic appeal of protected wooden worktops in the kitchen. Neglecting maintenance leads to accelerated wear, diminished protectant effectiveness, and potential compromise of the underlying material.

- Regular Cleaning

Routine cleaning removes food particles, spills, and grime that can degrade the protector over time. The use of appropriate cleaning agents is paramount; harsh chemicals damage the protector and the wood. For example, daily wiping with a damp cloth and mild soap prevents the build-up of residue and preserves the sealant’s effectiveness.

- Reapplication of Protectant

Periodic reapplication of the protective coat reinforces the barrier against moisture and physical damage. The frequency depends on the type of protector and usage patterns. For instance, oil-based protectors often require more frequent reapplication compared to polyurethane finishes. Neglecting this step results in diminished protection and increased susceptibility to staining and warping.

- Addressing Scratches and Imperfections

Prompt repair of minor scratches and imperfections prevents further damage and preserves the surface’s appearance. Small scratches can be addressed with specialized wood repair products or by lightly sanding and reapplying protector. Failure to address these issues can lead to deeper damage that requires more extensive repairs.

- Proper Oiling (If Applicable)

For worktops protected with oil-based finishes, consistent oiling maintains the wood’s moisture content and prevents drying and cracking. The type of oil used is critical; food-safe mineral oil or specialized wood oils are appropriate choices. Infrequent oiling leads to wood desiccation and potential structural damage.

The interconnectedness of these maintenance facets ensures the longevity and beauty of wooden worktops. Consistent attention to cleaning, protector reapplication, scratch repair, and, when applicable, oiling, guarantees a durable, aesthetically pleasing, and functional surface in the kitchen.

5. Application

The manner in which a wood protector is applied to a kitchen counter dictates the protector’s efficacy and the aesthetic outcome. A meticulous approach is essential to achieve the desired level of protection and visual appeal. Improper application compromises the protective barrier and detracts from the wood’s natural beauty.

- Surface Preparation

Prior to protector application, the wood surface necessitates thorough preparation. This includes the removal of existing finishes, sanding to achieve a smooth texture, and cleaning to eliminate contaminants. Inadequate preparation inhibits protector adhesion and results in an uneven appearance. For instance, residual sanding dust prevents uniform absorption, leading to blotchy results.

- Application Technique

The method of application significantly affects the protector’s distribution and penetration. Brushing, rolling, or spraying are common techniques, each requiring specific skills to achieve optimal results. Uneven brush strokes or excessive roller pressure can lead to pooling and an uneven finish. Spraying requires proper equipment and technique to avoid overspray and ensure uniform coverage.

- Environmental Conditions

Ambient temperature and humidity impact the protector’s drying and curing process. Application in excessively humid conditions can prolong drying times and lead to clouding or blistering. High temperatures can cause rapid drying, preventing proper penetration and adhesion. Maintaining optimal environmental conditions, as specified by the protector manufacturer, is crucial.

- Number of Coats

The quantity of protective layers applied determines the overall durability and protective capacity. Insufficient coats provide inadequate protection against moisture, scratches, and stains. Excessive coats can result in a thick, plastic-like appearance and increase the risk of cracking or peeling. Adhering to the manufacturer’s recommendations regarding the number of coats is essential for achieving optimal performance.

These facets highlight the critical role of careful application in realizing the full potential of a wood surface protector on a kitchen counter. A diligent approach, encompassing thorough preparation, appropriate technique, controlled environmental conditions, and adherence to recommended application guidelines, ensures a durable, aesthetically pleasing, and long-lasting result.

6. Wood Species

The selection of wood species is a fundamental determinant of the suitability and longevity of a kitchen worktop. The inherent properties of different woods, such as hardness, grain pattern, and natural oil content, directly influence the choice of protector and the required maintenance regime. For instance, a soft wood like pine, while aesthetically pleasing, necessitates a more robust and frequently reapplied surface protectant compared to a dense hardwood like maple due to its susceptibility to scratching and denting. The interaction between a chosen species and the applied protector influences water resistance and prevents warping from kitchen moisture.

Consider the practical implications of this selection. A high-traffic surface crafted from porous oak, if not properly sealed, will readily absorb spills, leading to staining and potential bacterial growth. Conversely, teak, naturally rich in oils, inherently offers improved water resistance, requiring less aggressive protectors and reducing maintenance frequency. Similarly, the grain pattern of the wood impacts the visibility of scratches; a close-grained wood, such as cherry, tends to conceal minor imperfections more effectively than a more open-grained wood like ash. Wood hardness, measured by the Janka scale, dictates the protector’s ability to withstand everyday wear and tear, requiring different protectors for hardwoods and softwoods.

In conclusion, the informed pairing of wood species and protector is crucial for ensuring durability, hygiene, and aesthetic satisfaction. Careful consideration of these factors allows for selection, maximizing the lifespan and functionality of kitchen worktops. Prioritizing the right wood species and the ideal “kitchen counter wood finish” minimizes issues and helps preserve the integrity of worktops.

7. Food Safety

The intersection of food safety and kitchen worktop protection necessitates careful consideration of materials and maintenance. A compromised protector creates an environment conducive to bacterial growth, posing a direct threat to food preparation. Porous surfaces, such as wood with cracks or an inadequate seal, harbor microorganisms, leading to potential contamination of food items. For example, Salmonella or E. coli can thrive in the crevices of a poorly sealed butcher block, transferring to foods prepared on the surface. Consequently, the selection of a food-safe protector and the implementation of rigorous cleaning protocols are paramount.

Furthermore, the protector itself must be non-toxic and resistant to degradation from food acids and cleaning agents. Certain traditional protector, such as varnishes containing volatile organic compounds (VOCs), pose a risk of chemical leaching into food. Similarly, cleaners with harsh chemicals can damage the protector, compromising its integrity and potentially contaminating food. The use of food-grade mineral oil or protectants specifically designed for food contact surfaces mitigates these risks. For instance, a food-safe protectant forms a barrier preventing food from being absorbed into the wood, simplifying sanitation. Proper and safe cleanup includes a simple wipe-down of the work surface.

In summary, achieving food safety on wooden kitchen worktops hinges on a dual strategy: selection of appropriate non-toxic protectors and diligent adherence to strict hygiene practices. Regularly cleaning and maintaining the worktop and re-applying the protector as needed eliminates the buildup of harmful bacteria and preserves the integrity of the wood, mitigating the risk of foodborne illness. Only an understanding of the connection between “Food Safety” and “kitchen counter wood finish” helps protect surfaces and minimizes risks.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, application, and maintenance of surfaces on wooden worktops.

Question 1: What are the primary factors to consider when selecting a finish for a wooden worktop?

The species of wood, intended use (food preparation vs. general surface), desired aesthetic, and anticipated level of maintenance are crucial considerations. Durability, water resistance, and food safety certifications should influence decision-making.

Question 2: How does the type of wood affect the choice of finish?

Softwoods necessitate harder, more durable coatings than hardwoods. Woods with open grains benefit from pore fillers to ensure a smooth, uniform coating. Oily woods require protector that promote adhesion and prevent rejection.

Question 3: What are the key differences between oil-based and water-based finishes for kitchen surfaces?

Oil-based options typically offer enhanced penetration and a richer color, while water-based provide superior durability, lower VOC emissions, and faster drying times. Oil-based protector often require more frequent reapplication.

Question 4: How can one ensure a finish is food-safe for surfaces used for food preparation?

Select protector specifically labeled as food-safe or food-grade, such as mineral oil or certain tung oil formulations. Verify compliance with relevant regulatory standards and avoid finishes containing harmful chemicals or heavy metals.

Question 5: What is the recommended maintenance routine for preserving the integrity of a finished wood surface?

Regular cleaning with a damp cloth and mild soap, prompt spill cleanup, and periodic reapplication of the finish are essential. Avoid abrasive cleaners and harsh chemicals that can damage the surface.

Question 6: How can scratches or minor damage to a finished wood surface be repaired?

Minor scratches can often be buffed out with a fine-grit sandpaper and reapplication of the surface. Deeper scratches may require filling with a wood filler and reapplication of the finish to the entire surface for uniform appearance.

The information presented clarifies essential aspects of selecting, applying, and maintaining wood surfaces in the kitchen. Careful consideration of these points contributes to a durable, hygienic, and aesthetically pleasing result.

The subsequent section will provide a glossary of terms related to materials and application techniques.

Conclusion

The preceding exploration of “kitchen counter wood finish” underscores its crucial role in kitchen design and functionality. From selecting the appropriate wood species to applying food-safe protectants and establishing rigorous maintenance protocols, each facet contributes to the longevity, hygiene, and aesthetic appeal of this surface. Neglecting any of these areas compromises the integrity and usefulness of this essential kitchen element.

Therefore, careful consideration of these protective measures becomes necessary in ensuring kitchen counters not only enhance the space’s design but provide an environment that is both safe and easy to maintain. Continuing research and education in material science and application techniques will further refine these protective methods, safeguarding kitchen surfaces and ensuring long-term satisfaction.