Dark-toned timber, achieved through various staining or painting techniques, presents a sophisticated aesthetic for furniture, flooring, and architectural details. This treatment modifies the surface of lumber to impart a deep, often opaque, color. For example, a maple dining table treated in this manner can transform from a light, natural appearance to a bold, contemporary centerpiece.

The popularity of surfaces treated in this way stems from its ability to convey elegance and drama. Its use in interior design offers a versatile foundation for contrasting brighter elements or harmonizing with monochromatic schemes. Historically, darkened woods have been associated with luxury and craftsmanship, evident in antique furnishings and period architecture, where it was used to enhance the visual weight and perceived value of materials.

The subsequent sections of this discussion will delve into the specific methods used to achieve these dark surfaces, the diverse applications in home decor and construction, and practical considerations for maintaining its long-term beauty and integrity.

Working with Darkened Timber Surfaces

Achieving a desirable outcome with dark-toned lumber requires careful planning and execution. Adherence to proven methods ensures a professional result and prolongs the lifespan of the treated material. The following tips offer guidance for those working with these surfaces.

Tip 1: Surface Preparation is Paramount: Thoroughly sand the lumber prior to application of any staining or coating. This removes imperfections and ensures even absorption of the finish, preventing blotchiness and uneven color distribution.

Tip 2: Select Appropriate Products: Choose stains and sealants designed specifically for lumber. Oil-based stains often penetrate deeper and provide richer color saturation, while water-based options offer faster drying times and lower VOC emissions. Consider the project’s environment when selecting the appropriate coating.

Tip 3: Apply Multiple Thin Coats: Avoid applying thick, heavy coats of stain or paint. Multiple thin coats, allowing each to dry completely, provide better control over color intensity and prevent runs or drips. This also ensures proper curing and adhesion.

Tip 4: Use a Sealer: Applying a clear sealant after staining is crucial for protecting the color and providing a durable surface. Polyurethane, lacquer, or varnish offer varying levels of protection against scratches, moisture, and UV damage. Select a sealant appropriate for the intended use and desired sheen.

Tip 5: Regular Cleaning and Maintenance: Dust frequently with a soft cloth to prevent the buildup of dirt and grime. Use a mild, pH-neutral cleaner specifically designed for wood surfaces. Avoid harsh chemicals or abrasive cleaners, which can damage the finish.

Tip 6: Address Scratches Promptly: Minor scratches can be concealed with touch-up markers or stain pens matching the finish. For deeper scratches, consider lightly sanding the affected area and reapplying stain and sealant.

Tip 7: Control Environmental Factors: Excessive humidity or direct sunlight can damage the finish over time. Use humidifiers or dehumidifiers to maintain a stable humidity level, and consider using curtains or blinds to shield the surface from direct sunlight.

By implementing these recommendations, professionals and enthusiasts alike can realize the full potential of darkened timber surfaces, creating beautiful and long-lasting pieces. The subsequent sections of this discussion will focus on more advanced staining techniques.

1. Aesthetics

The aesthetic qualities of dark-toned timber significantly contribute to its appeal in interior design and architectural applications. The choice of such a finish is driven by the desire to achieve a specific visual impact, ranging from modern sophistication to classic elegance. The cause-and-effect relationship is evident: the finish’s color directly affects the mood and perception of the space it occupies. For example, darkened hardwood floors in a minimalist living room can provide a grounding contrast to lighter walls and furnishings, creating a sense of depth and visual interest.

Dark surface treatment impacts the perception of texture and form. The deep color can enhance the grain patterns of the timber, adding a layer of complexity. Conversely, an opaque finish can minimize the grain, creating a smoother, more uniform surface. Consider the use of blackened timber cladding on a contemporary building facade. This choice highlights the clean lines of the structure while providing a dramatic contrast to the surrounding environment. The intentional use of dark wood tones allows designers to shape the viewer’s experience, directing focus and creating a desired ambiance.

Understanding the aesthetic implications is of practical significance for designers and homeowners alike. Informed decisions regarding the specific shade and finish are essential to avoid visual dissonance or unintended effects. The interplay between darkened timber and other design elements, such as lighting, color palettes, and spatial arrangements, must be carefully considered to achieve a harmonious and visually pleasing outcome. Ultimately, appreciating the nuanced impact of black finish enables informed application and appreciation of its intended design purpose.

2. Durability

The longevity of darkened timber surfaces is inextricably linked to the finishing process and the materials employed. The application of a black finish, whether through staining, painting, or other treatments, directly influences the wood’s resistance to wear, moisture, and UV exposure. The choice of finishing product acts as the primary defense against environmental degradation, affecting the material’s overall durability. For example, an exterior door treated with a low-quality black paint may show signs of fading, cracking, and peeling within a short period, while a similar door treated with a marine-grade stain and sealant could withstand years of exposure with minimal degradation. Therefore, the type of black finish is not merely an aesthetic consideration but a critical determinant of long-term structural integrity.

Consider the practical implications of insufficient protection. Furniture with a delicate black lacquer finish may be susceptible to scratches and chipping from everyday use. Flooring with a poorly applied dark stain could exhibit premature wear and tear in high-traffic areas. In construction, the selection of appropriate coatings and sealants is crucial for preventing moisture damage, insect infestation, and decay in darkened timber elements. The long-term cost of maintaining a surface with inadequate protection far exceeds the initial investment in higher-quality finishes. Furthermore, the lifespan of the treated lumber itself is contingent upon the performance of the dark finish, with degradation leading to costly replacements and repairs.

In summary, the durability of surfaces finished in black is a composite outcome of material selection, application technique, and environmental exposure. Careful consideration of these factors is essential for ensuring the long-term beauty and structural integrity of such surfaces. Recognizing the interplay between the chosen finish and the wood’s inherent properties is of practical significance for professionals and consumers alike. Challenges related to UV resistance, moisture protection, and abrasion resistance can be effectively addressed through informed product selection and meticulous application, contributing to the overall sustainability of the treated lumber.

3. Application

The practical application of dark finishes to timber significantly determines the ultimate aesthetic and functional properties of the material. The selection of an appropriate application method, encompassing techniques such as spraying, brushing, or dipping, directly influences the uniformity and depth of color achieved. Furthermore, the specific application protocol dictates the penetration of the finishing agent, impacting its adhesion and protective qualities. For instance, the application of a black stain to hardwood flooring requires careful consideration of wood grain, moisture content, and the application environment to ensure consistent color absorption and prevent blotching. Improper application can cause uneven tones and premature failure of the finish, thus undermining the intended aesthetic.

The implications of the application process extend beyond surface appearance. In the construction of furniture or architectural elements using darkly finished lumber, the method of application directly affects resistance to wear and environmental factors. A poorly applied finish may be susceptible to scratches, moisture damage, or UV degradation, leading to premature deterioration. Contrastingly, the meticulous application of multiple thin coats of a high-quality black lacquer, followed by appropriate curing, can create a durable and aesthetically pleasing surface capable of withstanding substantial use. Industrial applications of dark finishes, such as those found on musical instruments or automotive interiors, may involve specialized techniques like electrostatic spraying to ensure consistent and robust coverage, highlighting the range of application methods dictated by end-use requirements.

In summary, the successful implementation of darkened lumber projects hinges on an understanding of the crucial role played by application techniques. From the selection of appropriate tools and materials to the execution of precise application protocols, each stage influences the outcome. Careful consideration must be given to the wood’s properties, the environmental conditions, and the intended use of the final product. Addressing these factors proactively mitigates potential challenges and contributes to the creation of both visually appealing and durable structures and products.

4. Maintenance

The long-term preservation of timber treated with a dark or black finish is intrinsically linked to consistent and appropriate maintenance practices. The finish, while aesthetically pleasing, introduces unique vulnerabilities that necessitate specific care protocols. The cause-and-effect relationship is evident: neglecting regular maintenance invariably leads to premature degradation, necessitating costly repairs or replacements. The type of finish whether paint, stain, lacquer, or another coating dictates the specific maintenance requirements. A matte finish, for instance, might show fingerprints and smudges more readily than a glossy one, requiring more frequent cleaning. Similarly, exterior applications of darkened lumber are susceptible to weathering and require periodic re-sealing to prevent moisture damage and UV-induced fading. The importance of maintenance, therefore, cannot be overstated, as it directly influences both the aesthetic appeal and the structural integrity of the treated wood. A real-life example would be a black-stained deck that, without regular cleaning and sealing, will fade, warp, and crack due to moisture and sun damage, versus one that is properly maintained and retains its deep color and integrity for many years.

Practical application of appropriate maintenance techniques involves several key considerations. Regular dusting with a soft cloth prevents the accumulation of abrasive particles that can scratch the finish. Use of pH-neutral cleaning solutions is crucial to avoid stripping the protective coating or altering the color. For exterior applications, periodic inspection for signs of wear, such as cracking, peeling, or fading, allows for timely intervention before significant damage occurs. Reapplication of sealants or topcoats, as recommended by the manufacturer, provides an additional layer of protection against environmental factors. Moreover, the environment in which the darkened lumber is situated impacts maintenance requirements. High-humidity environments, for example, demand more frequent cleaning to prevent mold and mildew growth. Direct exposure to sunlight necessitates UV-resistant coatings and regular reapplication to mitigate fading. In commercial settings, such as restaurants or retail spaces, the finish will be subject to wear and tear and will require more robust cleaning practices and potentially more frequent refinishing.

In conclusion, the effective maintenance of timber finished in black or a similarly dark tone is not merely an optional consideration but a critical component of its long-term viability. Understanding the specific vulnerabilities introduced by the finish, implementing appropriate cleaning protocols, and proactively addressing signs of wear are essential for preserving both the aesthetic appeal and the structural integrity of the material. Furthermore, by considering the environmental context and adapting maintenance practices accordingly, one can significantly extend the lifespan of darkly finished lumber, reducing the need for costly repairs or replacements and ensuring the longevity of the project. The challenges associated with maintenance can be effectively addressed through informed decision-making and diligent execution of recommended care practices, ultimately contributing to the sustainability of the treated lumber.

5. Material Selection

The suitability of lumber for a dark finish is fundamentally determined by its inherent characteristics. Species with tight, uniform grain patterns, such as maple or birch, tend to accept stains and paints more evenly than those with open grains, like oak or ash. The natural color of the lumber also plays a role; lighter-toned species require fewer coats to achieve a uniform black, while darker woods may necessitate more intensive treatment to fully mask the underlying color. The hardness of the wood affects its ability to withstand sanding and finishing processes without splintering or denting. Moreover, the stability of the wood, its propensity to expand and contract with changes in humidity, is a crucial factor; unstable woods can cause finishes to crack or peel over time. Consequently, the initial selection of lumber directly impacts the aesthetic quality and longevity of the blackened surface. For example, employing a softwood like pine might result in a blotchy, uneven stain absorption, whereas using a hardwood like walnut inherently provides a smoother, richer finish.

Consider the practical implications of material choices in various applications. In furniture making, hardwoods are generally preferred for black finishes due to their durability and resistance to wear. In architectural millwork, the selection of lumber should align with the environmental conditions; moisture-resistant species like cedar or redwood may be necessary for exterior applications. The impact of material selection extends to the finishing process itself. Certain woods, such as those with high resin content, might require specialized pre-treatments to ensure proper adhesion of the finish. The choice of finish must also be compatible with the wood; some stains and paints may not adhere properly to certain species or may react adversely with the wood’s natural oils. Therefore, thoughtful material selection is not merely a preliminary step but an integral aspect of achieving a successful outcome. An improper lumber choice can lead to challenges that arise during the staining process, the finished look and long term durability. For example, painting a softwood black for a floor that gets heavy use will cause wear and damage more quickly than painting a hardwood floor black.

In summary, the selection of timber for a black finish involves a complex interplay of factors related to the wood’s species, grain pattern, hardness, stability, and compatibility with the chosen finish. Careful consideration of these elements is essential for ensuring the aesthetic quality, durability, and longevity of the treated surface. Challenges related to uneven staining, finish adhesion, and environmental degradation can be effectively addressed through informed lumber selection. This understanding has practical significance for professionals and consumers alike, guiding the design and execution of projects involving timber treated with a dark surface. Challenges with the wrong material selection can be costly and time consuming. Proper material selection helps with the intended use and desired result.

6. Finishing Techniques

The application of a dark or black finish to timber relies on a range of specialized techniques that influence both the aesthetic outcome and the long-term durability of the treated material. Selection of appropriate finishing protocols is paramount to achieving the desired visual effect and ensuring the protection of the wood substrate. The following lists detail key facets of finishing techniques relevant to achieving a dark surface on timber.

- Staining

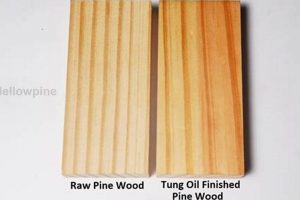

Staining involves the application of a pigmented solution that penetrates the wood fibers, imparting a dark color while allowing the natural grain pattern to remain visible. This technique is commonly used to enhance the aesthetic appeal of furniture and flooring. An example is the use of an oil-based stain on oak to create a deep ebony finish. The implication is that the wood’s inherent texture and character are preserved, but the surface receives a darker tone.

- Painting

Painting entails the application of an opaque coating that completely obscures the wood’s natural color and grain. This technique provides a uniform, solid-color finish and offers greater control over the final appearance. Painting is used to create a contemporary aesthetic or to mask imperfections in the wood. An example includes the use of black lacquer on MDF for a high-gloss finish in modern cabinetry. The implication is that the underlying wood becomes less relevant as the paint dictates the final look.

- Ebonizing

Ebonizing refers to a chemical process that darkens the wood through a reaction with tannic acid and iron acetate. This technique produces a deep, rich black color that penetrates the wood deeply, providing a durable finish. Ebonizing is commonly used on woods with high tannin content, such as oak or walnut, to simulate the appearance of ebony. The implication is that it can give less expensive wood a similar look to expensive woods, enhancing the aesthetic and creating an authentic, dark finish.

- Sealing and Topcoating

Sealing involves the application of a clear coating that protects the stained or painted surface from moisture, scratches, and UV damage. A topcoat, such as polyurethane or lacquer, provides an additional layer of protection and can impart a specific sheen (matte, satin, or gloss). For example, applying a UV-resistant sealant to exterior applications of blackened wood prevents fading and weathering. The implication is that sealing and topcoating are essential for long-term durability and aesthetic preservation.

These distinct finishing techniques play crucial roles in determining the aesthetic and protective qualities of timber treated with dark surfaces. Selection of the appropriate method depends on the desired visual outcome, the wood species, the intended application, and the level of durability required. While staining is beneficial when one wants to see some of the wood’s natural grain, painting obscures the grain completely to get a solid consistent color. In conjunction, ebonizing allows a wood substrate to obtain authentic, dark tones to look like expensive woods, and sealing and topcoating are used for moisture and UV protection. Overall, challenges related to aesthetics, durability, and cost can be addressed with informed understanding.

7. Cost

The economic considerations surrounding blackened timber surfaces are multifaceted, extending beyond the initial purchase price of materials and labor. The selection of lumber species directly influences project expenses. Hardwoods, favored for their durability and aesthetic qualities, often command a higher price than softwoods. The chosen finishing technique also impacts cost. For example, while staining may be more economical upfront, the need for specialized sealants and UV protectants in certain environments can elevate the total expenditure. Painting, conversely, may involve a lower material cost but require more extensive surface preparation and multiple coats for optimal coverage, offsetting any initial savings. Consider the contrast between a mass-produced, black-painted pine bookcase and a custom-built, black-stained walnut cabinet. The latter represents a significantly higher investment due to material quality, craftsmanship, and finishing complexity.

Long-term maintenance and potential replacement costs are crucial elements of the overall economic assessment. Inferior finishing products may necessitate more frequent refinishing or repairs, incurring substantial cumulative expenses over time. In outdoor applications, the choice between naturally durable wood species and chemically treated alternatives presents a trade-off between initial outlay and ongoing maintenance. Chemically treated lumber, while initially less costly, requires periodic reapplication of preservatives and poses environmental concerns. Natural species like cedar or redwood, though more expensive to acquire, offer inherent resistance to decay and insect infestation, potentially reducing long-term maintenance expenditures. For example, the cost to replace a blackened, pressure-treated deck every 10-15 years may ultimately exceed the cost of building a deck from naturally rot-resistant lumber in the first place.

In summary, the economic dimension of blackened timber involves a complex interplay of material costs, labor expenses, finishing techniques, and long-term maintenance considerations. While initial price points may be a primary factor in decision-making, a comprehensive assessment of the life-cycle costs is essential for optimizing value and ensuring the sustainability of the project. In this way, awareness of economic implications informs responsible materials selection and appropriate finish application, reducing financial burdens and maintaining aesthetic appeal.

Frequently Asked Questions About Timber Treated with Black Finishes

This section addresses common inquiries regarding surfaces finished in black, providing information to assist in informed decision-making.

Question 1: Is darkened lumber suitable for outdoor use?

The suitability of timber treated with a black finish for outdoor applications depends largely on the wood species and the type of finish employed. Certain hardwoods, when properly sealed and maintained, can withstand outdoor exposure. However, the dark color absorbs heat, which can accelerate degradation. Regularly inspecting and re-sealing the surface is essential.

Question 2: How does sunlight affect a black finish on wood?

Direct sunlight can cause fading and degradation of many finishes, especially dark colors like black. The intensity of fading varies depending on the UV resistance of the finish. Use of UV-resistant coatings or sealants can mitigate these effects.

Question 3: What is the best way to clean a surface that is treated in a black coloring?

Cleaning should be done with a mild, pH-neutral cleaner specifically designed for wood surfaces. Avoid abrasive cleaners or solvents, which can damage the finish. Dust frequently with a soft cloth to prevent the buildup of grime.

Question 4: How can scratches and blemishes be repaired?

Minor scratches can often be concealed with touch-up markers or stain pens that match the finish. Deeper scratches may require sanding the affected area, followed by reapplication of stain and sealant.

Question 5: Does this surface treatment affect the resale value of furniture or a home?

The impact on resale value is subjective and depends on market trends and buyer preferences. A well-executed, high-quality installation using durable materials can enhance perceived value. However, a poorly maintained or outdated aesthetic may have a negative impact.

Question 6: Is there an environmental impact associated with finishing timber in black?

Some finishes contain volatile organic compounds (VOCs), which can have negative environmental impacts. Choosing low-VOC or water-based products can minimize these effects. Additionally, sourcing lumber from sustainably managed forests can contribute to responsible environmental practices.

In summary, thoughtful material selection, appropriate application techniques, and diligent maintenance are essential for ensuring the long-term beauty and durability of surfaces darkened in a black color tone. Understanding the nuances of various finishing options and environmental factors is critical to maximizing value and minimizing potential issues.

The discussion now shifts to future trends and innovations in the field of darkened timber treatments.

Conclusion

This exposition has explored the multifaceted characteristics of black finished wood, encompassing aesthetics, durability, application, maintenance, material selection, finishing techniques, and cost implications. It has been established that achieving optimal results with this surface treatment requires careful consideration of various factors, ranging from the inherent properties of the wood species to the selection of appropriate finishing products and techniques. Moreover, it highlights the critical role of ongoing maintenance in preserving the long-term beauty and structural integrity of surfaces treated with such finishes.

As design trends evolve and technological advancements introduce new materials and methods, the enduring appeal of black finished wood remains evident in architectural and decorative applications. Further research and innovation in sustainable finishes and enhanced durability promise to expand its versatility and longevity. The continued exploration of its aesthetic possibilities and practical applications will ensure its significance in both contemporary and traditional design contexts. By carefully considering the factors discussed here, professionals and enthusiasts can ensure that timber treated with a black finish maintains its beauty and function for years to come.