The selection of a top-performing protective coating for wooden surfaces is paramount for both aesthetics and longevity. This coating provides a barrier against environmental factors, wear, and potential damage, significantly impacting the appearance and durability of the wood. For instance, a carefully chosen coating can safeguard a hardwood floor from scratches and moisture, or enhance the natural grain of a piece of furniture.

Employing a high-quality surface treatment offers several advantages, including protection from UV radiation, water damage, and daily use. Historically, various natural oils and waxes were utilized; however, modern chemical formulations offer superior resistance and longevity. This crucial step can preserve the integrity and appearance of wooden items, increasing their lifespan and value.

The subsequent sections will explore different types of coatings, application techniques, and factors to consider when selecting the appropriate option for specific projects. Understanding these aspects will enable informed decisions to achieve optimal results in wood finishing endeavors.

Tips for Achieving the Best Wood Finish

Achieving a professional and durable surface on wood requires careful attention to detail and the application of effective techniques. The following tips provide guidance for optimizing results during the finishing process.

Tip 1: Surface Preparation is Key: Prior to any coating application, ensure the wood surface is clean, smooth, and free of imperfections. Sanding with progressively finer grits is crucial. For example, start with 120-grit sandpaper to remove major flaws, then move to 180-grit, and finish with 220-grit for a polished base.

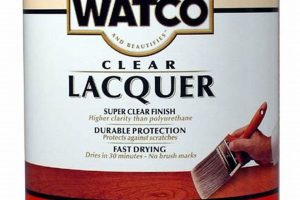

Tip 2: Choose the Right Coating for the Job: Different coatings offer varying levels of protection and aesthetic effects. Polyurethane is highly durable for high-traffic areas, while lacquer provides a fast-drying, clear finish. Oil-based products enhance the natural grain, whereas water-based options are lower in VOCs and dry quickly.

Tip 3: Proper Application Techniques are Essential: Apply coatings in thin, even layers to prevent runs and drips. Use a high-quality brush, roller, or spray gun suitable for the chosen coating. For instance, use a natural bristle brush for oil-based products and a synthetic brush for water-based finishes.

Tip 4: Sand Between Coats: Lightly sand between coats with fine-grit sandpaper (e.g., 320-grit) to create a smooth surface and improve adhesion. Remove all sanding dust with a tack cloth or vacuum before applying the next coat.

Tip 5: Control Environmental Conditions: Temperature and humidity can significantly impact the drying and curing process. Apply coatings in a well-ventilated area with moderate temperature and humidity levels to ensure optimal results. Avoid applying coatings in direct sunlight or extreme conditions.

Tip 6: Consider a Sealer or Wood Conditioner: Using a sealer or wood conditioner before the final coating can help to create a more even and consistent finish, particularly on porous woods. This step helps to prevent the wood from absorbing the stain or finish unevenly, resulting in a more professional appearance.

Tip 7: Always Test the Coating: Before applying any coating to the entire project, test it on an inconspicuous area or a scrap piece of wood to ensure compatibility and desired appearance. This step can prevent costly mistakes and ensure satisfaction with the final result.

Adhering to these guidelines will contribute to a superior surface, enhancing both the appearance and durability of wooden projects. Meticulous preparation, appropriate product selection, and precise application are the cornerstones of successful wood finishing.

In the next section, this article will conclude by summarizing the benefits of proper coating techniques and providing final recommendations for preserving wood surfaces.

1. Durability

Durability constitutes a cornerstone attribute of any top-tier surface application for wood. It defines the capacity of the coating to withstand wear, impact, and environmental stressors over an extended period. The inherent effectiveness of the chosen coating directly affects the long-term protection and aesthetic preservation of the wood substrate. A compromised level of durability invariably leads to premature degradation, necessitating frequent repairs or replacements.

The interplay between the coating and the wood’s environment underscores the significance of durability. For example, exterior applications, such as decks or siding, demand coatings capable of resisting ultraviolet radiation, moisture, and temperature fluctuations. Polyurethane coatings, known for their abrasion resistance, are frequently employed in high-traffic areas like hardwood floors. Conversely, less durable coatings, though potentially appealing in initial appearance, are susceptible to scratches, chipping, and water damage, ultimately diminishing the value and integrity of the wooden item.

In conclusion, the selection of a coating exhibiting high durability is not merely an aesthetic preference but a crucial investment in the longevity and preservation of wooden assets. By carefully considering the specific environmental conditions and anticipated usage, one can make informed decisions that safeguard against premature deterioration, thereby maximizing the value and lifespan of the wood.

2. Clarity

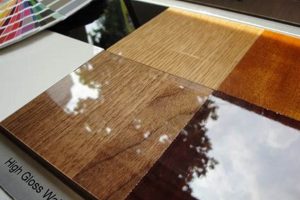

Clarity, in the context of wood coatings, refers to the ability of the protective layer to allow the natural grain and color of the wood to be seen without distortion or discoloration. It is a crucial attribute of a top-performing protective layer, as it directly influences the aesthetic outcome of the finished product. A coating lacking in clarity can obscure the beauty of the wood, diminishing its intrinsic value. Conversely, a coating with exceptional clarity enhances the wood’s natural characteristics, resulting in a visually appealing surface.

The importance of clarity is particularly evident in high-end furniture and cabinetry. For example, a clear lacquer applied to a finely grained cherry wood table allows the rich color and intricate patterns of the wood to be fully appreciated. In contrast, a hazy or yellowing coating would detract from the wood’s natural beauty, making it appear dull and lifeless. The choice of coating directly impacts the perceived quality and value of the finished piece. Furthermore, achieving optimal clarity requires careful consideration of the coating’s formulation and application technique. Factors such as the presence of additives, the thickness of the applied layer, and the drying conditions can all affect the final clarity of the surface.

In conclusion, clarity is a critical component of a superior coating, directly influencing the aesthetic appeal and perceived value of the treated wood. Selecting a coating that provides optimal clarity ensures that the natural beauty of the wood is preserved and enhanced, resulting in a visually stunning and durable finished product. The understanding of clarity helps professionals make informed decisions that balance protection and aesthetic considerations, delivering outcomes that meet both functional and artistic requirements.

3. Application Ease

Application ease is a significant determinant in achieving a superior outcome for wooden surfaces. The manageability of a protective coating during application directly influences the uniformity, consistency, and ultimately, the effectiveness of the protective barrier. A difficult-to-apply coating can lead to imperfections, compromising both aesthetics and the protective qualities.

- Viscosity and Flow

The viscosity of a coating dictates its flow characteristics during application. A coating that is too viscous may be difficult to spread evenly, leading to brush strokes or uneven coverage. Conversely, a coating with excessively low viscosity may run or drip, resulting in thin spots and a compromised barrier. The ideal viscosity allows for smooth, self-leveling application, contributing to a uniform surface and reduced likelihood of imperfections.

- Drying Time

Drying time significantly impacts application ease. Coatings with excessively long drying times are prone to dust contamination and require extended periods of immobility for the coated item. Rapid-drying coatings, while efficient, may present challenges in achieving even coverage, as they leave little room for error or correction. The optimal drying time balances the need for efficiency with the opportunity for careful and controlled application.

- Surface Preparation Requirements

The level of surface preparation required for a particular coating directly affects its application ease. Some coatings necessitate extensive sanding, cleaning, and priming to ensure proper adhesion and a smooth finish. Others are more forgiving and can be applied to less meticulously prepared surfaces. The complexity of surface preparation must be considered when selecting a coating, as it significantly impacts the overall effort and time required for application.

- Application Method Versatility

Coatings that can be applied using a variety of methods, such as brushing, rolling, or spraying, offer greater versatility and adaptability to different project requirements. This versatility allows for efficient application on both large and small surfaces, as well as on intricate or complex shapes. A coating that is compatible with multiple application methods enhances its ease of use and broadens its applicability.

In summation, application ease is not merely a matter of convenience but a critical factor influencing the final quality and longevity of the treated wooden surface. The ease of application factors into the final quality outcome of the surface treatment, directly impacting both the final aesthetics and protective characteristics. The user should consider this when choosing a coating to use.

4. UV Protection

Ultraviolet (UV) protection is a critical attribute in determining the suitability of any coating for wood exposed to sunlight. The sun’s radiation degrades wood and can compromise the integrity of surface coatings, leading to premature failure and aesthetic decline. Therefore, the inclusion of UV-inhibiting agents is paramount in any product designed for outdoor use or in areas with substantial sun exposure.

- Preventing Color Fading and Discoloration

UV radiation causes lignin, a component of wood, to break down, resulting in graying or yellowing. Coatings formulated with UV absorbers or blockers mitigate this process by absorbing or reflecting harmful rays. For example, a marine-grade varnish with UV inhibitors will prevent the discoloration of a wooden boat deck, maintaining its natural hue and appearance over time. Without this protection, the wood would fade and require more frequent refinishing.

- Maintaining Coating Integrity

UV exposure can also degrade the coating itself, causing it to become brittle, crack, or peel. This degradation compromises the barrier function of the surface treatment, leaving the wood vulnerable to moisture and other environmental factors. A high-quality coating with adequate UV protection will maintain its elasticity and adhesion, prolonging its lifespan and protecting the wood underneath. An exterior door coated with a UV-resistant finish will resist cracking and peeling, ensuring continued protection against the elements.

- Extending Lifespan of Wood

By protecting both the wood and the coating from UV damage, UV protection extends the lifespan of the wooden item. Reduced fading, cracking, and peeling translate to less frequent maintenance and replacement. A properly protected wooden fence, for instance, can last years longer than one treated with a finish lacking UV inhibitors, saving considerable time and expense.

- Enhancing Aesthetic Appeal

UV protection preserves the aesthetic appeal of the wood finish, ensuring that it retains its color, gloss, and overall appearance for an extended period. This is particularly important for high-value items such as outdoor furniture or architectural elements. A UV-resistant coating on a garden bench will maintain its rich color and sheen, enhancing the overall look of the outdoor space.

In summary, UV protection is an indispensable component of a high-performance wood finish, particularly for exterior applications. It safeguards against discoloration, maintains coating integrity, extends wood lifespan, and preserves aesthetic appeal. The absence of adequate UV protection can significantly reduce the longevity and visual quality of wooden surfaces, making its inclusion a crucial consideration in the selection of a surface protectant.

5. Water resistance

Water resistance is a fundamental attribute of a top-performing protective layer for wood, particularly in environments prone to moisture exposure. Water penetration into wood structures initiates degradation processes such as rot, decay, and swelling, thereby compromising the structural integrity and aesthetic appeal. A superior surface treatment must effectively prevent moisture intrusion, safeguarding the underlying wood from these detrimental effects. The efficacy of water resistance directly correlates with the longevity and preservation of wooden surfaces.

Various protective layers offer different levels of water resistance. Film-forming coatings, such as polyurethanes and varnishes, create a physical barrier that prevents water from contacting the wood. Penetrating oils, conversely, impregnate the wood fibers, rendering them hydrophobic and reducing water absorption. The selection of an appropriate coating depends on the specific application and the degree of water exposure anticipated. For example, a wooden deck exposed to constant rain requires a highly water-resistant coating, whereas interior furniture may suffice with a less robust treatment. Inadequate water resistance results in swelling, warping, and eventual decay, leading to costly repairs or replacements. The practical significance of water resistance is evident in marine applications, where coatings are engineered to withstand constant immersion and saltwater exposure.

In conclusion, water resistance is an indispensable characteristic of a high-quality surface treatment for wood, particularly in damp or humid environments. By preventing water penetration, the selected protective layer preserves the structural integrity, inhibits decay, and prolongs the lifespan of wooden items. The appropriate choice of water-resistant coating is paramount for ensuring the long-term performance and aesthetic preservation of wood exposed to moisture.

6. Scratch resistance

Scratch resistance constitutes a crucial determinant of longevity and aesthetic preservation in surface treatments applied to wood. The propensity of a coating to withstand abrasive forces directly correlates with its ability to maintain a pristine surface appearance over time. A superior coating effectively mitigates the formation of superficial imperfections, thereby prolonging the visual appeal and reducing the need for frequent maintenance or refinishing. The absence of adequate scratch resistance leads to a diminished appearance, necessitating costly interventions to restore the original surface quality. The effectiveness of scratch resistance influences the long-term value and utility of the wood product. For example, a dining table finished with a highly scratch-resistant coating will withstand the rigors of daily use, maintaining its appearance and value, whereas one with poor scratch resistance will quickly show signs of wear and tear.

The implementation of scratch-resistant coatings extends beyond mere aesthetics. In high-traffic areas, such as flooring, the protective function of a scratch-resistant finish is paramount. Hardwood floors coated with durable polyurethane formulations retain their luster and integrity, even under constant foot traffic and potential abrasion from furniture movement. Conversely, softer finishes, like wax, are more susceptible to scratching and require frequent reapplication to maintain their protective qualities. The specific formulation of the coating, including the presence of additives such as ceramic particles or UV inhibitors, contributes significantly to its scratch-resistant properties.

In conclusion, scratch resistance is not merely a desirable attribute of a superior surface protectant for wood, but a critical factor affecting its performance and longevity. Understanding the implications of scratch resistance enables informed decision-making in the selection of coatings appropriate for specific applications, maximizing both the aesthetic and functional lifespan of the wood product. While challenges remain in balancing scratch resistance with other desirable coating characteristics, the pursuit of improved scratch-resistant formulations continues to drive innovation in the wood finishing industry, enhancing the performance and durability of treated surfaces.

7. Adhesion

Adhesion, the ability of a surface coating to bond effectively to a substrate, is a foundational element of a high-quality wood finish. Without proper adhesion, the protective and aesthetic benefits of a coating are severely compromised, leading to premature failure and diminished performance.

- Surface Preparation Influence

The condition of the wood surface directly affects the adhesion of any coating. Contaminants such as dirt, oil, or existing coatings must be thoroughly removed to ensure proper bonding. Sanding creates a profile on the wood surface, increasing the surface area available for the coating to grip. For instance, applying a polyurethane finish to a poorly sanded surface will result in weak adhesion and eventual peeling. Therefore, meticulous surface preparation is paramount for achieving optimal adhesion and a durable surface.

- Coating Compatibility Impact

The chemical compatibility between the coating and the wood species also plays a critical role in adhesion. Some wood species, such as oily hardwoods, may require specific primers or pretreatments to promote adhesion. Using an incompatible coating can lead to adhesion failure, resulting in blistering, cracking, or peeling. Selecting coatings specifically formulated for the intended wood type enhances adhesion and ensures a lasting surface.

- Application Techniques and Their Effect

Proper application techniques are essential for maximizing adhesion. Applying coatings in thin, even layers allows for proper drying and curing, promoting a strong bond with the wood. Over-application can lead to trapped solvents, hindering adhesion and resulting in a soft, easily damaged surface. Following manufacturer’s recommendations regarding application methods and drying times is crucial for achieving optimal adhesion.

- Environmental Factors at Play

Environmental conditions during application and curing significantly influence adhesion. High humidity or extreme temperatures can interfere with the drying process, preventing the coating from properly bonding to the wood. Applying coatings in a controlled environment, with appropriate temperature and humidity levels, ensures proper curing and optimal adhesion. Failing to consider these factors can compromise the integrity and longevity of the surface treatment.

The interplay between surface preparation, coating compatibility, application techniques, and environmental conditions underscores the importance of adhesion in achieving a long-lasting, aesthetically pleasing wood surface. A comprehensive understanding of these factors is essential for selecting and applying coatings that provide optimal protection and enhance the natural beauty of wood.

Frequently Asked Questions About Wood Coatings

This section addresses common inquiries regarding the selection, application, and maintenance of surface treatments for wooden items. The information provided aims to clarify misconceptions and offer guidance for achieving optimal results.

Question 1: What constitutes the most durable coating for hardwood flooring?

Polyurethane finishes, both oil-based and water-based, are generally recognized as offering the highest level of durability for hardwood flooring. Oil-based polyurethanes provide excellent abrasion resistance and a warm tone, while water-based polyurethanes offer lower VOC emissions and faster drying times. The selection depends on specific project requirements and environmental considerations.

Question 2: How does surface preparation impact the longevity of a wood coating?

Meticulous surface preparation is critical for ensuring proper adhesion and longevity. Proper sanding, cleaning, and repair of imperfections provide an optimal surface for the coating to bond effectively. Failure to adequately prepare the surface can result in premature peeling, cracking, or blistering of the protective layer.

Question 3: What factors should influence the choice between oil-based and water-based coatings?

The decision between oil-based and water-based products depends on project priorities. Oil-based coatings typically offer enhanced durability and a richer, amber tone. Water-based options are favored for their lower VOC content, faster drying times, and non-yellowing characteristics. Consider the environmental impact, drying time constraints, and desired aesthetic outcome when making this determination.

Question 4: How can UV damage to exterior wood surfaces be minimized?

To minimize UV damage, select coatings specifically formulated with UV absorbers or blockers. These additives protect the wood and the coating itself from the harmful effects of sunlight. Regular maintenance and reapplication of the product, as recommended by the manufacturer, further prolong the lifespan of the protective layer.

Question 5: What are the best practices for applying a coating to prevent brush strokes or uneven coverage?

To prevent brush strokes or uneven coverage, use a high-quality brush or applicator appropriate for the selected coating. Apply the coating in thin, even layers, following the grain of the wood. Sand lightly between coats with fine-grit sandpaper to ensure a smooth surface. Maintaining a “wet edge” during application prevents lap marks and ensures consistent coverage.

Question 6: How frequently should wood surfaces be recoated to maintain protection and appearance?

Recoating frequency depends on the type of coating, the level of use, and environmental conditions. High-traffic areas may require more frequent recoating than low-use areas. Inspect the surface regularly for signs of wear, such as scratches, fading, or loss of sheen. Follow the manufacturer’s recommendations for maintenance and recoating intervals to preserve the protective and aesthetic qualities of the wood.

In summary, the proper selection, application, and maintenance of surface treatments are essential for preserving the integrity and appearance of wooden surfaces. Careful attention to these factors ensures a long-lasting, visually appealing outcome.

The subsequent section of this article will explore advanced techniques and emerging trends in wood finishing.

Conclusion

The preceding discussion has illuminated the multifaceted considerations inherent in achieving the best wood finish. The selection process necessitates a rigorous evaluation of durability, clarity, application ease, UV protection, water resistance, scratch resistance, and adhesion properties. Each factor contributes significantly to the longevity, aesthetic appeal, and overall performance of the treated surface. A deficiency in any of these areas compromises the integrity of the coating and the underlying wood structure.

The informed application of this knowledge is paramount. The ongoing refinement of coating technologies and application techniques promises further advancements in wood preservation and enhancement. Continued diligence in material selection and meticulous execution will ensure that wooden surfaces retain their beauty and structural soundness for generations to come.