A protective coating applied to the surface of a wooden kitchen implement shields it from moisture, bacteria, and physical wear. This coating, typically food-safe, enhances durability and simplifies cleaning. For example, applying mineral oil or beeswax creates a barrier against water absorption, preventing warping and cracking.

Implementing such surface treatments is paramount for maintaining hygiene and extending the lifespan of the item. Historically, various oils and waxes have been used for this purpose, reflecting the desire to preserve wood and protect food preparation surfaces. A proper application contributes significantly to safety and longevity.

The following sections will delve into specific types of coatings, application techniques, and considerations for selecting the optimal treatment based on wood type and intended use. Factors such as food safety regulations and maintenance requirements will also be addressed.

Application Guidance

The following guidelines provide critical information regarding the appropriate use of a surface protectant for wooden cutting boards. Careful adherence to these tips ensures both safety and optimal performance.

Tip 1: Prioritize Food-Safe Products: Verify that any selected protectant is explicitly designated as food-safe. The chosen product must lack toxic components that could leach into food during preparation.

Tip 2: Thoroughly Clean and Dry the Board: Before application, meticulously clean the cutting board with a mild detergent and water. Allow the wood to air dry completely to ensure proper absorption. Residual moisture can impede the efficacy of the treatment.

Tip 3: Apply Liberally and Evenly: Use a clean cloth or applicator to distribute the protectant generously across the entire surface. Ensure uniform coverage to prevent uneven absorption and potential weak spots.

Tip 4: Allow Adequate Soak Time: Permit the product to penetrate the wood fibers for a sufficient duration, as indicated by the manufacturer’s instructions. This saturation is crucial for maximizing its protective properties.

Tip 5: Remove Excess Coating: After the recommended soak time, wipe away any excess material with a clean, dry cloth. Failure to remove surplus may result in a sticky or tacky surface.

Tip 6: Regular Reapplication is Essential: Reapply the coating periodically, typically every few weeks or months, depending on usage frequency and environmental conditions. Regular maintenance is vital for sustained protection.

Tip 7: Consider the Type of Wood: Different wood species exhibit varying absorption rates. Hardwoods like maple may require less product and shorter soak times than softer woods.

By consistently implementing these strategies, one can effectively preserve the integrity and functionality of a wooden cutting board, ensuring both sanitation and longevity.

The subsequent sections will examine specific coating options and provide detailed maintenance schedules.

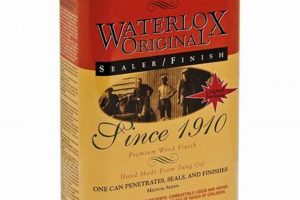

1. Food-safe sealant

The selection of a food-safe sealant is paramount when considering a protective coating for wooden cutting boards. Its primary role is to provide a barrier between the wood and food products, preventing the transfer of potentially harmful substances.

- Prevention of Bacterial Contamination

A food-safe sealant minimizes the risk of bacteria harboring within the wood’s porous structure. By creating a non-permeable surface, it restricts microbial growth. For instance, oils like mineral oil, when properly applied, fill the pores, inhibiting bacterial colonization.

- Barrier Against Chemical Leaching

Certain wood treatments, if not food-grade, can leach harmful chemicals into food. A verified food-safe sealant eliminates this risk, ensuring that only inert substances come into contact with food during preparation. Beeswax, for example, is a natural, food-safe option that creates a protective layer without chemical contamination.

- Enhancement of Cleanability

A properly sealed cutting board is easier to clean and sanitize. The coating prevents food particles and liquids from penetrating the wood, simplifying the removal of residues and reducing the likelihood of cross-contamination. Cutting boards treated with food-safe polyurethane, though less common due to application complexity, offer a durable, easily cleaned surface.

- Maintenance of Wood Integrity

While primarily focused on food safety, a good sealant also protects the wood itself. By preventing excessive moisture absorption, it minimizes the risk of warping, cracking, and other forms of damage. Regular application of food-safe oil, such as tung oil (when fully cured), helps maintain the wood’s structural integrity while providing a safe surface for food preparation.

These aspects collectively highlight the integral role of food-safe sealants in ensuring the hygienic and enduring functionality of a wooden cutting board. The choice of sealant directly impacts the board’s safety, cleanability, and overall longevity.

2. Water resistance

Water resistance is a critical characteristic of any effective surface application for wooden cutting boards. Excessive moisture absorption degrades the wood fibers, leading to warping, cracking, and the proliferation of harmful bacteria. A coatings ability to repel water directly influences the board’s lifespan and hygienic properties.

- Prevention of Warping and Cracking

Wood expands and contracts with moisture content. A water-resistant surface treatment minimizes this fluctuation, preventing dimensional changes that cause warping or cracking. Regular application of oil-based treatments, such as mineral oil, creates a hydrophobic barrier, reducing water uptake and maintaining structural integrity.

- Inhibition of Bacterial Growth

Moist environments foster bacterial growth. By reducing water absorption, a water-resistant coating limits the conditions conducive to microbial proliferation. This is particularly crucial for cutting boards used to prepare food, as bacteria can contaminate the surface and pose a health risk. The application of beeswax, often combined with mineral oil, provides an additional layer of protection against moisture penetration and microbial activity.

- Enhancement of Cleanability and Sanitization

Water-resistant coatings facilitate easier cleaning and sanitization. The treated surface repels liquids, preventing food particles and bacteria from penetrating the wood. This allows for more effective removal of contaminants during routine cleaning. Cutting boards treated with water-resistant coatings can be thoroughly cleaned with soap and water, followed by sanitization with food-safe disinfectants.

- Prolongation of Cutting Board Lifespan

By mitigating the effects of moisture, a water-resistant surface application extends the overall lifespan of the cutting board. Preventing warping, cracking, and bacterial growth reduces the need for frequent replacements, resulting in cost savings and reduced waste. Consistent maintenance with water-resistant treatments helps preserve the board’s functionality and aesthetic appeal over an extended period.

The implementation of surface treatments that enhance water resistance is thus indispensable for the preservation of wooden cutting boards. These treatments safeguard against structural damage, inhibit bacterial growth, facilitate cleaning, and ultimately prolong the functional lifespan of the board. A well-maintained, water-resistant cutting board provides a safe and durable surface for food preparation.

3. Easy maintenance

The ease with which a cutting board can be maintained is directly contingent upon the type of protectant applied. Surface treatments offering simplified upkeep contribute significantly to both the longevity and hygiene of the wooden implement. A primary cause-and-effect relationship exists: specific protectants facilitate effortless cleaning and sanitation, which, in turn, prevents bacterial growth and extends the lifespan of the board. For example, a cutting board treated regularly with mineral oil requires only simple washing with soap and water, followed by occasional reapplication of the oil. This uncomplicated process contrasts sharply with finishes that demand specialized cleaning agents or laborious scrubbing, making mineral oil a popular choice for ease of use.

The importance of easy maintenance extends beyond mere convenience. Cutting boards are frequently exposed to foodborne pathogens during preparation. A protectant that allows for swift and thorough cleaning minimizes the risk of cross-contamination and foodborne illness. Conversely, difficult-to-maintain finishes may harbor bacteria in hard-to-reach crevices, posing a significant health hazard. Consider polyurethane, a more durable finish; while providing a robust, water-resistant surface, it can be more challenging to repair if scratched, potentially creating areas for bacterial accumulation. Therefore, the practical significance of choosing a finish that aligns with the user’s ability and willingness to perform regular maintenance cannot be overstated.

In conclusion, easy maintenance is a critical component of any suitable surface application for a cutting board. It directly impacts hygiene, longevity, and the overall practicality of the wooden implement. While durability and water resistance are essential, the ease with which the finish can be cleaned and maintained dictates its long-term effectiveness. Addressing the challenges associated with rigorous maintenance requirements is crucial for preserving the integrity and safety of wooden cutting boards in any kitchen environment. This understanding links to the broader theme of responsible kitchen practices and informed consumer choices.

4. Durability

Durability, in the context of coatings for wooden cutting boards, refers to the finish’s capacity to withstand the rigors of repeated use, cleaning, and exposure to moisture and food substances. The surface treatment’s inherent resistance to scratching, chipping, and degradation directly affects the board’s lifespan and its ability to maintain a hygienic surface. For example, a finish exhibiting poor durability may quickly develop scratches that harbor bacteria, compromising food safety. Conversely, a robust, durable finish provides a smooth, impermeable surface that resists microbial growth and simplifies cleaning protocols.

The choice of finish significantly influences the cutting board’s long-term performance. Cutting boards treated with durable finishes, such as properly cured polymerized tung oil or certain resin-based coatings, withstand the repeated impact of knives and the abrasive effects of cleaning agents. This resistance minimizes the need for frequent refinishing or replacement, representing a practical benefit for both home cooks and professional chefs. Furthermore, a durable finish retains its aesthetic appeal over time, preserving the cutting board’s visual characteristics and adding to its overall value in the kitchen.

In conclusion, durability is a crucial element in assessing the suitability of any surface treatment for wooden cutting boards. Its direct impact on the board’s lifespan, hygiene, and aesthetic qualities underscores its importance. While other factors, such as food safety and ease of maintenance, are also paramount, durability serves as a foundational attribute that determines the long-term effectiveness and value of the chosen protectant. Understanding the relationship between finish durability and cutting board performance enables informed decision-making, ultimately leading to the selection of products that offer both safety and lasting service.

5. Wood protection

Wood protection, concerning a cutting board, directly correlates with preserving the structural integrity and hygienic properties of the wood itself. Surface treatments designed to protect the wood mitigate the detrimental effects of moisture, bacteria, and physical wear, thereby extending the lifespan and usability of the implement.

- Prevention of Moisture Absorption

Wood is inherently porous and susceptible to absorbing moisture, which leads to warping, cracking, and the proliferation of bacteria. Protective coatings create a barrier against water penetration, reducing these risks. For instance, applying mineral oil fills the wood’s pores, hindering moisture absorption and preventing structural damage.

- Resistance to Microbial Growth

Moist environments encourage bacterial growth, potentially contaminating food prepared on the cutting board. Protective coatings with antimicrobial properties inhibit microbial colonization, maintaining a safer food preparation surface. Certain natural oils, such as those containing natural resins, exhibit antimicrobial effects and contribute to a hygienic surface.

- Mitigation of Physical Wear

Repeated cutting and chopping can cause scratches and gouges on the cutting board’s surface, creating crevices that harbor bacteria and compromise hygiene. Protective coatings, particularly those with enhanced durability, minimize physical wear and maintain a smooth, easily cleanable surface. Hard-wax oil finishes, for example, provide a durable layer of protection against scratches and abrasion.

- Enhancement of Cleanability

Protective coatings facilitate easier cleaning and sanitization by preventing food particles and liquids from penetrating the wood. This allows for more effective removal of contaminants during routine cleaning. Cutting boards treated with protective coatings can be thoroughly cleaned with soap and water, followed by sanitization with food-safe disinfectants, ensuring a hygienic preparation environment.

These facets collectively underscore the importance of wood protection in maintaining the functionality and safety of a cutting board. Protective surface treatments not only extend the board’s lifespan but also create a hygienic environment for food preparation. The selection of an appropriate finish that effectively addresses moisture absorption, microbial growth, physical wear, and cleanability is paramount for ensuring the long-term utility and safety of wooden cutting boards.

Frequently Asked Questions

This section addresses common inquiries regarding the appropriate application and maintenance of protectants for wooden cutting boards. The information provided aims to clarify best practices and dispel misconceptions surrounding this topic.

Question 1: What are the primary benefits of applying a finish to a wooden cutting board?

The application of a surface treatment enhances the board’s durability, inhibits bacterial growth, facilitates cleaning, and prevents excessive moisture absorption. These benefits collectively contribute to an extended lifespan and a safer food preparation surface.

Question 2: What distinguishes a “food-safe” surface treatment from other types of finishes?

A food-safe sealant lacks toxic components that could leach into food during preparation. Such treatments meet specific regulatory standards designed to ensure consumer safety and prevent the ingestion of harmful substances.

Question 3: How often should a cutting board be re-oiled?

Reapplication frequency depends on usage, environmental conditions, and the type of protectant employed. Generally, a cutting board should be re-oiled every few weeks or months, or whenever the wood appears dry and exhibits increased water absorption.

Question 4: Can any type of oil be used to protect a cutting board?

No. Only oils designated as food-safe, such as mineral oil or certain polymerized oils, should be used. Vegetable oils can become rancid over time, creating an unsanitary surface.

Question 5: How should a cutting board be cleaned after each use?

Cutting boards should be cleaned with warm soapy water and thoroughly dried after each use. A diluted bleach solution can be used for sanitization, followed by a thorough rinsing and drying to prevent residue buildup.

Question 6: Is it necessary to sand a cutting board before reapplying a finish?

Sanding is generally recommended only when the cutting board’s surface is rough, damaged, or uneven. Light sanding removes imperfections and allows for better absorption of the new sealant. However, excessive sanding can weaken the wood and should be avoided.

The appropriate surface application plays a crucial role in maintaining the hygiene and longevity of wooden cutting boards. Adherence to established best practices ensures a safe and durable food preparation surface.

The following section will address specific types of surface treatments and their respective advantages and disadvantages.

Surface Treatments for Cutting Boards

This exploration has elucidated the critical role of surface treatment in preserving wooden cutting boards. Key considerations encompass food safety, water resistance, ease of maintenance, durability, and fundamental wood protection. The selection of an appropriate protectant, coupled with consistent application and upkeep, directly influences the longevity and hygienic integrity of the implement.

Therefore, informed decisions regarding the appropriate application should prioritize these key factors. Neglecting the proper surface treatment compromises both the board’s lifespan and the safety of food preparation practices. Subsequent research and adherence to established guidelines remain paramount in upholding the standards of kitchen hygiene and responsible woodworking.

![Why Creative Works: Abandoned, Not Finished [Truth] Best Final Touch: Elevate Your Projects with Professional Finishing Why Creative Works: Abandoned, Not Finished [Truth] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2025/12/th-149-300x200.jpg)