These specialized solutions constitute a range of materials meticulously designed to enhance and protect surfaces across diverse applications. They encompass sealants, coatings, and adhesives, each engineered with specific performance characteristics. For example, a particular formulation might offer superior resistance to abrasion in high-traffic areas, while another could provide exceptional ultraviolet (UV) protection for exterior components.

The significance of these formulations lies in their capacity to extend the lifespan of treated materials, reduce maintenance costs, and improve aesthetic appeal. Historically, the development of advanced finishing technologies has paralleled advancements in materials science, resulting in ever-more durable and effective solutions. This evolution reflects a consistent drive to optimize performance and address increasingly demanding application requirements.

The following sections will delve into the specific attributes of various surface treatments, exploring their applications across industries such as automotive, aerospace, and construction. Furthermore, the discussion will highlight the crucial role they play in ensuring longevity, sustainability, and overall product quality. The advantages, performance considerations, and future trends in this field will also be examined.

Application Guidelines for Optimal Results

Achieving desired outcomes requires careful consideration of several factors. The subsequent guidelines offer key insights for maximizing the performance and longevity of surface treatments. Proper implementation of these techniques is paramount for effective protection and enhancement.

Tip 1: Surface Preparation is Paramount: Ensure the substrate is clean, dry, and free from contaminants such as grease, dust, and rust. Inadequate preparation can compromise adhesion and lead to premature failure.

Tip 2: Adhere to Recommended Mixing Ratios: Dilution or alteration of the prescribed mixing ratios can adversely affect the chemical properties of the material. Strictly adhere to manufacturer specifications to maintain intended performance characteristics.

Tip 3: Control Ambient Temperature and Humidity: Environmental conditions significantly influence drying and curing times. Refer to product data sheets for optimal temperature and humidity ranges to prevent blistering, cracking, or other defects.

Tip 4: Apply Uniformly: Consistent application thickness is critical for achieving uniform protection and aesthetics. Utilize appropriate spraying techniques or application tools to ensure even coverage across the entire surface.

Tip 5: Observe Recommended Drying Times: Allowing sufficient drying time is essential for proper film formation and development of desired mechanical properties. Premature exposure to stress or environmental factors can compromise the integrity of the treatment.

Tip 6: Consider Multiple Coats for Enhanced Protection: Depending on the severity of the environment and the desired level of protection, multiple coats may be necessary. Follow the manufacturer’s recommendations regarding the number of coats and intercoat adhesion requirements.

Tip 7: Proper Storage is Crucial: Store unused materials in a cool, dry place, away from direct sunlight and extreme temperatures. Improper storage can lead to degradation and reduced performance.

These guidelines are essential for realizing the full potential of advanced surface treatments. By meticulously following these steps, users can ensure long-lasting protection, enhanced aesthetics, and optimal performance across a wide range of applications.

The article will now move into the specific industries that use these solutions.

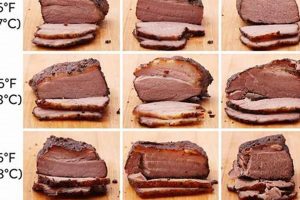

1. Durability

Durability represents a critical performance metric for surface treatments, directly influencing the lifespan, maintenance requirements, and overall cost-effectiveness of coated materials. Within the context of proform finishing products, durability refers to the capacity of a coating or sealant to withstand environmental stressors and physical wear over an extended period, without significant degradation of its protective or aesthetic properties.

- Abrasion Resistance

Abrasion resistance defines the ability of the coating to withstand surface wear caused by friction or contact with abrasive materials. High abrasion resistance is crucial for applications involving frequent handling, exposure to particulate matter, or high-traffic areas. For example, a durable coating on industrial machinery must resist abrasion from metal shavings and debris, maintaining its protective barrier against corrosion.

- Impact Resistance

Impact resistance measures the coating’s ability to absorb and dissipate energy from sudden impacts without cracking, chipping, or delaminating. This is particularly relevant for components exposed to potential collisions or impacts during operation. A durable coating on automotive parts, for example, must withstand impacts from road debris to prevent substrate damage.

- Chemical Resistance

Chemical resistance signifies the coating’s ability to resist degradation or damage upon exposure to various chemicals, solvents, or corrosive substances. The level of chemical resistance required depends on the specific application and potential exposure scenarios. For instance, a durable coating used in a laboratory setting must withstand exposure to a wide range of chemical reagents without dissolving, softening, or losing its protective properties.

- Environmental Stability

Environmental stability encompasses the coating’s ability to withstand prolonged exposure to environmental factors such as ultraviolet (UV) radiation, humidity, temperature fluctuations, and atmospheric pollutants. A durable coating formulated for outdoor applications must resist UV degradation, prevent moisture penetration, and maintain its integrity across a wide range of temperature conditions to ensure long-term protection.

These facets of durability collectively determine the long-term performance of these products. Selecting a product with appropriate durability characteristics is essential to optimize service life, minimize maintenance, and ensure the ongoing protection of treated materials. The interplay of these factors informs the selection process and ensures the chosen coating aligns with the intended operational environment and performance expectations.

2. Adhesion

Adhesion is a fundamental property governing the performance and longevity of these products. The term refers to the ability of the finishing product to bond and remain firmly attached to the substrate material. Insufficient adhesion leads to premature failure of the finish, negating its protective or aesthetic benefits. This occurs because external stresses, such as temperature changes, impacts, or exposure to corrosive substances, can cause the finish to detach from the substrate. A direct consequence of poor adhesion is the exposure of the underlying material to these detrimental factors, leading to degradation, corrosion, or structural weakening.

The effectiveness of adhesion is directly influenced by surface preparation techniques. Contaminants, such as grease, oil, or dust, impede the formation of a strong bond. Therefore, proper cleaning and pretreatment of the substrate are essential steps. For example, in automotive painting, inadequate surface preparation can result in peeling or blistering of the paint film shortly after application. Similarly, in industrial coatings, failure to remove mill scale or rust from steel surfaces will compromise the adhesion of the coating, accelerating corrosion beneath the film. The practical significance lies in the potential for costly rework, increased maintenance, and premature replacement of components when adhesion is compromised.

Understanding and optimizing adhesion requires careful consideration of the materials involved and the intended application environment. Factors such as surface energy, chemical compatibility, and application techniques all play crucial roles. Successful application, and therefore, effective performance of surface treatments hinges on ensuring a robust and durable bond between the finish and the substrate. Overcoming challenges associated with adhesion ensures enhanced product lifespan, reduced maintenance needs, and sustained performance of treated components in diverse operational conditions.

3. Resistance

Resistance, in the context of surface treatments, directly relates to the ability of these products to withstand degradation or damage from various external factors. This characteristic is pivotal in determining the longevity and performance of coated or sealed materials. The following facets highlight key aspects of resistance and their implications.

- Chemical Resistance

Chemical resistance refers to a product’s ability to withstand exposure to various chemicals without undergoing significant alteration in its physical or chemical properties. Industrial environments, laboratories, and manufacturing facilities frequently expose surfaces to solvents, acids, alkalis, and other reactive substances. Selection of a suitable finishing product with high chemical resistance prevents corrosion, staining, softening, or dissolution of the coating, ensuring long-term protection of the substrate. For example, epoxy coatings applied to chemical storage tanks require robust chemical resistance to prevent leakage and environmental contamination.

- UV Resistance

Ultraviolet (UV) resistance describes the ability of a coating to withstand degradation caused by prolonged exposure to sunlight. UV radiation can break down the chemical bonds within the coating, leading to fading, chalking, cracking, and loss of adhesion. Automotive coatings, architectural paints, and marine finishes require high UV resistance to maintain their appearance and protective function over time. The addition of UV absorbers or stabilizers to the formulation enhances the coating’s ability to withstand UV exposure.

- Moisture Resistance

Moisture resistance defines the ability of the coating to prevent the penetration of water or water vapor into the substrate. Moisture penetration can lead to corrosion, blistering, and delamination of the coating, as well as promote the growth of mold and mildew. Marine coatings, exterior paints, and coatings for humid environments require high moisture resistance to prevent water damage. Barrier coatings and hydrophobic treatments enhance moisture resistance by creating a water-repellent surface.

- Thermal Resistance

Thermal resistance signifies the coating’s ability to withstand high or low temperatures without undergoing significant degradation or loss of performance. Extreme temperature fluctuations can induce cracking, blistering, or softening of the coating. Coatings used in high-temperature applications, such as engine components or industrial ovens, require exceptional thermal resistance to maintain their protective properties. Formulations containing ceramic or silicone components enhance thermal stability.

These facets of resistance are interconnected and collectively contribute to the overall durability and performance of surface treatments. Consideration of these properties is critical when selecting a product for a specific application, ensuring optimal protection against the environmental stressors and operational conditions encountered in service. Choosing the right level of resistance prolongs the lifespan of coated materials, reduces maintenance requirements, and enhances their aesthetic appeal.

4. Aesthetics

The aesthetic qualities of these products constitute a critical aspect of their overall value, influencing not only the visual appeal but also the perceived quality and marketability of the treated item. While functionality and protection are primary concerns, the final appearance often dictates consumer preference and brand perception. The connection lies in the fact that a well-executed finish can elevate a product from merely functional to highly desirable, impacting its commercial success. A pleasing aesthetic contributes to a sense of quality and attention to detail, signaling that the underlying item is well-made and worthy of consideration.

Real-world examples abound. In the automotive industry, the gloss and depth of a vehicle’s paint finish are major selling points. Similarly, in consumer electronics, the texture and color of a device’s casing play a significant role in its perceived value. In architectural applications, the color consistency and sheen of exterior cladding materials influence the overall aesthetic impression of a building. These scenarios highlight the direct link between finish quality and the perceived worth of the end product. The practical significance of understanding this relationship lies in the ability to tailor finishing solutions to meet specific aesthetic targets, thereby enhancing product appeal and competitiveness. Achieving the desired visual impact requires careful consideration of factors such as color selection, gloss level, surface texture, and the absence of defects such as orange peel or inconsistencies.

In summary, the aesthetic component of surface treatments is integral to product success. The ability to provide visually appealing, high-quality finishes is not merely a cosmetic concern but a fundamental requirement in many industries. Addressing the aesthetic dimension effectively presents challenges, including maintaining consistency across production runs and meeting evolving consumer preferences. However, embracing this aspect as a key element of product design and manufacturing leads to enhanced brand perception, increased sales, and ultimately, greater market share. Further research and development in this area is crucial for continued innovation and meeting the dynamic demands of the global marketplace.

5. Application

The application of these products is not merely a superficial step but a crucial determinant of their ultimate effectiveness and longevity. The method by which these finishes are applied directly influences their ability to adhere properly, provide uniform coverage, and deliver the intended protective or aesthetic benefits. Consequently, selecting the appropriate application technique is paramount for achieving optimal results. Improper application can lead to premature failure, diminished performance, and compromised visual appearance.

- Surface Preparation

Surface preparation is a foundational step in the application process, significantly impacting adhesion and overall coating performance. The substrate must be clean, dry, and free from contaminants such as grease, rust, or loose particles. Techniques like abrasive blasting, chemical etching, or solvent cleaning are often employed to ensure a suitable surface profile. For example, in applying a protective coating to steel structures, failure to remove existing rust will result in the coating detaching prematurely, exposing the steel to further corrosion. Proper surface preparation ensures a sound foundation for the finishing product to bond effectively, maximizing its durability and protective qualities.

- Application Methods

Various application methods exist, each offering distinct advantages depending on the type of finishing product, the substrate material, and the desired finish quality. Spraying, brushing, rolling, and dipping are common techniques. Spraying provides uniform coverage for large areas and intricate shapes, while brushing is suitable for smaller areas or touch-up work. Rolling offers a cost-effective solution for flat surfaces, and dipping is ideal for coating small parts in bulk. The selection of the application method should consider factors such as viscosity of the material, required film thickness, and the presence of complex geometries. In automotive refinishing, spraying is the preferred method for achieving a smooth, consistent finish across the vehicle’s body panels.

- Environmental Conditions

Environmental conditions during application play a critical role in the curing and performance of the finishing product. Temperature, humidity, and air circulation can significantly affect drying times, adhesion, and the development of desired mechanical properties. High humidity can interfere with the curing process, leading to blistering or poor adhesion. Extreme temperatures can cause the coating to dry too quickly or too slowly, resulting in an uneven or defective finish. Controlled environments, such as spray booths, are often used to maintain optimal conditions and ensure consistent application quality. For instance, applying a moisture-sensitive epoxy coating in a humid environment can lead to amine blush, compromising the coating’s durability and chemical resistance.

- Curing Process

The curing process involves the chemical reactions that transform the applied finish from a liquid to a solid, durable film. Curing can occur through air drying, heat curing, or chemical reactions. Adequate curing time is essential for the finish to develop its full performance characteristics, including hardness, chemical resistance, and adhesion. Premature exposure to stress or environmental factors can disrupt the curing process, leading to a compromised finish. For example, allowing insufficient curing time for a two-component epoxy coating can result in a soft, tacky finish that is susceptible to damage and degradation. Following the manufacturer’s recommendations for curing conditions and times is crucial for achieving the intended performance benefits.

These facets highlight the intrinsic connection between application techniques and the overall success of these products. Careful consideration of surface preparation, selection of application methods, control of environmental conditions, and adherence to proper curing procedures are essential for maximizing the lifespan, protection, and aesthetic appeal of treated materials. The effectiveness of even the most advanced finishing product can be undermined by inadequate application practices. Therefore, a thorough understanding of application principles is indispensable for achieving optimal and long-lasting results.

Frequently Asked Questions About Proform Finishing Products

The following questions address common inquiries and concerns regarding the selection, application, and performance characteristics of these surface treatments. The intent is to provide clarity and facilitate informed decision-making.

Question 1: What factors determine the appropriate selection of proform finishing products for a specific application?

The selection process hinges on several key considerations. These include the substrate material, the intended operating environment, the expected level of exposure to chemical, physical, or environmental stressors, and the desired aesthetic outcome. Careful evaluation of these factors ensures compatibility, durability, and long-term performance.

Question 2: How does surface preparation impact the efficacy of proform finishing products?

Surface preparation is paramount. The presence of contaminants such as grease, rust, or loose debris can compromise adhesion and lead to premature failure of the finish. Proper cleaning, degreasing, and, if necessary, abrasion are essential steps in ensuring a sound bonding surface.

Question 3: What are the common causes of proform finishing products failure?

Primary causes of failure include inadequate surface preparation, improper application techniques, selection of an incompatible product for the substrate or environment, and exposure to conditions exceeding the product’s resistance capabilities. Understanding these failure modes allows for proactive mitigation strategies.

Question 4: How should proform finishing products be stored to maintain their integrity and performance?

Proper storage involves maintaining a controlled environment, typically cool, dry, and away from direct sunlight. Specific temperature and humidity requirements should be adhered to according to the manufacturer’s guidelines. Improper storage can lead to degradation, reduced shelf life, and compromised performance.

Question 5: Can proform finishing products be applied in all weather conditions?

No. Environmental conditions, particularly temperature and humidity, can significantly influence the application and curing process. Extremes of temperature or high humidity can adversely affect adhesion, drying times, and overall finish quality. Consult product data sheets for recommended application parameters.

Question 6: What safety precautions should be observed when working with proform finishing products?

Adherence to safety protocols is critical. This includes wearing appropriate personal protective equipment (PPE) such as respirators, gloves, and eye protection. Adequate ventilation is essential to minimize exposure to harmful vapors. Refer to the product’s Safety Data Sheet (SDS) for detailed safety information and handling guidelines.

In summary, selecting and applying these surface treatments requires diligence, attention to detail, and adherence to best practices. Addressing these common questions provides a foundation for informed decision-making and successful outcomes.

The subsequent section will explore emerging trends and future directions in the field of surface finishing.

Conclusion

This exploration has delineated the multifaceted nature of proform finishing products, emphasizing their crucial role in protecting and enhancing materials across diverse industries. Key aspects such as durability, adhesion, resistance, aesthetics, and application have been examined, underscoring the importance of careful selection and meticulous implementation for optimal results. Furthermore, common challenges and frequently asked questions have been addressed, providing a comprehensive understanding of the subject matter.

The continued advancement of proform finishing products promises further improvements in material longevity, performance characteristics, and aesthetic appeal. A commitment to ongoing research and development, coupled with adherence to best practices, will be essential in realizing the full potential of these technologies. Stakeholders must remain informed and proactive in embracing innovation to meet the evolving demands of the global marketplace.