An air-powered tool designed for precise fastening tasks where aesthetics are paramount, it drives small gauge fasteners to attach trim, molding, and other delicate materials. Utilizing compressed air for operation, this type of stapler minimizes surface marring and provides a clean, nearly invisible hold. For example, it is often used to secure decorative elements in cabinetry or install intricate wood detailing.

Its significance lies in the ability to provide a secure hold without detracting from the visual appeal of the finished product. The small fasteners it employs result in minimal impact damage, preserving the integrity and beauty of the materials being joined. Historically, similar fastening tasks relied on nails or screws, which often required filling and sanding to conceal their presence. This type of stapler streamlines the finishing process, saving time and labor while achieving a superior aesthetic outcome.

Understanding its functionality is crucial when discussing precision fastening techniques, trim carpentry applications, and the selection of appropriate tools for delicate woodworking projects. The subsequent sections will delve deeper into specific uses, maintenance considerations, and the selection criteria for optimal performance in various professional settings.

Using Finish Staplers Effectively

This section outlines crucial guidelines for maximizing the performance and lifespan of these tools, ensuring optimal results in various applications.

Tip 1: Select the Appropriate Fastener Length: Employing staples that are too long can result in punch-through, damaging the material’s surface. Conversely, fasteners that are too short may lack adequate holding power. Conduct test drives on scrap material to determine the ideal staple length for the project.

Tip 2: Adjust Air Pressure Appropriately: Excessive air pressure can cause the tool to sink fasteners too deep, leading to unsightly indentations. Insufficient pressure may result in incomplete drives, leaving staples protruding. Refer to the tool manufacturer’s specifications for recommended pressure settings.

Tip 3: Maintain Consistent Stapler Placement: Uneven staple placement can compromise the structural integrity and aesthetic appeal of the finished product. Use a consistent angle and pressure when operating the tool to ensure uniform staple penetration.

Tip 4: Employ Safety Gear: While seemingly innocuous, these tools can propel fasteners with considerable force. Always wear safety glasses to protect against flying debris and potential eye injuries.

Tip 5: Perform Regular Maintenance: Clean and lubricate the tool regularly to prevent jams and ensure smooth operation. A well-maintained tool performs more reliably and extends its service life.

Tip 6: Use the Correct Staple Type: Different gauges and crown widths are designed for specific applications. Using an inappropriate staple type can lead to improper fastening and potential material damage. Consult the manufacturer’s recommendations for compatible fasteners.

Tip 7: Understand the Grain Direction: When working with wood, driving staples perpendicular to the grain often provides the strongest hold and minimizes the risk of splitting. However, aesthetic considerations may necessitate alternative approaches.

Mastering these techniques ensures accurate and efficient performance, promoting high-quality results and prolonging the operational life of the equipment.

The following section will address common troubleshooting issues and provide solutions for maintaining optimal operational efficiency.

1. Gauge and Crown

The characteristics of gauge and crown dimensions are fundamentally critical when specifying fasteners for use in a finish stapler. These parameters directly influence the fastener’s holding power, visibility, and overall suitability for various finish carpentry applications. The interaction between gauge and crown determines the tool’s effectiveness in achieving a seamless, professional result.

- Gauge’s Impact on Material Integrity

Gauge refers to the thickness of the staple wire. A higher gauge number indicates a thinner wire. Thinner gauge staples are preferable when working with delicate materials to minimize the risk of splitting or marring the surface. However, thinner staples offer reduced holding power compared to thicker gauges. Conversely, a lower gauge number represents a thicker, sturdier staple suitable for denser materials where a stronger hold is required. Selection necessitates a balance between minimizing visual impact and ensuring adequate fastening strength.

- Crown Width and Surface Area

The crown refers to the width of the staple’s top, the portion that rests against the material’s surface. A wider crown provides a larger surface area for fastening, distributing the holding force over a broader region. This characteristic is advantageous when attaching materials prone to tearing or when increased holding power is necessary. Narrower crowns are less visible but may compromise the fastening’s security in less dense materials. The visible aspect of the crown heavily contributes to the overall aesthetic quality of the job.

- Compatibility Considerations

Not all finish staplers are compatible with every gauge and crown size. Tools are designed to accommodate specific ranges of fastener dimensions. Attempting to use incompatible fasteners can result in tool malfunctions, misfires, and potential damage to the workpiece. Consulting the manufacturer’s specifications to ensure compatibility is essential for safe and effective operation.

- Crown and staple leg Length Proportion

Proportionality between staple leg length and crown width is fundamental to ensure a secure bond when using any kind of stapler. If staple legs are too short relative to the crown, the holding power is diminished due to insufficient material penetration. Conversely, legs too long may compromise the material on the opposite side. Selection criteria need to consider density and overall surface properties to ensure bond is secure.

In summary, the judicious selection of staple gauge and crown width, considering material properties and tool compatibility, is indispensable for achieving a professional-quality finish. The optimal choice balances the need for sufficient holding power with the minimization of visible imperfections, contributing to the overall aesthetic appeal and structural integrity of the finished product.

2. Air Pressure Control

Precise regulation of compressed air supply is paramount for optimal performance and longevity of any pneumatically-driven finish stapler. Deviations from recommended pressure ranges can lead to operational inefficiencies, material damage, and compromised tool integrity. A thorough understanding of air pressure control mechanisms and their impact on fastening outcomes is, therefore, essential for professionals utilizing these tools.

- Regulation Mechanisms and Calibration

Finish staplers typically incorporate an adjustable air pressure regulator. This component allows the operator to modify the incoming air pressure to match the material being fastened and the desired staple depth. Accurate calibration of this regulator is crucial. Use of a dedicated pressure gauge to verify the output ensures consistent and repeatable results, mitigating the risk of over-driving or under-driving staples.

- Impact on Fastener Depth and Consistency

Excessive air pressure forces staples too deeply into the material, creating unsightly indentations and potentially compromising the structural integrity of the substrate. Conversely, insufficient pressure results in staples that are not fully seated, leaving them protruding and diminishing the fastening’s effectiveness. Consistent pressure is vital for uniform staple depth across the entire workpiece.

- Effects on Tool Longevity and Maintenance

Operating a finish stapler outside its recommended pressure range can accelerate wear and tear on internal components, such as seals, O-rings, and pistons. Over-pressurization places undue stress on these parts, leading to premature failure. Adhering to the manufacturer’s specified pressure range extends the tool’s lifespan and reduces the frequency of required maintenance.

- Material-Specific Pressure Considerations

Different materials require varying levels of air pressure for optimal fastening. Softwoods, such as pine, typically require lower pressures compared to hardwoods like oak or maple. Brittle materials, such as MDF or particleboard, are particularly susceptible to damage from excessive pressure. Careful adjustment of the air pressure based on the material’s density and composition is essential for achieving a clean and secure fastening without causing surface imperfections.

In conclusion, effective air pressure control is not merely a procedural step but an integral aspect of skillful operation. Appropriate management yields enhanced fastening quality, extends equipment durability, and contributes significantly to the overall efficiency and effectiveness of finish carpentry operations.

3. Fastener Length Selection

The selection of appropriate fastener length is a crucial determinant of both the structural integrity and aesthetic quality achieved when utilizing a finish stapler. Insufficient fastener length compromises the holding power, potentially leading to joint failure or loosening over time. Conversely, excessive length can result in staple protrusion, creating an unsightly finish and posing a safety hazard. The correlation between fastener length and material thickness is thus a central consideration. For instance, when attaching thin trim to a solid wood substrate, a shorter staple prevents breakthrough while still providing adequate grip. Incorrect length selection represents a common source of substandard results and unnecessary material waste.

Practical application demonstrates the significance of precise fastener length selection. When installing crown molding, using staples that are too short may cause the molding to detach due to seasonal wood movement. Using staples that are too long, however, could damage drywall or other backing materials. The correct length allows the staple to penetrate sufficiently into the substrate without causing damage, ensuring a secure and visually appealing installation. Moreover, understanding the specific requirements of different materials, such as hardwoods versus softwoods or composite materials, informs the selection of an optimal fastener length.

In summary, fastener length selection is not a perfunctory task but a critical element in the successful application of a finish stapler. Failure to consider material thickness, substrate composition, and aesthetic requirements can lead to compromised structural integrity and unsatisfactory finish quality. A deliberate and informed approach to fastener length selection is therefore essential for achieving professional-grade results in finish carpentry and related applications.

4. Material Compatibility

Material compatibility is a paramount concern when employing a finish stapler. The selection of appropriate fasteners and air pressure settings must align with the specific properties of the materials being joined to ensure structural integrity and prevent aesthetic damage. Disregarding these factors can lead to compromised joints, surface imperfections, and ultimately, a substandard finished product.

- Wood Density and Fastener Penetration

The density of wood species directly impacts staple penetration. Hardwoods, such as oak or maple, require greater force to drive fasteners effectively, necessitating adjustments to air pressure or the selection of smaller-gauge staples. Conversely, softwoods like pine or cedar are more susceptible to splitting if excessive force is applied. Precise air pressure regulation and the use of appropriate staple gauge are critical for achieving secure fastening without damaging the material. For example, using a heavy-gauge staple in pine trim at high pressure will almost certainly result in unsightly splits and indentations.

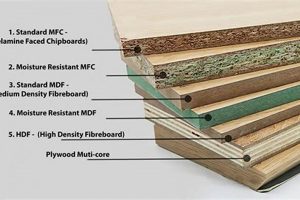

- Composite Materials and Adhesion

Composite materials, including MDF and particleboard, present unique challenges due to their heterogeneous composition and tendency to crumble or delaminate. Fasteners must be carefully selected to ensure adequate adhesion without causing structural damage. The use of specialized staples with barbed shanks or adhesive coatings can improve holding power in these materials. Furthermore, lower air pressure settings are typically required to prevent blowout or surface imperfections. For instance, when attaching trim to an MDF cabinet face, staples with a resin coating can provide superior grip compared to standard staples.

- Trim Thickness and Fastener Length

The thickness of the trim being attached dictates the appropriate fastener length. Staples that are too short will lack sufficient holding power, resulting in loose or detached trim. Conversely, staples that are too long can protrude through the back of the material, creating a safety hazard and detracting from the finished appearance. A general rule is to select a fastener length that allows for approximately two-thirds of the staple to penetrate the substrate. For example, when attaching 1/4-inch thick trim to a 3/4-inch thick cabinet frame, a 1-inch staple would be a suitable choice.

- The Role of Adhesives

While staples provide mechanical fastening, the supplemental use of adhesives can significantly enhance joint strength and prevent movement, particularly in high-stress applications. Construction adhesives or wood glues can be applied in conjunction with staples to create a more durable and resilient bond. This approach is especially beneficial when working with materials prone to expansion and contraction due to changes in temperature or humidity. For instance, when installing baseboards, applying a bead of construction adhesive along the wall prior to stapling can minimize gaps and prevent the baseboard from separating from the wall over time.

In conclusion, a thorough understanding of material properties and their interaction with staple characteristics is essential for achieving successful and aesthetically pleasing results with a finish stapler. Careful consideration of wood density, composite material composition, trim thickness, and the potential use of adhesives will ensure that fasteners are selected and applied appropriately, resulting in a durable and visually appealing finished product.

5. Maintenance Regimen

A consistent maintenance regimen is indispensable for ensuring the sustained operational efficiency and extending the service life of a finish stapler. The intricate mechanisms within these tools, subjected to repetitive high-pressure cycles and contact with compressed air, are susceptible to wear, corrosion, and the accumulation of debris. Neglecting scheduled maintenance can lead to diminished performance, increased risk of malfunction, and ultimately, premature tool failure. A well-defined maintenance protocol addresses these potential issues proactively, preserving the tool’s functionality and minimizing downtime. For example, the accumulation of moisture and oil within the air lines can cause internal rusting and damage to the tool’s seals, leading to air leaks and reduced stapling power. Regular cleaning and lubrication mitigate this risk.

Practical application of a maintenance regimen involves several key steps. First, consistent lubrication of internal components with the recommended oil type reduces friction and prevents wear. Second, periodic cleaning of the air filter and staple magazine removes accumulated debris that can obstruct the tool’s operation. Third, regular inspection of hoses and fittings ensures airtight connections and prevents air leaks. For instance, a cracked or damaged O-ring can cause a significant loss of air pressure, rendering the tool ineffective. Replacing worn components promptly prevents more extensive damage from occurring. Adherence to these practices ensures consistent performance and minimizes the likelihood of costly repairs.

In summary, the implementation of a thorough maintenance regimen for a finish stapler represents a critical investment in the tool’s longevity and operational effectiveness. By proactively addressing potential issues through regular cleaning, lubrication, and inspection, users can mitigate the risk of malfunction, maintain consistent performance, and extend the tool’s service life. This disciplined approach not only safeguards the investment in the tool itself but also contributes to the overall efficiency and quality of finish carpentry operations.

6. Application Precision

Application precision, in the context of finish staplers, denotes the degree of accuracy and control with which fasteners are deployed to achieve optimal results. It encompasses not only the physical placement of the fastener but also the consistency of depth, angle, and spacing, all of which contribute to the structural integrity and aesthetic appeal of the finished product. Precision in application is paramount for minimizing material waste, preventing damage, and ensuring a professional-quality outcome.

- Angled Driving for Concealed Fastening

Employing a finish stapler at a specific angle allows for fasteners to be driven into concealed locations, minimizing their visibility on the finished surface. This technique is particularly useful when attaching trim or molding where a clean, uninterrupted aesthetic is desired. The angle of application requires careful consideration to ensure the fastener still provides adequate holding power while remaining hidden from view. For instance, driving staples at a 45-degree angle into the back of a cabinet frame allows for secure attachment of the face frame without visible fastener holes on the front surface.

- Consistent Depth Control for Uniform Finish

Maintaining consistent fastener depth is critical for achieving a uniform and aesthetically pleasing finish. Overdriving fasteners can create unsightly indentations or damage the material’s surface, while underdriving can leave fasteners protruding, posing a safety hazard and detracting from the overall appearance. Precise depth control, facilitated by adjustable depth settings on the finish stapler, ensures that fasteners are driven to the optimal depth for secure fastening without compromising the material’s surface. Consistently setting the depth when applying crown molding provides a flush surface.

- Strategic Spacing for Structural Integrity

The spacing between fasteners directly influences the structural integrity of the joint or assembly being fastened. Insufficient spacing can result in weak or unstable joints, while excessive spacing may compromise the material’s ability to resist stress or deformation. Strategic fastener spacing, determined by factors such as material type, load-bearing requirements, and environmental conditions, ensures that the fasteners provide adequate support and prevent premature failure. Adequate staple density ensures stability of baseboards.

- Flush Finish Placement

Deliberate consideration of where fastener will be placed ensures the end product meets the intended specification. For instance, if wood filler will be used to cover the hole made by fastener, that spot needs to be prepped for filler. Failing to consider the placement of fastener results in either poor fill quality, or additional labor costs to correct it. In applications where surfaces will be viewed frequently, deliberate planning minimizes poor aesthetic outcomes.

The integration of these facets of application precision into the use of a finish stapler allows for a higher standard of craftsmanship. Recognizing and addressing these nuanced elements transforms the tool from a mere fastener driver into an instrument capable of achieving superior structural and aesthetic outcomes, contributing significantly to the overall quality and durability of finished carpentry projects.

Frequently Asked Questions about Finish Staplers

The following addresses common inquiries and concerns regarding the proper use and maintenance of finish staplers. These questions are designed to provide clarity and guidance for achieving optimal results in various applications.

Question 1: What is the appropriate air pressure setting for driving staples into hardwood trim?

Recommended air pressure settings vary based on the specific hardwood species and the gauge of staple employed. Consulting the tool manufacturer’s specifications is advisable, though testing on scrap material to determine the optimal pressure that prevents over-driving or under-driving is essential.

Question 2: How frequently should a finish stapler be lubricated?

Lubrication frequency depends on the intensity of tool usage. For daily, professional use, lubricating the tool with pneumatic tool oil at the start of each workday is recommended. For intermittent use, lubricating before each project is sufficient. Refer to the tools manual to determine proper amount needed, and how to lubricate.

Question 3: What staple gauge is best suited for attaching delicate molding?

A higher-gauge staple, typically 20- or 22-gauge, minimizes the risk of splitting or marring delicate molding. Thinner-gauge staples offer reduced holding power, so they are best used on trim that also use adhesive to reinforce.

Question 4: Can a finish stapler be used to attach upholstery fabric?

While a finish stapler can secure fabric in some instances, a dedicated upholstery stapler is generally more suitable. Upholstery staplers are designed to drive staples with greater precision and control, preventing damage to the fabric.

Question 5: What causes a finish stapler to misfire or jam frequently?

Common causes of misfires and jams include using incorrect staple types, insufficient air pressure, and inadequate tool maintenance. Inspecting the staple magazine for debris and ensuring the tool is properly lubricated can mitigate these issues.

Question 6: How can staple breakthrough be prevented when working with thin materials?

Employing shorter staple lengths, reducing air pressure, and using a backing material can help prevent staple breakthrough. Testing different settings on scrap material is crucial to determine the optimal combination for the specific application.

These FAQs address fundamental aspects of finish stapler use and maintenance. The adherence to these guidelines promotes efficient operation and high-quality results.

The following section will provide a summary of finish stapler best practices and their applications.

Conclusion

This exploration has addressed critical aspects of the finish stapler, encompassing fastener selection, air pressure regulation, material compatibility, maintenance protocols, and application precision. Mastery of these elements is essential for achieving consistently high-quality results in finish carpentry and related applications. Failure to adhere to established best practices results in compromised structural integrity and diminished aesthetic appeal.

Ongoing adherence to the principles outlined herein represents a commitment to professional excellence. The proper utilization and maintenance of the finish stapler remain paramount for those dedicated to achieving superior outcomes in their craft. Continued vigilance in refining these techniques guarantees not only optimal performance but also the sustained longevity of the tools themselves.