A protective coating of zinc applied to a metal surface is a common technique used to prevent corrosion. This layer acts as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal. An example is the coating applied to fasteners used in outdoor construction, extending their lifespan significantly.

This application is valued for its ability to safeguard metal components from environmental degradation, increasing the durability and longevity of treated items. Historically, its use has been crucial in industries ranging from automotive to construction, where exposure to the elements is unavoidable, ensuring structural integrity and reducing maintenance costs.

The following sections will explore the various methods of application, types of available coatings, and performance characteristics that determine the suitability of this protective measure for specific applications. Further details will be provided regarding surface preparation requirements, post-treatment options, and industry standards relevant to the use of these coatings.

Practical Considerations for Applied Zinc

The effective utilization of zinc coatings requires careful attention to several key factors. Proper implementation will maximize its protective benefits and extend the lifespan of coated components.

Tip 1: Surface Preparation: Thorough surface preparation is paramount. Remove all traces of rust, scale, oil, or other contaminants before application. Inadequate preparation compromises adhesion and reduces corrosion resistance.

Tip 2: Coating Thickness: Specify the appropriate coating thickness for the intended application environment. Thicker coatings provide enhanced protection in harsh conditions, but may impact dimensional tolerances.

Tip 3: Application Method: Select the appropriate application method (e.g., electroplating, hot-dip galvanizing, mechanical plating) based on part geometry, required thickness, and budget considerations. Each method offers distinct advantages and limitations.

Tip 4: Post-Treatment: Consider post-treatment options, such as passivation or sealants, to further enhance corrosion resistance and improve the aesthetic appearance of the coated surface. Chromate conversion coatings are a common, though regulated, post-treatment.

Tip 5: Compatibility: Ensure the selected coating is compatible with other materials in the assembly. Galvanic corrosion can occur if dissimilar metals are in direct contact in the presence of an electrolyte. Insulation or barrier coatings may be necessary.

Tip 6: Inspection and Testing: Implement rigorous inspection and testing procedures to verify coating thickness, adhesion, and corrosion resistance. Regular inspections can identify potential issues early, preventing costly failures.

Tip 7: Environmental Considerations: Adhere to all applicable environmental regulations regarding the handling and disposal of zinc-containing materials. Proper waste management practices are essential.

Adhering to these guidelines will ensure the effective deployment of zinc coatings, providing reliable corrosion protection and extending the service life of valuable assets.

The next section will delve into specific industry applications and case studies, illustrating the diverse range of scenarios where zinc coatings play a critical role in protecting against corrosion.

1. Corrosion Protection

The strategic application of zinc to metallic surfaces represents a fundamental approach to mitigate corrosion, a degradation process that compromises structural integrity and functional performance. Understanding the mechanisms and factors involved in this protection is essential for effective implementation.

- Barrier Protection

The coating functions as a physical barrier, preventing corrosive elements such as moisture, chlorides, and sulfur dioxide from directly contacting the underlying metal substrate. A practical example is the galvanization of steel bridges, where the layer isolates the steel from atmospheric conditions, extending the structure’s lifespan and minimizing maintenance.

- Sacrificial Anode

Zinc acts as a sacrificial anode due to its lower electrochemical potential relative to many common metals, including steel. When the coating is breached, zinc corrodes preferentially, protecting the base metal. This is evident in marine applications, where coatings applied to ship hulls corrode in place of the steel, safeguarding the hull’s integrity.

- Galvanic Corrosion Prevention

The process mitigates galvanic corrosion, which arises when dissimilar metals are in electrical contact in the presence of an electrolyte. By acting as the anode, the system prevents the accelerated corrosion of the other metal. This approach is critical in electronic components where dissimilar metals are often joined.

- Passivation Enhancement

Zinc can promote the formation of a passive layer on the underlying metal. This passive layer further enhances corrosion resistance. For example, zinc coatings on aluminum can encourage the formation of an aluminum oxide layer, creating a durable and self-healing protective film.

These facets collectively demonstrate the diverse mechanisms by which zinc coatings provide robust corrosion protection. The selection of a particular method and thickness depends heavily on the specific application environment and the desired service life of the coated component, emphasizing the need for a thorough understanding of the principles involved.

2. Application Methods

The method of applying a zinc coating directly influences the properties, performance, and ultimate effectiveness of the resulting protective layer. Each technique offers distinct advantages and limitations, impacting factors such as coating thickness, uniformity, adhesion, and cost. The selection of an appropriate method is therefore a critical decision in engineering design and material selection. For instance, hot-dip galvanizing is well-suited for large structural steel components due to its ability to provide a thick, durable coating, while electroplating is often preferred for smaller, more intricate parts requiring a thinner, more precise layer. Mechanical plating offers an alternative approach for components susceptible to hydrogen embrittlement, a concern associated with some electroplating processes. Consequently, the chosen method dictates the specific characteristics of the resulting application.

Further, the practical application environment significantly influences the suitability of a particular coating method. Components exposed to highly corrosive environments, such as marine or industrial settings, may necessitate a thicker coating achieved through hot-dip galvanizing or thermal spraying. In contrast, components used in less demanding environments may benefit from the thinner, more aesthetically pleasing coatings produced by electroplating. The aerospace industry, for example, requires coatings that offer both corrosion protection and minimal weight addition, leading to the use of specialized techniques such as zinc-nickel alloy plating. Therefore, matching the application method to the intended service conditions is paramount for ensuring long-term performance and reliability.

In summary, the selection of a suitable application method is integral to achieving the desired performance characteristics. A thorough understanding of the capabilities and limitations of each technique, coupled with a detailed assessment of the application environment, is essential for maximizing the effectiveness of zinc coatings. The interplay between method, environment, and performance highlights the complex decision-making process involved in specifying these protective measures.

3. Coating Thickness

The thickness of the layer is a critical determinant of its performance, influencing the durability, corrosion resistance, and overall lifespan of the protected component. Precise control over this parameter is essential for achieving the desired functional requirements. The interplay between thickness, application method, and environmental conditions defines the ultimate effectiveness of the finish.

- Corrosion Resistance as a Function of Thickness

Corrosion resistance generally increases proportionally with thickness. A thicker layer provides a more substantial barrier against corrosive elements, extending the time required for these elements to penetrate to the underlying metal. In marine environments, where exposure to chlorides is high, components typically require significantly thicker coatings to achieve adequate protection. This relationship underscores the importance of specifying appropriate thickness levels based on the anticipated exposure conditions.

- Impact on Mechanical Properties

Coating thickness can influence the mechanical properties of the coated component. Excessive thickness may lead to reduced fatigue strength or increased susceptibility to cracking, particularly in high-stress applications. Conversely, insufficient thickness may compromise corrosion resistance. Therefore, a careful balance must be struck to optimize both mechanical performance and corrosion protection. For example, thin coatings on fasteners may provide adequate corrosion protection in mild environments while preserving joint integrity.

- Application Method Limitations

Each application method has inherent limitations regarding the achievable thickness. Hot-dip galvanizing typically produces thicker coatings compared to electroplating. These limitations must be considered when selecting an application method. Components requiring very thick coatings may necessitate hot-dip galvanizing, while those requiring precise thickness control or intricate geometries may be better suited for electroplating or other methods.

- Cost Implications

Coating thickness directly impacts the cost of the treatment. Thicker coatings require more material and may increase processing time, resulting in higher overall costs. Therefore, specifying the minimum acceptable thickness that meets performance requirements is crucial for cost optimization. Over-specifying thickness can lead to unnecessary expenses without a commensurate increase in performance.

In conclusion, coating thickness is a pivotal factor in determining the performance of a zinc coating. Its selection must be based on a thorough understanding of the intended application environment, mechanical requirements, and cost constraints. Optimal performance is achieved by carefully balancing these factors and specifying the appropriate thickness levels.

4. Surface Preparation

Surface preparation is an indispensable prerequisite for the successful application of zinc finishes. The effectiveness and longevity of the protective coating are directly contingent upon the condition of the substrate prior to treatment. Contaminants such as rust, scale, oil, grease, and existing coatings act as barriers, preventing proper adhesion of the zinc to the base metal. Incomplete removal of these substances leads to premature coating failure, compromised corrosion resistance, and ultimately, a reduced service life for the treated component. For example, inadequately prepared steel structures subjected to hot-dip galvanizing often exhibit blistering, peeling, and localized corrosion, necessitating costly repairs or replacements. Therefore, a meticulous approach to surface preparation is not merely a procedural step, but rather a fundamental determinant of the quality and durability of the zinc finish.

The specific methods employed for surface preparation vary depending on the type of base metal, the nature and extent of contamination, and the selected zinc application technique. Common methods include mechanical cleaning (e.g., abrasive blasting, wire brushing), chemical cleaning (e.g., acid pickling, alkaline degreasing), and thermal cleaning (e.g., flame cleaning). Abrasive blasting, for instance, is widely used to remove rust and mill scale from steel surfaces, creating a rough profile that enhances mechanical bonding of the layer. Chemical cleaning, on the other hand, is effective for removing oil and grease, ensuring a chemically clean surface for optimal adhesion. The selection of an appropriate preparation method requires careful consideration of both the contaminants present and the potential impact on the base metal. Overly aggressive cleaning techniques can damage the substrate, while insufficient cleaning compromises the effectiveness of the finish.

In conclusion, surface preparation is an integral component of the zinc finishing process, directly impacting the performance and longevity of the coating. Ignoring or underestimating its importance is a false economy that inevitably leads to increased maintenance costs, premature component failure, and potential safety hazards. Proper surface preparation, coupled with appropriate application techniques and quality control measures, ensures that zinc finishes provide reliable and durable corrosion protection, safeguarding valuable assets across diverse industries. The inherent challenge lies in consistently implementing rigorous preparation protocols and adapting these protocols to suit the specific requirements of each application.

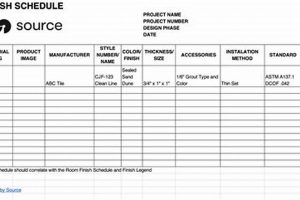

5. Industry Standards

Industry standards serve as critical benchmarks for zinc finishes, dictating performance parameters, application procedures, and quality control measures. These standards, often developed by organizations such as ASTM International, ISO, and SAE, establish uniform requirements for various aspects of zinc coatings, ensuring consistency and reliability across different manufacturers and applications. A direct consequence of adherence to these standards is enhanced product quality and predictable performance. For instance, ASTM B633 specifies the requirements for electrodeposited zinc coatings on iron and steel, outlining parameters such as coating thickness, adhesion, and corrosion resistance. Compliance with such a standard ensures that the applied coating meets defined performance criteria, providing a level of assurance to end-users. Failure to adhere to these standards can result in coatings that fail to provide adequate corrosion protection, leading to premature component failure and potential safety hazards.

The practical significance of industry standards is evident in diverse sectors. In the automotive industry, for example, zinc coatings on fasteners and body panels are subject to stringent performance requirements outlined in SAE standards. These standards address factors such as salt spray resistance, humidity exposure, and thermal cycling, ensuring that the zinc finish can withstand the harsh environmental conditions encountered during vehicle operation. Similarly, in the construction industry, galvanized steel used in bridges and buildings must comply with ASTM A123, which specifies the requirements for hot-dip galvanizing of steel products. This standard dictates coating thickness, adherence, and freedom from defects, ensuring the structural integrity and longevity of galvanized steel components. Without these standards, there would be a lack of uniformity and predictability in the performance of zinc finishes, making it difficult for engineers and designers to specify appropriate coatings for specific applications.

In summary, industry standards are an indispensable component of the zinc finishing process, providing a framework for ensuring quality, consistency, and reliability. Adherence to these standards is not merely a matter of compliance, but rather a critical factor in achieving the desired performance characteristics and extending the service life of zinc-coated components. The challenge lies in staying abreast of evolving standards and adapting processes accordingly. Furthermore, the global nature of supply chains necessitates the harmonization of standards across different regions to facilitate international trade and ensure consistent product quality worldwide.

6. Environmental Impact

The application of zinc coatings, while providing crucial corrosion protection, presents several environmental considerations that warrant careful attention and proactive mitigation strategies. These concerns span the entire lifecycle of coatings, from raw material extraction to end-of-life disposal, necessitating a holistic approach to minimize adverse environmental effects.

- Zinc Mining and Processing

The extraction and refining of zinc ore can lead to habitat destruction, soil erosion, and water contamination. Mining operations often generate significant quantities of waste rock and tailings, which may contain heavy metals and other pollutants. Smelting processes release sulfur dioxide and other air pollutants, contributing to acid rain and respiratory problems. Implementing responsible mining practices, such as minimizing land disturbance, managing wastewater effectively, and capturing emissions, is crucial to mitigating these impacts. For example, advanced flotation techniques and closed-loop water systems can significantly reduce water usage and pollutant discharge at zinc mines.

- Coating Application Processes

Certain coating application methods, such as electroplating, can generate hazardous waste streams containing heavy metals and cyanide. Hot-dip galvanizing produces zinc-containing dross and ash, which require proper disposal or recycling. Volatile organic compounds (VOCs) may be released during spray application of certain zinc-rich paints. Utilizing alternative coating technologies, such as mechanical plating or powder coating, and implementing closed-loop chemical recycling systems can minimize waste generation and reduce VOC emissions. Transitioning to trivalent chromium passivates instead of hexavalent chromium passivates reduces the toxicity of post-treatment processes.

- Leaching and Runoff

In certain applications, zinc can leach from coated surfaces into the environment, particularly in acidic conditions or when exposed to rainwater. This leaching can contaminate soil and water bodies, potentially affecting aquatic life and human health. Using sealants and topcoats can reduce the rate of zinc leaching. Additionally, promoting proper drainage and stormwater management practices can minimize the transport of zinc-containing runoff to sensitive ecosystems. Developing bio-based or environmentally friendly coatings is an active area of research focused on reducing this leaching effect.

- End-of-Life Management

The disposal of zinc-coated materials at the end of their service life presents challenges. Incineration of these materials can release heavy metals into the atmosphere, while landfilling can lead to soil and water contamination. Recycling and reuse of coated materials are preferable alternatives. Technologies such as hydrometallurgical extraction can recover zinc from waste streams, reducing the demand for primary zinc production. Design for Disassembly (DfD) principles should be adopted to facilitate the separation and recycling of zinc-coated components at end-of-life. Efforts in the steel industry to enhance the recyclability of galvanized steel exemplify this approach.

Addressing the environmental impacts associated with application requires a comprehensive and proactive approach encompassing responsible sourcing of raw materials, adoption of cleaner production technologies, and implementation of effective waste management and recycling strategies. Continuous innovation in coating materials and application techniques, coupled with stringent environmental regulations, is essential for minimizing the environmental footprint and ensuring the long-term sustainability of this critical corrosion protection method. Life Cycle Assessments (LCAs) are increasingly used to evaluate and compare the environmental performance of different zinc coating systems.

Frequently Asked Questions About Zinc Finishes

This section addresses common inquiries regarding zinc finishes, providing concise and informative answers to clarify key aspects of their application and performance.

Question 1: What are the primary advantages of employing a zinc finish on metal components?

A layer provides corrosion protection by acting as a barrier and, in many cases, as a sacrificial anode. It extends the lifespan of metal components, reducing maintenance costs and enhancing structural integrity.

Question 2: What are the distinct types of available zinc finishes and their respective applications?

Common types include electroplated, hot-dip galvanized, mechanically plated, and zinc-rich paints. Electroplating is suitable for precise applications, while hot-dip galvanizing is preferred for robust, heavy-duty protection. Mechanical plating offers an alternative for components sensitive to hydrogen embrittlement.

Question 3: How does the thickness of the zinc finish influence its effectiveness?

Generally, a thicker application offers greater corrosion resistance. However, excessive thickness may negatively impact mechanical properties or dimensional tolerances. Determining optimal thickness requires careful consideration of the application environment and performance requirements.

Question 4: Is surface preparation critical prior to the application of a zinc finish?

Yes. Thorough surface preparation is essential to ensure proper adhesion and prevent premature coating failure. Removal of rust, scale, oil, and other contaminants is a necessary step.

Question 5: Are there any environmental considerations associated with the use of zinc finishes?

Yes. The extraction, processing, and disposal of zinc can pose environmental challenges. Responsible sourcing, cleaner production technologies, and effective waste management practices are essential to minimize adverse impacts.

Question 6: What industry standards govern the application and performance of zinc finishes?

Organizations such as ASTM International, ISO, and SAE develop standards that specify requirements for coating thickness, adhesion, corrosion resistance, and other performance parameters. Adherence to these standards ensures consistency and reliability.

In summary, these FAQs provide a foundational understanding of application, addressing its advantages, types, thickness considerations, the importance of surface preparation, environmental impacts, and relevant industry standards.

The following section will delve into a comparative analysis of different protective coatings, assessing their strengths and weaknesses relative to zinc finishes.

Conclusion

This exploration has detailed the multifaceted nature of zinc finish, underscoring its role as a critical corrosion protection strategy. The discussion encompassed application methods, performance characteristics tied to coating thickness, the imperative of surface preparation, and the influence of industry standards. Environmental considerations were also addressed, emphasizing the need for responsible practices. This information collectively highlights the complexities involved in selecting and implementing this protective measure.

Effective utilization of this corrosion protection method requires informed decision-making, balancing technical requirements with environmental responsibility. As materials science advances, continued refinement of application techniques and the development of more sustainable zinc-based solutions will further solidify its importance in diverse industries, ensuring the longevity and reliability of metallic infrastructure.