This entity represents a specific business organization operating within the metal finishing sector. The organization specializes in applying surface treatments to aluminum components, enhancing their properties and aesthetics. These treatments can include anodizing, powder coating, and other specialized finishes. As an example, a manufacturer of aluminum window frames might engage this type of company to improve the corrosion resistance and durability of their products.

Organizations of this nature are crucial to industries reliant on aluminum components. Their services provide enhanced corrosion protection, increased wear resistance, improved paint adhesion, and decorative finishes. Historically, the development of advanced finishing techniques has significantly expanded the applications of aluminum across diverse sectors, including aerospace, automotive, construction, and consumer goods. The ability to tailor surface properties allows aluminum to meet stringent performance requirements in demanding environments.

The following sections will delve into specific aspects of aluminum finishing processes, including the types of treatments offered, the quality control measures employed, and the environmental considerations relevant to these operations. The focus will be on providing a detailed understanding of the factors that contribute to the success and sustainability of aluminum finishing enterprises.

Aluminum Finishing Best Practices

The following represents essential guidelines derived from industry experience, designed to optimize outcomes in aluminum finishing applications.

Tip 1: Alloy Selection: The choice of aluminum alloy significantly impacts the finishing process and the final product’s properties. Certain alloys are better suited for specific finishes, such as anodizing or powder coating. Careful consideration of alloy composition is critical for achieving desired results.

Tip 2: Surface Preparation: Thorough surface preparation is paramount. This involves cleaning, degreasing, and potentially etching the aluminum to remove contaminants and create a receptive surface for the finish. Inadequate preparation can lead to adhesion failures and compromised performance.

Tip 3: Controlled Processing Parameters: Maintaining precise control over process parameters, such as temperature, current density (in anodizing), and coating thickness, is essential for consistent quality. Deviations can result in variations in color, hardness, and corrosion resistance.

Tip 4: Proper Rinsing: After each stage of the finishing process, thorough rinsing is crucial to remove residual chemicals. Inadequate rinsing can cause contamination of subsequent process solutions and negatively impact the final finish.

Tip 5: Sealing Optimization: In anodizing, proper sealing is necessary to hydrate the oxide layer and provide corrosion protection. Sealing processes should be carefully monitored and controlled to ensure optimal results.

Tip 6: Consistent Quality Control: Implement rigorous quality control measures throughout the entire process. This includes visual inspections, thickness measurements, and corrosion testing to verify that the finish meets specified requirements.

Tip 7: Environmental Responsibility: Adhere to environmentally sound practices in waste management and chemical handling. Proper disposal of chemicals and minimization of water usage are essential for sustainable operations.

Adherence to these practices promotes superior finishes, extended product lifespan, and environmentally responsible manufacturing processes. It ensures aluminum components consistently meet performance and aesthetic expectations.

The subsequent sections will elaborate on specific finishing techniques and their applications, building upon the foundational knowledge presented here.

1. Specialized Surface Treatments

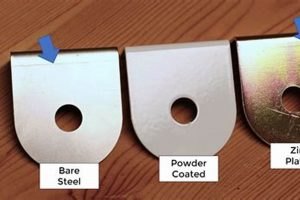

Specialized surface treatments are integral to the operations of firms such as this one. These treatments, which include anodizing, powder coating, and various chemical conversion coatings, directly influence the final properties of aluminum components. The selection and application of a specific treatment are determined by the intended use of the aluminum part. For example, an aluminum component used in an outdoor architectural application will require a surface treatment that provides superior corrosion resistance. This is often achieved through anodizing, which creates a durable oxide layer on the aluminum surface. Conversely, if the aluminum part requires a specific color or aesthetic finish, powder coating might be the preferred treatment method. These specialized processes are not merely cosmetic; they directly impact the component’s performance, longevity, and overall value.

The expertise in applying these specialized treatments is a critical differentiator for companies in the aluminum finishing industry. The process parameters, such as temperature, voltage (in anodizing), or coating thickness, must be precisely controlled to achieve the desired results. Deviation from these parameters can lead to defects, reduced corrosion resistance, or inconsistent appearance. Therefore, an organizations capability to consistently deliver high-quality surface treatments is paramount. This requires not only specialized equipment but also a deep understanding of the chemical and physical processes involved. Consider, for instance, a manufacturer of aerospace components. They require extremely precise and consistent anodizing to meet stringent performance requirements. The successful completion of such contracts depends on the companys mastery of these specialized surface treatment techniques.

In summary, specialized surface treatments are not simply an add-on service but rather a core competency for an aluminum finishing business. The ability to select the appropriate treatment, control the process parameters, and ensure consistent quality directly affects the value proposition for clients. Challenges include staying abreast of new technologies, complying with increasingly stringent environmental regulations, and managing the complexities of finishing different aluminum alloys. Ultimately, the success of such a company hinges on its proficiency in providing these specialized surface treatments, contributing to the broader advancement of aluminum applications across diverse industries.

2. Alloy Compatibility Expertise

The proficiency in understanding aluminum alloy compatibility is a critical determinant of success for a metal finishing enterprise. The specific chemical composition and metallurgical properties of an aluminum alloy dictate its response to various surface treatments. Mastery of alloy compatibility ensures optimal results, minimizes defects, and maximizes the longevity of the finished product.

- Surface Preparation Optimization

Different aluminum alloys require specific surface preparation techniques prior to finishing. For instance, certain alloys may be more susceptible to etching, requiring careful control of etchant concentration and exposure time. Inadequate surface preparation can lead to poor coating adhesion and premature failure. An organization specializing in aluminum finishing must possess the expertise to tailor surface preparation methods to the specific alloy being processed, ensuring optimal adhesion and coating performance.

- Anodizing Parameter Adjustments

The anodizing process, which involves the electrochemical formation of an oxide layer on the aluminum surface, is highly sensitive to alloy composition. Certain alloying elements can interfere with the oxide layer formation, leading to variations in coating thickness, color, and corrosion resistance. A company must be able to adjust anodizing parameters, such as voltage and electrolyte composition, to accommodate different aluminum alloys. This requires a thorough understanding of the electrochemical behavior of each alloy and the ability to fine-tune the anodizing process accordingly.

- Coating Selection and Application

The choice of coating material, such as powder coating or liquid paint, must be compatible with the specific aluminum alloy being finished. Certain alloys may exhibit poor adhesion with specific coating formulations. A company must have the expertise to select the appropriate coating material based on the alloy composition and the intended application of the finished product. This includes understanding the chemical compatibility between the alloy and the coating, as well as the mechanical properties of the coating. Further, the correct application technique is critical to ensure the proper coating thickness and uniform coverage.

- Corrosion Resistance Prediction

The corrosion resistance of finished aluminum components is significantly influenced by both the alloy composition and the surface treatment applied. A firm should possess the expertise to predict the corrosion performance of different alloy/finish combinations in specific environmental conditions. This requires a comprehensive understanding of corrosion mechanisms and the ability to conduct accelerated corrosion testing to validate performance predictions. Providing clients with accurate corrosion resistance data allows them to make informed decisions about material selection and finishing options, ensuring the longevity of their products.

The ability to effectively manage alloy compatibility challenges is a critical competitive advantage. This enables the firm to offer a wider range of finishing options, provide customized solutions, and ensure the long-term performance of finished aluminum components. Organizations possessing this expertise are better positioned to meet the demands of diverse industries, from aerospace and automotive to architecture and consumer products.

3. Quality Assurance Protocols

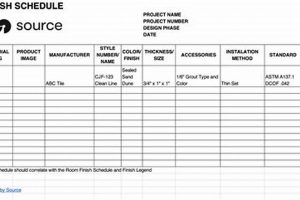

Effective Quality Assurance Protocols are a cornerstone of successful operations within organizations such as Southern Aluminum Finishing Company Inc. These protocols are not merely procedural checklists but rather comprehensive systems designed to ensure consistent conformance to specified requirements and industry standards throughout the aluminum finishing process. The direct consequence of robust Quality Assurance Protocols is a reduction in defects, improved product performance, and enhanced customer satisfaction. For instance, meticulously documented procedures for anodizing thickness measurements, salt spray testing, and color matching are essential for maintaining the integrity of the finished product. Without rigorous adherence to these protocols, the company risks producing components that fail to meet critical performance criteria, leading to costly rework, warranty claims, and reputational damage. The ability to consistently deliver high-quality finishes is directly linked to the effectiveness of its Quality Assurance Protocol implementation.

Consider the practical application of Quality Assurance Protocols in powder coating. The protocol must encompass meticulous surface preparation, controlled coating application, precise curing temperatures, and thorough inspection for defects such as pinholes or orange peel. Documented procedures, regular equipment calibration, and operator training are integral components of this protocol. Failure to adhere to these standards can result in inconsistent coating thickness, poor adhesion, and compromised corrosion protection. Similarly, in the anodizing process, Quality Assurance Protocols dictate the monitoring of electrolyte composition, voltage control, and sealing procedures. Deviation from these protocols can lead to inconsistencies in oxide layer formation and diminished corrosion resistance. These examples highlight the importance of Quality Assurance Protocols as a mechanism for identifying and mitigating potential quality issues before they escalate into significant problems. These also underscore its significance as a differentiating factor. It demonstrates the firm’s commitment to meeting and exceeding industry expectations.

In summary, Quality Assurance Protocols are not optional add-ons but rather fundamental components of a well-managed aluminum finishing operation. They ensure consistent product quality, minimize defects, and enhance customer satisfaction. The challenges associated with implementing and maintaining effective Quality Assurance Protocols include the need for ongoing training, rigorous documentation, and continuous improvement. However, the benefits of a robust Quality Assurance system far outweigh the costs, positioning the company for long-term success and competitive advantage.Southern Aluminum Finishing Company Inc.s commitment to these standards reflects an understanding of the critical role quality plays in establishing and maintaining industry leadership.

4. Industry Sector Focus

An aluminum finishing enterprise’s industry sector focus directly shapes its operational priorities, technological investments, and marketing strategies. A company that strategically aligns its capabilities with the specific needs of targeted industries gains a competitive advantage through specialized expertise and tailored solutions. This focus determines the types of finishes offered, the quality control standards implemented, and the certifications pursued. For example, a business concentrating on the aerospace sector must adhere to stringent aerospace material specifications and quality requirements, necessitating advanced anodizing processes and rigorous testing procedures. Conversely, a firm focusing on the architectural sector may prioritize decorative finishes and weather resistance, investing in powder coating technologies and accelerated weathering tests. The industry sector focus is not a static choice; rather, it is a dynamic aspect of an aluminum finishing enterprises business strategy. It is essential to have consistent market demand. The key is to invest in the training, equipment, and processes necessary to serve the identified industries effectively.

To illustrate further, consider a firm primarily serving the automotive industry. Such an enterprise would likely invest heavily in high-volume, automated finishing lines capable of meeting the industry’s demanding production schedules. Expertise in applying corrosion-resistant coatings and achieving consistent color matching would be essential. In contrast, a business targeting the medical device industry would emphasize biocompatible finishes and stringent cleanliness standards, requiring specialized equipment and processes to minimize contamination. The industry sector focus therefore dictates the technical capabilities, quality assurance protocols, and regulatory compliance requirements of the aluminum finishing enterprise. Businesses must maintain awareness of evolving industry trends and technological advancements to effectively serve their chosen markets. This requires continuous investment in research and development, employee training, and equipment upgrades to remain competitive and meet the evolving needs of clients in each industry.

In summary, an aluminum finishing enterprises industry sector focus is a key determinant of its success. It influences operational priorities, technological investments, and marketing strategies. A well-defined industry sector focus enables the firm to develop specialized expertise, tailor solutions to specific client needs, and gain a competitive advantage. This focus requires continuous investment in research and development, employee training, and equipment upgrades to remain competitive and meet the evolving needs of clients. Challenges include adapting to evolving industry standards, managing diverse quality requirements, and navigating fluctuating market demands. Ultimately, an organizations industry sector focus is a strategic decision that shapes its long-term growth and profitability. It drives decision-making in resource allocation, technological innovation, and market penetration.

5. Environmental Compliance

Environmental compliance represents a critical operational and ethical imperative for organizations involved in metal finishing. The sector inherently utilizes chemicals and processes that necessitate stringent adherence to environmental regulations to mitigate potential adverse impacts. For entities such as Southern Aluminum Finishing Company Inc., effective environmental compliance is essential for maintaining operational licenses, minimizing liability, and fostering a positive corporate image.

- Wastewater Management

Aluminum finishing processes generate significant volumes of wastewater containing pollutants such as heavy metals, acids, and alkalis. Effective wastewater management is essential to prevent contamination of surface and groundwater resources. Compliance necessitates the implementation of advanced treatment technologies, such as chemical precipitation, filtration, and reverse osmosis, to remove pollutants and meet stringent discharge limits. Regular monitoring and reporting are required to demonstrate compliance with regulatory standards. Improper wastewater management can lead to substantial fines, legal action, and damage to the environment.

- Air Emissions Control

Certain aluminum finishing processes, such as anodizing and powder coating, can release air pollutants, including volatile organic compounds (VOCs) and particulate matter. Air emissions control measures are necessary to minimize these pollutants and protect air quality. These measures may include the use of scrubbers, filters, and thermal oxidizers to capture and destroy pollutants before they are released into the atmosphere. Continuous monitoring and reporting of air emissions are required to ensure compliance with regulatory limits. Failure to control air emissions can result in enforcement actions and negative impacts on public health.

- Hazardous Waste Management

Aluminum finishing processes generate hazardous waste streams, including spent chemicals, sludges, and contaminated materials. Proper hazardous waste management is essential to prevent soil and water contamination and protect human health. Compliance necessitates the implementation of comprehensive waste management plans, including proper storage, handling, and disposal of hazardous waste. Regular waste characterization and reporting are required to comply with regulatory requirements. Illegal disposal of hazardous waste can result in severe penalties and long-term environmental damage.

- Chemical Management and Reporting

Aluminum finishing relies on a wide range of chemicals, some of which may be classified as hazardous substances. Proper chemical management is essential to prevent accidental releases and protect worker safety. Compliance necessitates the implementation of chemical inventory tracking systems, safety data sheet (SDS) management, and spill prevention and response plans. Reporting requirements, such as those under the Emergency Planning and Community Right-to-Know Act (EPCRA), mandate the reporting of chemical releases and inventories to regulatory agencies. Failure to comply with chemical management and reporting requirements can lead to fines, penalties, and potential liability for environmental damage.

These interconnected facets highlight the complexities of achieving comprehensive environmental compliance within the aluminum finishing sector. Companies such as Southern Aluminum Finishing Company Inc. must prioritize environmental stewardship by implementing robust management systems, investing in pollution control technologies, and fostering a culture of environmental responsibility among employees. These measures not only ensure compliance with regulations but also contribute to sustainable business practices and long-term operational viability. Continuous improvement in environmental performance is essential for maintaining a competitive edge and minimizing environmental impact.

6. Technological Advancement

Technological advancement is inextricably linked to the operational capabilities and competitive advantage of entities such as Southern Aluminum Finishing Company Inc. The adoption and integration of novel technologies directly impact efficiency, precision, and sustainability within the aluminum finishing sector. Consequently, proactive engagement with technological advancements is not merely beneficial but essential for maintaining relevance and achieving sustained growth.

For instance, the implementation of automated process control systems enables precise regulation of critical parameters such as temperature, voltage, and chemical concentrations. This results in improved consistency, reduced waste, and enhanced product quality. Similarly, the adoption of advanced coating technologies, such as nano-coatings and plasma electrolytic oxidation, provides superior corrosion resistance and enhanced performance characteristics compared to traditional finishing methods. Non-destructive testing techniques, such as ultrasonic testing and eddy current inspection, allow for accurate assessment of coating thickness and integrity without damaging the finished product, further enhancing quality control processes. These concrete applications of technological innovation highlight the significant impact on output quality and production efficiency.

Furthermore, technological advancements in environmental control technologies are crucial for mitigating the environmental impact of aluminum finishing operations. Advanced wastewater treatment systems, air pollution control devices, and resource recovery technologies enable companies to minimize waste generation, reduce emissions, and comply with increasingly stringent environmental regulations. The company must adapt and invest accordingly. Ongoing investment in technological advancements is imperative for Southern Aluminum Finishing Company Inc. to maintain its competitive edge, optimize its operations, and meet the evolving needs of its customers and the broader industry. Challenges include the initial investment costs, the need for skilled personnel to operate and maintain advanced technologies, and the continuous monitoring of technological advancements to identify and adopt relevant innovations. In order to maintain standards, these need to be addressed.

Frequently Asked Questions

The following addresses common inquiries related to operations within the aluminum finishing industry, providing clarity on key aspects.

Question 1: What constitutes “aluminum finishing” as a core business function?

Aluminum finishing encompasses various surface treatment processes applied to aluminum alloys. These treatments enhance properties such as corrosion resistance, wear resistance, and aesthetic appearance. Core processes include anodizing, powder coating, and chemical conversion coating, each tailored to specific performance requirements.

Question 2: What factors determine the selection of an appropriate aluminum finishing method?

Selection of a finishing method depends on multiple factors. These factors include the alloy composition, the intended application of the component, the desired performance characteristics (e.g., corrosion resistance, hardness), and aesthetic considerations. Cost and environmental impact are also relevant factors.

Question 3: What are the primary benefits of anodizing aluminum?

Anodizing enhances the corrosion resistance of aluminum by forming a protective oxide layer on the surface. This process also improves wear resistance, provides a decorative finish, and enhances paint adhesion. The anodic layer is integral to the aluminum and does not peel or flake.

Question 4: How does powder coating compare to liquid painting for aluminum finishing?

Powder coating offers several advantages over liquid painting, including increased durability, improved chemical resistance, and reduced VOC emissions. Powder coating also provides a thicker, more uniform finish. However, liquid painting may offer greater color matching flexibility and be more suitable for complex geometries.

Question 5: What quality control measures are essential in aluminum finishing?

Essential quality control measures include surface preparation assessment, coating thickness measurement, adhesion testing, corrosion testing (e.g., salt spray testing), and visual inspection. Statistical process control (SPC) techniques are often used to monitor and control process variations.

Question 6: What environmental considerations are relevant to aluminum finishing operations?

Environmental considerations include wastewater treatment, air emissions control, hazardous waste management, and chemical management. Regulations often mandate the use of best available technologies (BAT) to minimize pollution. Sustainability initiatives, such as resource recovery and waste reduction, are also increasingly important.

In summary, aluminum finishing represents a complex and multifaceted field requiring expertise in materials science, chemical processing, and environmental regulations. The selection of appropriate finishing methods and the implementation of robust quality control measures are essential for achieving desired performance characteristics and ensuring long-term durability.

The following sections will delve into emerging trends and future directions within the aluminum finishing industry.

Conclusion

This analysis explored the core components defining entities within the aluminum finishing sector, exemplified by Southern Aluminum Finishing Company Inc. Key aspects included specialized surface treatments, alloy compatibility expertise, quality assurance protocols, industry sector focus, environmental compliance, and technological advancement. Each element contributes to the operational effectiveness and market positioning of organizations providing aluminum finishing services.

The ability to deliver consistent quality, adapt to evolving industry standards, and minimize environmental impact remains paramount. Future success hinges on a commitment to continuous improvement, technological innovation, and a strategic alignment with the needs of diverse industries relying on aluminum components. Vigilance and investment will ensure continued relevance and a sustainable future within the competitive landscape.