The uppermost layer applied to a table, designed to protect the underlying material while enhancing its aesthetic appeal, is a crucial element in furniture construction. This protective coating shields the table from scratches, stains, water damage, and general wear and tear, extending its lifespan and maintaining its visual appeal. For example, a durable and visually appealing layer safeguards a dining table from spills and daily use, preserving its condition over time.

The correct selection extends the longevity of the piece and can significantly impact its overall value and usability. Historically, these protective layers were rudimentary, often consisting of natural oils or waxes. Modern options offer advanced protection and diverse aesthetic choices, ranging from matte to high-gloss appearances. Proper application preserves the investment in quality furniture and reduces the need for frequent repairs or replacements.

Subsequent sections will detail the various types available, outlining their specific properties, advantages, disadvantages, and suitability for different applications. Considerations for selecting the right option, application techniques, and maintenance procedures will also be addressed to provide a comprehensive understanding.

Guidance on Selecting a Table’s Protective Layer

The selection and application of a suitable protective layer are critical for preserving the integrity and appearance of a table. These guidelines offer advice on making informed decisions.

Tip 1: Evaluate Table Usage: Assess the table’s intended environment and the anticipated level of use. A dining table requires a more durable and stain-resistant layer than a decorative side table.

Tip 2: Consider Material Compatibility: Ensure the chosen layer is compatible with the table’s material. Certain wood types react differently to various coatings, affecting adhesion and finish quality.

Tip 3: Prioritize Durability: Opt for options known for their resistance to scratches, water damage, and chemical spills. Polyurethane and epoxy resins are generally more resilient than wax or oil-based alternatives.

Tip 4: Assess Aesthetic Preferences: Balance protection with desired appearance. Matte, satin, semi-gloss, and high-gloss options offer different levels of sheen and visual impact.

Tip 5: Inquire About VOC Content: Consider the volatile organic compound (VOC) content of the material. Low-VOC or water-based options are environmentally preferable and often safer for indoor use.

Tip 6: Understand Application Requirements: Research the application process for the chosen layer. Some require specialized equipment or techniques, impacting the overall project cost and complexity.

Tip 7: Investigate Maintenance Needs: Different options necessitate varying levels of maintenance. Some are easily cleaned and require minimal upkeep, while others may need periodic reapplication.

Correct choice is crucial for safeguarding the piece, enhancing its beauty, and ensuring its longevity. Careful planning and informed decisions are essential for achieving optimal results.

The following sections provide a deeper dive into specific types of options and their application, enabling a more nuanced understanding.

1. Durability

Durability is a paramount characteristic when evaluating options for table protection. It dictates the lifespan of the coating and the underlying table surface, determining resistance to various forms of damage encountered during normal use.

- Resistance to Abrasion

A protective layer’s capacity to withstand scratching, scuffing, and rubbing is crucial, especially for surfaces subject to frequent contact with objects. A high abrasion resistance ensures the table maintains its appearance over time, resisting the dulling effect of repeated use. Examples include polyurethane and conversion varnishes, known for their robust resistance to physical wear.

- Resistance to Chemical Damage

The ability to resist damage from spilled liquids, including water, alcohol, and household cleaning agents, is essential. Chemical resistance prevents staining, discoloration, and degradation of the protective layer and underlying material. Epoxy resins and certain catalyzed lacquers are formulated for superior chemical resistance.

- Resistance to Impact

A coating’s capacity to absorb impacts without cracking, chipping, or denting is critical for preventing structural damage to the table. Impact resistance safeguards against accidental drops or forceful contact. Options with higher flexibility and hardness ratings demonstrate improved impact resistance.

- Resistance to Heat and UV Exposure

Prolonged exposure to heat or ultraviolet (UV) radiation can cause fading, discoloration, or structural weakening of the protective layer. Resistance to these environmental factors ensures the table maintains its integrity and appearance over time, particularly when placed near windows or heat sources. Certain formulations include UV inhibitors to mitigate damage from sunlight.

The facets of abrasion, chemical, impact, and environmental resistance collectively define a protective layer’s overall durability. The selection of a coating with appropriate durability characteristics is fundamental to safeguarding the table, preserving its aesthetic appeal, and ensuring its long-term usability.

2. Appearance

The visual characteristics of a table’s protective layer significantly influence its perceived value and integration within a space. A layer’s appearance dictates the initial impression and long-term aesthetic contribution of the furniture piece. The selection process involves carefully matching the protective layer’s visual properties to the intended style and functional requirements of the table.

Cause and effect are intrinsically linked in this context. The protective layer directly affects the table’s sheen, color, and texture, consequently impacting the overall ambience of the room. For example, a matte layer might lend a casual, understated elegance to a rustic dining table, while a high-gloss option could enhance the modern aesthetic of a minimalist design. The Importance of “Appearance” as a component of a protective layer’s selection involves determining the desired aesthetic impact. A table in a formal dining room may necessitate a different protective layer than one used in a more casual kitchen setting. Real-life examples underscore this. A water-based polyurethane on a light-colored wood table can maintain the wood’s natural tone while providing a durable, clear layer. Conversely, an oil-based varnish can deepen the wood’s color, creating a warmer, richer appearance. Understanding this interplay is significant, enabling informed decisions that achieve both desired protection and visual appeal.

In summary, the impact of the protective layer’s appearance extends beyond surface-level aesthetics. It dictates how the furniture interacts with its environment and contributes to the overall design. Challenges in selection often arise from balancing desired durability with specific visual preferences. Ultimately, a well-chosen protective layer enhances the table’s beauty while safeguarding its integrity, representing a harmonious blend of form and function.

3. Application

The method of applying a protective layer to a table surface is integral to the ultimate performance and aesthetic quality of the resultant coating. Proper execution directly influences adhesion, uniformity, and durability, and is therefore paramount in achieving a successful and lasting outcome.

- Surface Preparation

The state of the table’s surface prior to application profoundly impacts the adhesion and appearance of the protective layer. Thorough cleaning, sanding, and removal of contaminants are essential. Failure to properly prepare the surface can lead to adhesion failures, uneven finish, and compromised durability. For instance, applying a polyurethane layer over an unclean surface can result in bubbling or peeling.

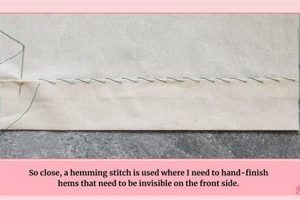

- Application Techniques

The specific technique employed for applying the protective layer significantly influences the finish quality. Brushing, spraying, and wiping methods each offer distinct advantages and disadvantages. Spraying typically provides a more uniform and smooth finish compared to brushing, but requires specialized equipment and ventilation. Careful attention to application technique is crucial to minimize imperfections like brush strokes, drips, or orange peel texture.

- Environmental Conditions

Ambient temperature, humidity, and dust levels can significantly affect the application process and the curing of the protective layer. High humidity can interfere with the drying process, leading to cloudiness or poor adhesion. Dust particles can become trapped in the coating, resulting in a textured or contaminated surface. Maintaining a controlled environment is critical for achieving a flawless and durable layer.

- Curing and Drying

Allowing the protective layer sufficient time to cure and dry completely is essential for achieving its intended properties. Premature use or handling can result in damage to the uncured coating. The recommended curing time varies depending on the type of protective layer and the ambient conditions. Following the manufacturer’s instructions regarding curing time is crucial for ensuring the coating achieves its full hardness, durability, and chemical resistance.

These facets of surface preparation, application techniques, environmental conditions, and curing time are inextricably linked to the success of the protective layer application. Precise attention to each aspect is required to maximize the protective and aesthetic qualities of the chosen layer, and to ensure the longevity of the table’s appearance and function.

4. Maintenance

Ongoing upkeep is intrinsically linked to the longevity and continued aesthetic appeal of any protective layer applied to a table surface. Consistent and appropriate maintenance practices are essential to preserve the integrity of the material and to prevent premature degradation or damage, irrespective of the inherent qualities of the “best table finish” selected.

- Regular Cleaning

Routine cleaning is paramount for removing dust, dirt, and spills that can compromise the protective layer over time. Abrasive cleaners or harsh chemicals can damage the surface, leading to dullness, scratching, or discoloration. Gentle cleaning agents and soft cloths are recommended to maintain the integrity of the protective layer. For instance, a simple solution of mild soap and water is often sufficient for cleaning polyurethane or varnish layers on dining tables following meals.

- Preventative Measures

Implementing preventative measures minimizes the risk of damage to the table surface. Utilizing coasters under beverages, placemats beneath dishes, and avoiding placing hot items directly on the table can significantly reduce the potential for staining, heat damage, or scratching. These proactive steps safeguard the protective layer, extending its lifespan and preserving its appearance. An example is the consistent use of heat-resistant pads under hot plates to prevent the protective layer from blistering or developing white rings.

- Addressing Minor Damage

Promptly addressing minor scratches or blemishes is crucial to prevent them from escalating into more significant issues. Minor imperfections can often be repaired using specialized products or techniques tailored to the specific protective layer. Ignoring these small damages can lead to moisture penetration, further degradation, and more costly repairs in the future. For example, applying a touch-up pen designed for varnish can effectively conceal a small scratch on a coffee table, preventing further damage.

- Periodic Reapplication

Depending on the type and level of use, some protective layers may require periodic reapplication to maintain their protective properties. Over time, wear and tear can diminish the effectiveness of the protective layer, necessitating a fresh coat to restore its original luster and resistance to damage. The frequency of reapplication depends on factors such as the specific material used, the intensity of table use, and the environmental conditions. For example, a wax coating on a frequently used dining table may require reapplication every few months to maintain its protective qualities.

The efficacy of any “best table finish” is directly proportional to the degree and consistency of its maintenance. Regular cleaning, preventative measures, timely repair of minor damage, and periodic reapplication collectively ensure the continued protection and aesthetic appeal of the table. Diligence in these maintenance practices is essential for maximizing the investment in both the table itself and the protective layer applied to it.

5. Cost

The expenditure associated with a protective layer for tables directly influences the selection process and long-term financial implications. Cost considerations encompass not only the initial purchase price of the material but also the associated application costs, maintenance expenses, and potential costs of repair or replacement. The interplay between these factors determines the overall economic value of a given option.

The initial price point of various materials can vary significantly. For instance, wax or oil-based protective layers often present a lower upfront cost compared to more durable options such as polyurethane or epoxy resins. However, the lower initial cost may be offset by increased maintenance requirements and a shorter lifespan. Polyurethane layers, while initially more expensive, may offer superior durability and resistance to damage, potentially reducing long-term maintenance costs and extending the lifespan of the table. Application costs also contribute to the overall expenditure. Certain materials, such as spray-applied lacquers, require specialized equipment and professional application, increasing the overall project cost. Conversely, wipe-on finishes can be applied by individuals with basic skills, reducing labor costs. A real-life example illustrates this: a small coffee table might benefit from a less expensive wax coating applied by the owner, while a large, high-value dining table might warrant the higher cost of a professionally applied polyurethane layer for optimal protection and appearance.

In summary, the economic evaluation of table protective layers requires a holistic view that extends beyond the initial purchase price. Factors such as durability, maintenance requirements, application costs, and potential repair expenses must be considered to determine the most cost-effective solution over the lifespan of the table. Balancing the desire for high-quality protection with budgetary constraints is a common challenge. Ultimately, a thorough cost-benefit analysis ensures a financially sound decision that aligns with both the functional requirements and the economic realities of the project.

6. Safety

The selection of a protective layer for table surfaces necessitates careful consideration of safety implications. Exposure to harmful substances during application, as well as potential off-gassing from the cured coating, pose health risks that must be mitigated through informed material selection and appropriate handling procedures.

- Volatile Organic Compounds (VOCs)

VOCs are emitted from certain protective layers during and after application. Prolonged exposure to high levels of VOCs can cause respiratory irritation, headaches, and other adverse health effects. Low-VOC or zero-VOC options minimize these risks, promoting safer indoor air quality. For example, water-based polyurethanes typically contain lower VOC levels compared to solvent-based alternatives, making them a preferable choice for households with sensitivities.

- Flammability

Certain protective layers contain flammable solvents that pose a fire hazard during application and storage. Proper ventilation and avoidance of ignition sources are crucial when working with flammable materials. Water-based options are generally less flammable, reducing the risk of fire-related accidents. An example of the danger is improper disposal of rags soaked in flammable protective layer, which can spontaneously combust.

- Food Contact Safety

For tables intended for food preparation or dining, the protective layer must be non-toxic and safe for contact with food. Materials certified as food-safe ensure that no harmful substances will leach into food products. Certain epoxy resins and specialized varnishes are formulated to meet food contact safety standards. Using a non-food-safe protective layer on a cutting board, for example, could lead to contamination of food with potentially harmful chemicals.

- Skin and Eye Irritation

Some protective layers can cause skin or eye irritation upon contact. Wearing appropriate personal protective equipment, such as gloves and eye protection, during application is essential to prevent adverse reactions. In case of contact, thorough washing with soap and water is recommended. Individuals with sensitive skin should consider using hypoallergenic options or consulting a medical professional prior to handling potentially irritating materials. Certain wood finishing products contain allergens that can cause dermatitis in susceptible individuals.

The safety aspects of “best table finish” encompass a range of considerations, from the chemical composition of the material to its potential for causing harm during application and use. Diligent attention to these safety factors is paramount for safeguarding the health of individuals applying the coating, as well as those who will ultimately use the finished table. Choosing options with low VOCs, appropriate flammability ratings, food-safe certifications, and minimal irritant potential contributes to a safer and healthier environment.

7. Compatibility

The success of any protective layer application is inextricably linked to its compatibility with both the substrate material and the intended environment. A mismatch can lead to adhesion failures, premature degradation, and compromised aesthetic outcomes, irrespective of the theoretical qualities of the chosen material. The underlying material’s properties, including porosity, density, and chemical composition, dictate its interaction with the protective layer. For instance, applying a water-based polyurethane over an oil-based stain can result in poor adhesion and subsequent peeling. A protective layer intended for interior use may degrade rapidly if exposed to prolonged sunlight or moisture in an exterior setting.

The importance of compatibility stems from its direct impact on the protective layer’s performance and longevity. Selecting a material without considering its interaction with the table’s substrate can lead to costly repairs and rework. Real-life examples underscore this significance: A flexible protective layer is required for tables constructed from wood species prone to expansion and contraction with changes in humidity. Using a rigid layer in such instances can result in cracking and delamination. Similarly, certain wood species contain natural oils or resins that can inhibit the curing or adhesion of some protective layers. Applying a shellac without properly dewaxing the wood can result in a soft, sticky layer that never fully hardens. Understanding this interplay is crucial for avoiding common pitfalls and ensuring the long-term effectiveness of the protective treatment.

In summation, compatibility represents a critical determinant of the success or failure of a protective layer application. The challenges in achieving optimal results often stem from a lack of understanding of the material properties and their interactions. However, careful consideration of the substrate, environmental factors, and the specific characteristics of the protective layer enables informed decision-making that ensures both durable protection and lasting aesthetic appeal.

Frequently Asked Questions Regarding Table Protective Layers

The following section addresses common inquiries and clarifies misconceptions surrounding the selection, application, and maintenance of table protective layers.

Question 1: Does a higher price invariably indicate superior quality in table protective layers?

No. While higher-priced options may offer advanced features or enhanced durability, the “best table finish” is determined by the specific requirements of the table and its intended use. A less expensive material, appropriately matched to the application, may provide adequate protection and aesthetic appeal.

Question 2: Is a single application of a protective layer sufficient for long-term protection?

Generally, no. Multiple coats are typically required to achieve the desired level of protection and durability. The number of coats and application method depend on the specific material and manufacturer’s recommendations.

Question 3: Can any cleaning product be safely used on a protected table surface?

No. Abrasive cleaners and harsh chemicals can damage or degrade protective layers. Mild soap and water or cleaning products specifically designed for finished wood surfaces are recommended.

Question 4: Does a protective layer completely eliminate the risk of damage to the table?

No. While protective layers enhance resistance to scratches, stains, and other forms of damage, they do not provide absolute protection. Care should still be taken to avoid extreme heat, sharp objects, and prolonged exposure to harsh substances.

Question 5: Are all protective layers suitable for use on tables intended for food preparation?

No. Only materials specifically certified as food-safe should be used on surfaces that come into direct contact with food. Verify the product label or manufacturer’s specifications to ensure compliance with food safety standards.

Question 6: Can a damaged protective layer be easily repaired?

The ease of repair depends on the type and extent of the damage, as well as the type of protective layer. Minor scratches or blemishes may be repairable with touch-up products, while more extensive damage may require professional refinishing.

Proper selection, application, and maintenance are critical to maximize the effectiveness and longevity of any table protective layer. Understanding the nuances of these processes ensures informed decisions and optimal outcomes.

The following section provides a comprehensive overview of specific protective layer types and their respective properties.

Conclusion

This exposition has detailed the multifaceted considerations inherent in selecting a protective layer for tables. The optimal choice hinges on a careful evaluation of durability, appearance, application requirements, maintenance demands, cost implications, safety parameters, and material compatibility. The interplay of these factors determines the ultimate efficacy of the protective measure.

The informed selection and diligent application of an appropriate protective layer safeguard the integrity and extend the lifespan of valued furniture. The continued pursuit of innovative materials and refined application techniques remains crucial for enhancing both the performance and sustainability of future table protection strategies.