Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

A pneumatic tool designed for driving finish nails into wood surfaces, it is frequently employed in woodworking and carpentry applications. These tools utilize compressed air to rapidly and precisely insert nails, offering an efficient alternative to manual hammering. An example of its application includes installing trim, molding, and cabinetry where a less conspicuous nail head is desired.

The significance of this type of equipment lies in its ability to enhance productivity and provide a consistent, professional finish. Its use reduces the likelihood of surface damage and minimizes operator fatigue compared to manual methods. The development of these devices has significantly streamlined the process of completing detailed woodworking tasks, tracing its origins back to the broader evolution of pneumatic fastening systems.

This article will delve into the key features, operational considerations, maintenance practices, and selection criteria associated with these tools, providing a detailed understanding of their application and optimization within various professional and DIY contexts.

Operating a Finish Nailer

This section provides crucial guidelines for safe and effective operation of a pneumatic finish nailer. Adherence to these tips will improve accuracy, extend the lifespan of the tool, and minimize the risk of injury.

Tip 1: Verify Air Pressure. Consistent performance requires maintaining the correct air pressure, as specified by the manufacturer. Insufficient pressure can result in incomplete nail sets, while excessive pressure can damage the work surface or the tool itself. Use a regulator to precisely control the incoming air supply.

Tip 2: Utilize Appropriate Fasteners. Employ only nails of the correct gauge and length, as recommended for the specific model. Mismatched fasteners can cause jams, misfires, and damage the internal mechanisms of the equipment. Consult the tool’s manual for approved fastener specifications.

Tip 3: Maintain Consistent Contact. Ensure firm and consistent contact between the tool’s nosepiece and the work surface before actuation. This stabilizes the tool and promotes accurate nail placement. Inconsistent contact can lead to nail slippage or double firing.

Tip 4: Practice Proper Tool Angle. Maintain the appropriate angle relative to the work surface, usually 90 degrees unless a specific angled application is required. An incorrect angle can cause the nail to bend or deflect upon entry, compromising the structural integrity of the fastening.

Tip 5: Employ Safety Precautions. Always wear appropriate personal protective equipment, including safety glasses, to guard against flying debris. Disconnect the air supply before performing any maintenance or clearing jammed nails. Treat the equipment with the same respect as any potentially dangerous power tool.

Tip 6: Regularly Inspect and Lubricate. Check the tool for wear and tear before each use. Apply a few drops of pneumatic tool oil to the air inlet to ensure smooth operation and prevent internal corrosion. Regular maintenance will significantly extend the service life of the nailer.

Adherence to these guidelines fosters efficient and safe utilization of the tool. Consistent application of these practices will improve the quality of the finished product and the longevity of the equipment.

The subsequent section will address common troubleshooting scenarios and their respective resolutions, ensuring continuous and productive operation.

1. Gauge

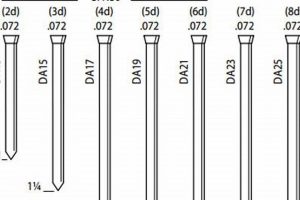

Gauge, in the context of a Bostitch finish nailer, denotes the diameter or thickness of the nails the tool is designed to drive. The gauge specification is a critical parameter that determines the tool’s suitability for various woodworking and finishing applications. Selection of the correct gauge ensures proper fastening and prevents damage to both the workpiece and the tool itself.

- Nail Compatibility

A Bostitch finish nailer is engineered to accept nails of a specific gauge range. Using nails outside this range can lead to jamming, misfires, or damage to the internal mechanisms. For example, a 16-gauge finish nailer cannot effectively drive 18-gauge nails, as the narrower nails may not feed properly, and the driving force will be misaligned. Similarly, attempting to use 15-gauge nails could physically damage the tool.

- Application Appropriateness

The gauge of the nail influences the application for which the finish nailer is best suited. Higher gauge numbers (e.g., 18-gauge) correspond to thinner nails, ideal for delicate trim work where minimal visibility and splitting are desired. Lower gauge numbers (e.g., 15-gauge) indicate thicker nails suitable for heavier materials and applications requiring greater holding power, such as cabinet construction. Choosing the appropriate gauge ensures structural integrity and aesthetic quality.

- Tool Model Variation

Bostitch offers a range of finish nailer models, each designed for a specific gauge or a narrow range of gauges. Certain models are dedicated to 15-gauge nails for demanding applications, while others accommodate 16-gauge or 18-gauge nails for finer work. Understanding the gauge specification of a particular Bostitch model is essential for selecting the appropriate tool for a given task. Referencing the manufacturer’s specifications is crucial for proper tool selection.

- Material Density

The density and type of material being fastened also dictate the appropriate nail gauge. Softwoods like pine require thinner nails (higher gauge) to prevent splitting, while hardwoods like oak require thicker nails (lower gauge) for adequate penetration and holding power. Selecting the correct gauge in relation to the material density ensures a secure and aesthetically pleasing finish. Incorrect gauge selection can lead to either insufficient holding power or undesirable surface damage.

The gauge specification is a fundamental consideration when selecting and using a Bostitch finish nailer. Proper understanding of gauge characteristics in relation to nail compatibility, application appropriateness, tool model variations, and material density is essential for achieving optimal results in various woodworking and finishing tasks. Improper gauge selection can compromise both the structural integrity and the aesthetic quality of the finished product.

2. Air Pressure

Air pressure is a critical operational parameter for a Bostitch finish nailer, directly influencing its performance and the quality of the fastening. The nailer relies on compressed air to drive nails into the workpiece. Insufficient air pressure results in incomplete nail sets, where the nail head does not fully recess into the material. Conversely, excessive air pressure can cause the nail to be driven too deep, damaging the surrounding surface and potentially splitting the wood. Precise regulation of air pressure is therefore essential for achieving consistent and professional results. For instance, when working with softwoods, a lower pressure setting is typically required to prevent over-driving the nail, whereas hardwoods often necessitate a higher pressure to ensure adequate penetration.

The recommended air pressure range for a specific Bostitch finish nailer model is typically specified in the tool’s manual. Adhering to these guidelines is imperative for maximizing tool efficiency and minimizing potential damage. Real-world examples demonstrate the importance of this parameter: a trim carpenter installing delicate molding might utilize a lower pressure setting to avoid marring the wood surface, while a cabinet maker assembling face frames might require a higher pressure setting to securely fasten dense hardwood components. Regular monitoring of air pressure, using a calibrated regulator, ensures the nailer operates within its optimal performance envelope.

In summary, air pressure serves as a foundational element in the functionality of a Bostitch finish nailer, impacting fastening quality and material integrity. Understanding and properly adjusting air pressure, according to material density and manufacturer specifications, is crucial for successful and efficient operation. Challenges may arise from fluctuating air supply or inaccurate pressure gauges, underscoring the need for consistent monitoring and calibration. This understanding contributes to the broader theme of precision and control in woodworking and construction trades.

3. Nail Length

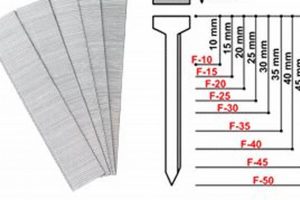

The functionality of a Bostitch finish nailer is intrinsically linked to nail length. The tool is designed to accommodate a specific range of nail lengths, directly influencing its application and fastening capability. Employing nails outside this specified range can result in tool malfunction, inadequate fastening, or damage to the workpiece. For example, attempting to use nails that are too long can cause jamming or prevent the nail from being fully driven, while nails that are too short may not provide sufficient holding power. A practical understanding of nail length is therefore crucial for effective operation and optimal results.

Real-world applications illustrate the importance of matching nail length to the material thickness and intended use. Installing thin trim often requires shorter nails to prevent protrusion on the opposite side of the wood. Conversely, fastening thicker materials, such as cabinet frames, demands longer nails to ensure secure and lasting connections. The choice of nail length also impacts the structural integrity of the finished product. Using nails that are too short in structural applications compromises the strength of the joint, while excessively long nails can increase the risk of splitting or damage to the surrounding material.

In summary, nail length is a critical parameter in the effective utilization of a Bostitch finish nailer. Careful selection of the appropriate nail length, based on material thickness and application requirements, is essential for achieving secure, aesthetically pleasing, and structurally sound results. Challenges may arise from imprecise estimations of material thickness or inconsistent nail dimensions, emphasizing the need for careful measurement and adherence to manufacturer specifications. Proper nail length selection supports the overall goal of precise and reliable fastening in woodworking and construction.

4. Firing Mode

The firing mode of a Bostitch finish nailer dictates how the tool actuates to drive nails. It’s a fundamental aspect of operation, influencing both speed and safety. Two primary firing modes are commonly available: sequential actuation and contact actuation. Sequential actuation requires the user to depress the safety contact tip against the work surface and then pull the trigger to fire a single nail. This method prioritizes safety, reducing the risk of unintentional nail discharge. In contrast, contact actuation, sometimes referred to as bump firing, allows the user to keep the trigger depressed and drive nails rapidly by “bumping” the safety contact tip against the work surface. Each mode caters to distinct application needs and operator preferences.

The selection of firing mode significantly impacts productivity and risk mitigation. Sequential mode is often preferred for precision work where accurate nail placement is paramount, such as intricate trim installation. It minimizes the chance of misfires and ensures each nail is driven precisely where intended. Contact actuation, conversely, is advantageous for high-volume applications where speed is crucial, such as sheathing or fencing. However, this mode demands a higher level of operator awareness and control to prevent accidental nail discharge, thereby increasing potential safety hazards. The impact on safety protocols in different job environments necessitates choosing the appropriate firing mode.

The firing mode of a Bostitch finish nailer presents a trade-off between speed and safety. Sequential actuation offers enhanced safety through deliberate nail placement, whereas contact actuation enables rapid nail deployment at the expense of heightened risk. Proper understanding and application of these firing modes, coupled with rigorous adherence to safety guidelines, are critical for maximizing efficiency and minimizing potential hazards in diverse construction and woodworking scenarios. The choice hinges on evaluating specific project requirements and weighing the importance of speed against the necessity for precision and control.

5. Maintenance

Consistent and appropriate maintenance is fundamentally linked to the longevity, performance, and safety of a Bostitch finish nailer. This connection operates on a cause-and-effect basis: neglecting maintenance procedures inevitably leads to decreased efficiency, increased risk of malfunction, and a shortened lifespan of the tool. For example, the accumulation of debris and dried lubricant within the nailer’s internal mechanisms can impede the movement of critical components, resulting in misfires or complete operational failure. The importance of maintenance stems from the pneumatic nature of the device; its reliance on compressed air and intricate mechanical linkages necessitates regular attention to prevent wear, corrosion, and the buildup of contaminants.

Practical maintenance routines for a Bostitch finish nailer include daily lubrication with pneumatic tool oil, regular inspection of air hoses and fittings for leaks, and periodic cleaning of the nail magazine and firing mechanism. A specific example involves the use of compressed air to blow out accumulated sawdust and debris from the tool’s internal components, preventing jams and ensuring smooth operation. The absence of such maintenance can manifest in a variety of issues, ranging from inconsistent nail depth to complete tool shutdown, leading to project delays and increased repair costs. Implementing a proactive maintenance schedule extends the tool’s service life, maintains consistent performance, and minimizes the risk of accidents caused by malfunctioning equipment.

In summary, maintenance is not merely an ancillary task but an integral component of owning and operating a Bostitch finish nailer. Its diligent execution directly affects the tool’s reliability, performance, and operator safety. Challenges in maintaining the tool may arise from a lack of awareness regarding proper procedures or time constraints within demanding work schedules. However, the long-term benefits of a consistent maintenance regimen far outweigh the initial investment of time and effort, ensuring the continued utility and efficiency of the Bostitch finish nailer in various construction and woodworking applications.

6. Applications

The utility of a Bostitch finish nailer is directly defined by its range of applications. Its design characteristics, such as adjustable depth control, varying firing modes, and compatibility with specific nail gauges and lengths, dictate its suitability for diverse tasks. The absence of appropriate applications renders the tool functionally irrelevant; therefore, understanding its intended uses is paramount. A finish nailer excels in scenarios demanding a refined finish and concealed fasteners. For instance, installing decorative trim, crown molding, or baseboards showcases its ability to secure materials without leaving prominent nail heads. Similarly, the assembly of cabinets, drawers, and other fine woodworking projects benefits from the tool’s precision and control.

Examining specific applications reveals the practical advantages of employing a Bostitch finish nailer. Consider the installation of window casings. The tools ability to drive nails at precise depths prevents damage to the surrounding wall surface and ensures a flush, professional appearance. In cabinet making, the finish nailer facilitates the secure attachment of face frames to cabinet boxes, providing both structural integrity and a clean aesthetic. Furthermore, its use in constructing furniture, such as chairs or tables, allows for concealed fastening, enhancing the overall visual appeal. The range of applications highlights the tool’s versatility and its capacity to improve both the efficiency and quality of woodworking and construction projects.

In summary, the applications of a Bostitch finish nailer are intrinsically linked to its design and functionality. A comprehensive understanding of its suitable applications is crucial for maximizing its benefits and ensuring optimal results. Potential challenges arise when attempting to use the tool outside its intended range, leading to compromised performance or damage to the workpiece. The tool’s diverse applications underscore its importance in achieving professional-grade results in various woodworking and construction tasks, solidifying its role as a valuable asset for both professionals and DIY enthusiasts.

Frequently Asked Questions Regarding Bostitch Finish Nailers

This section addresses common inquiries concerning the operation, maintenance, and application of Bostitch finish nailers, providing concise and informative answers to ensure optimal tool utilization.

Question 1: What is the appropriate air pressure setting for a Bostitch finish nailer?

The optimal air pressure varies depending on the model and the material being fastened. Consult the tool’s manual for recommended pressure ranges. Generally, start with the lowest recommended pressure and increase gradually until nails are driven flush without damaging the surface.

Question 2: What type of lubricant should be used in a Bostitch finish nailer?

Use pneumatic tool oil specifically designed for air-powered tools. Avoid using general-purpose lubricants or oils that may contain additives harmful to the tool’s seals and internal components.

Question 3: How frequently should a Bostitch finish nailer be cleaned?

Regular cleaning is essential. At minimum, clean the nailer after each use by disconnecting the air supply and blowing out any accumulated sawdust or debris. More thorough cleaning, including disassembly and lubrication, should be performed periodically, depending on usage frequency.

Question 4: What causes a Bostitch finish nailer to misfire or jam?

Common causes include incorrect air pressure, using the wrong type or size of nails, a dirty or damaged driver blade, and a worn or damaged o-ring. Inspect these components and address any issues accordingly.

Question 5: Can a Bostitch finish nailer be used on all types of wood?

While versatile, a finish nailer’s effectiveness varies with wood density. Softer woods generally pose no issues. Harder woods may require higher air pressure or pre-drilling to prevent splitting or bending of the nails.

Question 6: What safety precautions should be observed when operating a Bostitch finish nailer?

Always wear safety glasses to protect against flying debris. Disconnect the air supply before performing any maintenance or clearing jams. Never point the nailer at oneself or others. Follow all instructions and warnings provided in the tool’s manual.

Proper understanding and adherence to these guidelines ensure the safe and efficient operation of a Bostitch finish nailer, maximizing its performance and prolonging its lifespan.

The subsequent section will explore advanced techniques and specialized applications for maximizing the capabilities of this tool.

In Conclusion

The preceding exploration has detailed various facets of the bostitch finish nailer, including operational guidelines, essential features, and application-specific considerations. Understanding air pressure management, nail length selection, firing mode options, and maintenance protocols are paramount for maximizing its effectiveness. Further, careful consideration of gauge relative to material density enables a craftsman to achieve consistent performance.

The bostitch finish nailer, when properly utilized, stands as a valuable asset across diverse woodworking and construction contexts. Continued adherence to established safety procedures and best practices remains critical for ensuring operator well-being and preserving the tool’s functional integrity. Investing in ongoing education and skill development will optimize the tool’s capabilities and contribute to superior workmanship.