Small, slender fasteners with minimal heads are designed to be driven flush with the surface of the material. These types of nails are typically used in woodworking and carpentry where the appearance of the finished product is a primary concern. For example, these fasteners might be used to attach decorative molding or trim to furniture or walls.

The primary advantage of these nearly headless fasteners lies in their ability to be easily concealed. The small head size allows for it to be punched below the surface of the wood using a nail set, and the resulting hole can be filled with wood filler or putty, creating a seamless and aesthetically pleasing finish. Historically, this characteristic made them indispensable in crafting intricate woodwork and fine furniture, where visible nail heads would detract from the overall design.

The following sections will delve into the various aspects of these fasteners, including their different types, appropriate applications, and best practices for their use, ensuring a high-quality, professional result in any woodworking project.

Tips for Using Finishing Nails Effectively

The proper application of these fasteners is crucial for achieving a professional and aesthetically pleasing result in woodworking projects. Consider these tips to ensure optimal performance and minimize potential issues.

Tip 1: Select the Appropriate Gauge and Length: Matching fastener size to the material thickness is paramount. Using an overly large fastener can cause splitting, while an undersized one will lack sufficient holding power. A general rule is to ensure the fastener penetrates at least two-thirds of the way into the receiving material.

Tip 2: Utilize a Nail Set: To conceal the fastener effectively, employ a nail set to drive the head slightly below the surface. This creates a small indentation that can be filled with wood filler for a seamless finish. Exercise caution to avoid damaging the surrounding wood fibers during this process.

Tip 3: Pre-Drill Pilot Holes in Hardwoods: When working with dense hardwoods, pre-drilling pilot holes is recommended to prevent splitting and ensure accurate placement. The pilot hole should be slightly smaller than the diameter of the fastener.

Tip 4: Consider Using an Air-Powered Nailer: For larger projects or repetitive tasks, an air-powered nailer can significantly increase efficiency and precision. Ensure the tool is properly calibrated to avoid overdriving or underdriving the fasteners.

Tip 5: Countersink for Optimal Filling: When filling the fastener hole, countersinking it slightly ensures the filler adheres properly and creates a smooth, level surface after sanding.

Tip 6: Choose the Right Type: Several types are available, including brads and headless pins. Select the type best suited for the application based on the desired holding power and aesthetic requirements.

Tip 7: Be Mindful of Wood Grain Direction: Driving fasteners parallel to the wood grain can increase the risk of splitting. Orient fasteners perpendicular to the grain whenever possible to maximize holding power and minimize the risk of damage.

By adhering to these guidelines, users can maximize the benefits of these fasteners, achieving secure and aesthetically pleasing results in a variety of woodworking applications. Careful selection, proper technique, and attention to detail are all essential for successful implementation.

The following sections will discuss common problems when using the fasteners, as well as the solutions.

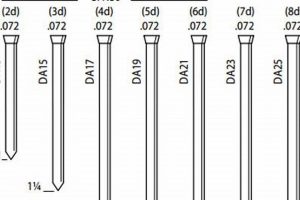

1. Gauge

Gauge, referring to the diameter of a fastener’s shank, is a critical consideration when selecting slender, headless fasteners. A higher gauge number indicates a smaller diameter. The choice of gauge directly affects the fastener’s holding power and its propensity to split the wood. Thinner gauges are generally preferred to minimize visible damage and reduce the risk of splitting, particularly in delicate or brittle wood. For instance, when attaching thin trim to a cabinet face, a higher gauge may be necessary to prevent splitting.

However, the reduced diameter of higher-gauge fasteners also means diminished shear strength and holding power. Applications requiring greater structural integrity, such as securing thicker molding or joining frame components, necessitate lower-gauge fasteners to provide adequate support. Therefore, selection involves a careful balancing act between minimizing visual impact and ensuring sufficient mechanical strength for the intended purpose. The selection process often involves a test drive or practical application, that way can determine which gauge to use for specific applications.

Ultimately, understanding the relationship between gauge, material properties, and application requirements is paramount for achieving secure, aesthetically pleasing results with small headless fasteners. Selecting an inappropriate gauge can lead to structural failure, unsightly damage, or the need for rework. Thus, careful consideration of the fastener gauge represents a fundamental step in any woodworking or carpentry project where aesthetics and structural integrity are equally important.

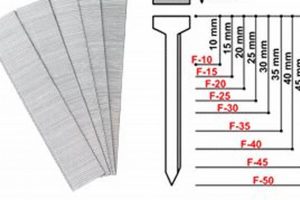

2. Length

The length of headless fasteners is a critical parameter directly influencing their holding power and suitability for a given application. Selection requires careful consideration of the materials being joined. A fastener that is too short will lack sufficient penetration into the receiving material, resulting in a weak or unstable connection. Conversely, a fastener that is too long may protrude through the back of the material, compromising the aesthetic finish and potentially creating a safety hazard. For example, when attaching a thin piece of trim to a thicker substrate, selecting an appropriate length ensures secure adhesion without visible protrusion.

The “two-thirds rule” is a common guideline: at least two-thirds of the fastener’s length should penetrate the second material. This ensures adequate grip and resistance to pullout. In practice, this means measuring the thickness of both materials and selecting a length that meets this criterion. Hardwoods often require longer fasteners compared to softwoods, due to their increased density and resistance to penetration. Furthermore, consider the presence of adhesives; if glue is used in conjunction with the fasteners, the required length can be slightly reduced, as the adhesive contributes to the overall bond strength.

In summary, the appropriate length of slender, headless fasteners is a balance between securing sufficient holding power and maintaining a clean, professional finish. Selection must account for material thickness, density, and the presence of adhesives. Incorrect length selection can lead to structural weakness, aesthetic imperfections, or safety hazards. Careful measurement and adherence to the two-thirds rule provide a practical framework for ensuring optimal performance.

3. Head Type

The head type of slender, headless fasteners is a defining characteristic that directly influences their suitability for various applications. The primary goal is concealment, and the head design dictates how effectively this can be achieved. Minimizing head visibility is essential for achieving a clean, professional aesthetic, particularly in woodworking projects where surface appearance is paramount. Several variations exist, each offering a different balance between holding power and concealment. For example, a brad head is slightly larger than a pin head, providing increased holding power but requiring more effort to conceal completely with wood filler. The intended application and desired finish quality determine the optimal head type.

The brad head, a common choice, features a small, slightly convex shape designed to be driven flush with the surface or slightly countersunk using a nail set. This facilitates filling the resulting hole with wood filler or putty, creating a nearly invisible repair. Pin heads are even smaller and are often used when minimal visibility is required, sacrificing some holding power for superior concealment. The headless pin, as the name implies, has no discernible head and is employed in situations where the primary function is temporary fastening or positioning before a more permanent method, such as gluing, is applied. The effectiveness of each head type is dependent on proper installation techniques, including consistent depth control and the use of appropriate filling materials.

In conclusion, the head type represents a critical design element of slender, headless fasteners, directly impacting both aesthetics and functional performance. Understanding the specific attributes of each type brad, pin, headless and their respective advantages and disadvantages allows for informed selection based on project requirements. The choice of head type directly influences the final appearance, emphasizing the importance of this design element in achieving the desired result in woodworking and carpentry applications.

4. Material

The material composition of slender, headless fasteners directly correlates with their performance characteristics and application suitability. The chosen material influences strength, corrosion resistance, and ultimately, the longevity of the fastened joint. For instance, fasteners manufactured from low-carbon steel are suitable for general interior applications where exposure to moisture is minimal. However, their lack of inherent corrosion resistance renders them inappropriate for outdoor projects or environments with high humidity. The direct consequence of using an unsuitable material is premature failure of the fastening, leading to structural instability or aesthetic degradation. The importance of selecting the correct material cannot be overstated; it is a fundamental component determining the integrity of the finished work.

Consider stainless steel fasteners. These offer superior corrosion resistance, making them ideal for marine applications, outdoor furniture, or projects exposed to harsh weather conditions. The increased cost associated with stainless steel is often justified by the extended lifespan and reduced maintenance requirements. Brass fasteners, another option, provide moderate corrosion resistance and a decorative appearance, often used in antique furniture restoration or projects where visual appeal is a priority. Furthermore, specialized coatings such as galvanization can be applied to steel fasteners to enhance their resistance to rust and corrosion, effectively expanding their application range. The selection matrix should encompass the environmental conditions, load requirements, and aesthetic demands of the specific project. For example, in constructing a cedar fence, galvanized fasteners are commonly used due to cedar’s acidic properties, which can accelerate corrosion in standard steel fasteners.

In conclusion, the material from which these small headless fasteners are made plays a crucial role in their functionality and suitability for specific applications. A thorough understanding of the properties of different materials, from basic steel to specialized alloys and coatings, is essential for making informed decisions. The material choice dictates the durability, aesthetics, and ultimately, the success of the project. Neglecting this aspect can lead to costly repairs and compromised structural integrity. Thus, material selection constitutes a critical element in the proper utilization of these fasteners across diverse woodworking and construction endeavors.

5. Coating

Coatings applied to slender, headless fasteners play a critical role in determining their performance and longevity, particularly concerning corrosion resistance and aesthetic integration within a finished project. The application of a suitable coating extends the lifespan of the fastener and enhances its ability to seamlessly blend with the surrounding material.

- Corrosion Resistance

Many coatings are designed to protect the underlying metal from corrosion, a significant concern in environments with high humidity or exposure to moisture. Galvanization, for example, involves coating steel with a layer of zinc, which sacrificially corrodes to protect the steel underneath. This is crucial in outdoor applications or when using fasteners in contact with treated lumber, which can accelerate corrosion. Uncoated fasteners in such conditions would quickly rust, weakening the joint and potentially staining the surrounding wood.

- Aesthetic Integration

Some coatings are applied to match the color or finish of the surrounding wood, allowing the fastener to blend in more seamlessly. For instance, fasteners with a blackened or blued finish are often used in projects involving dark-stained woods, minimizing their visibility. Other coatings can provide a paintable surface, enabling the fastener to be easily concealed after installation. These aesthetic considerations are particularly important in fine woodworking and furniture making, where the goal is to create a flawless finish.

- Reduced Friction

Certain coatings, such as PTFE (Teflon), can reduce friction during installation, making it easier to drive the fastener into the wood and reducing the likelihood of bending or breaking. This is especially useful when working with hardwoods or using power-driven nailers, where excessive force can damage the fastener. Reduced friction also minimizes the risk of splitting the wood, leading to a cleaner and more professional result.

- Chemical Compatibility

Specialized coatings are available to protect fasteners from chemical reactions in specific environments. For example, epoxy coatings are often used in applications involving exposure to solvents, acids, or other corrosive chemicals. These coatings create a barrier between the metal and the chemical, preventing corrosion and maintaining the integrity of the joint. The selection of a chemically compatible coating is crucial in industrial or marine environments where exposure to harsh chemicals is unavoidable.

The choice of coating significantly influences the overall performance and lifespan of small, headless fasteners. Selecting the appropriate coating based on environmental conditions, aesthetic requirements, and material compatibility is essential for ensuring a durable and visually appealing result. The benefits of a well-chosen coating extend beyond simple aesthetics, contributing to the structural integrity and long-term stability of the project.

6. Application

The practical utility of slender, headless fasteners is intricately linked to their intended application. The choice of fastener type, size, material, and coating must align with the specific demands of the project to ensure both structural integrity and aesthetic appeal.

- Trim and Molding Installation

One of the most common uses is attaching trim and molding to walls, ceilings, or furniture. These fasteners are ideal because their small heads can be easily concealed, resulting in a clean, professional finish. For instance, installing crown molding often involves securing it with them, then filling the resulting holes with wood filler before painting.

- Cabinetry and Furniture Assembly

These fasteners play a crucial role in assembling cabinets and furniture, particularly in situations where aesthetics are a primary concern. They can be used to attach decorative panels, drawer fronts, or other components where visible fasteners would detract from the overall design. An example is attaching a decorative door panel on a cabinet, providing a near seamless appearance.

- Paneling and Wainscoting

Securing paneling and wainscoting often involves using them to minimize visibility and maintain a smooth surface. The small heads allow for easy concealment, preserving the aesthetic integrity of the wall covering. Applying a wainscoting to a wall demonstrates this, as using large headed fasteners would impact aesthetic.

- Crafts and Model Making

In smaller-scale applications, such as crafts and model making, they are invaluable for joining delicate pieces without causing damage or leaving unsightly marks. Their small size and ease of use make them ideal for intricate work where precision and aesthetics are paramount. For example, small models can be secured, which would provide nearly invisible joins.

These diverse applications demonstrate the versatility of small, headless fasteners in projects ranging from large-scale construction to delicate craftwork. The key to successful implementation lies in understanding the specific requirements of each application and selecting the appropriate fastener type, size, and material to achieve the desired result.

Frequently Asked Questions About Finishing Nails

The following addresses common inquiries regarding slender, headless fasteners, offering clarity on their use, selection, and performance characteristics. This information aims to provide practical guidance for achieving optimal results in various woodworking and carpentry applications.

Question 1: What distinguishes finishing nails from other types of nails?

The primary distinction lies in the head design. These fasteners possess minimal heads designed to be driven flush with or slightly below the surface of the material, facilitating concealment. Other types of nails, such as common nails or framing nails, have larger heads designed for increased holding power but are less aesthetically pleasing.

Question 2: What factors should be considered when selecting the appropriate length of finishing nail?

Material thickness is paramount. A general rule dictates that at least two-thirds of the fastener’s length should penetrate the receiving material. The density of the wood also plays a role; hardwoods generally require longer fasteners compared to softwoods. Overly long fasteners risk protruding through the back of the material.

Question 3: Is it necessary to pre-drill pilot holes when using finishing nails?

Pre-drilling is highly recommended when working with hardwoods to prevent splitting, which is especially true when working near the edge of the piece. Pilot holes are also beneficial when driving fasteners at an angle or in dense materials. A drill bit slightly smaller than the fastener’s diameter is typically used.

Question 4: What is the best method for concealing finishing nail heads?

A nail set should be used to drive the head slightly below the surface of the wood. The resulting indentation can then be filled with wood filler or putty, sanded smooth, and finished to match the surrounding material. Color-matched wood filler ensures a seamless repair.

Question 5: Are there specific types of coatings that are recommended for finishing nails?

Galvanized coatings are recommended for outdoor applications or environments with high humidity to prevent corrosion. Brass or copper fasteners offer natural corrosion resistance and can add a decorative element. Coatings with a reduced friction, like PTFE, make insertion easier.

Question 6: Can finishing nailers be used effectively with all types of wood?

While nailers can significantly increase efficiency, care must be taken to avoid overdriving or damaging the wood, especially with delicate or brittle materials. Proper adjustment of the nailer’s depth setting is crucial to achieve consistent results without compromising the integrity of the wood. Some nailers are designed specifically for smaller fasteners.

Careful consideration of these factors enables the effective utilization of slender, headless fasteners in achieving both structurally sound and aesthetically pleasing results. Understanding the nuances of selection and application is paramount for woodworking and carpentry endeavors where quality and appearance are equally valued.

The subsequent sections will discuss common problems when using these fasteners, as well as solutions.

Conclusion

This exploration has elucidated the critical aspects of finishing nails, emphasizing their role in achieving both structural integrity and aesthetic excellence in woodworking and carpentry. Careful consideration of gauge, length, head type, material, coating, and application, as detailed throughout this article, remains paramount. These fasteners, when properly selected and employed, enable the creation of seamless and refined finished products.

Mastery of this seemingly simple element of joinery empowers the craftsman to elevate the quality and visual appeal of their work. A continued focus on best practices and adherence to established guidelines will ensure the enduring value and functional performance of projects where the nuanced application of finishing nails makes all the difference.