A clear coating designed to protect wood surfaces from water damage while allowing the natural grain and color of the wood to remain visible. This type of product is often applied to decks, fences, and other exterior wood structures to prevent warping, cracking, and decay caused by moisture exposure.

The application of such a product extends the lifespan of wooden structures, reducing the need for frequent repairs or replacements. By preventing water penetration, the coating inhibits the growth of mold and mildew, contributing to a healthier environment. Historically, various oils and waxes were used for similar purposes, but modern formulations offer superior protection and durability.

The following sections will explore the specific properties, application techniques, and maintenance considerations for this type of protective treatment. These areas will allow a better grasp of how to effectively utilize these treatments to safeguard wood investments.

Application Best Practices

Proper application is crucial for achieving optimal results. Adhering to the following guidelines will maximize the protective qualities of the product and ensure long-lasting performance.

Tip 1: Surface Preparation: Ensure the wood surface is clean, dry, and free of any existing coatings, dirt, or mildew. Pressure washing or sanding may be necessary to achieve a suitable surface for application.

Tip 2: Weather Conditions: Apply the coating during dry weather with temperatures within the recommended range specified by the manufacturer. Avoid application in direct sunlight or when rain is imminent.

Tip 3: Application Method: Use a high-quality brush, roller, or sprayer designed for exterior wood coatings. Apply the product evenly, following the grain of the wood, to ensure consistent coverage.

Tip 4: Number of Coats: Apply the recommended number of coats as specified by the manufacturer. Typically, two coats are necessary for optimal protection, allowing sufficient drying time between each coat.

Tip 5: Proper Ventilation: Ensure adequate ventilation during and after application to facilitate drying and prevent the accumulation of harmful vapors.

Tip 6: Back-Brushing: After spraying, back-brush the coating into the wood grain to ensure proper penetration and adhesion, particularly on rough or textured surfaces.

Tip 7: Edge and End Grain Protection: Pay particular attention to the edges and end grain of the wood, as these areas are most susceptible to water penetration. Apply extra coats to these areas for enhanced protection.

Following these application best practices maximizes the effectiveness of the waterproofing treatment, contributing to the longevity and aesthetic appeal of the wood surface.

The subsequent section will address maintenance procedures to further extend the life and performance of the treated wood.

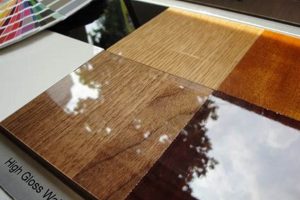

1. Transparency

Transparency, in the context of waterproofing wood finishes, refers to the degree to which the coating allows the underlying wood grain and color to remain visible. This characteristic is particularly important when preserving the natural aesthetic of wood is desired while providing protection against water damage.

- Aesthetic Preservation

The primary role of transparency is to maintain the natural beauty of the wood. Unlike opaque paints or stains, a transparent finish allows the wood’s inherent texture and color variations to be seen. For example, applying a transparent finish to a cedar deck will protect it from water damage while allowing the reddish-brown hues and grain patterns to remain prominent. This is crucial for projects where the visual appeal of the wood is a significant design consideration.

- UV Protection Considerations

While prioritizing visibility, transparent finishes must also address UV protection. Ultraviolet radiation can cause wood to fade, discolor, or degrade over time. High-quality transparent waterproofing finishes often incorporate UV absorbers or stabilizers to mitigate these effects. The balance between transparency and UV protection is critical in maintaining both the aesthetic and structural integrity of the wood.

- Application Requirements

The application of a transparent waterproofing finish requires careful attention to surface preparation and coating thickness. Imperfections in the wood, such as scratches or uneven staining, will be more visible with a transparent finish. Similarly, applying the coating too thickly can diminish its transparency and create an undesirable sheen. Proper application techniques are essential to achieving the desired aesthetic result.

- Maintenance Implications

Transparent finishes may require more frequent maintenance than opaque coatings, as they typically offer less protection against physical abrasion and wear. Regular cleaning and reapplication may be necessary to maintain both the waterproofing properties and the aesthetic appearance of the wood. The lifespan of a transparent finish will depend on factors such as exposure to sunlight, foot traffic, and the type of wood being treated.

In conclusion, transparency in a waterproofing wood finish represents a trade-off between aesthetic preservation and protective performance. While allowing the natural beauty of the wood to be showcased, it necessitates careful consideration of UV protection, application techniques, and maintenance requirements to ensure long-lasting protection and visual appeal. Selecting a transparent waterproofing product involves balancing these factors to achieve the desired outcome for the specific project.

2. Water Repellency

Water repellency is a fundamental property of a transparent waterproofing wood finish, serving as the primary mechanism by which the coating protects the underlying wood from moisture damage. The efficacy of the treatment is directly related to its ability to prevent water absorption, which, if unchecked, leads to warping, rot, and structural degradation. The application of a transparent waterproofing finish creates a hydrophobic barrier on the wood’s surface. This barrier functions by increasing the surface tension, causing water to bead up and roll off rather than penetrate the wood fibers. A practical example of this can be seen on exterior decking, where the water-repellent coating prevents rain and snow from soaking into the wood, thereby reducing the risk of decay and extending the deck’s lifespan.

The importance of water repellency is further emphasized in environments with high humidity or frequent precipitation. Without such protection, wood structures are susceptible to fungal growth and insect infestation, both of which accelerate deterioration. The choice of formulation impacts the level and duration of water repellency. Some finishes contain additives that enhance their hydrophobic qualities, improving their ability to shed water even after exposure to UV radiation and physical wear. Regular maintenance, including cleaning and reapplication, is critical for preserving water-repellent characteristics.

In summary, water repellency is integral to the protective function of transparent waterproofing wood finishes. Its effectiveness in preventing water absorption directly influences the longevity and structural integrity of wooden structures. While the initial application provides immediate protection, sustained performance requires adherence to recommended maintenance practices and selection of appropriate product formulations tailored to environmental conditions. Without adequate water repellency, the benefits of transparency and aesthetic appeal are negated by the potential for accelerated wood damage.

3. UV Protection

Ultraviolet (UV) protection is a critical consideration when evaluating the performance of a transparent waterproofing wood finish. While transparency emphasizes the natural aesthetic of wood, prolonged exposure to UV radiation can degrade the wood structure and alter its appearance. The integration of UV protection mechanisms within the finish is, therefore, vital to maintaining the longevity and visual appeal of treated wood surfaces.

- Minimizing Photo-degradation

UV radiation causes photo-degradation, a process where the lignin in wood breaks down, leading to discoloration, surface checking, and eventual structural weakening. A transparent waterproofing wood finish formulated with UV absorbers or stabilizers mitigates this process. These additives function by absorbing UV radiation and converting it into heat, preventing it from reaching and damaging the wood fibers. For example, a deck exposed to intense sunlight benefits significantly from a finish with UV protection, reducing fading and cracking that would otherwise occur rapidly.

- Maintaining Transparency and Color

The inclusion of UV protection helps to maintain the clarity and color of the transparent finish itself. Without UV stabilizers, the finish can yellow or become cloudy over time, obscuring the natural wood grain and diminishing its aesthetic appeal. This is particularly important for premium wood species where the natural color and grain are highly valued. The UV protection component preserves the intended appearance of the wood, ensuring that the transparent finish remains visually unobtrusive.

- Extending Finish Lifespan

UV degradation affects not only the wood but also the finish itself. Prolonged UV exposure can cause the finish to become brittle, crack, or delaminate, compromising its waterproofing capabilities. By incorporating UV protection, the lifespan of the finish is extended, reducing the frequency of reapplication and maintenance. This translates to long-term cost savings and reduced effort in maintaining the wood surface. A properly UV-protected finish can withstand harsh environmental conditions for an extended period before requiring recoating.

- Types of UV Protection Additives

Various types of UV protection additives are used in transparent wood finishes, each with its own characteristics and effectiveness. UV absorbers, such as benzotriazoles and hydroxyphenyl triazines, absorb UV radiation. Hindered amine light stabilizers (HALS) scavenge free radicals produced by UV degradation, preventing further damage. The combination of UV absorbers and HALS often provides synergistic protection, enhancing the overall effectiveness of the finish. The specific type and concentration of additives influence the level of UV protection provided by the finish.

The presence and effectiveness of UV protection is, therefore, a key differentiator in transparent waterproofing wood finishes. It directly impacts the long-term performance and appearance of treated wood surfaces. Selecting a finish with appropriate UV protection mechanisms ensures that the benefits of transparency are not overshadowed by the detrimental effects of solar radiation, preserving both the aesthetic and structural integrity of the wood.

4. Wood Preservation

Wood preservation encompasses various methods and techniques employed to extend the service life of wood and wood products. In the context of a transparent waterproofing wood finish, preservation focuses on protecting wood from biological decay, insect attack, and environmental degradation while maintaining its natural appearance. This approach aligns with the functional attributes of such finishes, emphasizing both protection and aesthetic retention.

- Moisture Control

Moisture is a primary catalyst for wood decay. Fungi and insects thrive in damp environments, leading to rot and structural damage. A transparent waterproofing wood finish acts as a barrier against moisture intrusion, thereby inhibiting the conditions necessary for biological degradation. For example, applying such a finish to a wooden fence can prevent water absorption, reducing the likelihood of fungal growth and extending the fence’s lifespan. The effectiveness of this moisture control directly impacts the long-term preservation of the wood.

- Protection Against UV Degradation

Exposure to ultraviolet (UV) radiation causes lignin, a component of wood, to degrade, leading to discoloration, surface checking, and eventual weakening of the wood structure. Many transparent waterproofing wood finishes incorporate UV absorbers or stabilizers to mitigate these effects. These additives shield the wood from harmful UV rays, preserving its color and structural integrity. This is particularly crucial for exterior applications, such as siding or decks, where prolonged sun exposure is unavoidable.

- Inhibition of Biological Attack

While a transparent waterproofing finish primarily addresses moisture control, some formulations also include biocides or fungicides to directly inhibit the growth of decay-causing organisms. These additives provide an additional layer of protection against biological attack, especially in environments with high humidity or persistent moisture. The inclusion of such biocides enhances the wood’s resistance to rot and decay, contributing to its long-term preservation. However, the use of biocides must be balanced against potential environmental and health concerns.

- Maintenance and Longevity

Effective wood preservation requires ongoing maintenance. Regular inspection, cleaning, and reapplication of the transparent waterproofing finish are necessary to maintain its protective properties. Over time, the finish may degrade due to weathering, UV exposure, and physical wear, reducing its ability to repel water and protect against biological attack. Periodic reapplication ensures that the wood remains adequately protected, extending its service life and preventing costly repairs or replacements. The frequency of maintenance depends on factors such as climate, wood species, and the specific formulation of the finish.

The facets of moisture control, UV protection, biological attack inhibition, and ongoing maintenance are intrinsically linked to the overall effectiveness of wood preservation when using a transparent waterproofing wood finish. These finishes not only enhance the aesthetic appeal of wood but also provide a crucial barrier against the elements and biological threats, thereby contributing to the long-term preservation of wooden structures and components. Proper application and regular maintenance are essential to maximizing the preservative benefits of these finishes.

5. Application Ease

Application ease is a significant factor influencing the selection and utilization of a transparent waterproofing wood finish. The user-friendliness of a product directly impacts project efficiency, reduces the likelihood of application errors, and ultimately contributes to the long-term performance of the protective coating.

- Surface Preparation Requirements

The extent of surface preparation required prior to applying a transparent waterproofing wood finish directly affects application ease. Products necessitating minimal sanding or stripping of previous coatings streamline the process. For example, a finish that can be applied directly to a clean, dry wood surface without extensive preparation reduces the time and effort involved. Conversely, finishes requiring meticulous surface preparation, such as the removal of all previous coatings and thorough sanding, increase the complexity and time investment of the application process.

- Viscosity and Spreadability

The viscosity of the finish and its ease of spreadability contribute to the smoothness and uniformity of the coating. Finishes with a low viscosity and good leveling properties are easier to apply evenly, reducing the risk of runs, drips, and uneven coverage. A product that spreads smoothly with a brush, roller, or sprayer simplifies the application process and minimizes the potential for application errors. Conversely, thick or viscous finishes can be challenging to apply evenly, requiring more skill and effort to achieve a uniform coating.

- Drying Time and Recoat Windows

The drying time and recoat windows specified by the manufacturer influence the overall duration of the application process. Finishes with short drying times and flexible recoat windows allow for faster project completion and greater flexibility in scheduling. A product that dries quickly and can be recoated within a reasonable timeframe enables multiple coats to be applied in a single day, accelerating the completion of the project. Conversely, finishes with long drying times or strict recoat windows can prolong the application process and require careful planning to avoid delays.

- Cleanup Procedures

The ease of cleanup after application is another aspect of application ease. Products that can be easily cleaned with soap and water are more convenient to use than those requiring specialized solvents or cleaning agents. A finish that allows for easy cleanup of brushes, rollers, and spray equipment simplifies the post-application process and reduces the time and effort involved in maintaining equipment. Conversely, finishes requiring specialized cleaning procedures can be more time-consuming and costly to clean up.

The level of ease of application directly correlates with user satisfaction and the likelihood of successful project outcomes. When selecting such finishes, considering the surface preparation requirements, viscosity, drying time, and cleanup procedures are essential to optimizing the application process and achieving a durable and aesthetically pleasing protective coating.

6. Durability

Durability, in the context of transparent waterproofing wood finishes, refers to the coating’s capacity to withstand environmental stressors and physical wear over an extended period, maintaining its protective and aesthetic properties. The durability of this finish is a critical determinant of its long-term value and performance.

- Resistance to Abrasion

Abrasion resistance describes the coating’s ability to withstand surface wear caused by foot traffic, furniture, and other physical contact. A durable finish resists scratching, scuffing, and erosion, preserving its integrity and appearance. For example, on a heavily used deck, a durable finish maintains its protective barrier against water penetration despite constant wear from foot traffic and outdoor furniture. The implications of poor abrasion resistance include premature coating failure, requiring more frequent reapplication.

- Weathering Performance

Weathering performance refers to the coating’s ability to withstand the damaging effects of sunlight, temperature fluctuations, and moisture. A durable finish resists cracking, peeling, blistering, and discoloration under prolonged exposure to the elements. A real-world example would be a wooden fence exposed to intense sunlight and seasonal temperature changes; a durable finish would maintain its waterproofing properties and color without degrading or failing prematurely. Poor weathering performance leads to reduced protection against water damage and accelerated deterioration of the wood substrate.

- Chemical Resistance

Chemical resistance describes the coating’s ability to withstand exposure to common household chemicals, cleaning agents, and pollutants without degrading or staining. A durable finish maintains its integrity and appearance even when exposed to spills or cleaning solutions. For instance, a durable finish on a wooden countertop in a kitchen resists staining and damage from spills of common household cleaners and food products. Poor chemical resistance results in discoloration, softening, or even dissolution of the finish, compromising its protective properties.

- Adhesion Strength

Adhesion strength refers to the coating’s ability to bond firmly to the wood substrate, preventing peeling or delamination over time. A durable finish maintains a strong bond to the wood, even under conditions of moisture, temperature changes, and physical stress. As an illustration, consider a transparent finish applied to a wooden boat; a durable finish maintains its adhesion even when subjected to constant immersion in water and the stress of wave action. Poor adhesion strength leads to peeling or flaking of the finish, leaving the wood exposed to the elements and accelerating deterioration.

The durability of transparent waterproofing wood finishes is contingent upon a combination of resistance to abrasion, weathering, chemical exposure, and strong adhesion. These factors collectively determine the coating’s ability to protect wood from water damage and maintain its aesthetic appeal over an extended period. Selecting a finish with robust durability characteristics ensures long-term performance and minimizes the need for frequent maintenance or reapplication. The economic benefits derived from a durable finish are substantial, as it reduces the life-cycle costs associated with wood preservation.

Frequently Asked Questions

This section addresses common inquiries regarding transparent waterproofing wood finishes, providing concise and informative answers to enhance understanding and proper application.

Question 1: What constitutes a “transparent” wood finish?

A transparent wood finish is defined by its ability to allow the underlying wood grain and color to remain visible after application. It does not obscure the natural appearance of the wood.

Question 2: How does a waterproofing wood finish prevent water damage?

The finish creates a hydrophobic barrier on the wood’s surface, increasing surface tension and causing water to bead up and roll off, preventing absorption and subsequent damage.

Question 3: Does a transparent finish offer adequate UV protection?

Many transparent finishes incorporate UV absorbers or stabilizers to mitigate the harmful effects of ultraviolet radiation, thereby preventing fading, discoloration, and structural degradation of the wood.

Question 4: What surface preparation is necessary before applying this type of finish?

Surfaces must be clean, dry, and free of any existing coatings, dirt, or mildew. Sanding or pressure washing may be required to ensure proper adhesion.

Question 5: How often should a transparent waterproofing wood finish be reapplied?

The frequency of reapplication depends on factors such as climate, sun exposure, and traffic. Regular inspection is recommended, with reapplication typically needed every one to three years.

Question 6: Can a transparent waterproofing wood finish be used on all types of wood?

While suitable for many wood types, certain exotic or oily woods may require specific formulations or application techniques. Consulting the product manufacturer’s guidelines is advisable.

Understanding these key aspects of transparent waterproofing wood finishes ensures proper selection, application, and maintenance, leading to effective wood protection and preservation.

The following section will delve into the environmental considerations associated with wood finishes.

Conclusion

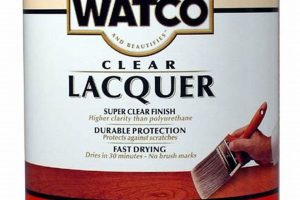

The preceding analysis has outlined the critical characteristics, application methodologies, and maintenance considerations surrounding Behr transparent waterproofing wood finish. Emphasis has been placed on the balance between aesthetic preservation and robust protection against environmental elements, particularly water and ultraviolet radiation. A thorough understanding of these factors facilitates informed decision-making regarding wood surface treatment.

The effective utilization of Behr transparent waterproofing wood finish ultimately hinges on adherence to best practices and ongoing stewardship. By prioritizing proper surface preparation, application technique, and periodic maintenance, stakeholders can safeguard the longevity and aesthetic appeal of their wood investments, mitigating the costs associated with premature deterioration. Responsible wood preservation is a prudent undertaking that yields both economic and environmental benefits.