A natural protective coating derived from the honeycomb of honeybees, this substance serves as a surface treatment for wooden objects. Applied to furniture, carvings, and other wooden items, it enhances the wood’s natural grain and provides a subtle luster. For example, a craftsman might use it to protect a newly crafted wooden bowl.

This coating offers several advantages, including its non-toxic nature and ability to create a breathable surface that allows wood to expand and contract with changes in humidity. It has been used for centuries to preserve and beautify wooden artifacts, evident in antique furniture pieces that still retain their original sheen.

Subsequent sections will delve into the application methods, maintenance procedures, and comparative analysis with alternative wood treatments, ensuring a thorough understanding of its properties and practical usage.

Application and Maintenance Guidance

The following provides essential guidelines to optimize the use and longevity of the coating, ensuring desirable results and sustained protection for wooden surfaces.

Tip 1: Surface Preparation: Ensure the wood surface is clean, dry, and free of any existing finishes. Sanding the wood beforehand with fine-grit sandpaper (220 or higher) creates an optimal surface for penetration and adhesion.

Tip 2: Application Technique: Apply a thin, even coat using a clean, lint-free cloth. Avoid applying excessive amounts, as this can lead to a sticky or uneven finish. A circular motion followed by wiping along the grain ensures even distribution.

Tip 3: Buffing Procedure: After application, allow the coating to penetrate the wood for approximately 15-30 minutes. Then, buff the surface vigorously with a clean cloth to remove excess residue and create a smooth, lustrous finish. Repeat the buffing process as necessary to achieve the desired sheen.

Tip 4: Number of Coats: Multiple thin coats are generally more effective than a single thick coat. Apply two to three thin coats, allowing each coat to dry and buffing between applications. This builds a stronger protective layer and enhances the wood’s natural beauty.

Tip 5: Temperature and Humidity Considerations: Application in a well-ventilated area with moderate temperature and humidity is recommended. Extreme temperatures or high humidity can affect the drying time and overall finish quality.

Tip 6: Periodic Maintenance: To maintain the finish, reapply a thin coat every six months to a year, or as needed based on usage and environmental conditions. Regular dusting and cleaning with a soft, dry cloth will also help preserve the finish.

Tip 7: Test Area: Always test the product on an inconspicuous area before applying it to the entire surface. This ensures compatibility and allows for adjustments to the application technique, if necessary.

Adhering to these guidelines will facilitate the successful application and preservation of the coating, extending the life and beauty of the treated wood.

The subsequent section will discuss the various types and formulations available, as well as address common challenges encountered during application and maintenance.

1. Natural Ingredient

The designation of “natural ingredient” is paramount when considering beeswax wood finish. It defines the core characteristic of the product and dictates many of its properties, applications, and implications for both the user and the environment.

- Source and Composition

The primary component originates from the honeycomb of honeybees (Apis mellifera). This wax is a complex mixture of esters, fatty acids, and hydrocarbons, resulting from the bee’s metabolic processes. Its natural sourcing means it is renewable and biodegradable, offering an alternative to petroleum-based products.

- Absence of Synthetic Additives

A defining feature of a truly natural beeswax finish is the minimal or complete absence of synthetic solvents, dyes, or preservatives. This reduces the potential for off-gassing harmful volatile organic compounds (VOCs), contributing to improved indoor air quality and lessened environmental impact.

- Impact on Wood Properties

The natural composition interacts uniquely with the wood. Unlike synthetic coatings that form a hard, impermeable layer, this substance penetrates the wood fibers to a degree, providing protection from within. It enhances the wood’s natural grain and imparts a soft, warm luster, retaining the wood’s tactile qualities.

- Biodegradability and Sustainability

Its inherent biodegradability offers a key advantage. Waste or excess material will decompose naturally over time, lessening the environmental footprint. Furthermore, the responsible harvesting of the natural ingredient ensures the long-term sustainability of the product, considering the wellbeing of bee colonies and their ecosystems.

Therefore, the “natural ingredient” status of beeswax wood finish profoundly influences its characteristics and appeals. It offers an environmentally conscious choice that protects and enhances wood while minimizing health and environmental risks, contrasting sharply with many synthetic alternatives.

2. Protective Coating

As a protective coating, beeswax wood finish offers a barrier against environmental factors that degrade wood. The wax forms a hydrophobic layer, reducing the absorption of water and thus minimizing the risk of swelling, warping, or cracking. This protection is particularly relevant in environments with fluctuating humidity levels. For instance, furniture treated with this coating will resist moisture damage in a bathroom setting, prolonging its lifespan. The coating’s effectiveness depends on its consistent application and periodic reapplication.

The protective properties are derived from the wax’s inherent characteristics. Its density and composition prevent penetration by most common household substances, like dust and spills. The coating also acts as a barrier against abrasion, reducing the appearance of scratches and scuffs on the wood surface. Consider the impact on wooden countertops in kitchens; the protective quality helps maintain the surface despite daily use and potential exposure to food and liquids. However, it is important to note that its protection is not as robust as synthetic alternatives like polyurethane, so care must be taken to avoid harsh chemicals and abrasive cleaners.

In summary, the substance functions as a protective coating for wood by providing a water-resistant and abrasion-resistant layer, extending the wood’s durability and aesthetic appeal. While it offers notable protection, understanding its limitations and applying appropriate maintenance procedures are essential to maximizing its effectiveness. The coating’s vulnerability to heat and strong chemicals requires attention to avoid damage and ensure long-term preservation.

3. Enhances Grain

The capacity to “Enhance Grain” is a significant attribute associated with beeswax wood finish. This characteristic refers to the enhancement and accentuation of the wood’s natural patterns and textures, resulting in an aesthetically pleasing surface. It’s a key factor in why craftspeople and woodworkers choose this particular finish.

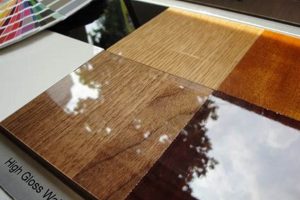

- Optical Clarity and Depth

Beeswax, unlike some film-forming finishes, penetrates the wood surface, rather than sitting on top of it. This allows the natural grain pattern to remain visible and un obscured. By filling the pores and micro-crevices in the wood, beeswax increases light refraction, creating a greater sense of depth and highlighting the inherent figure of the wood. For example, the grain pattern in a piece of oak furniture will appear more prominent and three-dimensional after the application of this substance.

- Warmth and Tone Enhancement

The finish imparts a subtle warmth and richness to the wood’s natural color. The natural amber hue of the wax adds depth and accentuates the grain’s darker elements, creating a pleasing contrast. This effect is particularly noticeable in lighter-toned woods, such as maple or ash, where the finish provides a subtle but noticeable enhancement of the grain’s inherent beauty. This adds to the visual appeal of the piece, making it more inviting.

- Tactile Feel and Smoothness

Enhancing the grain is not solely a visual effect; it also contributes to the tactile quality of the wood surface. By filling in imperfections and rough areas, the finish creates a smoother, more refined feel. This enhanced tactile quality encourages interaction with the object, increasing its overall appeal. This also contributes to the longevity of the piece, as it will be handled more carefully.

- Contrast and Definition

The finish highlights the contrast between the earlywood and latewood in the grain pattern. Earlywood, the less dense portion of the growth ring, typically absorbs more of the finish, resulting in a darker tone, while the denser latewood remains lighter. This differential absorption enhances the visual separation of the grain elements, making the pattern more distinct and visually interesting. This is especially evident in ring-porous woods like oak or ash, where the contrast between the large earlywood pores and the denser latewood creates a striking visual effect.

In conclusion, the “Enhances Grain” characteristic of beeswax wood finish plays a crucial role in its appeal, contributing to both the aesthetic beauty and tactile quality of the wood. By increasing optical clarity, enhancing warmth and tone, improving tactile feel, and accentuating contrast, beeswax maximizes the wood’s natural potential, creating visually stunning and inviting pieces.

4. Easy Application

The accessibility of beeswax wood finish is significantly determined by its “Easy Application.” This characteristic broadens its appeal to both professional woodworkers and hobbyists seeking a straightforward method for protecting and enhancing wooden surfaces. The minimal skill and equipment required distinguish it from more complex finishing systems.

- Minimal Preparation

The preparation required prior to applying beeswax is typically less involved than that needed for other finishes. While a clean, dry surface is essential, extensive sanding or priming is often unnecessary. This reduces the time and effort involved in the overall finishing process, making it accessible to individuals with limited experience. An example includes refinishing a small wooden box: minimal sanding is required before applying the wax, streamlining the project.

- Simple Tools and Techniques

Application can be achieved with basic tools, such as a clean cloth or brush. No specialized equipment, such as spray guns or ventilation systems, is generally needed. The process typically involves applying a thin, even coat, allowing it to penetrate, and then buffing the surface to achieve the desired sheen. The simplicity of this process makes it suitable for use in various settings, including workshops, homes, and even outdoor environments with appropriate weather conditions.

- Forgiveness and Correction

Beeswax finish is relatively forgiving in terms of application errors. Over-application can often be remedied by buffing off the excess, and minor imperfections can be easily corrected with additional applications. This characteristic minimizes the risk of costly mistakes, providing a greater margin for error compared to more demanding finishes. For instance, if streaks occur, they can be buffed away without requiring a complete stripping and reapplication.

- Quick Drying and Curing

Compared to many other wood finishes, beeswax typically exhibits relatively quick drying and curing times. This allows for faster project completion and reduced downtime. Items can often be handled and used shortly after application, making it a practical choice for time-sensitive projects. This is particularly useful in situations where quick turnaround is necessary, such as preparing items for sale at a craft fair.

The facets of easy application inherent in beeswax wood finish contribute to its widespread appeal and usability. The minimal preparation, simple tools, forgiveness, and quick drying times collectively simplify the finishing process, making it an accessible option for a wide range of users and projects.

5. Non-Toxic Option

The designation of beeswax wood finish as a “Non-Toxic Option” stems directly from its composition and manufacturing process. Unlike many synthetic wood finishes containing volatile organic compounds (VOCs), formaldehyde, or other harmful chemicals, pure beeswax finishes typically consist of natural beeswax, often combined with plant-based oils. This inherently reduces the potential for off-gassing and exposure to toxins, making it safer for users and the environment. The cause is the natural sourcing; the effect is a reduction in harmful emissions.

The importance of this non-toxic aspect is particularly pronounced in applications involving items frequently handled or used in close proximity to individuals, especially children or those with sensitivities. For instance, wooden toys coated with a non-toxic wax finish pose minimal risk of chemical exposure compared to those treated with synthetic coatings. Similarly, the use of this type of finish on cutting boards or food preparation surfaces prevents the leaching of harmful chemicals into food. The practical application of this understanding lies in the conscious selection of safer alternatives for various wood finishing projects, promoting healthier indoor environments and reducing potential health risks.

In summary, the non-toxic nature of beeswax wood finish arises from its natural constituents and the absence of harmful additives. This attribute is significant due to its positive impact on human health and environmental sustainability. While not all wax-based finishes are created equal, careful selection based on ingredients and manufacturing processes can ensure a genuinely non-toxic option, aligning with a growing demand for safer and more eco-conscious wood finishing solutions. Future considerations involve transparency in product labeling and rigorous testing to validate non-toxic claims, fostering consumer confidence and promoting responsible manufacturing practices.

6. Buffable Sheen

The attribute of a “Buffable Sheen” is intrinsically linked to beeswax wood finish, representing a key characteristic that defines its aesthetic appeal and distinguishes it from alternative wood treatments. The inherent properties of beeswax allow for the creation of a lustrous surface through manual or mechanical polishing. The application process involves spreading the wax across the wood’s surface, allowing it to penetrate, and then removing excess material through buffing. This action generates friction, which in turn smooths and polishes the wax, resulting in a sheen that ranges from a soft satin to a gentle gloss, contingent upon the intensity and duration of the buffing.

The importance of a “Buffable Sheen” as a component of beeswax wood finish lies in its ability to enhance the wood’s natural grain and color, imparting depth and visual warmth. Unlike film-forming finishes that create a distinct layer atop the wood, beeswax penetrates the surface, accentuating its inherent qualities. Consider the example of antique furniture restoration: the application of beeswax followed by meticulous buffing revives the wood’s original beauty, showcasing its grain patterns and lending it a subtle glow. This effect is achieved without obscuring the wood’s texture or creating a plastic-like appearance, a common drawback of synthetic coatings. The degree of sheen achievable is directly controllable by the user, offering a customisable aesthetic outcome.

In summary, the capacity to produce a “Buffable Sheen” is not merely a superficial quality of beeswax wood finish but rather an integral aspect that contributes significantly to its aesthetic value, ease of application, and ability to showcase the wood’s natural characteristics. The manual control over the final sheen, coupled with the finish’s natural composition, renders it a sought-after choice for those seeking a traditional, environmentally conscious, and visually appealing method of wood preservation. The resulting aesthetic, however, necessitates periodic maintenance to retain its luster, a consideration for practical applications.

7. Maintenance Simplicity

The characteristic of “Maintenance Simplicity” significantly contributes to the appeal and practicality of beeswax wood finish. The inherent properties of the wax dictate the ease with which treated surfaces can be preserved and restored. Unlike more complex finishing systems that require specialized cleaning agents or extensive reapplication procedures, beeswax finishes often benefit from simple and infrequent attention. This ease of maintenance stems from the wax’s protective qualities and the method of application, which allows for straightforward touch-ups and revitalization.

The importance of “Maintenance Simplicity” as a component of this finish is evident in its suitability for frequently used items. For example, wooden furniture receiving regular handling can be easily revitalized with a light cleaning and reapplication of wax, requiring minimal disruption. A gentle dusting and occasional buffing typically suffice to preserve the sheen and protective qualities. This simplicity makes it a practical choice for individuals seeking a sustainable and manageable approach to wood care, particularly in households with high traffic or limited time for extensive upkeep. The absence of harsh chemicals in the maintenance process also aligns with environmentally conscious practices.

In summary, the “Maintenance Simplicity” associated with beeswax wood finish is a crucial factor driving its adoption. The straightforward cleaning, buffing, and reapplication processes make it a user-friendly option for preserving and restoring wooden surfaces. This ease of maintenance contributes to the longevity of the finish and reduces the overall effort required for wood care, making it a practical and sustainable choice for a wide range of applications. The primary challenge lies in educating users on the proper techniques and frequency of maintenance to maximize the finish’s benefits, ensuring the continued preservation of wooden items.

Frequently Asked Questions

The following addresses common inquiries regarding the properties, application, and maintenance of surfaces treated with beeswax wood finish.

Question 1: What is the typical lifespan of a beeswax wood finish and how does it compare to other wood finishes?

The lifespan is generally shorter than that of synthetic finishes like polyurethane, typically requiring reapplication every few months to a year, depending on usage and environmental conditions. Polyurethane, conversely, can last for several years without requiring reapplication.

Question 2: Can beeswax wood finish be applied over existing finishes, such as varnish or lacquer?

Application over existing finishes is generally not recommended. The wax may not properly adhere to or penetrate the underlying finish, potentially leading to an uneven or unsatisfactory result. The existing finish should ideally be removed before applying beeswax.

Question 3: Is beeswax wood finish suitable for outdoor use?

This finish is not ideal for outdoor applications due to its limited resistance to moisture, UV radiation, and temperature fluctuations. Exterior environments necessitate more robust protective coatings designed to withstand these elements.

Question 4: How should surfaces treated with this finish be cleaned?

Cleaning should be performed using a soft, dry cloth to remove dust and debris. Avoid harsh chemicals or abrasive cleaners, as these can damage the wax finish. A damp cloth can be used sparingly for more stubborn dirt, but the surface must be dried immediately.

Question 5: Does beeswax wood finish offer protection against water damage and stains?

It provides some degree of water resistance but is not entirely waterproof. Prolonged exposure to water or staining agents can still penetrate the finish and damage the wood. Spills should be wiped up promptly to prevent staining.

Question 6: Can beeswax wood finish be tinted or colored?

While pure beeswax is typically not tinted, some commercially available products may incorporate natural pigments or dyes. However, the color intensity is usually subtle. The color can change the surface for the aesthetic point of view.

In summary, while it provides a natural and aesthetically pleasing finish, its limited durability and protective qualities necessitate careful consideration of its suitability for specific applications.

The subsequent section will explore comparative analyses with alternative wood finishes, highlighting their respective advantages and disadvantages.

Conclusion

The preceding discourse has examined beeswax wood finish, detailing its origins, application methods, characteristics, and limitations. The exploration encompassed its inherent properties, protective capabilities, aesthetic contributions, and maintenance requirements. A comprehensive understanding of these facets is crucial for informed decision-making regarding its suitability for specific wood finishing projects.

Given its unique combination of natural composition, ease of use, and aesthetic appeal, beeswax wood finish remains a viable option for certain applications. Continued research and development efforts may enhance its durability and broaden its applicability, ensuring its continued relevance in the realm of wood preservation. Further exploration of the intersection between traditional methods and modern advancements is warranted.