A surface treatment created through controlled combustion imparts unique aesthetic and protective qualities to timber. This technique alters the wood’s outer layer, resulting in a darkened, textured appearance. An example of its application can be seen in exterior siding, where the char layer contributes to weather resistance.

The process offers several advantages, including enhanced durability and a natural resistance to pests and decay. Historically, this method has been employed in various cultures to prolong the lifespan of wooden structures and objects. Its application provides a low-maintenance solution and a distinctive visual appeal that integrates well with natural surroundings.

Subsequent sections will delve into the specific techniques employed, the types of wood most suitable for this treatment, and the various finishing options available to further enhance its performance and aesthetic properties. Discussions will also cover safety precautions and best practices for achieving optimal results.

Burned Wood Finish

Achieving a durable and aesthetically pleasing surface requires adherence to specific techniques and considerations. The following tips offer guidance for optimal results.

Tip 1: Wood Selection is Critical: Certain wood species, like cedar and cypress, respond favorably due to their inherent resin content. Dense hardwoods may require extended exposure and careful monitoring to prevent over-charring.

Tip 2: Preparation is Paramount: Ensure the wood surface is clean, dry, and free of any existing coatings. Sanding to a consistent grit ensures uniform charring.

Tip 3: Controlled Exposure is Essential: Employ a consistent heat source and maintain a measured distance to avoid scorching. Practice on scrap pieces to gauge the appropriate exposure time for the selected wood.

Tip 4: Uniform Char Layer: Rotate the wood frequently to achieve an even layer of char. Uneven charring can compromise the protective qualities and aesthetic appeal.

Tip 5: Brushing and Cleaning: After charring, thoroughly brush the surface with a stiff brush to remove loose debris. This reveals the textured grain and prepares the surface for subsequent finishing.

Tip 6: Oil Application for Enhancement: Applying a penetrating oil finish after brushing enhances the grain pattern and provides additional protection. Select an oil specifically formulated for exterior use if the finished product will be exposed to the elements.

Tip 7: Safety Precautions are Non-Negotiable: Perform the process in a well-ventilated area and wear appropriate protective equipment, including gloves, eye protection, and a respirator, to mitigate the risks associated with smoke and airborne particles.

The successful implementation of these tips will result in a visually striking and durable protective layer. Careful attention to detail throughout the process is crucial for achieving the desired outcome.

The following sections will further elaborate on advanced techniques and long-term maintenance strategies for preserving the integrity of the surface.

1. Aesthetic Enhancement

The application of controlled combustion to wood surfaces yields a range of aesthetic possibilities, transforming the material’s appearance and imbuing it with unique visual characteristics. This technique moves beyond mere surface protection, offering opportunities for artistic expression and design integration.

- Depth of Texture

The charring process creates a textured surface with varying depths, highlighting the wood’s natural grain. The extent of the char influences the depth, ranging from subtle undulations to pronounced ridges. This textural variation contributes to the tactile and visual interest of the material.

- Color Palette Modification

The degree and duration of heat exposure manipulate the wood’s color, resulting in a spectrum from light browns to deep blacks. This altered color palette allows for the creation of striking contrasts and nuanced visual effects. The resulting color is determined by wood species and treatment parameters.

- Grain Pattern Accentuation

The controlled combustion process accentuates the wood’s inherent grain pattern. The heat preferentially chars the softer wood, leaving the harder grain lines more pronounced. This differential charring enhances the visual impact of the grain, adding a layer of complexity and depth to the surface.

- Unique Surface Character

Each application of controlled combustion yields a unique surface character, characterized by variations in texture, color, and grain pattern. This inherent variability ensures that each piece possesses an individual aesthetic, contributing to the distinctiveness of the finished product. This variability is a significant advantage for bespoke design projects.

The interplay of these facets demonstrates the potent aesthetic possibilities inherent in this surface treatment. The resultant surface exhibits visual complexity, depth, and a unique character that differentiates it from conventional finishes. This technique offers designers and artisans a powerful tool for achieving specific aesthetic goals, ranging from rustic charm to contemporary sophistication.

2. Protective Qualities

Controlled combustion, employed to create a distinct surface on wood, extends beyond aesthetic enhancement, conferring significant protective qualities that enhance the material’s resilience and longevity. These properties are integral to its suitability for various applications, particularly in environments demanding durability.

- Enhanced Resistance to Decay

The charred layer acts as a barrier against fungal and microbial attack, principal agents of wood decay. This carbonized surface is less susceptible to decomposition, effectively extending the lifespan of the treated wood. Examples include its use in traditional Japanese architecture (Shou Sugi Ban), where the char provides long-term protection against rot in humid climates.

- Pest Deterrence

The carbonized surface presents an inhospitable environment for many wood-boring insects. The altered chemical composition and texture discourage insect infestation, reducing the need for chemical treatments. This characteristic is valuable in outdoor applications, where wood is exposed to a range of potential pests.

- Increased Fire Resistance

While counterintuitive, a controlled burn can enhance fire resistance. The charred layer acts as an insulator, slowing the spread of flames to the underlying wood. This effect provides a degree of protection in the event of a fire, increasing the time available for intervention. However, this should not be mistaken for fireproofing; the wood will still burn if exposed to prolonged high heat.

- Improved Weathering Properties

The charred layer reduces the wood’s permeability to moisture, minimizing expansion and contraction cycles that can lead to cracking and warping. This enhanced dimensional stability contributes to the material’s ability to withstand harsh weather conditions. Its application can be seen in exterior cladding and siding, where it provides long-term protection against the elements.

The protective qualities imparted by controlled combustion are multifaceted, addressing key threats to wood’s structural integrity. These enhancements collectively contribute to the long-term performance and sustainability of the material, making it a practical choice for demanding applications. The synergistic effect of decay resistance, pest deterrence, fire resistance, and improved weathering significantly enhances the overall durability of the treated wood.

3. Wood Selection

Wood selection is a critical determinant in the success and longevity of a surface created through controlled combustion. The inherent properties of different wood species directly influence the outcome of the process, affecting both the aesthetic appearance and the protective qualities achieved.

- Resin Content and Char Formation

Wood species with high resin content, such as cedar and cypress, exhibit superior char formation. The resins ignite readily, creating a consistent and durable carbon layer. This natural process reduces the need for prolonged heat exposure, minimizing the risk of damage to the underlying wood. Examples include the widespread use of cedar in traditional charred wood siding due to its natural resistance and ease of charring.

- Density and Char Depth

The density of wood affects the depth and uniformity of the charred layer. Denser hardwoods may require more intense heat and longer exposure times to achieve the desired level of char. However, over-charring can lead to cracking and structural weakening. Softer woods char more readily but may be more susceptible to erosion over time. Careful control of the combustion process is essential to balance char depth with material integrity. Examples are the use of softer woods for interior decor where erosion is less of a concern and hardwoods for exterior applications, after proper process.

- Grain Pattern and Aesthetic Impact

The inherent grain pattern of different wood species becomes accentuated through the charring process. Tight, uniform grain patterns result in a more consistent surface appearance, while more open or irregular grains create a more textured and visually dynamic surface. The choice of wood species directly influences the final aesthetic outcome. An example is the use of woods with distinct grain patterns to enhance the visual impact of the finished surface.

- Durability and Species-Specific Resistance

Certain wood species possess inherent resistance to decay, insects, and moisture. These natural properties, combined with the protective qualities of the charred layer, result in a highly durable and long-lasting surface. Selecting a species with inherent resistance enhances the overall performance of the charred wood finish. An example is the selection of naturally rot-resistant woods to maximize the longevity of exterior applications.

The interplay between wood selection and the controlled combustion process highlights the importance of informed decision-making. Considering the resin content, density, grain pattern, and inherent durability of different wood species is essential for achieving optimal results and ensuring the long-term performance of the resulting surface. Failure to account for these factors can compromise both the aesthetic appeal and the protective qualities of the finished product.

4. Combustion Control

Combustion control is paramount in achieving a predictable and desirable outcome when creating a surface modification through controlled burning. The process involves carefully regulating the intensity, duration, and consistency of heat applied to the wood surface. Inadequate control leads to uneven charring, structural weakening, and unpredictable aesthetic results. Effective control transforms raw wood into a protective and aesthetically pleasing material. For instance, applying too much heat too quickly causes cracking and deep charring, compromising structural integrity. Conversely, insufficient heat results in a superficial char that lacks protective qualities. Proper combustion control is the determining factor between a successful and a failed application.

Practical application requires selecting an appropriate heat source, maintaining a consistent distance from the wood surface, and carefully monitoring the charring process. Propane torches, for example, offer precise control over flame intensity and direction, while open fires are more challenging to manage consistently. Regular rotation of the wood ensures uniform exposure. Visual inspection, coupled with tactile assessment of the char layer, informs adjustments to heat application. Real-world applications include exterior siding, where a uniform char layer is critical for weather resistance, and interior design elements, where aesthetic consistency is paramount. The expertise in combustion control defines the quality and consistency of the resultant finish.

In summary, combustion control is an indispensable component of the charring process. It dictates both the aesthetic appeal and the protective properties of the finished material. Challenges arise from variations in wood species, environmental conditions, and operator skill. Mastery of combustion control, however, is essential for realizing the full potential of this technique, delivering durable, visually striking surfaces that stand the test of time and environmental exposure.

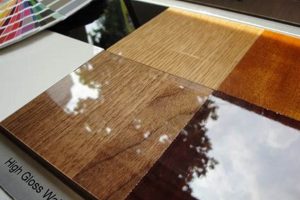

5. Finishing Options

The strategic application of finishing options significantly influences the performance and aesthetic characteristics of a surface created through controlled combustion. Selecting the appropriate finish is crucial for optimizing protection, enhancing visual appeal, and ensuring the long-term durability of the treated wood.

- Penetrating Oil Finishes

Penetrating oil finishes, such as tung oil or linseed oil, are absorbed into the charred wood, enhancing the grain pattern and providing a degree of water resistance. These finishes do not form a surface film, allowing the wood to breathe and minimizing the risk of cracking or peeling. Their application is particularly suitable for exterior surfaces where maintaining a natural aesthetic is desired.

- Surface Sealants and Varnishes

Surface sealants and varnishes create a protective barrier on the exterior, offering increased resistance to water, UV radiation, and abrasion. These finishes are available in a range of sheens, from matte to gloss, allowing for customization of the final appearance. However, their use may require careful surface preparation to ensure proper adhesion and prevent peeling over time. Examples include marine-grade varnishes used in boat building to protect against harsh environmental conditions.

- Stains and Colorants

Stains and colorants can be used to modify the color of the charred wood, enhancing its visual impact or creating a more uniform appearance. These finishes penetrate the wood, imparting color without obscuring the grain pattern. Careful selection of stains formulated for exterior use is essential to ensure long-term color retention and resistance to fading. An example includes the use of tinted oils to achieve a specific color tone while preserving the natural texture of the wood.

- Preservatives and Stabilizers

Preservatives and stabilizers are applied to mitigate the effects of moisture and UV radiation, preventing decay and minimizing dimensional changes in the wood. These finishes are particularly important for exterior applications, where the wood is exposed to harsh environmental conditions. Examples include the use of borate-based preservatives to protect against insect attack and UV inhibitors to prevent fading and discoloration.

The selection of appropriate finishing options complements the inherent protective qualities created through controlled combustion. Integrating these elements leads to optimized performance, enhanced aesthetics, and extended durability. The strategic choice of finishing techniques is, therefore, an essential consideration in maximizing the value and longevity of the resulting surface.

6. Durability Maintenance

The longevity of a surface treated through controlled combustion is intrinsically linked to consistent and appropriate durability maintenance practices. The char layer, while initially protective, is subject to gradual degradation from environmental factors, necessitating periodic intervention to preserve its integrity. Neglecting maintenance undermines the initial investment in the process, diminishing the material’s resistance to decay, pests, and weathering. For example, direct sunlight exposure can cause the char layer to fade and erode, reducing its effectiveness as a protective barrier. Similarly, repeated exposure to moisture can lead to fungal growth and eventual decay, particularly in areas where water pools or remains trapped. Durability maintenance serves as a critical component in ensuring the continued efficacy of the charred surface, mitigating these potential detriments and extending the lifespan of the treated material.

Effective maintenance strategies encompass several key practices. Regular cleaning to remove dirt, debris, and organic matter prevents the accumulation of moisture and the proliferation of harmful organisms. Periodic re-oiling with penetrating oils replenishes the natural oils lost through weathering, maintaining the char layer’s flexibility and water resistance. Inspection for signs of cracking, splitting, or decay allows for timely repairs, preventing minor issues from escalating into more significant problems. In cases where damage is extensive, re-charring may be necessary to restore the protective layer. The frequency and intensity of these maintenance tasks are contingent upon environmental conditions, wood species, and the type of finishing applied. For instance, exterior cladding in coastal regions requires more frequent cleaning and re-oiling compared to interior applications in drier climates. A proactive and tailored maintenance schedule optimizes the long-term performance and aesthetic appeal of the surface.

In conclusion, the inherent benefits of a surface created through controlled combustion are contingent upon diligent and appropriate durability maintenance. Addressing the environmental stressors, implementing a proactive maintenance strategy, and selecting appropriate maintenance products significantly contributes to the longevity and sustainability of the finished material. The long-term performance and cost-effectiveness of this surface modification are directly correlated with the commitment to consistent and informed maintenance practices, thereby realizing the full potential of the treatment. Ignoring maintenance diminishes the protective properties and aesthetic qualities, negating the initial investment and potentially compromising the structural integrity of the underlying wood.

Frequently Asked Questions

The following addresses common inquiries and misconceptions concerning surface treatments created through controlled combustion.

Question 1: Does the process render wood completely fireproof?

No. The controlled burn process enhances fire resistance by creating a carbonized layer that slows the spread of flames. However, it does not make the wood immune to fire. Prolonged exposure to high heat will still result in combustion.

Question 2: What is the expected lifespan of a surface created using this technique?

Lifespan varies depending on wood species, environmental conditions, and maintenance practices. With proper maintenance, surfaces can last for several decades. However, neglecting upkeep will significantly reduce longevity.

Question 3: Is the procedure environmentally sustainable?

The environmental impact depends on factors such as wood sourcing and the finishing products used. Utilizing sustainably harvested wood and eco-friendly finishes can minimize the environmental footprint. Additionally, the increased durability reduces the need for frequent replacements.

Question 4: What types of wood are most suitable for this surface treatment?

Softwoods with high resin content, such as cedar and cypress, are generally preferred. However, hardwoods can also be treated with careful monitoring and adjustments to the combustion process.

Question 5: Is this technique suitable for interior applications?

Yes, with appropriate precautions and finishing techniques. It is important to ensure adequate ventilation during the combustion process and to seal the surface properly to prevent soot transfer. The technique can add unique character to interior design elements.

Question 6: How does the cost compare to other wood finishing methods?

The initial cost may be higher due to the labor-intensive nature of the process. However, the increased durability and reduced maintenance requirements can result in long-term cost savings compared to conventional finishes.

Key takeaways include the importance of understanding the limitations of the process, selecting appropriate materials, and implementing proper maintenance practices.

The subsequent section will detail specific case studies illustrating successful applications of this surface treatment across diverse projects.

Conclusion

This exploration of burned wood finish has demonstrated its multifaceted nature, encompassing both aesthetic enhancement and protective functionalities. The technique requires careful consideration of wood species, combustion control, and finishing options to achieve optimal results. Its successful implementation yields surfaces with increased durability, resistance to pests and decay, and a distinctive visual appeal.

The sustained utilization of burned wood finish hinges on adherence to best practices and informed decision-making. Continued research and development will further refine the process, expanding its applications and optimizing its performance in diverse environments. Its long-term viability as a sustainable and aesthetically compelling surface treatment depends on responsible application and a commitment to ongoing maintenance.