Protective and decorative coatings applied to cabinetry surfaces, altering their appearance and providing resistance against wear, moisture, and staining. An example includes a catalyzed lacquer applied to maple cabinetry, resulting in a durable, satin sheen.

Proper application significantly extends the lifespan of cabinetry, preserving the aesthetic appeal and structural integrity. Historically, natural oils and waxes were prevalent; modern formulations offer enhanced durability and a broader range of aesthetic options. Their utilization prevents damage from daily use, humidity, and temperature variations, contributing to long-term value and reduced maintenance costs.

The selection process involves careful consideration of factors such as material type, intended use, desired aesthetic, and budget constraints. Subsequent sections will address the various types available, application techniques, and best practices for maintenance and care.

Enhancing Longevity and Aesthetics

The following guidelines provide essential considerations for achieving optimal results and ensuring lasting protection for cabinetry.

Tip 1: Material Compatibility: Verify the selected substance is chemically compatible with the cabinet substrate. Incorrect pairings can lead to adhesion failures, discoloration, or structural damage. Consult manufacturer specifications for guidance.

Tip 2: Surface Preparation: Prior to application, meticulously clean and prepare the surface. Remove all contaminants, such as dust, grease, and existing coatings. Proper preparation ensures optimal adhesion and a uniform appearance.

Tip 3: Environmental Control: Maintain consistent temperature and humidity levels during application and curing. Deviations can negatively impact drying times, surface smoothness, and overall durability.

Tip 4: Application Technique: Employ consistent and even application techniques, whether using spraying equipment, brushes, or rollers. Avoid excessive build-up or uneven distribution, which can result in runs, drips, or inconsistencies in sheen.

Tip 5: Number of Coats: Apply the recommended number of coats, adhering to manufacturer specifications for film thickness. Multiple thin coats are generally preferable to a single thick coat, enhancing durability and preventing cracking.

Tip 6: Curing Time: Allow adequate curing time as specified by the manufacturer before exposing the cabinetry to regular use. Premature exposure can result in damage to the uncured coating and diminished performance.

Tip 7: Regular Maintenance: Implement a routine cleaning schedule using appropriate cleaning agents. Avoid abrasive cleaners or excessive moisture, which can damage or degrade the protective barrier.

Adherence to these guidelines will maximize the lifespan and aesthetic appeal of cabinet surfaces, mitigating potential issues and ensuring long-term satisfaction.

The following sections will delve into specific product recommendations and troubleshooting common issues.

1. Durability

Durability, in the context of cabinetry, refers to the capacity of a surface treatment to withstand wear, impacts, chemical exposure, and environmental stressors over an extended period. Selection directly impacts the long-term structural integrity and aesthetic appeal of the cabinets.

- Abrasion Resistance

Abrasion resistance denotes the coating’s ability to resist scratching and marring from everyday use. High-traffic areas, such as kitchens, necessitate surfaces capable of withstanding repeated contact with utensils, cleaning implements, and other abrasive elements. For example, a catalyzed conversion varnish offers superior protection against abrasion compared to a standard lacquer.

- Chemical Resistance

Chemical resistance is the ability of the coating to withstand exposure to household cleaning agents, solvents, and food spills without degradation. Kitchen and bathroom cabinets are frequently exposed to a variety of chemicals, necessitating treatments with robust chemical resistance properties. Epoxies and certain polyurethane formulations exhibit exceptional chemical resistance.

- Moisture Resistance

Moisture resistance dictates the coating’s ability to prevent water penetration and subsequent damage to the underlying substrate. Cabinets in bathrooms and kitchens are particularly vulnerable to moisture-related issues, such as swelling, warping, and delamination. Conversion varnishes and two-part polyurethanes provide enhanced moisture protection.

- Impact Resistance

Impact resistance refers to the coating’s ability to withstand sudden impacts without cracking, chipping, or denting. Cabinets, especially drawer fronts and door panels, are susceptible to accidental impacts. Pre-catalyzed lacquers and certain acrylic coatings offer moderate impact resistance.

The interplay between these factors determines the overall longevity and performance of cabinetry. Careful consideration of the intended use environment and potential stressors is paramount in selecting a coating system that optimizes durability and preserves the investment in quality cabinetry.

2. Aesthetics

The visual attributes imparted by surface treatments significantly influence the perceived value and overall design coherence of interior spaces. The selection of appropriate materials dictates not only the color and sheen but also the tactile qualities and perceived depth of the cabinetry.

- Color and Tone

Color and tone exert a profound influence on the emotional and psychological impact of a space. Light colors tend to create a sense of spaciousness and airiness, while darker hues can convey sophistication and intimacy. The choice of color must align with the overall design concept and complement the surrounding elements. For example, a muted gray stain on shaker-style cabinets evokes a sense of modern minimalism, whereas a warm cherry finish on raised-panel doors lends a traditional aesthetic.

- Sheen Level

Sheen level, or the degree of light reflectivity, plays a critical role in defining the character of the surface. High-gloss finishes offer a sleek and contemporary look, enhancing the vibrancy of the color and reflecting light to create a sense of luminosity. Matte or satin surfaces, conversely, minimize glare and provide a more subdued and understated aesthetic. The selection of sheen level should consider the ambient lighting conditions and the desired level of visual impact.

- Texture and Grain

The inherent texture and grain patterns of the wood species, further enhanced by surface treatments, contribute significantly to the tactile and visual interest of the cabinetry. Smooth, uniform surfaces convey a sense of refinement, while textured or distressed finishes add depth and character. Open-grain woods, such as oak or ash, exhibit prominent grain patterns that can be accentuated with staining techniques, whereas closed-grain woods, such as maple or cherry, offer a smoother and more uniform appearance.

- Clarity and Depth

The clarity and depth achieved in the final appearance enhance the richness and perceived quality. Transparent coatings, such as clear lacquers or varnishes, allow the natural beauty of the wood grain to shine through, while pigmented treatments obscure the grain to varying degrees. Achieving optimal clarity and depth requires careful surface preparation, the use of high-quality materials, and meticulous application techniques.

These aesthetic considerations are integral to the successful integration of cabinetry within a cohesive interior design scheme. Strategic application of surface treatments can transform ordinary cabinets into focal points, enhancing the overall ambiance and reflecting the unique style of the occupants. The final aesthetic result should harmonize with other design elements, such as countertops, flooring, and hardware, to create a unified and visually pleasing environment.

3. Protection

The primary function of surface treatments is the safeguarding of the underlying cabinetry material against various detrimental factors. These factors include, but are not limited to, moisture intrusion, physical abrasion, chemical exposure, and ultraviolet (UV) radiation. Effective protection ensures the structural integrity of the cabinets is maintained, thereby prolonging their functional lifespan. Untreated wood, for instance, is susceptible to warping, cracking, and fungal growth when exposed to high humidity environments. Similarly, direct contact with acidic substances, such as lemon juice or vinegar, can etch or stain unprotected surfaces, permanently altering their aesthetic appearance.

The selection of a specific protection method should align with the anticipated environmental conditions and usage patterns. For example, cabinetry installed in a bathroom requires a treatment possessing a high degree of moisture resistance, such as a catalyzed varnish or a two-part polyurethane. In contrast, cabinetry in a low-traffic area might benefit from a less robust, yet aesthetically pleasing, coating, such as a lacquer or a stain-and-sealant combination. The protective barrier offered by these treatments mitigates damage from daily use, extending the time between necessary refinishing or replacement, resulting in considerable cost savings over the lifecycle of the installation.

In summary, the protective qualities of surface treatments are integral to the long-term performance and value of cabinetry. Understanding the specific environmental risks and matching them with appropriate protective strategies is crucial. While aesthetic considerations are important, the primary objective remains safeguarding the material from degradation, thereby ensuring the longevity and functionality of the investment. Neglecting this critical aspect leads to premature failure and the need for costly repairs or replacements.

4. Application

The method by which protective and decorative materials are applied to cabinetry surfaces exerts a profound influence on the ultimate appearance, durability, and longevity of the surface treatment. Precise execution is paramount, as inconsistencies or errors in the application process can compromise the integrity of even the highest-quality materials.

- Surface Preparation

Prior to the application of any finish, meticulous surface preparation is indispensable. This includes cleaning to remove contaminants such as grease, dust, and existing coatings, followed by sanding to create a uniform and receptive surface profile. Improper surface preparation can lead to adhesion failures, uneven coloration, and premature degradation of the applied finish. The specific preparation techniques vary depending on the substrate material and the type of finish being used; for example, oak requires grain filling prior to certain finish applications to ensure a smooth, uniform surface.

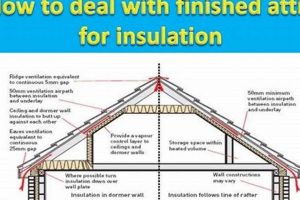

- Environmental Control

Ambient conditions, including temperature, humidity, and air circulation, play a crucial role in the proper curing and adhesion of cabinet finishes. Elevated humidity levels can impede the drying process, leading to tackiness or blistering, while extreme temperatures can affect the viscosity and flow properties of the finish. A controlled environment, typically within specified temperature and humidity ranges, is essential for achieving optimal results. Many professional finishing shops utilize climate-controlled spray booths to mitigate the impact of environmental variables.

- Application Techniques

The choice of application technique, whether brushing, rolling, or spraying, directly impacts the uniformity, thickness, and overall quality of the applied finish. Spraying, particularly with HVLP (High Volume Low Pressure) equipment, generally yields the most consistent and professional results, minimizing brush marks and providing even coverage. However, spraying requires specialized equipment and expertise. Brushing and rolling are viable alternatives for smaller projects or when spraying is not feasible, but they demand careful technique to avoid visible brush strokes or roller marks.

- Layering and Curing

Most cabinet finishes require multiple coats to achieve the desired level of protection and aesthetic appeal. Each coat must be applied in a thin, even layer and allowed to cure completely before the subsequent coat is applied. Insufficient curing time can lead to trapped solvents, which can compromise the long-term durability of the finish. Proper layering and curing techniques are crucial for achieving a smooth, durable, and visually appealing surface. The manufacturer’s recommendations regarding drying times and recoating intervals must be strictly followed.

Ultimately, the success of any cabinet finishing project hinges on a thorough understanding of the materials, the proper application techniques, and the importance of environmental control. Neglecting any of these aspects can compromise the outcome, resulting in a finish that is aesthetically unappealing, structurally unsound, or both. Therefore, it is essential to prioritize meticulous attention to detail and adherence to best practices throughout the entire application process to ensure the long-term performance and value of the cabinetry.

5. Maintenance

The longevity and aesthetic appeal of cabinetry are inextricably linked to diligent maintenance practices. Appropriate maintenance protocols preserve the integrity of surface treatments, safeguarding against degradation and ensuring sustained visual appeal. Neglecting these practices precipitates premature deterioration, necessitating costly repairs or replacements.

- Regular Cleaning

Routine cleaning protocols prevent the accumulation of dust, grease, and other contaminants that can compromise the protective barrier of surface treatments. Frequency and methods vary depending on the finish type and environmental conditions. A mild soap solution and a soft cloth are generally recommended for most surfaces, while abrasive cleaners should be avoided, as they can scratch or dull the finish. For instance, the accumulation of grease around stovetop cabinetry necessitates more frequent cleaning to prevent its hardening and subsequent difficulty in removal, which could damage the underlying surface.

- Humidity Control

Maintaining stable humidity levels minimizes the potential for moisture-related damage to both the cabinetry and its surface treatment. Excessive humidity can lead to swelling, warping, and delamination of wood substrates, compromising the adhesion of coatings. Dehumidifiers or ventilation systems are recommended in environments prone to high humidity, such as bathrooms and kitchens. Fluctuations in humidity can also cause cracking or crazing in certain types of surface treatments, such as lacquer or varnish.

- Scratch and Damage Repair

Prompt attention to scratches and minor damages prevents further deterioration of the finish and the underlying material. Minor scratches can often be repaired with touch-up markers or wax sticks that match the finish color. Deeper scratches or chips may require professional refinishing to restore the original appearance and prevent moisture intrusion. Early intervention is crucial; a small scratch left unattended can expand over time due to repeated exposure to moisture and abrasion.

- Hardware Maintenance

Hardware components, such as hinges and drawer pulls, also contribute to the overall condition of cabinetry. Loose or damaged hardware can cause excessive wear and tear on the surrounding finish, leading to unsightly marks and potential structural damage. Regular tightening of screws and lubrication of hinges can prevent these issues. Additionally, replacing worn or damaged hardware not only improves functionality but also enhances the overall aesthetic appeal of the cabinetry.

These facets of maintenance, when diligently implemented, contribute significantly to the preservation of surface treatments and the overall longevity of cabinetry. A proactive approach to maintenance, characterized by regular cleaning, humidity control, prompt damage repair, and hardware upkeep, represents a sound investment in the long-term value and aesthetic appeal of cabinet installations.

Frequently Asked Questions

The following addresses commonly encountered queries regarding the selection, application, and maintenance of coatings applied to cabinetry surfaces.

Question 1: What is the expected lifespan of a typical cabinet finish?

The lifespan of a surface treatment is contingent upon several factors, including the type of material used, the quality of application, the environmental conditions, and the diligence of maintenance practices. A professionally applied conversion varnish, under moderate usage conditions and with regular cleaning, may last for 10-15 years or more. Conversely, a poorly applied lacquer in a high-humidity environment may exhibit signs of degradation within a few years.

Question 2: How does one differentiate between various types of cabinet coatings?

Coatings can be broadly categorized into lacquers, varnishes, polyurethanes, and acrylics. Lacquers are known for their fast drying times and ease of application, but they offer limited durability and chemical resistance. Varnishes provide enhanced durability and moisture resistance. Polyurethanes offer superior chemical and abrasion resistance. Acrylics are typically water-based and offer good color retention and low VOC (Volatile Organic Compounds) emissions. Identifying the specific properties of each type is crucial for matching the appropriate coating to the intended use.

Question 3: What are the potential consequences of neglecting proper surface preparation?

Inadequate surface preparation results in compromised adhesion, uneven coloration, and premature failure of the applied coating. Contaminants, such as grease, dust, or existing coatings, prevent proper bonding between the new coating and the substrate. Improper sanding creates an uneven surface profile, leading to inconsistencies in the final appearance. These deficiencies significantly reduce the lifespan and aesthetic appeal of the finish.

Question 4: Is it possible to apply cabinet finishes as a DIY project?

While it is feasible to apply certain types of coatings as a DIY project, achieving professional-quality results requires specialized knowledge, equipment, and skill. Spraying equipment, in particular, demands considerable experience to operate effectively. Brushing or rolling can be viable alternatives for smaller projects, but achieving a smooth, uniform finish requires meticulous technique. If a high-quality, durable finish is desired, professional application is generally recommended.

Question 5: What are the most common causes of cabinet finish failure?

Common causes include exposure to excessive moisture, abrasion from repeated contact, chemical exposure from cleaning agents or spills, and inadequate maintenance practices. Improper application techniques, such as applying coatings too thickly or failing to allow sufficient curing time, also contribute to premature failure. Understanding these factors allows for proactive prevention and mitigation strategies.

Question 6: How does the choice of wood species impact the selection of a cabinet coating?

The wood species significantly influences the selection. Open-grained woods, such as oak and ash, require grain filling to achieve a smooth surface. Resinous woods, such as pine, necessitate specific primers to prevent bleed-through. Hardwoods, such as maple and cherry, generally require less preparation and are compatible with a wider range of coatings. The inherent properties of the wood must be considered to ensure optimal adhesion and aesthetic results.

In summary, the successful application and maintenance of cabinet finishes rely on informed decision-making and adherence to best practices. A thorough understanding of material properties, application techniques, and maintenance protocols is essential for achieving long-lasting results.

The subsequent section will explore specific product recommendations and case studies.

Cabinet Surface Treatments

This exploration has underscored the critical role of surface treatments in preserving cabinetry’s structural integrity and visual appeal. Factors ranging from material selection and application techniques to ongoing maintenance practices have been detailed. The interplay between these elements dictates the long-term performance and value of cabinetry installations. The diverse range of available materials, each possessing unique properties, necessitates careful consideration based on environmental conditions, usage patterns, and desired aesthetic outcomes.

As advancements in materials science continue to evolve, ongoing education and adaptation to emerging technologies remain paramount. A commitment to informed decision-making and adherence to best practices will ensure that investments in cabinetry are safeguarded, thereby maximizing longevity and aesthetic satisfaction. Professionals are encouraged to consult manufacturers’ specifications and industry guidelines to maintain the highest standards of quality and performance. The selection of appropriate coatings contributes significantly to the long-term value and functionality of cabinetry.