Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

This specialized power tool drives fasteners into wood surfaces, completing projects with a smooth, nearly invisible hold. Often utilized in cabinetry and trim work, this tool uses battery power, granting a degree of freedom on the job site where pneumatic hoses or cords might prove cumbersome. An example of its use would be attaching decorative molding to a wall, or securing door and window casings.

The significance of this device lies in its portability and convenience. Prior to battery-operated models, finish nailers required an air compressor, restricting movement and often requiring additional setup time. The development of a self-contained, battery-powered alternative has increased efficiency and accessibility, allowing professionals and hobbyists alike to execute tasks more easily. The initial introduction of these models also marked a shift in power tool design towards increased user autonomy.

The subsequent sections will delve into a detailed examination of the features, advantages, selection criteria, and maintenance procedures relevant to achieving optimal performance and longevity. These sections will provide the reader with a well-rounded understanding to make informed decisions related to this type of equipment.

Operational Guidance for Cordless Finish Nailers

The following guidelines promote optimal utilization and extend the lifespan of the equipment. Adherence to these suggestions enhances project outcomes and reduces the likelihood of malfunctions.

Tip 1: Battery Management: Fully charge batteries prior to initial use and maintain consistent charging habits. Inconsistent charging can reduce battery capacity over time. Utilize the charger designated by the manufacturer.

Tip 2: Fastener Selection: Employ the correct fastener length and gauge for the application. Using inappropriate fasteners can result in damage to the tool, material splitting, or inadequate holding power. Consult the tool’s manual for approved fastener types.

Tip 3: Depth Adjustment: Calibrate the depth of drive setting prior to beginning any project. A test piece of the same material being used in the actual project should be used to determine the optimal setting that sets the nail flush without damaging the surrounding surface.

Tip 4: Regular Cleaning: Maintain the tool by regularly cleaning the nail magazine and nosepiece. Accumulated debris can impede proper fastener feeding and firing. Use compressed air to remove sawdust and small particles.

Tip 5: Proper Storage: Store the tool in a dry, secure location when not in use. Extreme temperatures or humidity can negatively impact both the tool and the batteries. Remove the battery for extended storage periods.

Tip 6: Maintain Consistent Pressure: Apply consistent, even pressure when firing. Inconsistent pressure leads to uneven nail placement and potential damage to the work surface.

Tip 7: Safety Precautions: Always wear appropriate personal protective equipment, including eye protection and hearing protection. Disconnect the battery before performing any maintenance or adjustments.

By implementing these practices, users can ensure efficient operation, reduce the risk of damage, and extend the lifespan of their devices. Prioritizing maintenance and safety enhances the overall value and effectiveness of this tool.

The article will conclude with a review of emerging technologies and a look toward future advancements in this category.

1. Battery Capacity

Battery capacity is a critical determinant of a cordless finish nailer’s usability and overall effectiveness. It dictates the runtime of the tool, directly impacting the size and scope of projects that can be completed on a single charge. A careful consideration of battery specifications is therefore essential when selecting a model.

- Amp-Hour Rating (Ah)

The amp-hour rating is the primary indicator of battery capacity. A higher Ah rating signifies a greater energy storage capability, allowing for more nails to be driven before requiring a recharge. For example, a 5.0 Ah battery will generally power a nailer for longer than a 2.0 Ah battery under the same operating conditions. This is particularly important for tasks involving extensive trim work or on-site projects where access to power outlets may be limited.

- Voltage (V) and Power Delivery

Voltage, in conjunction with amp-hours, determines the overall power output of the battery. Higher voltage batteries can often deliver more power, enabling the nailer to drive fasteners into harder materials with greater force and consistency. Cordless finish nailers commonly operate on 18V or 20V platforms, with higher voltages typically reserved for models designed for heavier-duty applications.

- Battery Technology (Lithium-Ion)

Lithium-ion (Li-ion) batteries are the prevailing technology in cordless power tools due to their high energy density, low self-discharge rate, and relatively long lifespan. Li-ion batteries offer significant advantages over older battery technologies like Nickel-Cadmium (Ni-Cd), including lighter weight and the absence of a “memory effect” that could reduce battery capacity over time. Understanding the specific Li-ion chemistry used in a given battery can further inform its performance characteristics and longevity.

- Interchangeability and Battery Systems

Many manufacturers offer cordless power tool systems where batteries are interchangeable across different tools within their product line. This can be a significant cost-saving benefit, as users can purchase multiple tools without needing a separate battery and charger for each. Evaluating the availability and cost of additional batteries within a given system is a crucial consideration for users anticipating the need for extended runtime or multiple tools.

In summary, battery capacity is a pivotal factor influencing the operational capabilities of cordless finish nailers. Understanding the relationship between amp-hour ratings, voltage, battery technology, and system compatibility enables informed decision-making, ensuring the selected tool meets the demands of the intended application. Overlooking this aspect can result in project delays, reduced productivity, and increased overall costs. For instance, choosing a lower Ah battery may suffice for small home repairs, while professional carpenters undertaking large-scale installations will likely benefit from higher capacity batteries.

2. Nail Gauge

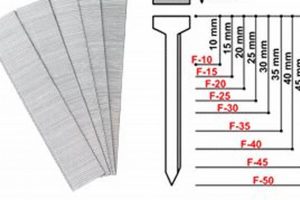

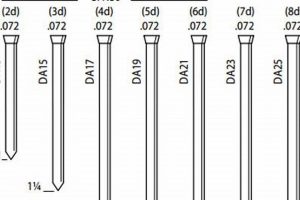

Nail gauge, a standardized measurement of nail wire diameter, is intrinsically linked to the functionality and application of a cordless finish nailer. This specification directly determines the types of fasteners the tool can accommodate, impacting the suitability of the nailer for specific woodworking tasks. A higher gauge number indicates a thinner nail, while a lower gauge number represents a thicker nail. The choice of nail gauge is dictated by the materials being joined and the desired holding power.

A finish nailer, typically utilizing 15-gauge or 16-gauge nails, is designed for applications where aesthetics are paramount. These finer gauge nails create smaller entry holes, minimizing the need for extensive filling and sanding after installation. For instance, securing delicate trim work, such as crown molding or baseboards, necessitates a higher gauge nail to prevent splitting the wood. Conversely, using a 23-gauge pin nailer would be inadequate for structural applications due to its limited holding strength. The nailer’s magazine and firing mechanism are specifically engineered to accept and drive a particular range of nail gauges; attempting to use incompatible nail sizes can result in jams, damage to the tool, or unsafe operation.

Understanding the relationship between nail gauge and the intended application is crucial for successful and safe operation. Selecting the correct gauge ensures the fastener provides adequate holding power without compromising the appearance or integrity of the workpiece. Ignoring this specification can lead to project failures, material damage, and potential injury. Therefore, consideration of the nail gauge is an indispensable step in the selection and utilization of cordless finish nailers.

3. Depth Control

Depth control is an essential component of a cordless finish nailer, significantly influencing the quality and appearance of finished work. It allows users to adjust the driving force of the tool, controlling how far the nail penetrates the material. Improper depth settings result in either nails protruding above the surface, necessitating manual setting with a nail set, or nails driven too deep, marring the surrounding wood. Consequently, this feature contributes directly to minimizing cosmetic imperfections and reducing post-installation labor.

The ability to fine-tune the depth setting is particularly crucial when working with materials of varying densities. For example, when attaching trim to soft pine, a shallower setting is required to prevent the nail from sinking too far. Conversely, when fastening into hardwood, a greater driving force is needed to ensure the nail is fully seated. Modern cordless finish nailers often incorporate tool-free depth adjustment mechanisms, allowing for quick and precise changes in the field. The presence of a clearly marked and easily manipulated depth control dial or lever directly enhances user efficiency and accuracy, leading to improved outcomes.

In summary, effective depth control is paramount to achieving professional-quality results with a cordless finish nailer. This feature provides the necessary flexibility to adapt to diverse materials and applications, minimizing surface damage and ensuring secure fastening. Ignoring the importance of depth adjustment can lead to compromised aesthetics and increased project time, underscoring its critical role in maximizing the tool’s utility and performance.

4. Brushless Motor

The integration of brushless motor technology into cordless finish nailers represents a significant advancement in tool performance and longevity. This design replaces traditional brushes with electronic commutation, resulting in numerous advantages relevant to the operational effectiveness of the equipment.

- Enhanced Efficiency and Power Delivery

Brushless motors exhibit superior energy conversion efficiency compared to their brushed counterparts. This translates to longer runtime on a single battery charge and more consistent power delivery throughout the discharge cycle. The electronic control system precisely manages the motor’s speed and torque, optimizing performance across a range of fastening tasks. For example, a brushless nailer will maintain a more consistent driving force when sinking nails into varying wood densities, reducing the likelihood of incomplete sets or surface damage.

- Extended Motor Lifespan and Reduced Maintenance

The absence of brushes eliminates a key wear component in the motor, significantly extending its operational lifespan. Brushed motors require periodic brush replacement, a maintenance task that is entirely obviated by brushless designs. This reduction in maintenance contributes to lower overall operating costs and increased tool uptime, particularly beneficial for professional users who rely on their equipment daily.

- Compact Size and Lighter Weight

Brushless motors can be designed to be more compact and lightweight than equivalent brushed motors. This reduction in size and weight improves the tool’s ergonomics, making it more comfortable to use for extended periods and reducing user fatigue. A lighter nailer is particularly advantageous when working overhead or in tight spaces where maneuverability is limited.

- Reduced Heat Generation

Brushless motors generate less heat during operation due to reduced friction and improved energy efficiency. This cooler operating temperature contributes to longer motor life and can also improve user comfort, particularly during prolonged use in warm environments. Furthermore, reduced heat minimizes the risk of overheating the battery, potentially extending its lifespan and maintaining consistent performance.

In conclusion, the incorporation of brushless motor technology into cordless finish nailers yields substantial benefits in terms of efficiency, durability, ergonomics, and user comfort. These advantages translate directly to improved performance and reduced operating costs, making brushless models a compelling choice for both professional and DIY users seeking a reliable and high-performing fastening solution.

5. Sequential/Contact Actuation

Actuation modes on a cordless finish nailer dictate the method by which fasteners are driven, influencing speed, precision, and safety. The two primary modes are sequential and contact actuation, each suited for distinct applications and user preferences. Understanding these modes is crucial for optimizing tool performance and minimizing the risk of unintended nail discharge.

- Sequential Actuation (Single Actuation)

Sequential actuation requires the user to depress the safety contact tip against the workpiece and then pull the trigger to fire a nail. This process must be repeated for each fastener. The primary benefit of sequential actuation is enhanced safety; it significantly reduces the risk of accidental nail discharge, particularly when maneuvering in tight spaces or working at awkward angles. This mode is generally favored for precision work where accuracy and control are paramount, such as detailed trim installation or delicate woodworking projects. An example would be installing intricate molding, where precise nail placement is essential and the risk of misfires must be minimized.

- Contact Actuation (Bump Actuation)

Contact actuation, also known as bump actuation, allows for rapid fastener placement. With this mode, the trigger is held down, and nails are driven each time the safety contact tip is bumped against the work surface. This mode significantly increases speed and productivity, making it well-suited for repetitive tasks, such as framing or sheathing. However, contact actuation presents a higher risk of accidental nail discharge if the tool is inadvertently bumped against a surface while the trigger is depressed. While faster, users must exercise extreme caution to prevent unintended firings. An instance of use would be quickly attaching a series of baseboards where speed is more important than absolute precision in each nail placement.

- Mode Selection and User Experience

Many cordless finish nailers offer a selectable actuation mode, allowing the user to switch between sequential and contact actuation based on the task at hand. The mode selection mechanism is typically a switch or dial located on the tool body. The user experience varies significantly between the two modes. Sequential actuation promotes deliberate and controlled nail placement, while contact actuation prioritizes speed and efficiency. The choice of actuation mode should be guided by the specific requirements of the project, the user’s skill level, and a careful assessment of the potential safety risks.

- Safety Implications and Training

Regardless of the actuation mode chosen, adherence to proper safety procedures is essential. Users should always wear appropriate personal protective equipment, including eye protection, and should be thoroughly familiar with the tool’s operating manual. Training on the proper use of both sequential and contact actuation modes is crucial for minimizing the risk of accidents and ensuring safe operation. It is especially important to emphasize the potential hazards associated with contact actuation, particularly the risk of unintended nail discharge. A safe practice is to always remove the battery when the tool is not in use, regardless of the selected actuation mode.

The choice between sequential and contact actuation on a cordless finish nailer represents a trade-off between safety and speed. By understanding the characteristics of each mode and carefully considering the requirements of the specific task, users can optimize tool performance while minimizing the risk of accidents. The adaptability offered by selectable actuation models provides an added layer of flexibility, allowing users to tailor the tool’s operation to their individual needs and preferences. For instance, a contractor might employ sequential mode for intricate finish work and contact mode for rapidly securing subflooring.

6. Ergonomic Design

Ergonomic design plays a crucial role in the functionality and user experience of cordless finish nailers. The cause-and-effect relationship is direct: thoughtful ergonomic features lead to reduced user fatigue, improved control, and enhanced safety, while a poorly designed tool can result in discomfort, decreased precision, and increased risk of musculoskeletal strain. This design consideration is paramount because these nailers are often used for extended periods in demanding environments, requiring sustained physical exertion. Real-life examples include contoured grips that minimize hand strain, balanced weight distribution that reduces arm fatigue, and strategically placed controls that are easily accessible without compromising grip or posture. The practical significance lies in the increased productivity, reduced worker injury, and improved quality of work that result from a well-engineered tool.

The importance of ergonomic design extends beyond mere comfort. Vibration dampening features, for example, mitigate the impact of repetitive nail firing on the user’s hands and wrists, reducing the likelihood of long-term injuries such as carpal tunnel syndrome. Angled magazines and adjustable belt hooks enhance maneuverability and accessibility in confined spaces, further contributing to reduced strain and improved efficiency. Furthermore, lightweight construction, often achieved through the use of advanced materials, is a key ergonomic factor, enabling users to work for longer durations without experiencing excessive fatigue. The integration of these features translates to tangible benefits in terms of worker health, safety, and productivity.

In summary, ergonomic design is an indispensable component of cordless finish nailers. It directly impacts user well-being, operational efficiency, and the quality of finished work. While technological advancements in battery power and motor efficiency are important, the ergonomic aspects of these tools deserve equal consideration. Prioritizing ergonomic design is not merely a matter of comfort; it is a crucial investment in worker safety, productivity, and the long-term success of projects that rely on the precision and efficiency of these specialized power tools.

Frequently Asked Questions

This section addresses common inquiries regarding the operation, maintenance, and selection of cordless finish nailers. The information provided aims to clarify misconceptions and offer practical guidance for maximizing tool performance and longevity.

Question 1: What is the expected lifespan of a battery used in this type of nailer?

The lifespan of a battery is contingent upon usage frequency, storage conditions, and adherence to manufacturer recommendations. Lithium-ion batteries, commonly used in cordless finish nailers, typically offer between 300 and 500 charge cycles before experiencing a significant reduction in capacity. Proper storage, away from extreme temperatures and humidity, can extend the battery’s lifespan.

Question 2: Can this nailer be used in wet or damp conditions?

Operating a cordless finish nailer in wet or damp conditions is strongly discouraged. Moisture can compromise the tool’s electrical components, posing a risk of electric shock and potentially causing irreparable damage. Furthermore, moisture can lead to corrosion of internal parts, reducing the tool’s overall lifespan.

Question 3: How frequently should maintenance be performed on a cordless finish nailer?

Regular maintenance is essential for ensuring optimal performance and extending the lifespan of the equipment. The nail magazine should be cleaned regularly to remove debris that may impede fastener feeding. The tool should also be inspected periodically for loose screws or damaged components. Adhering to the manufacturer’s recommended maintenance schedule is advisable.

Question 4: Is there a specific type of lubricant recommended for this tool?

Consult the manufacturer’s operating manual for specific lubrication recommendations. Generally, a light machine oil or silicone-based lubricant can be used to lubricate moving parts, such as the nail magazine and firing mechanism. Avoid using lubricants that are excessively viscous or that may attract dust and debris.

Question 5: What safety precautions should be observed when using a cordless finish nailer?

Safety precautions are paramount when operating any power tool. Always wear appropriate eye protection to guard against flying debris. Hearing protection is also recommended, particularly during prolonged use. Ensure the work area is clear of obstructions and that bystanders are at a safe distance. Disconnect the battery before performing any maintenance or adjustments.

Question 6: What is the appropriate nail length range for a typical cordless finish nailer?

The appropriate nail length range varies depending on the specific model and gauge of the nailer. Consult the manufacturer’s specifications to determine the acceptable nail length range. Using nails that are too long or too short can result in improper fastening, damage to the workpiece, or damage to the tool itself.

The preceding questions and answers provide fundamental insights into the operation and maintenance of cordless finish nailers. Adherence to these guidelines promotes safe and effective tool utilization.

The subsequent section will explore emerging trends and future developments in cordless finish nailer technology.

Cordless Finish Nailer

This exposition has thoroughly examined the cordless finish nailer, detailing its operation, benefits, selection criteria, maintenance, and prevalent actuation modes. Critical attributes such as battery capacity, nail gauge, and depth control have been underscored, alongside the advantages of brushless motor technology and the importance of ergonomic design. Frequently asked questions have been addressed to provide further clarity and guidance.

The cordless finish nailer represents a significant advancement in fastening technology, offering enhanced portability, efficiency, and precision. Continued adherence to recommended operating procedures and safety protocols remains paramount to maximizing its potential and ensuring a safe and productive work environment. As technology evolves, remaining informed about advancements in battery technology and nailer design will be crucial for professionals and hobbyists alike to leverage the full capabilities of this essential tool.