Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

This type of power tool represents a significant advancement in woodworking and construction. Operating without the constraint of air hoses or cords, it provides portability and ease of use. These tools are specifically designed for driving finish nails, which are characterized by their small head and are used to fasten trim, molding, and other fine woodworking elements where a concealed appearance is desired.

The convenience of a cordless system enhances productivity and reduces setup time on job sites. Eliminating the need for compressors or electrical outlets makes the tool ideal for tasks in remote locations or areas with limited power access. Historically, pneumatic nailers were the standard, but battery-powered alternatives offer comparable power and performance while mitigating the drawbacks associated with compressed air systems. This advancement allows for greater efficiency and flexibility on a variety of projects.

The following sections will delve into specific aspects, including operational features, performance metrics, maintenance requirements, and comparative analyses with similar tools on the market. This will offer a thorough understanding of its capabilities and limitations in various applications.

Operational and Maintenance Tips

This section provides guidance for optimal usage and longevity of the tool. Adhering to these recommendations will ensure consistent performance and minimize potential issues.

Tip 1: Battery Management: Always fully charge the battery before initial use. Consistent partial charging can diminish battery lifespan. Utilize the designated charger for optimal charging efficiency.

Tip 2: Depth Adjustment: Before beginning a project, adjust the drive depth to match the material’s density. Insufficient depth results in protruding nails; excessive depth damages the surrounding wood. Conduct test drives on scrap material to confirm appropriate settings.

Tip 3: Sequential Actuation vs. Contact Actuation: Understand the differences between actuation modes. Sequential actuation requires the safety contact to be depressed before the trigger is pulled, offering increased precision and safety. Contact actuation, also known as bump firing, allows for rapid nail placement but requires greater control and awareness.

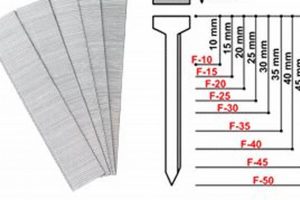

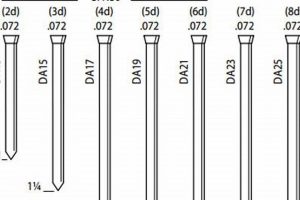

Tip 4: Nail Selection: Utilize finish nails that are compatible with the tool’s specifications. Using incorrect nail sizes or types can cause jams or damage to the internal mechanisms.

Tip 5: Regular Cleaning: Periodically clean the nailer’s nosepiece and magazine to remove debris. Accumulated sawdust and residue can impede smooth operation and increase the risk of malfunctions. Use compressed air or a small brush for cleaning.

Tip 6: Storage Practices: Store the nailer in a dry environment to prevent corrosion. Remove the battery during extended periods of inactivity to prevent slow discharge and potential damage.

Tip 7: Check Contact Tip Regularly: Inspect the contact tip (safety) for wear and tear. Replace a damaged contact tip immediately to ensure safe and reliable operation.

These tips aim to maximize the tool’s performance and lifespan, ensuring reliable operation throughout its use.

The concluding section will summarize the key aspects and provide a final perspective on its overall value and suitability.

1. Portability

The inherent design of the dewalt cordless finish nailer prioritizes ease of movement and operation in diverse work environments. Its cordless nature eliminates the dependence on external power sources, specifically air compressors and electrical outlets, which directly contributes to its enhanced mobility. This feature is particularly beneficial on construction sites where accessibility to power is limited or when working in confined spaces. The absence of hoses and cords reduces the risk of tripping hazards and allows for quicker setup and takedown times. The portability of this device increases the speed and safety of construction.

Construction crews, for example, find it advantageous when installing trim in newly built homes where electrical infrastructure may not be fully established. Similarly, remodelers working in occupied residences appreciate the reduced disruption caused by the lack of a noisy compressor. The tools compact size and relatively lightweight design further enhance its manageability, enabling users to transport it easily between job sites and navigate tight spaces with greater agility. This makes it a versatile solution for a range of tasks, from small-scale repairs to large-scale installations.

Ultimately, the portability of the dewalt cordless finish nailer represents a key advantage, fostering increased efficiency and adaptability in the field. The elimination of cords and compressors addresses a common constraint in construction and woodworking, while the tool’s lightweight design and compact size ensure user comfort and convenience. This translates to improved productivity and reduced downtime, underscoring the practical significance of its portability in real-world applications.

2. Battery Runtime

Battery runtime is a critical performance characteristic of any cordless power tool, directly influencing productivity and job completion rates. For a DeWalt cordless finish nailer, extended battery runtime minimizes downtime for recharging, enabling users to accomplish more work within a given timeframe. Several factors contribute to overall performance of runtime.

- Battery Capacity and Voltage

Higher capacity batteries, measured in amp-hours (Ah), store more energy and provide longer runtimes. Higher voltage batteries (e.g., 20V versus 18V) can deliver more power, potentially impacting efficiency. The optimal balance between capacity and voltage depends on the nailer’s design and intended use. For example, a 5.0Ah 20V battery will generally provide a longer runtime than a 2.0Ah 20V battery, allowing the user to drive more nails before needing a recharge. This is especially important on large projects where continuous operation is essential.

- Nailer Efficiency and Motor Design

The efficiency of the nailer’s mechanism and the design of its motor impact battery consumption. A well-designed nailer will drive nails with minimal energy waste, extending the battery’s usable life. Brushless motors, compared to brushed motors, are generally more efficient, reducing friction and heat generation, and thus conserving battery power. A more efficient motor will translate to more nails driven per battery charge, making the nailer more productive.

- Workload and Material Density

The type of material being fastened and the frequency of nail driving affect battery runtime. Driving nails into hardwoods requires more energy than driving them into softwoods, resulting in faster battery depletion. Similarly, continuous use at high speeds drains the battery more quickly than intermittent use. A user installing trim in oak will experience shorter battery runtime than one installing trim in pine, all other factors being equal. Adjusting work pace can extend battery life in demanding applications.

- Environmental Conditions

Extreme temperatures can impact battery performance. Cold temperatures reduce battery capacity, shortening runtime, while excessive heat can damage the battery and reduce its lifespan. Storing and using the nailer within the recommended temperature range is essential for optimal performance. For example, leaving the battery in a hot vehicle can significantly degrade its capacity, leading to shorter runtimes and reduced overall battery life.

In conclusion, the battery runtime of a DeWalt cordless finish nailer is influenced by a combination of battery characteristics, nailer design, workload, and environmental conditions. Understanding these factors is crucial for selecting the appropriate battery and optimizing usage to maximize productivity. Users should consider these elements to ensure the tool meets the demands of their specific applications, and take action to maintain batteries.

3. Nail Capacity

Nail capacity, in the context of a DeWalt cordless finish nailer, dictates the number of nails the tool’s magazine can hold at any given time. This specification has a direct impact on the user’s workflow and efficiency. A higher nail capacity reduces the frequency of reloading, allowing for longer periods of uninterrupted operation. Conversely, a lower nail capacity necessitates more frequent pauses to replenish the nail supply, potentially increasing the overall project completion time. For example, consider a trim carpenter installing baseboards around a large room. A nailer with a high nail capacity, such as 110 nails, would allow the carpenter to complete a significant portion of the work without stopping to reload. A nailer with a smaller capacity, say 50 nails, would require multiple reloadings, adding to the overall time required for the task.

The design of the nail magazine, including its loading mechanism and the type of collation used (e.g., strip or coil), influences both the nail capacity and the ease of reloading. Some nailers feature tool-free nail loading, which simplifies and expedites the reloading process. The type of collation affects the angle and size of the magazine, which is important when working in confined spaces. A DeWalt cordless finish nailer with a straight magazine and strip collation may be better suited for tight corners than one with a bulky coil magazine. The practical implication of understanding these design nuances is that users can select a tool that best fits the specific demands of their typical applications. A cabinet maker may prefer a nailer with a higher capacity and easier reloading for large projects, while a hobbyist might prioritize a compact design for maneuverability.

In conclusion, nail capacity is a significant factor to consider when evaluating the suitability of a DeWalt cordless finish nailer for a given task. It is directly related to the user’s efficiency and overall project completion time. By carefully assessing the nail capacity, magazine design, and the nature of the work, users can optimize their tool selection to maximize productivity and minimize unnecessary interruptions. Understanding this connection can prevent potential inefficiencies and ensure the tool is aligned with the project’s demands.

4. Depth Adjustment

The depth adjustment feature on a DeWalt cordless finish nailer is critical for controlling the penetration of the nail into the workpiece. This mechanism allows users to precisely regulate the driving force, ensuring that the nail is set flush with the surface or slightly countersunk, without damaging the surrounding material. The proper adjustment directly affects the quality of the finished product, preventing issues such as protruding nail heads or unsightly dents in the wood. For example, when installing delicate trim, setting the depth too deep could cause the nailer to punch through the material, splitting the wood and ruining the trim piece. Conversely, insufficient depth results in nail heads that protrude, requiring manual setting with a nail set and hammer, adding time and effort to the process.

The adjustment mechanism on a DeWalt cordless finish nailer typically involves a dial or knob that regulates the force applied to the nail. This allows for incremental adjustments, providing the user with fine-grained control over the driving depth. The specific range of adjustment varies depending on the model, but it is generally sufficient to accommodate a wide range of materials and nail sizes. The presence of this feature is significant because it allows the tool to adapt to different materials, ranging from softwoods like pine to hardwoods like oak. The accuracy of the adjustment is also paramount, as even slight variations in depth can affect the aesthetic appearance and structural integrity of the finished product. Improper depth adjustment can lead to structural weakness.

In summary, depth adjustment is an indispensable component of the DeWalt cordless finish nailer. Its accurate and reliable operation is paramount for achieving professional-quality results. The ability to fine-tune the driving depth ensures that nails are set correctly, preventing damage to the workpiece and minimizing the need for manual touch-ups. The practical significance of this feature extends to a wide range of applications, from delicate trim work to structural fastening, making it a vital tool for carpenters, contractors, and DIY enthusiasts alike.

5. Actuation Mode

Actuation mode is a fundamental setting on a DeWalt cordless finish nailer that determines how the tool is triggered to drive nails. The selection of actuation mode directly influences the speed, precision, and safety of nail placement. Understanding these modes is crucial for optimizing the tool’s performance for specific applications and ensuring user safety.

- Sequential Actuation

Sequential actuation requires the user to depress the safety contact tip against the workpiece before pulling the trigger. The nailer will only fire if the contact tip is fully engaged. This mode prioritizes precision and prevents accidental firing. It is often preferred for applications requiring careful nail placement, such as intricate trim work or delicate woodworking projects where accuracy is paramount. Its primary goal is to prevent accidental nail discharge.

- Contact Actuation

Contact actuation, also known as bump firing, allows the user to hold the trigger down and then bump the safety contact tip against the workpiece to drive a nail. This mode enables rapid nail placement and is often used for applications where speed is critical, such as framing or sheathing. However, it requires greater user control and increases the risk of accidental double firing if not used carefully. Operators have to be more careful for potential issues and safety.

- Actuation Mode Selection Mechanisms

DeWalt cordless finish nailers typically incorporate a switch or dial to allow the user to easily select between sequential and contact actuation modes. This mechanism enables quick adaptation to different tasks and user preferences. The design and placement of the selection switch are important considerations, as it should be easily accessible but also resistant to accidental changes during operation. This design should allow a professional to swap between actuation modes.

- Safety Implications

The choice of actuation mode has significant safety implications. Sequential actuation is generally considered safer, as it minimizes the risk of accidental firing. Contact actuation requires greater user awareness and control to prevent unintended nail discharge. Proper training and adherence to safety guidelines are essential when using contact actuation mode. Prioritizing safety can ensure successful projects.

The actuation mode setting on a DeWalt cordless finish nailer represents a critical parameter that directly affects the tool’s performance and user safety. The selection of the appropriate mode depends on the specific application, the user’s skill level, and the desired balance between speed and precision. Proper understanding and utilization of these modes are essential for maximizing the tool’s capabilities and ensuring safe and efficient operation. The modes selected allow the user to have more control with better safety.

Frequently Asked Questions

This section addresses common inquiries regarding the operation, maintenance, and capabilities of this power tool.

Question 1: What is the recommended nail length range for this device?

The specified nail length range is typically between 1-1/4 inches and 2-1/2 inches. Consult the tool’s manual for precise specifications, as deviations can cause malfunctions.

Question 2: How often should the nailer be cleaned and lubricated?

Cleaning should occur after each use to remove debris from the magazine and nosepiece. Lubrication is recommended after every 5000 nails or as needed, using a manufacturer-approved lubricant.

Question 3: What type of battery is compatible with this device?

This nailer is typically compatible with DeWalt 20V MAX lithium-ion batteries. Ensure compatibility before use, as using incompatible batteries can damage the tool and void the warranty.

Question 4: Can this nailer be used for both interior and exterior applications?

The device can be used for both, but appropriate nail types must be selected for the specific environment. Stainless steel or galvanized nails are recommended for exterior applications to prevent corrosion.

Question 5: What safety precautions should be observed when operating this device?

Eye protection is mandatory. Ensure the workpiece is securely supported before driving nails. Never point the nailer at oneself or others, and disengage the battery when not in use.

Question 6: How can nail jams be cleared effectively?

Disengage the battery, and utilize the tool’s jam-clearing mechanism, if equipped. If a jam persists, refer to the manual for detailed instructions, avoiding the use of excessive force.

Proper maintenance and adherence to safety guidelines are essential for the longevity and safe operation of this power tool.

The next section will delve into troubleshooting common issues and solutions.

Conclusion

This exploration has underscored the multifaceted nature of the DeWalt cordless finish nailer, encompassing operational mechanics, maintenance protocols, performance considerations, and safety imperatives. Key aspects, including battery management, depth adjustment, actuation mode selection, and nail capacity, significantly influence its efficacy across varied applications. Understanding these elements allows for informed decision-making and optimized tool utilization.

The inherent capabilities, when appropriately leveraged, contribute to enhanced efficiency and professional-grade results. However, consistent adherence to safety guidelines and diligent maintenance practices remain paramount. The future landscape may witness further refinements in battery technology and tool design, yet the fundamental principles governing its operation will endure. Proper application and sustained vigilance are essential for realizing its full potential and ensuring long-term utility.