Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

A pneumatic or cordless tool used for driving small-gauge nails into wood surfaces for delicate trim work, cabinetry, and other fine woodworking applications is a valuable asset for professionals and hobbyists alike. These tools are designed to leave minimal surface damage, concealing nail heads effectively for a polished, professional appearance. As an example, one might employ this type of tool to install decorative crown molding, securing it firmly while maintaining the aesthetic integrity of the finished product.

The importance of such a tool lies in its ability to significantly increase efficiency and precision compared to manual nailing methods. Benefits include reduced splitting of wood, consistent nail depth, and faster project completion. Historically, these devices have evolved from heavier, less precise models to lightweight, ergonomically designed instruments that offer enhanced control and maneuverability, catering to the evolving needs of the construction and woodworking industries.

The following sections will delve into the specific features, operation, maintenance, and selection criteria for this type of tool, providing a comprehensive overview for potential users and experienced professionals seeking to optimize their workflow.

Operational and Maintenance Guidance

The following guidelines are intended to optimize performance, extend the lifespan, and ensure safe operation. Adherence to these principles will contribute to achieving professional results and minimizing potential issues.

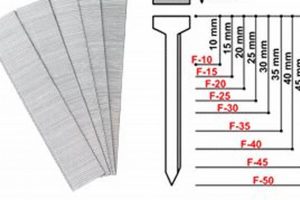

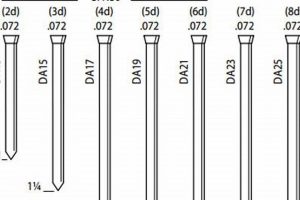

Tip 1: Nail Selection. Always utilize the appropriate nail gauge and length for the material being fastened. Using incorrect fasteners can lead to damage to both the tool and the workpiece. For example, driving a nail that is too long into thin trim will result in protrusion and compromise the finished look.

Tip 2: Consistent Air Pressure. For pneumatic models, maintaining a consistent air pressure within the manufacturer’s recommended range is crucial. Insufficient pressure may cause incomplete nail driving, while excessive pressure can damage the tool’s internal components and the material being fastened.

Tip 3: Regular Cleaning. Periodic cleaning of the tool’s nosepiece and magazine is essential to remove debris and prevent jamming. This includes disassembling the components as per the manufacturer’s instructions and using compressed air or a specialized cleaning solution.

Tip 4: Proper Storage. When not in use, store the tool in a dry, protected environment. This prevents rust and corrosion, particularly in pneumatic models where moisture can accumulate in the air compressor and delivery lines.

Tip 5: Lubrication. Pneumatic models require regular lubrication with the appropriate type of air tool oil. This ensures smooth operation of internal components and extends the tool’s service life. Apply a few drops of oil into the air inlet before each use.

Tip 6: Safety Precautions. Always wear appropriate personal protective equipment (PPE), including safety glasses and hearing protection. Ensure the workpiece is securely clamped or held in place to prevent movement during fastening.

Implementing these operational and maintenance practices contributes to the longevity and efficiency of the tool, ultimately leading to improved project outcomes.

The subsequent sections will address troubleshooting common issues and selecting the appropriate model for specific applications.

1. Nail Gauge

Nail gauge, referring to the thickness of the nail, is a critical parameter directly impacting the performance and suitability of a finishing nailer. The compatibility between nail gauge and the tool’s specifications determines the effectiveness and quality of fastening in various woodworking applications. Understanding this relationship is fundamental for selecting the appropriate tool and fasteners for a given task.

- Gauge Range and Tool Compatibility

Finishing nailers are designed to accommodate a specific range of nail gauges, typically ranging from 15 to 18 gauge. Using nails outside this range can lead to jamming, tool malfunction, or ineffective fastening. For instance, attempting to load a 15-gauge nail into a tool designed for 18-gauge nails will almost certainly cause the tool to fail to operate correctly.

- Impact on Surface Finish

The gauge of the nail directly influences the visibility of the nail head and the potential for surface damage. Finer gauges, such as 18-gauge, produce smaller holes, resulting in a more aesthetically pleasing finish, particularly in delicate trim work. Conversely, while providing greater holding power, coarser gauges may require more extensive filling and sanding to conceal the nail head.

- Holding Power and Material Thickness

Nail gauge is directly proportional to holding power. Thicker nails offer greater resistance to pull-out, making them suitable for heavier materials or applications requiring a stronger bond. Conversely, thinner nails are preferable for delicate materials to prevent splitting or damage. Therefore, selecting the appropriate gauge involves balancing holding power with the material’s susceptibility to damage.

- Application-Specific Considerations

Different woodworking applications necessitate specific nail gauges. For example, installing delicate trim might warrant an 18-gauge nail for minimal visibility, while securing baseboards to wall studs might require a 15 or 16-gauge nail for increased holding strength. Choosing the correct gauge is essential for both the structural integrity and aesthetic quality of the finished product.

In summary, nail gauge is an indispensable factor in the effective utilization of a finishing nailer. The selection process involves considering tool compatibility, desired surface finish, material thickness, and the specific requirements of the intended application. Adherence to these considerations ensures optimal performance, longevity of the tool, and a professional-quality outcome.

2. Power Source

The power source fundamentally dictates the operational characteristics and application suitability of a finishing nailer. Two primary power source options exist: pneumatic (compressed air) and cordless (battery-powered). Each system imparts distinct advantages and disadvantages, directly influencing performance, portability, and overall user experience. A pneumatic system derives its energy from an external air compressor, delivering consistent power and enabling extended operation without the limitations imposed by battery life. Cordless systems, conversely, offer enhanced mobility and convenience, eliminating the need for hoses and compressors at the expense of runtime and potentially, consistent power output.

The choice between pneumatic and cordless models directly impacts the tool’s applicability in various scenarios. For instance, a pneumatic finishing nailer is often preferred in high-volume production environments or stationary workshops where a readily available compressed air supply ensures continuous operation. Conversely, a cordless model proves advantageous on remote job sites, punch-list work, or applications requiring maneuverability in confined spaces. Consider the example of a trim carpenter installing molding on a multi-story building; a cordless nailer allows freedom of movement without the constraints of dragging an air hose, enhancing efficiency and reducing trip hazards. Furthermore, the power source directly affects the tool’s weight and balance, influencing user fatigue during prolonged use.

In summary, the power source constitutes a defining characteristic of a finishing nailer, shaping its performance profile and determining its optimal application domains. Pneumatic systems offer consistent power and extended runtime, suitable for stationary or high-demand environments. Cordless systems prioritize portability and convenience, making them ideal for mobile applications. The informed selection of a finishing nailer necessitates a thorough evaluation of power source attributes, aligning these characteristics with the specific requirements of the intended tasks, thus ensuring both efficiency and effectiveness.

3. Depth Adjustment

Depth adjustment, as a feature on a finishing nailer, provides control over the extent to which fasteners are driven into the workpiece. The tool achieves this control through a mechanism that regulates the force and travel of the nail-driving piston. Inadequate depth adjustment can result in nail heads protruding above the surface, compromising the aesthetic finish. Conversely, excessive depth can lead to nails being driven too deeply, potentially damaging the material. For example, when installing delicate trim around a window, precise depth adjustment ensures that the nail heads are flush with the surface, avoiding unsightly marks and the need for filling.

The relationship between depth adjustment and the quality of the finished product is direct and quantifiable. Proper adjustment minimizes surface marring, eliminates the need for extensive filling or sanding, and ensures a professional appearance. The absence of a reliable depth adjustment mechanism can lead to inconsistent nail placement, increasing the time and effort required to achieve satisfactory results. Using a finishing nailer without depth adjustment on hardwood materials could easily cause the nails to sink too deep, creating indentations and weakening the wood.

Effective use of a depth adjustment mechanism is crucial for achieving optimal results with a finishing nailer. Understanding the material properties and adjusting the tool accordingly is paramount. Depth adjustment directly impacts the finished product’s appearance and structural integrity. In summary, it allows for a precise, consistent, and professional-quality outcome, while its absence can lead to flawed work. Thus, this feature is a substantial component to the overall quality.

4. Ergonomics

Ergonomics, pertaining to the design and arrangement of tools and workspaces to fit the user, holds significant relevance in the context of a finishing nailer. The interaction between the user and the tool directly impacts efficiency, fatigue, and the potential for musculoskeletal disorders. Consequently, ergonomic design elements in a finishing nailer contribute directly to user productivity and long-term health. A tool with poor ergonomics, such as an unbalanced weight distribution or an awkwardly positioned grip, can lead to increased strain and reduced control during operation.

Design features contributing to a tool’s ergonomic profile include weight, balance, grip design, and trigger mechanism. A lightweight tool minimizes fatigue during prolonged use, while balanced weight distribution enhances control and reduces strain on the user’s wrist and arm. A well-designed grip conforms to the natural contours of the hand, reducing pressure points and improving comfort. A responsive trigger mechanism minimizes the force required for activation, further reducing fatigue. The cumulative effect of these ergonomic features translates into increased accuracy, reduced error rates, and improved overall user experience. For instance, consider the difference between using a nailer with a D-shaped handle and one with a contoured, rubberized grip; the latter provides a more secure and comfortable hold, enabling the user to maintain control and reduce hand fatigue, especially during extended tasks like installing wainscoting.

The integration of ergonomic principles into the design of finishing nailers presents a multifaceted challenge. Manufacturers must balance considerations of weight, size, power, and durability while optimizing user comfort and reducing the risk of injury. Overcoming this challenge requires incorporating user feedback, conducting thorough testing, and continuously refining design elements to enhance the tool’s ergonomic profile. Ultimately, the successful integration of ergonomics into the design of a finishing nailer yields tangible benefits for both the user and the overall quality of the finished product. A well-designed tool not only improves efficiency and reduces fatigue but also contributes to a safer and more productive work environment.

5. Maintenance

Consistent and appropriate maintenance is paramount to ensuring the long-term functionality and operational effectiveness of a finishing nailer. Neglecting maintenance procedures can lead to diminished performance, increased repair costs, and a shortened lifespan. A proactive maintenance regimen safeguards the investment in the tool and ensures consistent, reliable performance on the job site.

- Daily Cleaning

Daily cleaning protocols are essential for removing debris and preventing malfunctions. Sawdust, wood chips, and other particulate matter can accumulate in the nailer’s nosepiece and magazine, leading to jamming and reduced nail-driving power. A simple procedure involving compressed air and a clean cloth can significantly extend the tool’s operational life. For example, removing accumulated sawdust after each use prevents hardened residue buildup that can obstruct the nail feed mechanism.

- Lubrication

Proper lubrication is crucial for pneumatic models. Air tool oil introduced into the air inlet lubricates internal components, reducing friction and wear. A lack of lubrication can lead to increased wear on the piston and other moving parts, resulting in reduced performance and potential failures. Applying a few drops of air tool oil before each use can prevent premature wear and maintain optimal operational efficiency.

- Inspection and Replacement of O-Rings and Seals

O-rings and seals are critical components in pneumatic nailers, responsible for maintaining airtight seals and preventing air leaks. Over time, these components can degrade due to wear and tear, resulting in reduced pressure and diminished performance. Regular inspection and replacement of worn O-rings and seals are necessary to maintain optimal tool functionality. Failure to address degraded seals can result in a noticeable reduction in nail-driving power and increased air consumption.

- Cordless Model Battery Care

For cordless models, proper battery care is essential for maximizing battery life and ensuring consistent performance. This includes following the manufacturer’s recommendations for charging and storage, avoiding extreme temperatures, and preventing over-discharge. Neglecting battery care can lead to reduced runtime, diminished charging capacity, and premature battery failure. A well-maintained battery ensures the cordless nailer operates at its peak performance for extended periods.

These maintenance facets, when diligently observed, collectively contribute to the sustained performance and longevity of the finishing nailer. Implementing these practices minimizes downtime, reduces repair costs, and ensures consistent, reliable operation. Furthermore, adherence to recommended maintenance schedules often correlates with upholding warranty provisions, providing additional protection for the investment in the tool.

6. Safety Features

Incorporating safety features into the design and operation of a finishing nailer is essential for mitigating the inherent risks associated with using a high-powered fastening tool. These features are engineered to protect the operator and bystanders from potential injuries resulting from accidental nail discharge, improper handling, or tool malfunction. Their effectiveness hinges on proper usage, maintenance, and adherence to manufacturer guidelines.

- Contact Trip Mechanism

The contact trip mechanism, also known as a sequential or restrictive trigger, prevents accidental nail discharge. It requires the tool’s nosepiece to be fully depressed against the workpiece before the trigger can be activated. This mechanism ensures that the nail is only driven when the tool is intentionally positioned, minimizing the risk of unintentional firing. For example, if the tool is dropped, the nail will not discharge unless the nosepiece is pressed against a surface, significantly reducing the potential for injury.

- Adjustable Exhaust Deflector

An adjustable exhaust deflector allows the user to direct the exhaust air away from themselves and bystanders. High-pressure exhaust can stir up dust and debris, creating a potential hazard for eye and respiratory irritation. By adjusting the deflector, the user can control the direction of the exhaust, minimizing the risk of inhaling or being struck by airborne particles. In enclosed spaces, this feature is particularly important for maintaining a clean and safe working environment.

- Locking Mechanisms

Some models incorporate locking mechanisms to prevent unintentional firing when the tool is not in use or during maintenance. These mechanisms may involve a trigger lock or a power switch that disables the tool’s operation. Engaging the locking mechanism when changing nails or performing repairs prevents accidental discharge, reducing the risk of injury during non-operational periods. These mechanisms are particularly useful when transporting or storing the tool.

- Overload Protection

Cordless models are often equipped with overload protection circuitry that prevents damage to the motor and battery in the event of excessive load or overheating. This feature automatically shuts down the tool when it detects an overload condition, protecting the internal components from damage and preventing potential hazards such as battery fires. This is especially helpful in prevent any damages during use.

These safety features represent integral components in the design of a finishing nailer, significantly reducing the risk of accidents and injuries. Adhering to recommended safety practices, combined with the use of tools equipped with these features, contributes to a safer and more productive work environment. Furthermore, prioritizing safety in the selection and operation of a finishing nailer protects not only the user but also those working in the surrounding area.

7. Applications

The versatility of a finishing nailer is demonstrably evident in its broad range of applications across various construction and woodworking domains. The specific task dictates the required nail gauge, power source, and precision level, underscoring the importance of selecting the appropriate tool model and settings for each application.

- Trim and Molding Installation

A primary application involves securing trim and molding, including baseboards, crown molding, door casings, and window casings. The tool’s ability to drive nails flush with the surface, or slightly countersunk, is crucial for achieving a seamless and aesthetically pleasing finish. Precise depth control is essential to prevent damage to delicate trim pieces. Example: Securing intricate crown molding requires a consistent nail depth to avoid splitting the wood and maintaining a uniform appearance.

- Cabinetry and Furniture Assembly

Finishing nailers facilitate the assembly of cabinets, drawers, and other furniture components. The tool allows for the precise and rapid fastening of parts, contributing to efficient production workflows. The use of appropriate nail gauges minimizes the visibility of nail heads, maintaining the overall aesthetic quality of the finished product. Example: Assembling drawer boxes requires the secure fastening of sides, fronts, and backs, where a finishing nailer provides both speed and precision.

- Paneling and Wainscoting

Installation of paneling and wainscoting benefits from the controlled fastening capabilities of a finishing nailer. These tools enable installers to quickly and accurately secure panels to walls, ensuring a consistent and professional appearance. Appropriate nail spacing and depth adjustment are critical for preventing panel warping or loosening over time. Example: Installing wood paneling in a room requires consistent nail placement to avoid visible fasteners and ensure the panels remain securely attached to the wall studs.

- Staircase Construction

Component fastening in staircase construction benefits from a finishing nailer. These are utilized for installing risers, treads, and decorative elements, providing secure and consistent attachment without visible fasteners. For instance, installing stair treads often uses a finishing nailer to secure the treads to the stringers, providing added support while minimizing the visible nail holes.

These applications demonstrate the broad utility of a finishing nailer, highlighting its ability to improve efficiency, precision, and aesthetic quality in various construction and woodworking projects. Selection of the appropriate tool and careful consideration of the specific requirements of each application remain crucial for achieving optimal results. The diversity of these applications underscores the value of a well-maintained and versatile tool in a professional setting.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the operation, maintenance, and selection of these tools. The information presented aims to provide clarity and ensure informed decision-making.

Question 1: What nail gauge is appropriate for installing baseboards with this type of tool?

The selection of nail gauge depends on the material and thickness of the baseboard, as well as the substrate. Generally, 15- or 16-gauge nails are suitable for securing baseboards to wall studs, providing sufficient holding power. However, for thinner baseboards or when nailing into drywall only, an 18-gauge nail may be preferable to minimize splitting.

Question 2: How frequently should a pneumatic model be lubricated?

Pneumatic models require regular lubrication to ensure smooth operation and prevent premature wear. Lubrication with air tool oil should occur before each use, typically by adding a few drops into the air inlet. More frequent lubrication may be necessary in high-volume applications or dusty environments.

Question 3: What safety precautions should be observed when operating a finishing nailer?

Appropriate personal protective equipment (PPE), including safety glasses and hearing protection, is mandatory. The workpiece must be securely clamped or held in place to prevent movement during fastening. The tool must be inspected for proper functioning before each use. Additionally, the user must be familiar with the tool’s operating manual and safety guidelines.

Question 4: What is the advantage of a cordless model over a pneumatic model?

Cordless models offer enhanced portability and eliminate the need for an air compressor and hose, providing greater freedom of movement on the job site. This is particularly advantageous in remote locations or confined spaces where access to a compressed air source is limited. The trade-off involves battery life and potential differences in power output.

Question 5: How can nail jamming be prevented?

Nail jamming can be minimized by using the correct nail gauge and length for the tool, ensuring the nail magazine is properly loaded, and regularly cleaning the tool’s nosepiece and magazine to remove debris. Damaged or bent nails should be discarded to prevent further issues.

Question 6: What maintenance should be performed on a cordless model?

Maintenance of cordless models primarily focuses on battery care and regular cleaning. Batteries should be charged and stored according to the manufacturer’s recommendations to maximize their lifespan. The tool’s nosepiece and magazine should be cleaned periodically to remove debris. The tool’s housing should be wiped down to remove dust. The tool should be stored in a dry condition.

Understanding these frequently asked questions provides a foundation for the effective and safe use of these tools. Adherence to recommended practices ensures optimal performance and longevity.

The subsequent sections will explore advanced troubleshooting techniques and delve into specific application scenarios in greater detail.

Concluding Assessment of Finishing Nailers

This exploration has illuminated the essential characteristics of the dewalt finishing nailer, encompassing operational mechanics, maintenance necessities, power source considerations, safety protocols, and diverse applications. Precise nail gauge selection, depth adjustment proficiency, and consistent adherence to safety guidelines remain paramount for optimal tool performance and user protection.

Recognizing the intricacies of a finishing nailer empowers users to maximize its potential, thereby elevating workmanship quality and enhancing project efficiency. Continuous adherence to maintenance schedules and judicious component selection is critical for achieving enduring operational efficacy. Therefore, understanding these tools is not merely procedural; it is integral to ensuring long-term project success and user safety.