Warning: Undefined array key "https://bestfinaltouch.com/epoxy-resin-wood-finish" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

A durable, glossy coating applied to timber surfaces results from a two-part chemical reaction. This substance, when cured, forms a hard, protective layer. For example, a tabletop might be encased in this clear substance to enhance its appearance and protect it from damage.

The use of this approach provides significant protection against moisture, scratches, and UV damage. Its self-leveling properties often create a smooth, glass-like surface, enhancing the natural beauty of the wood. Historically, alternatives offered less robust protection, requiring more frequent maintenance and lacking the same level of aesthetic enhancement.

The following sections will detail application techniques, suitable wood types, safety precautions, and available options for achieving a professional, long-lasting result. These aspects are essential for maximizing the coating’s performance and ensuring the longevity of the treated wood.

Application Recommendations

Achieving optimal results with a clear coating requires careful preparation and precise execution. These recommendations outline essential steps for a professional outcome.

Tip 1: Surface Preparation is Paramount: Thoroughly sand the wood surface, progressing through increasingly finer grits. Remove all dust and debris with a tack cloth or vacuum. Any imperfections will be magnified by the clear coating.

Tip 2: Precise Measurement and Mixing: Adhere strictly to the manufacturer’s recommended ratio of resin to hardener. Inaccurate proportions can lead to incomplete curing, resulting in a soft or tacky surface. Use calibrated measuring tools.

Tip 3: Temperature Control is Crucial: Maintain a consistent temperature within the manufacturer’s specified range during mixing and curing. Extreme temperatures can affect the curing process and the final finish quality.

Tip 4: Slow, Deliberate Mixing Technique: Mix the resin and hardener slowly to minimize air bubble formation. Entrapped air bubbles will compromise the clarity and appearance of the finished surface. Avoid vigorous stirring.

Tip 5: Multiple Thin Coats Yield Superior Results: Apply several thin coats rather than one thick coat. This allows for better self-leveling and reduces the risk of trapped air bubbles and uneven curing.

Tip 6: Bubble Removal Techniques: After application, use a heat gun or torch with a low flame to gently remove any surface bubbles. Exercise caution to avoid scorching or damaging the surface. Work quickly and efficiently.

Tip 7: Curing Time and Protection: Allow sufficient curing time as specified by the manufacturer before subjecting the finished surface to use. Protect the surface from dust and contaminants during the curing process to maintain its clarity and gloss.

Adhering to these recommendations will contribute to a durable, visually appealing, and long-lasting protective layer on wood surfaces. The subsequent sections address advanced techniques and troubleshooting for specialized applications.

1. Protection Against Wear

The capacity of an epoxy resin wood finish to provide robust protection against wear is a primary determinant of its value and longevity. Wear, in this context, encompasses various forms of surface degradation, including scratches, abrasions, impacts, and the effects of repeated contact with objects. The inherent hardness and chemical resistance of the cured coating contribute directly to its ability to withstand these destructive forces. For example, a bar top coated with this finish is far less susceptible to scratches from glassware and spills of alcoholic beverages than one finished with traditional varnish.

The protective characteristics are not solely intrinsic to the material itself; they are significantly influenced by the application process. Adequate surface preparation, including proper sanding and cleaning, ensures optimal adhesion of the resin to the wood substrate. This strong bond prevents the finish from chipping or peeling, maintaining its barrier against wear. Furthermore, the thickness of the applied layers plays a critical role; multiple thin coats generally provide superior wear resistance compared to a single thick coat, as the former allows for more complete curing and reduces the likelihood of internal stresses that could lead to cracking. Consider the difference between a lightly used decorative wooden bowl coated with a thin layer and a heavily used butcher block counter coated with several thicker layers. The butcher block requires more durable coating.

In summary, protection against wear is an essential attribute of a well-executed synthetic resin timber application. The selection of appropriate materials, meticulous adherence to application guidelines, and a clear understanding of the intended use environment are all necessary for achieving a durable and long-lasting protective surface. Failure to prioritize wear resistance can result in premature degradation, necessitating costly repairs or replacements.

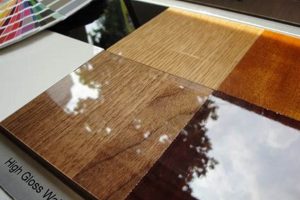

2. Aesthetic enhancement achievable

The application of a synthetic resin coating to wood directly influences its visual appeal, resulting in a significant aesthetic enhancement. This outcome stems from several properties inherent in the process. The cured resin creates a smooth, glossy surface that accentuates the natural grain and color of the wood. This effect is particularly noticeable on figured woods, where the clarity of the resin allows the intricate patterns to be seen without distortion. The resin also acts as a protective barrier, preventing oxidation and discoloration of the underlying wood, thereby preserving its original beauty over time. The ability to embed objects, such as coins, stones, or leaves, within the resin further expands the range of potential aesthetic outcomes, creating unique and personalized pieces. For example, a river table, where resin simulates a flowing river between two slabs of wood, exemplifies the transformative effect. Without the clarity and protective qualities of the synthetic resin, the natural beauty of the wood is prone to degradation.

Furthermore, the resin finish offers versatility in terms of color and texture. Pigments can be added to the resin to create opaque or translucent tints, allowing for customization to match specific design requirements. Various techniques, such as swirling or marbling, can be employed to create dynamic visual effects. The resin can also be sanded and polished to achieve different levels of sheen, from a matte finish to a high-gloss shine. This adaptability makes the finish suitable for a wide range of applications, from furniture and cabinetry to decorative art and architectural elements. A comparison between an untreated wooden item and one finished with this coating highlights the distinct improvement in visual appeal, showcasing the enhanced depth, clarity, and overall aesthetic quality.

In conclusion, the aesthetic enhancement achievable through the use of this coating is a crucial factor driving its widespread adoption. The combination of protective properties, visual clarity, and customization options provides a powerful tool for enhancing the inherent beauty of wood and creating visually stunning and durable surfaces. The ongoing refinement of resin formulations and application techniques continues to expand the possibilities for aesthetic expression, ensuring its continued relevance in woodworking and design. The main challenge is to apply the coat without the appearance of air bubbles, and doing so with precision.

3. Application Method Variations

The choice of application method is a critical determinant in the final quality and appearance of any synthetic resin coating on timber. Selecting the appropriate technique directly influences the coating’s uniformity, thickness, and the presence of imperfections, such as air bubbles or uneven surfaces. The nature of the project, the size and shape of the workpiece, and the desired aesthetic all factor into this decision.

- Pouring

Pouring is frequently used for coating large, flat surfaces, such as bar tops or table tops. This method involves carefully pouring the mixed resin onto the prepared surface and allowing it to self-level. The slow application reduces the introduction of air bubbles and promotes a smooth, consistent thickness. However, pouring requires careful control to prevent overflow and ensure even distribution, often necessitating the use of barriers or dams to contain the resin. An example is the creation of “river tables,” where colored resin is poured between wooden slabs to mimic a flowing river.

- Brushing

Brushing is suitable for smaller, more intricate projects or for applying thin coats. This method provides greater control over the application process, allowing for precise coverage of complex shapes and details. However, brushing can introduce brush strokes and air bubbles, requiring careful technique and the use of high-quality brushes designed for synthetic resins. Subsequent sanding may be needed to remove imperfections and achieve a smooth finish. Consider using a brush to apply a thin coat of protective resin to carved wooden ornaments.

- Spraying

Spraying offers the potential for achieving a very thin, even coat, particularly on large or complex surfaces. This method requires specialized equipment, including a spray gun and a well-ventilated work area, due to the atomization of the resin. The resulting finish can be exceptionally smooth and free of brush strokes, but spraying requires careful control of the resin’s viscosity and the spray gun settings to prevent runs or an uneven texture. An example is coating a guitar body with a thin, glossy layer for protection and aesthetic appeal.

- Rolling

Rolling is an option for applying coatings over large flat surfaces, similar to pouring but with a different application mechanic. Rollers must be designed for resin application to prevent bubbles and have short naps. Rolling can leave a textured look. Proper rollers avoid drips or pooling of resin. It’s a faster method than brushing but harder to control than pouring. For example, applying a coating on a large wooden door might use rolling to speed up the coating process.

In summary, the choice of application method should be carefully considered based on the project’s specific requirements. Factors such as surface area, complexity, desired finish quality, and available equipment all influence the selection process. Regardless of the chosen method, meticulous preparation and attention to detail are essential for achieving a durable, aesthetically pleasing result when utilizing synthetic resin as a wood finish.

4. Curing process essential

The curing process is an indispensable stage in the application of a synthetic resin timber application, fundamentally determining the final properties and performance of the coating. This chemical reaction, initiated by the mixing of resin and hardener, transforms the liquid mixture into a solid, durable, and protective layer. Incomplete or improper curing directly compromises the intended benefits, rendering the finish vulnerable to damage and diminishing its aesthetic appeal. For instance, a tabletop not fully cured will exhibit a soft, tacky surface, prone to scratches and easily marked by everyday use. The process is influenced by factors such as temperature, humidity, and the specific formulation of the resin, each requiring careful consideration for optimal results.

The effect of this transformation is widespread across applications. Consider a piece of furniture coated with this substance; its resistance to moisture, chemicals, and physical abrasion is directly proportional to the degree of cure achieved. Inadequate curing leads to a reduction in these protective qualities, potentially resulting in swelling, staining, or delamination of the finish. A properly cured bar top resists beverage spills and heavy use while an improperly cured one will become easily damaged and unsightly. The timeframe for curing varies based on the product. Careful monitoring and adherence to the manufacturer’s guidelines are critical to ensure that the chemical reaction proceeds to completion, resulting in a coating that meets the required performance standards.

In conclusion, the curing process represents a critical control point in the application. Achieving a thorough and uniform transformation is essential for realizing the intended protective and aesthetic benefits. Addressing the challenges associated with monitoring and controlling the curing environment, such as maintaining consistent temperatures and humidity levels, is vital for ensuring the longevity and performance. The efficacy of any synthetic resin on wood finish is ultimately dependent on the successful completion of this transformative chemical reaction.

5. Surface preparation imperative

Effective application of a synthetic resin timber application hinges critically on meticulous surface preparation. The quality and longevity of the resulting finish are directly correlated with the thoroughness of this initial stage. Surface preparation ensures proper adhesion of the resin, removes imperfections that could compromise the finish, and optimizes the aesthetic outcome.

- Removal of Existing Coatings and Contaminants

Any pre-existing finishes, such as paint, varnish, or stain, must be completely removed prior to the application of the resin. These coatings impede the direct bonding of the resin to the wood fibers, potentially leading to peeling or delamination. Contaminants like grease, wax, or dust also hinder adhesion and can cause blemishes in the finished surface. For example, failing to remove old varnish from a wooden table before applying the resin will result in a patchy, uneven finish that is prone to cracking.

- Sanding to Create a Mechanical Key

Sanding the wood surface creates a mechanical key, providing a textured surface that the resin can grip onto. Progressively finer grits of sandpaper are used to smooth the surface while simultaneously creating microscopic irregularities that enhance adhesion. Without proper sanding, the resin may not bond securely, resulting in a weak and easily damaged finish. Imagine trying to apply adhesive to a perfectly smooth piece of glass versus a slightly roughened surface; the latter provides a much stronger bond.

- Dust and Debris Removal

After sanding, it is imperative to remove all dust and debris from the surface. Even minuscule particles can become trapped within the resin, creating visible imperfections and compromising the smoothness of the finish. A tack cloth, vacuum, or compressed air can be used to thoroughly clean the surface. Failing to remove dust particles from the surface of a intricate carved wooden surface will cause air bubbles within the epoxy coat.

- Addressing Wood Imperfections

Prior to resin application, any imperfections in the wood, such as cracks, knots, or gouges, should be addressed. These imperfections can create weak points in the finish or detract from its overall aesthetic. Filling these areas with appropriate wood fillers or epoxy resins ensures a smooth, uniform surface that is suitable for the synthetic resin topcoat. The appearance of wood imperfections in a table will be magnified by the epoxy, a poorly prepared surface impacts the overall appeal.

In summary, surface preparation is not merely a preliminary step but rather an integral component of the process. By meticulously removing existing coatings, sanding to create a mechanical key, eliminating dust and debris, and addressing wood imperfections, one ensures that the applied synthetic resin coating achieves its full potential in terms of adhesion, durability, and aesthetic appeal. A well-prepared surface provides the foundation for a high-quality, long-lasting finish that enhances the natural beauty of the wood and protects it from wear and tear.

Frequently Asked Questions

This section addresses common inquiries regarding the application, properties, and maintenance of timber surfaces protected by a synthetic resin coating. The information provided aims to clarify misconceptions and offer practical guidance for achieving optimal results.

Question 1: What is the expected lifespan of a synthetic resin application on wood?

The lifespan is influenced by several factors, including the quality of the resin, the thoroughness of surface preparation, the application technique, and the level of exposure to wear and environmental factors. Under ideal conditions, a properly applied and maintained finish can last for several years, providing durable protection and aesthetic enhancement.

Question 2: Is it possible to repair scratches or damage to a resin-coated surface?

Minor scratches can often be buffed out using specialized polishing compounds. Deeper scratches or more extensive damage may require a more involved repair process, potentially involving sanding the affected area and applying a fresh layer of resin. The repair’s success depends on the extent of the damage and the skill of the repair technician.

Question 3: Does a synthetic resin finish yellow over time?

Some resins are susceptible to yellowing when exposed to ultraviolet (UV) light. However, formulations containing UV inhibitors are available, which significantly reduce this tendency. Selecting a product specifically designed for UV resistance is crucial for outdoor applications or surfaces exposed to direct sunlight. The correct selection helps to improve and protect from damaging the wood.

Question 4: What safety precautions should be observed during application?

Appropriate personal protective equipment (PPE), including gloves, respirators, and eye protection, is essential when working with these products. Adequate ventilation is also crucial to minimize exposure to harmful vapors. Always consult the manufacturer’s safety data sheet (SDS) for specific safety recommendations.

Question 5: Can a synthetic resin coating be applied to all types of wood?

While generally compatible with most wood species, certain oily or resinous woods may require special preparation to ensure proper adhesion. Consulting the manufacturer’s guidelines and performing a test application on a small, inconspicuous area is recommended to verify compatibility.

Question 6: How does temperature affect the curing process?

Temperature significantly influences the rate of the curing process. Higher temperatures generally accelerate curing, while lower temperatures can slow it down or even prevent it from occurring altogether. Maintaining a consistent temperature within the manufacturer’s recommended range is crucial for achieving optimal results. Proper temperature results in a strong and healthy coat and protection to wood.

These answers provide a general overview of common questions and concerns. Consulting with a qualified professional or referring to the manufacturer’s documentation is always recommended for specific applications or complex issues.

The subsequent section will delve into advanced techniques and considerations for specialized woodworking projects involving synthetic resin application.

Conclusion

The preceding sections have explored various facets of applying synthetic resin to wood, encompassing application techniques, material selection, and essential safety considerations. The attributes of protective qualities and aesthetic enhancement were examined, with particular emphasis on achieving a durable and visually appealing result. Surface preparation and a controlled curing process were established as critical determinants of the coating’s long-term performance. The intent has been to provide a comprehensive understanding of the variables influencing the successful implementation of this process.

Mastering these key elements enables professionals and hobbyists alike to leverage the full potential of synthetic resin in woodworking projects. Continued research and refinement of resin formulations promise further advancements in durability, UV resistance, and aesthetic possibilities. A commitment to informed practices and rigorous quality control remains paramount to ensuring the enduring value and integrity of any wood product finished with synthetic resin.The application of the synthetic resin should be with great caution and precision to create the best experience and appeal to the wood used.