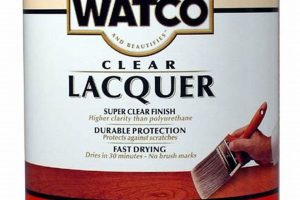

A durable, high-gloss coating system applied to wooden surfaces, it typically consists of two parts: a resin and a hardener. When combined, these components undergo a chemical reaction, creating a rigid, protective layer. Its application on a tabletop, for example, yields a smooth, seamless surface resistant to scratches, stains, and water damage.

This surface treatment offers significant advantages in both aesthetic appeal and practical longevity. Its inherent properties provide enhanced protection against environmental factors, extending the lifespan of the underlying wood. Historically, similar coatings have been utilized to preserve and enhance the appearance of wooden objects, though modern formulations offer superior performance characteristics.

The subsequent sections will delve into the specific application techniques, diverse product types available, and considerations for ensuring optimal results when utilizing such coatings.

Application Guidance for Durable Wood Coating Systems

Achieving a professional, long-lasting result with resin-based surface treatments requires careful planning and execution. The following tips outline crucial steps for successful application.

Tip 1: Surface Preparation is Paramount: Ensure the wood surface is thoroughly cleaned, sanded, and free from any contaminants such as dust, oil, or wax. Proper preparation promotes optimal adhesion and prevents imperfections in the final finish. For example, sanding to a 220-grit sandpaper is generally recommended.

Tip 2: Precise Measurement and Mixing are Critical: Adhere strictly to the manufacturer’s recommended mixing ratios for the resin and hardener. Inaccurate proportions can result in incomplete curing, leading to a soft or tacky finish. Utilize calibrated measuring containers for precise volume control.

Tip 3: Controlled Pouring Technique: Pour the mixed product slowly and evenly over the wood surface to minimize air entrapment. A gradual, consistent pour reduces the likelihood of bubbles forming within the coating. Starting in the center and working outwards is a common approach.

Tip 4: Bubble Removal is Essential: Immediately after pouring, use a heat gun or propane torch to gently pass over the surface and eliminate any trapped air bubbles. Keep the heat source moving to avoid scorching the coating. Multiple passes may be necessary.

Tip 5: Environmental Control During Curing: Maintain a consistent ambient temperature and humidity level during the curing process, as specified by the manufacturer. Fluctuations can affect the curing time and the overall integrity of the finish. A controlled environment minimizes potential issues.

Tip 6: Consider Multiple Thin Coats: For enhanced durability and a smoother finish, apply multiple thin coats rather than a single thick coat. This technique reduces the risk of air entrapment and minimizes the potential for uneven curing. Allow each coat to cure fully before applying the next.

Tip 7: Proper Safety Measures: Always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator, when working with such materials. Adequate ventilation is crucial to minimize exposure to harmful fumes.

By adhering to these guidelines, a durable, aesthetically pleasing, and professionally finished surface can be achieved, enhancing the value and longevity of wooden projects.

The subsequent section will provide a comparative analysis of various products on the market.

1. Durability

Durability, a critical attribute of any surface treatment, significantly influences the longevity and utility of wooden objects. In the context of resin-based coatings, durability encompasses resistance to various forms of wear and degradation, ensuring that the wood beneath remains protected and aesthetically pleasing over extended periods.

- Abrasion Resistance

Abrasion resistance refers to the coating’s capacity to withstand scratching, scuffing, and other forms of surface damage caused by physical contact. A high degree of abrasion resistance is essential for surfaces subjected to frequent use, such as countertops or flooring. The formulation of the resin, including the type and concentration of reinforcing particles, directly impacts its ability to resist abrasive forces.

- Impact Resistance

Impact resistance defines the finish’s ability to absorb and dissipate energy from sudden impacts without cracking or chipping. This is particularly relevant for furniture or architectural elements that may be subject to accidental blows or dropped objects. The flexibility and hardness of the cured resin contribute to its impact resistance, with more flexible formulations generally exhibiting greater resilience.

- Chemical Resistance

Chemical resistance signifies the coating’s capacity to withstand exposure to various chemicals, including household cleaners, solvents, and acids, without undergoing degradation or discoloration. This property is crucial for surfaces in kitchens and laboratories where chemical spills are likely. The molecular structure of the resin and the presence of protective additives determine its resistance to chemical attack.

- UV Resistance

UV resistance denotes the coating’s ability to withstand prolonged exposure to ultraviolet (UV) radiation from sunlight without yellowing, cracking, or losing its protective properties. UV stabilizers are often added to resin formulations to mitigate the harmful effects of UV radiation, ensuring long-term clarity and structural integrity, especially for outdoor applications.

The collective contribution of these facets defines the overall durability of resin-based wood coatings. High durability translates to a longer lifespan, reduced maintenance requirements, and sustained aesthetic appeal, making it a pivotal consideration in the selection and application of such finishes. Selecting a product with superior durability characteristics is a significant factor in protecting wooden assets and maximizing their functional lifespan.

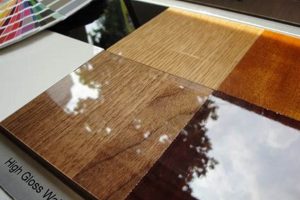

2. Clarity

The optical clarity of a resin-based coating directly influences the aesthetic outcome of wood finishing projects. A clear finish allows the natural grain, color, and texture of the wood to be fully visible, enhancing its inherent beauty. Conversely, a hazy or discolored finish obscures these features, diminishing the visual appeal of the underlying wood. This attribute is especially critical in high-end woodworking and furniture design where showcasing the natural characteristics of the wood is paramount.

The degree of clarity achieved is dependent on several factors, including the quality of the resin used, the presence of impurities, and the application technique. Impurities or air bubbles trapped within the coating can scatter light, reducing clarity. Proper mixing, degassing, and surface preparation are essential to minimize these issues. Certain resins are specifically formulated for exceptional clarity, often incorporating UV inhibitors to prevent yellowing over time. This formulation ensures the wood’s appearance remains unaltered, preserving its natural tone and character.

In summary, clarity is not merely a cosmetic attribute but a fundamental aspect of resin-based wood finishing that directly impacts the overall success of the project. Achieving optimal clarity requires careful attention to material selection, preparation, and application, ultimately resulting in a finish that enhances and protects the inherent beauty of the wood. This attribute also faces challenge from enviromental or man made condition, proper product selection is important

3. Adhesion

Adhesion is a fundamental property dictating the success and longevity of any resin-based wood coating system. It refers to the ability of the coating to form a strong and durable bond with the wood substrate, preventing delamination, peeling, or other forms of failure. Without adequate adhesion, the protective and aesthetic benefits of the finish are compromised, leading to premature deterioration and costly repairs.

- Surface Preparation Influence

Surface preparation plays a crucial role in achieving optimal adhesion. Contaminants such as dust, oil, wax, or loose particles interfere with the formation of a strong bond. Sanding creates a roughened surface, increasing the surface area available for adhesion and promoting mechanical interlocking. Cleaning with appropriate solvents removes contaminants, ensuring a clean and receptive surface for the coating. Failure to properly prepare the surface is a leading cause of adhesion failure.

- Resin Formulation Impact

The chemical composition of the resin directly affects its adhesive properties. Certain resins are formulated to provide superior adhesion to wood surfaces, often incorporating specific additives or modifiers to enhance their bonding capabilities. The molecular structure of the resin determines its ability to wet the wood surface and form strong chemical bonds. Choosing a resin specifically designed for wood substrates is essential for achieving reliable adhesion.

- Application Technique Significance

Application technique also influences the degree of adhesion. Applying the coating too thickly can lead to poor curing and reduced bond strength. Conversely, applying too thinly may not provide adequate coverage or penetration into the wood pores. Proper mixing of the resin and hardener, as well as consistent application pressure, are crucial for ensuring uniform adhesion. Following the manufacturer’s instructions carefully is essential for optimal results.

- Environmental Condition Considerations

Environmental conditions during application and curing can impact adhesion. High humidity or extreme temperatures can interfere with the curing process, reducing bond strength. Applying the coating to damp wood can also prevent proper adhesion. Maintaining optimal temperature and humidity levels, as recommended by the manufacturer, is critical for achieving a strong and durable bond.

In conclusion, adhesion is a multifaceted property that relies on careful surface preparation, appropriate resin selection, precise application techniques, and controlled environmental conditions. The integration of all these factors ensures that a high-performance, long-lasting finish is achieved. Compromising on any of these aspects increases the risk of adhesion failure, resulting in a diminished service life and compromised appearance. Utilizing a product with proven adhesive properties, coupled with meticulous execution, is paramount for ensuring the enduring protection and enhancement of wooden structures.

4. Leveling

Leveling, in the context of resin-based wood coatings, describes the ability of the applied product to self-smooth and create a uniform, even surface. This property is critical because manual application inherently introduces variations in thickness and minor imperfections. A product with excellent leveling characteristics effectively mitigates these irregularities, resulting in a professional-grade finish with minimal intervention. Without adequate leveling, the coating will exhibit brush strokes, ripples, or uneven thickness, detracting from both the aesthetic appeal and the protective function. For instance, a bar top resin, known for its high-gloss finish, relies heavily on its leveling capabilities to achieve that signature, smooth appearance. Uneven curing can also occur where the resin pools if leveling is poor.

The leveling performance of a resin-based coating is influenced by its viscosity, surface tension, and curing rate. Lower viscosity allows the product to flow more readily, filling in minor surface imperfections. Lower surface tension promotes wetting of the substrate, ensuring uniform coverage and minimizing surface irregularities. A slower curing rate provides more time for the product to self-level before solidifying. Manufacturers often incorporate additives to optimize these properties, tailoring the product for specific applications. As an illustration, formulations designed for large surface areas, such as conference tables, often prioritize enhanced leveling to minimize the need for extensive manual adjustments during application.

In summary, leveling is an indispensable attribute of resin-based wood coatings, playing a pivotal role in achieving a flawless, professional finish. Its absence necessitates laborious manual intervention, potentially compromising the integrity and appearance of the final product. Understanding the factors influencing leveling and selecting products with optimized leveling characteristics are, therefore, crucial considerations for anyone undertaking wood finishing projects. Future advancements might focus on creating systems with active leveling agents, further simplifying the application process and improving the quality of the result.

5. Curing

The process of curing is central to realizing the desired properties and performance characteristics of resin-based wood coatings. This chemical transformation from a liquid to a solid state dictates the hardness, durability, and overall resilience of the final finish, directly impacting its ability to protect and enhance wooden surfaces.

- Chemical Reaction Dynamics

Curing involves a chemical reaction between the resin and hardener components, typically initiated upon mixing. This reaction forms a cross-linked polymer network, providing structural integrity and resistance to degradation. The specific chemical makeup of the resin and hardener, as well as their mixing ratio, influence the curing rate and the properties of the resulting polymer. For instance, an improperly mixed formulation may result in incomplete cross-linking, yielding a soft or tacky finish.

- Temperature Sensitivity and Control

The curing process is highly sensitive to temperature. Elevated temperatures generally accelerate the curing rate, while lower temperatures can significantly slow it down or even prevent complete curing. Maintaining the manufacturer’s recommended temperature range during application and curing is critical for achieving optimal results. Inadequate temperature control can lead to inconsistencies in the finish, such as variations in hardness or clarity. For example, curing in an unheated workspace during winter months can result in a finish that remains pliable and prone to damage.

- Shrinkage and Stress Mitigation

During curing, most resin-based coatings undergo some degree of shrinkage as the polymer network forms. This shrinkage can induce stress within the coating and at the interface with the wood substrate, potentially leading to cracking or delamination. Formulations designed for wood applications often incorporate additives or fillers to minimize shrinkage and stress. Applying the coating in thin layers also helps to distribute stress more evenly, reducing the risk of failure.

- Complete vs. Incomplete Curing Indicators

Recognizing the signs of complete versus incomplete curing is essential for ensuring a durable and long-lasting finish. A fully cured finish will exhibit a hard, smooth surface that is resistant to scratching and indentation. In contrast, an incompletely cured finish may remain tacky, soft, or exhibit a lingering odor. Testing the hardness and chemical resistance of the finish can provide further confirmation of complete curing. Addressing any signs of incomplete curing promptly, such as by extending the curing time or increasing the temperature, is critical for preventing future problems.

The nuances of the curing process directly determine the success or failure of resin-based wood finishing projects. Thoroughly understanding the chemical dynamics, temperature sensitivity, shrinkage effects, and indicators of complete curing enables practitioners to achieve finishes that are both aesthetically pleasing and functionally robust. Careful monitoring and adherence to best practices throughout the curing phase are paramount for realizing the full potential of these surface treatment systems.

6. Protection

Resin-based wood coatings provide a crucial protective barrier against a range of environmental and physical stressors that can degrade wood. The primary function of such a finish is to isolate the wood from moisture, preventing warping, rot, and fungal growth. The impermeable nature of the cured resin acts as a shield, effectively blocking liquid penetration. For instance, a resin-coated bar top resists staining from spilled beverages, whereas untreated wood would readily absorb the liquid, leading to discoloration and eventual damage. Moreover, this type of finish provides a robust defense against physical abrasions, such as scratches and dents, maintaining the aesthetic integrity of the underlying wood. This is evident in high-traffic areas, such as flooring or table surfaces, where the coating preserves the wood’s appearance despite constant use.

Beyond moisture and physical damage, the protective qualities extend to resistance against chemical exposure. Many household cleaners and solvents can damage or discolor unprotected wood surfaces. However, a correctly applied and cured resin-based coating forms a chemically resistant barrier, safeguarding the wood from such corrosive agents. Laboratories and workshops, where chemical spills are common, greatly benefit from surfaces finished in this way. UV protection is another vital aspect, preventing fading and discoloration caused by sunlight. UV inhibitors incorporated into the resin formulation shield the wood from harmful ultraviolet rays, preserving its natural color and grain pattern over extended periods. This is particularly crucial for outdoor furniture and architectural elements exposed to direct sunlight.

In summation, the protective characteristics of resin-based wood coatings are fundamental to their value and utility. By providing a multi-faceted defense against moisture, physical abrasion, chemical exposure, and UV radiation, these finishes significantly extend the lifespan and maintain the aesthetic appeal of wooden objects. Overlooking the necessity for protection when selecting a wood finish can lead to premature degradation and costly repairs, highlighting the practical importance of understanding the protective capabilities of this type of coating.

7. Application

The application process is an inseparable component of achieving a successful resin-based wood finish. It is the practical execution of the theoretical potential inherent in the product itself. Any deviation from recommended application procedures can drastically impact the final result, irrespective of the product’s quality. Improper mixing, for example, will prevent the resin and hardener from reacting correctly, leading to a soft or uneven finish. Similarly, neglecting surface preparation, such as adequate sanding or cleaning, will compromise adhesion, resulting in peeling or bubbling.

The technique employed also dictates the aesthetic and functional characteristics of the finish. A controlled pouring method minimizes air entrapment, reducing the likelihood of unsightly bubbles. The use of appropriate tools, such as notched spreaders or brushes, ensures a uniform coating thickness, promoting even curing and leveling. Environmental factors, such as temperature and humidity, must also be carefully managed, as they can significantly affect the curing rate and the overall integrity of the finish. For instance, attempting to apply a resin coating in a cold, damp environment will almost certainly lead to a compromised result.

Ultimately, the application phase is where the inherent properties of a resin-based wood coating are either fully realized or irrevocably diminished. A meticulous approach, adherence to manufacturer guidelines, and careful consideration of environmental factors are essential for achieving a durable, aesthetically pleasing, and long-lasting finish. Overlooking the significance of application effectively negates the investment in a high-quality product, underscoring its pivotal role in the success of any wood finishing endeavor. The knowledge and skill in application ensures the full potential of this wood coating to be realised.

Frequently Asked Questions About Epoxy Wood Finish

The following addresses common inquiries regarding the use, application, and properties of resin-based wood coating systems.

Question 1: What distinguishes a quality resin-based wood coating from a lower-grade alternative?

A superior product generally exhibits enhanced clarity, UV resistance, and durability, resulting in a longer-lasting and more aesthetically pleasing finish. Lower-grade options may yellow over time, lack scratch resistance, and exhibit poor adhesion.

Question 2: Is specialized equipment required for the application of resin-based wood coatings?

While basic tools such as mixing containers, stir sticks, and application brushes are essential, specialized equipment like heat guns or propane torches may be necessary to eliminate air bubbles and ensure a smooth, even surface.

Question 3: What are the potential health and safety concerns associated with resin-based wood coatings?

These materials often contain chemicals that can cause skin irritation, respiratory problems, or other adverse health effects. It is imperative to wear appropriate personal protective equipment, including gloves, eye protection, and a respirator, and to ensure adequate ventilation during application and curing.

Question 4: How should a resin-coated wood surface be properly maintained and cleaned?

Regular cleaning with mild soap and water is generally sufficient. Abrasive cleaners or solvents should be avoided as they can damage the finish. Periodic application of a specialized polish may help to maintain the surface’s luster and protect it from scratches.

Question 5: Can resin-based wood coatings be applied to all types of wood?

While generally compatible with most wood species, certain oily or resinous woods may require special preparation to ensure proper adhesion. Testing a small, inconspicuous area is recommended before applying the coating to the entire surface.

Question 6: What is the typical lifespan of a resin-based wood coating?

The lifespan varies depending on the quality of the product, the application technique, and the environmental conditions to which it is exposed. However, a properly applied and maintained coating can provide protection and aesthetic enhancement for many years.

In summary, resin-based wood coatings offer significant benefits in terms of protection and aesthetics, but require careful selection, application, and maintenance to realize their full potential.

The subsequent section will provide an overview of suppliers of these products.

Epoxy Wood Finish

This exploration has illuminated the multifaceted characteristics of epoxy wood finish, encompassing its application, durability, clarity, adhesion, leveling, curing, and protective qualities. The analysis underscores the necessity for meticulous surface preparation, precise mixing ratios, and controlled environmental conditions to achieve optimal outcomes. Variations in product quality, ranging from inferior to superior formulations, significantly impact the longevity and aesthetic appeal of the finished surface.

Given its capacity to enhance both the visual appearance and the long-term integrity of wooden structures, a comprehensive understanding of epoxy wood finish remains paramount for professionals and enthusiasts alike. Continued advancements in material science and application technologies promise further refinements in its performance and ease of use, solidifying its position as a leading solution for wood preservation and aesthetic enhancement.