The completion of an unserialized receiver blank, often called an “80% lower,” involves machining the remaining portions necessary to function as a firearm receiver. This process typically requires specialized tools and a degree of technical skill to ensure proper tolerances and functionality. An example would be milling out the fire control cavity and drilling pin holes to allow installation of the trigger, hammer, and safety selector.

This process allows individuals to privately manufacture firearms for personal use, circumventing certain regulations associated with purchasing commercially manufactured firearms. Historically, this practice has roots in individual gunsmithing and the desire for self-reliance. Benefits include customization options and the potential for cost savings, though these are often offset by the investment in tools and the time required for completion.

The following sections will delve into specific aspects of the process, including required tooling, safety precautions, and legal considerations involved with completing such a project.

Tips on Finishing an 80 Lower

Proper technique and adherence to safety protocols are paramount when completing an 80% lower receiver. Diligence and meticulousness will contribute significantly to a safe and functional outcome.

Tip 1: Prioritize Safety: Always wear appropriate personal protective equipment, including safety glasses and hearing protection, when operating machinery. Ensure adequate ventilation to avoid exposure to metal filings and fumes.

Tip 2: Use Precise Measurement Tools: Employ calipers and depth gauges to verify dimensions throughout the machining process. Accurate measurements are crucial for proper component fit and function.

Tip 3: Follow a Detailed Blueprint: Adhere strictly to established blueprints and technical specifications for the specific receiver being completed. Deviations from these specifications can compromise the structural integrity and functionality.

Tip 4: Secure the Workpiece: Employ a robust vise or jig designed for firearm receiver work. A secure and stable workpiece is essential for achieving accurate machining and preventing damage to the receiver or tooling.

Tip 5: Use Appropriate Cutting Fluids: Apply cutting fluids liberally during machining to reduce friction, dissipate heat, and extend the life of cutting tools. The correct fluid also contributes to a smoother finish.

Tip 6: Take Gradual Cuts: Avoid removing excessive material in a single pass. Gradual, controlled cuts minimize the risk of chatter, tool breakage, and dimensional inaccuracies.

Tip 7: Deburr Thoroughly: After machining, meticulously deburr all edges and surfaces to remove sharp corners and prevent potential malfunctions. Burrs can interfere with the proper operation of internal components.

Adherence to these tips will increase the likelihood of successfully completing an 80% lower receiver with precision and safety. Remember, patience and attention to detail are essential.

The following sections will explore legal implications and considerations relevant to the private manufacture of firearms.

1. Tooling requirements

The successful completion of an 80% lower receiver is inextricably linked to appropriate tooling. Inadequate or improper tools directly impede the ability to achieve the necessary dimensional accuracy and surface finish required for a functional firearm receiver. For example, attempting to mill the fire control cavity with a hand drill, instead of a milling machine or drill press equipped with suitable end mills, invariably results in imprecise cuts and potential damage to the workpiece, rendering the receiver unusable.

Specific tooling requirements typically include a milling machine or drill press, precision measuring instruments (calipers, depth gauges), appropriate end mills and drill bits, a vise or jig designed to secure the lower receiver blank, and cutting fluids. The quality and condition of these tools directly impact the final product. Dull end mills, for instance, can cause chatter and poor surface finishes, while an unstable vise can lead to inaccurate cuts. A comprehensive understanding of machining principles and proper tool selection is therefore essential.

In summary, adequate tooling forms the foundation for completing an 80% lower receiver. Without the correct tools and the knowledge to use them effectively, achieving a functional and safe firearm receiver is highly improbable. Selecting the appropriate tools represents a critical investment that directly influences the outcome of the project and ensures compliance with safety standards.

2. Material Selection

The selection of appropriate materials is paramount to the successful completion and safe operation of an 80% lower receiver. The material’s properties directly influence the receiver’s strength, durability, and resistance to wear and corrosion under the stresses of firearm operation.

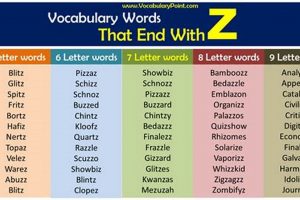

- Aluminum Alloys: 7075-T6 and 6061-T6

Aluminum alloys, particularly 7075-T6 and 6061-T6, are commonly used due to their high strength-to-weight ratio and machinability. 7075-T6 offers superior strength and fatigue resistance, making it suitable for high-stress applications. 6061-T6, while less strong, provides better corrosion resistance and is often used when cost is a primary factor. The selection between these alloys directly affects the receiver’s lifespan and ability to withstand repeated firing cycles.

- Steel Alloys: 4140 and 4150

Steel alloys, such as 4140 and 4150, offer superior strength and durability compared to aluminum, albeit at a greater weight. These alloys are typically used in critical components like the bolt carrier group and barrel extension. While less common for the entire lower receiver due to increased manufacturing complexity, steel reinforcement inserts may be used in high-stress areas to enhance longevity.

- Polymer Materials: Glass-Reinforced Nylon

Polymer-based lower receivers, typically made from glass-reinforced nylon, offer lightweight and corrosion-resistant alternatives. However, they generally lack the strength and rigidity of metal receivers. Polymer receivers are more susceptible to damage from high temperatures and impacts, and their dimensional stability may be affected by environmental conditions. These considerations impact the expected service life and overall reliability.

- Material Certification and Traceability

Ensuring the selected material meets specified standards is crucial for safety and reliability. Obtaining certified material from reputable suppliers and maintaining traceability throughout the manufacturing process helps verify that the material possesses the claimed properties. Using substandard or uncertified materials can compromise the receiver’s structural integrity and lead to catastrophic failures during operation.

The appropriate material selection for an 80% lower receiver requires a careful evaluation of factors such as strength, weight, corrosion resistance, and manufacturing complexity. The chosen material directly influences the receiver’s durability, reliability, and overall performance, ultimately impacting the safety and functionality of the completed firearm.

3. Dimensional Accuracy

Dimensional accuracy is a cornerstone of successfully completing an 80% lower receiver. The process involves machining a partially completed component to specified dimensions. Deviations from these dimensions directly correlate with functionality problems and potential safety hazards in the resulting firearm. The fire control cavity, for example, must be milled within close tolerances to ensure proper engagement and reliable operation of the trigger, hammer, and sear. Incorrect dimensions in this area may cause malfunctions, such as unintended firing or failure to fire.

Achieving dimensional accuracy necessitates the use of precision measuring tools, such as calipers and micrometers, and careful adherence to established blueprints and technical specifications. The location and diameter of pin holes, which secure the various components of the fire control group, are particularly critical. If these holes are misaligned or improperly sized, the pins may not fit correctly, leading to instability or even complete failure of the firearm’s operating mechanism. Similarly, the magazine well must be milled to precise dimensions to ensure reliable magazine insertion and feeding of ammunition.

In conclusion, dimensional accuracy is not merely a desirable attribute but a fundamental requirement for completing an 80% lower receiver safely and effectively. Failure to achieve the specified dimensions can have significant consequences, ranging from minor malfunctions to catastrophic failures that endanger the user. The meticulous attention to detail and commitment to precision are therefore paramount throughout the machining process.

4. Legal Compliance

Legal compliance is an indispensable aspect of completing an 80% lower receiver. The legal landscape surrounding privately manufactured firearms is complex and varies significantly depending on federal, state, and local jurisdictions. Understanding and adhering to these regulations is essential to avoid potential criminal penalties and ensure the lawful possession and use of any completed firearm.

- Federal Regulations: The Gun Control Act (GCA) and National Firearms Act (NFA)

The Gun Control Act of 1968 (GCA) and the National Firearms Act of 1934 (NFA) are the primary federal laws governing firearms. While the GCA generally permits the private manufacture of firearms for personal use, it prohibits individuals otherwise prohibited from possessing firearms (e.g., convicted felons) from engaging in such activities. The NFA regulates certain types of firearms, such as machine guns and short-barreled rifles. Completing an 80% lower receiver with the intent to create an NFA-regulated firearm without proper registration and tax payment is a federal crime.

- State Laws: Serialization Requirements and Restrictions

Many states have enacted their own laws regulating privately manufactured firearms. Some states require serialization of firearms manufactured from 80% lower receivers, mandating that the firearm be marked with a unique serial number registered with state authorities. Other states have outright prohibitions on the possession or manufacture of certain types of firearms, regardless of whether they were commercially manufactured or privately made. For example, some states classify assault weapons based on specific features, and manufacturing such a firearm from an 80% lower receiver may be illegal.

- Local Ordinances: Restrictions on Manufacturing and Possession

In addition to federal and state laws, local ordinances may impose further restrictions on the manufacture and possession of firearms. Some cities or counties may have regulations related to zoning, requiring specific licenses or permits for engaging in manufacturing activities. Furthermore, certain municipalities may have stricter prohibitions on certain types of firearms than state or federal laws require. Individuals must research and comply with all applicable local ordinances.

- Marking Requirements: Serialization and Identification

Federal regulations require that commercially manufactured firearms bear specific markings, including a serial number, the manufacturer’s name, city, and state. While privately manufactured firearms intended for personal use may not always be subject to the same federal marking requirements, some states mandate serialization. Even in the absence of legal requirements, marking a privately manufactured firearm with a unique identifier can be a responsible practice to deter theft and facilitate identification in the event of loss or recovery.

In conclusion, completing an 80% lower receiver entails significant legal responsibilities. The manufacture of any firearm, even for personal use, is subject to a complex web of federal, state, and local laws. Failure to comply with these regulations can result in severe criminal penalties and forfeiture of the firearm. Therefore, thorough research and adherence to all applicable laws are essential before undertaking the completion of an 80% lower receiver.

5. Safe machining practices

Safe machining practices are paramount when completing an 80% lower receiver. The process inherently involves the use of potentially dangerous power tools and equipment. Adherence to established safety protocols mitigates the risk of injury and ensures a controlled environment for completing the machining operations.

- Personal Protective Equipment (PPE)

The consistent use of appropriate PPE is a fundamental element of safe machining. Safety glasses protect against flying debris, such as metal chips, which can cause severe eye injuries. Hearing protection, in the form of earplugs or earmuffs, reduces exposure to the loud noises generated by machining equipment, preventing potential hearing damage. Gloves provide a barrier against sharp edges and cutting fluids, minimizing the risk of cuts, abrasions, and skin irritation. Neglecting PPE significantly increases the likelihood of injury during machining operations.

- Machine Guarding and Workholding

Ensuring that all machining equipment is properly guarded is essential. Machine guards prevent accidental contact with moving parts, such as rotating cutters. Furthermore, the workpiece, in this case, the 80% lower receiver, must be securely clamped in a vise or jig designed for the purpose. Inadequate workholding can lead to the workpiece becoming dislodged during machining, posing a significant safety hazard and potentially damaging the equipment or workpiece. Secure workholding is a critical factor in maintaining control and preventing accidents.

- Proper Tool Handling and Maintenance

Using the correct tool for the specific machining operation is critical. Attempting to use a drill bit as an end mill, for example, can result in tool breakage and potential injury. Tools must be inspected regularly for wear and damage. Sharp cutting edges are essential for efficient and safe machining. Dull tools require more force to operate, increasing the risk of slippage and loss of control. Regular maintenance, including sharpening or replacing worn tools, is crucial for maintaining a safe working environment.

- Ventilation and Material Handling

Machining operations generate metal chips, dust, and fumes from cutting fluids. Adequate ventilation is necessary to prevent the inhalation of these substances, which can cause respiratory irritation or other health problems. A dust collection system can help remove airborne particles. Proper handling and disposal of cutting fluids are also important to prevent skin contact and environmental contamination. Creating and maintaining a clean and well-ventilated workspace contributes significantly to a safe and healthy machining environment.

These safe machining practices are integral to the successful and responsible completion of an 80% lower receiver. Failure to adhere to these protocols not only increases the risk of personal injury but can also compromise the quality and safety of the finished product. Prioritizing safety ensures a controlled and predictable machining environment, contributing to a positive outcome.

6. Functional testing

Functional testing constitutes a critical step in the process of completing an 80% lower receiver. The machining operations performed transform a partially completed receiver blank into a functional firearm component. Functional testing is a series of evaluations conducted to verify that the finished receiver properly interfaces with other components and that the firearm operates as designed. Failure to perform adequate functional testing can result in malfunctions ranging from simple failures to feed to dangerous unintended discharges. A receiver, for example, which has a magazine well that is not machined to the correct specifications may not properly accept magazines, causing feeding failures or double feeds, rendering the firearm unreliable. The purpose of functional testing is to identify these issues and ensure their rectification.

The functional testing process typically involves several stages. Visual inspection is the first step, examining the receiver for any obvious defects, such as cracks, burrs, or dimensional inconsistencies. Next, component fit is assessed, verifying that all necessary parts, including the trigger, hammer, sear, and safety selector, fit correctly and move freely. Dummy rounds are then cycled through the action to ensure proper feeding, extraction, and ejection. Finally, if feasible and legally permissible, live-fire testing may be conducted at a designated range to confirm reliable operation under actual firing conditions. Each stage of testing identifies potential weaknesses or issues related to the dimensional accuracy and material integrity of the receiver.

In summary, functional testing is an indispensable component of completing an 80% lower receiver. It serves as the final quality control check, identifying and addressing any manufacturing defects that could compromise the firearm’s safety and reliability. Without thorough functional testing, there is no assurance that the completed receiver will perform as intended. This step is therefore critical for responsible firearm ownership and use.

7. Component compatibility

Component compatibility is a crucial consideration when finishing an 80% lower receiver. The process of transforming an unfinished receiver into a functional firearm component necessitates precise integration with a variety of other parts. Ensuring compatibility between the completed receiver and these components is fundamental to achieving a safe and reliable firearm.

- Fire Control Group Integration

The fire control group, comprised of the trigger, hammer, sear, and disconnector, dictates the firearm’s firing mechanism. The receiver must be machined to exacting specifications to accommodate these parts. Incorrectly sized or positioned pin holes can prevent proper installation, leading to malfunctions such as failures to fire, unintended full-automatic fire (in jurisdictions where this is illegal) or a complete inability to cycle the weapon. Proper fit and function testing of these components is critical.

- Upper Receiver and Barrel Assembly Mating

The completed lower receiver must properly interface with the upper receiver assembly, which houses the bolt carrier group and barrel. This interface determines the correct alignment of these critical components, directly influencing the firearm’s accuracy and reliability. An improperly machined receiver can cause misalignment, leading to excessive wear, malfunctions, or even catastrophic failure of the firearm. Headspace, for example, is a critical consideration.

- Magazine Compatibility and Feeding

The magazine well must be machined to precise dimensions to ensure reliable magazine insertion and feeding of ammunition. If the magazine well is too tight, magazines may not seat properly or may be difficult to insert. If it is too loose, magazines may wobble, leading to misfeeds and malfunctions. Compatibility with a range of magazine types is often a desired attribute. Testing with various magazines from different manufacturers is recommended.

- Buffer System Functionality

The buffer system, consisting of the buffer, buffer spring, and buffer tube, manages recoil and controls the cycling of the action. The lower receiver must be properly threaded to accept the buffer tube, and the buffer retainer must be correctly installed. An incorrectly installed or incompatible buffer system can cause excessive recoil, short stroking, or damage to the receiver or other components. Recoil management can dictate parts chosen.

Achieving full component compatibility when finishing an 80% lower requires meticulous attention to detail, precise machining, and thorough testing. The successful integration of all components into a functioning firearm is a direct testament to the accuracy and skill employed during the completion process, underscoring the critical importance of these factors in firearm construction.

Frequently Asked Questions

The following section addresses common inquiries regarding the process of completing an 80% lower receiver, focusing on legal, technical, and safety considerations.

Question 1: Is it legal to finish an 80 lower?

The legality of completing an 80% lower receiver is subject to federal, state, and local laws, which vary significantly. Federal law generally permits the private manufacture of firearms for personal use by individuals not otherwise prohibited from possessing firearms. However, state laws may impose serialization requirements, restrict the types of firearms that can be manufactured, or outright prohibit the practice. Local ordinances may further restrict manufacturing activities. Consult with legal counsel and thoroughly research all applicable laws before proceeding.

Question 2: What tools are required for finishing an 80 lower?

Finishing an 80% lower receiver typically necessitates a milling machine or drill press, precision measuring instruments (calipers, depth gauges), appropriate end mills and drill bits, a vise or jig designed for securing the lower receiver blank, and cutting fluids. The specific tools required may vary depending on the complexity of the receiver design and the desired level of precision.

Question 3: What material should be used for an 80 lower?

Common materials for 80% lower receivers include aluminum alloys (7075-T6 and 6061-T6), steel alloys (4140 and 4150), and polymer materials (glass-reinforced nylon). Aluminum alloys offer a balance of strength and machinability. Steel alloys provide superior strength and durability. Polymer materials offer lightweight and corrosion-resistant alternatives. The selection should depend on performance requirements.

Question 4: What are the key safety precautions when finishing an 80 lower?

Essential safety precautions include wearing appropriate personal protective equipment (safety glasses, hearing protection, gloves), ensuring adequate machine guarding, using secure workholding devices, employing proper tool handling and maintenance practices, and providing adequate ventilation to remove metal chips, dust, and fumes. Adherence to safety protocols is paramount to minimize the risk of injury.

Question 5: How can dimensional accuracy be ensured when finishing an 80 lower?

Dimensional accuracy is achieved through the use of precision measuring tools, such as calipers and micrometers, and meticulous adherence to established blueprints and technical specifications. Gradual, controlled cuts minimize the risk of chatter and dimensional inaccuracies. Frequent measurement and verification of dimensions are crucial throughout the machining process.

Question 6: What is the purpose of functional testing after finishing an 80 lower?

Functional testing is conducted to verify that the completed receiver properly interfaces with other components and that the firearm operates as designed. This process involves visual inspection, component fit assessment, cycling dummy rounds, and, if legally permissible, live-fire testing. Functional testing identifies and addresses any manufacturing defects that could compromise the firearm’s safety and reliability.

Proper planning, meticulous execution, and adherence to all relevant legal requirements are crucial for safely and successfully completing an 80% lower receiver.

The following section offers a concluding summary of the key points discussed in this article.

Conclusion

This article has explored the multifaceted aspects of finishing an 80 lower, emphasizing the critical interplay between legal compliance, technical proficiency, material selection, and adherence to safety protocols. Success in this endeavor is directly correlated with the commitment to meticulous planning, precise execution, and a comprehensive understanding of the governing regulations.

The private manufacture of firearms carries significant responsibilities. Prudence, thorough research, and adherence to applicable laws are paramount for those undertaking the process. Responsible and informed action ensures both the safety of the individual and compliance with legal requirements.