The process of applying a protective and enhancing coating to wooden countertops constructed from joined pieces of wood is a crucial step in their installation and maintenance. This procedure safeguards the wood from moisture, stains, and potential damage resulting from daily use. Effective completion of this task ensures a durable and aesthetically pleasing surface in kitchens and other environments. An example includes applying several coats of food-safe oil to a newly installed wooden countertop in a home kitchen.

Proper execution of this finishing process is vital for extending the lifespan and preserving the beauty of wooden countertops. It offers protection against water damage, prevents the absorption of food stains and odors, and enhances the natural grain and color of the wood. Historically, different oils and waxes have been employed to achieve this protection, adapting to available resources and evolving understanding of wood preservation techniques.

The following sections will detail the necessary preparation steps, explore different finishing options suitable for wooden countertops, and outline the proper application techniques to achieve optimal results. These detailed guidelines offer guidance for a successful project, ensuring a resilient and visually appealing surface for years to come.

Essential Guidelines for Butcher Block Countertop Finishing

Achieving a durable and aesthetically pleasing finish on butcher block countertops requires careful attention to detail and adherence to best practices. The following guidelines provide essential insights for completing the finishing process effectively.

Tip 1: Prioritize Surface Preparation: Thoroughly sand the butcher block surface, progressing through increasingly finer grits of sandpaper. This ensures a smooth and even base for the finish, promoting optimal adhesion and a professional appearance.

Tip 2: Choose a Food-Safe Finish: Select a finish specifically formulated for food contact surfaces. Options include mineral oil, beeswax, or specialized butcher block oils. These finishes are non-toxic and will not contaminate food prepared on the countertop.

Tip 3: Apply Thin, Even Coats: Avoid applying thick coats of finish, which can lead to uneven drying and a sticky surface. Instead, apply thin, even coats with a clean cloth or applicator, allowing each coat to fully dry before applying the next.

Tip 4: Observe Proper Drying Times: Adhere to the manufacturer’s recommended drying times for the chosen finish. Rushing the drying process can compromise the finish’s durability and longevity.

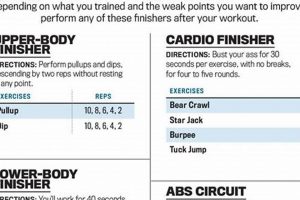

Tip 5: Consider Multiple Coats: Apply multiple coats of finish to provide adequate protection against moisture and stains. At least three coats are typically recommended, with additional coats increasing durability.

Tip 6: Regularly Maintain the Finish: Periodically reapply the finish to maintain the countertop’s protective layer and prevent moisture penetration. The frequency of reapplication depends on the countertop’s usage and exposure to moisture.

Tip 7: Address Scratches Promptly: Lightly sand any scratches or imperfections that appear on the surface and reapply the finish to the affected area. This prevents further damage and maintains the countertop’s appearance.

By following these guidelines, individuals can ensure a durable, attractive, and food-safe finish for their butcher block countertops, preserving their investment for years to come.

The subsequent sections will provide more details on finish types, application techniques, and maintenance procedures.

1. Surface Preparation

Surface preparation constitutes a foundational element in achieving a successful finish on butcher block countertops. Its influence extends beyond mere aesthetics, directly impacting the durability, longevity, and food safety of the finished surface. Proper execution ensures the chosen finish adheres correctly, providing optimal protection against moisture, stains, and bacterial growth.

- Sanding Techniques

Sanding removes imperfections, smooths the surface, and creates a mechanical key for the finish to adhere to. Progressing through increasingly finer grits of sandpaper is crucial. For instance, starting with 80-grit to remove significant imperfections, followed by 120-grit, and finishing with 220-grit, ensures a uniformly smooth surface. Improper sanding can lead to an uneven finish, visible scratches, and premature finish failure.

- Cleaning Protocols

Removing dust, debris, and oils from the sanded surface is essential for proper finish adhesion. Vacuuming followed by wiping with a tack cloth or a solvent-dampened rag effectively removes contaminants. Failure to clean thoroughly can result in the finish bonding to the contaminants rather than the wood, leading to peeling, bubbling, or discoloration.

- Moisture Content Management

Butcher block is susceptible to expansion and contraction with changes in moisture content. Ensuring the wood is properly acclimatized to its environment prior to finishing minimizes warping and cracking. Allowing the butcher block to sit in the intended location for several days before sanding and finishing allows it to stabilize. Finishing wood with excessive moisture content can trap moisture, leading to finish failure and potential mold growth.

- Repairing Imperfections

Addressing any cracks, gaps, or chips prior to finishing creates a seamless and durable surface. Wood filler or epoxy can be used to repair imperfections, ensuring a uniform surface for the finish to adhere to. Failure to address imperfections can result in them becoming more pronounced after finishing, compromising the appearance and hygiene of the countertop.

The multifaceted nature of surface preparation underscores its indispensable role in the process of finishing butcher block countertops. Neglecting any of these facets can compromise the quality and longevity of the finished product, impacting its functionality and aesthetic appeal. Prioritizing thorough surface preparation is therefore paramount for achieving a lasting and satisfactory result.

2. Finish Selection

The selection of an appropriate finish is a critical decision point in the process of applying a protective coating to butcher block countertops. This choice directly impacts the countertop’s durability, maintenance requirements, food safety, and overall aesthetic appeal. Careful consideration must be given to the properties of different finishes to ensure compatibility with the intended use and environment of the countertop.

- Food Safety Compliance

A primary consideration is selecting a finish certified as food-safe. Mineral oil, beeswax, and certain specialized butcher block oils meet this criterion. These finishes are non-toxic and do not leach harmful chemicals into food prepared on the surface. Conversely, varnishes or polyurethane finishes not specifically formulated for food contact may pose a health risk and should be avoided in direct food preparation areas. Selecting a compliant finish ensures adherence to health regulations and minimizes potential health hazards.

- Durability and Protection

The finish provides a barrier against moisture, stains, and scratches, thereby prolonging the lifespan of the butcher block. Oil-based finishes, while offering a natural look, typically require more frequent reapplication compared to more durable options like water-based acrylics or conversion varnishes. In high-traffic areas or where heavy use is anticipated, a more robust finish is advisable. The choice depends on balancing the desired aesthetic with the level of protection required. Examples include restaurants needing very durable protection, while a lightly used home counter might suffice with oil.

- Aesthetic Considerations

The finish influences the final appearance of the butcher block, enhancing or altering its natural grain and color. Mineral oil imparts a subtle sheen while highlighting the wood’s natural warmth. Polyurethane finishes offer a glossy surface and may slightly darken the wood. Tinted or stained finishes provide the opportunity to customize the countertop’s appearance to match the surrounding decor. Careful consideration of the desired visual outcome is essential to ensure the chosen finish complements the overall design.

- Maintenance Requirements

Different finishes necessitate varying levels of maintenance. Oil-based finishes require regular reapplication to maintain their protective properties. More durable finishes, such as acrylics or conversion varnishes, require less frequent upkeep but may necessitate specialized cleaning products. Understanding the maintenance requirements associated with each finish type is crucial for long-term satisfaction. An example includes oil-finished counters needing monthly oiling versus a varnished counter that is wiped clean.

The interconnected nature of these facets underscores the significance of careful finish selection. The optimal choice depends on a confluence of factors, including food safety requirements, desired durability, aesthetic preferences, and acceptable maintenance commitments. By thoroughly evaluating these considerations, individuals can ensure the chosen finish effectively protects and enhances their butcher block countertop for years to come, in accordance to the best approach on how to finish butcher block counters.

3. Application Method

The application method exerts a significant influence on the final quality and performance of a butcher block countertop finish. The chosen technique directly affects the uniformity, thickness, and overall effectiveness of the protective layer. Incorrect application can lead to a range of issues, including uneven coverage, air bubbles, streaks, and compromised durability, thereby negating the benefits of a high-quality finish. For instance, applying mineral oil with an inadequate wiping technique can result in a sticky, uneven surface, while improper brushwork with a varnish can leave visible brushstrokes.

Different finishes necessitate specific application methods to achieve optimal results. Oil-based finishes are typically applied using a clean cloth or lint-free rag, allowing for thin, even coats and thorough penetration into the wood fibers. Varnishes and polyurethanes often require the use of a high-quality brush or sprayer to ensure a smooth, consistent film thickness and minimize the risk of imperfections. The viscosity of the finish, the desired film thickness, and the surface area to be covered all factor into the selection of the appropriate application tool. A skilled artisan, knowing how to finish butcher block counters, understands these nuances and tailors the application method accordingly.

In summary, the application method is an integral component of successful butcher block countertop finishing. Mastery of various application techniques, combined with a thorough understanding of the finish’s properties, is essential for achieving a durable, aesthetically pleasing, and food-safe surface. While selecting the correct finish is important, its ultimate performance relies on the expertise applied during its application. A poorly applied high-quality finish is ultimately less effective than a well-applied standard finish, emphasizing the practical significance of this understanding when considering how to finish butcher block counters.

4. Curing Time

Curing time represents a critical phase following the application of a finish to butcher block countertops. It dictates the duration required for the finish to fully harden, achieve its intended protective properties, and ensure long-term durability. Adequate curing is essential for optimal performance and contributes significantly to the overall success of how to finish butcher block counters.

- Finish Hardness and Durability

Insufficient curing time compromises the finish’s hardness and resistance to scratches, impacts, and chemicals. For example, applying pressure or exposing a partially cured surface to moisture can result in blemishes or irreversible damage. The recommended curing period, as specified by the manufacturer, must be strictly adhered to for the finish to attain its full protective capabilities. A varnish that claims to be scratch-resistant will not live up to this claim if not allowed to cure fully.

- Solvent Evaporation and Off-Gassing

During curing, solvents within the finish evaporate, contributing to its hardening and reducing potential off-gassing. Premature use of the countertop can trap residual solvents, leading to lingering odors and potential health concerns. Complete solvent evaporation is vital for ensuring a food-safe surface, particularly when using finishes not specifically formulated for food contact. Some finishes, though food-safe once fully cured, release volatile organic compounds (VOCs) during the curing process, requiring well-ventilated conditions.

- Adhesion and Inter-Coat Bonding

Proper curing time facilitates optimal adhesion of the finish to the wood substrate and ensures strong bonding between multiple coats. Rushing the curing process can compromise the bond, leading to peeling, chipping, or delamination of the finish. For multi-coat applications, each layer must be allowed to cure sufficiently before applying the subsequent coat to ensure a cohesive and durable finish system. The failure to properly cure a first coat of stain can lead to uneven coloration when a top coat is applied.

- Environmental Factors Influence

Environmental conditions, such as temperature and humidity, significantly influence curing time. Lower temperatures and higher humidity levels can extend the curing period, while warmer and drier conditions accelerate the process. It is crucial to monitor and control these factors to ensure consistent and reliable curing. For instance, a finish that cures in 24 hours under ideal conditions may require 48 hours or more in a humid environment. Accurate assessment of these conditions is critical for how to finish butcher block counters effectively.

These facets directly tie back to how to finish butcher block counters, because adequate curing time is not merely a recommendation but an indispensable step for achieving a long-lasting, durable, and food-safe countertop surface. Failing to account for curing time can undermine the entire finishing process, resulting in premature wear, compromised aesthetics, and potential health hazards. Careful adherence to recommended curing schedules, coupled with consideration of environmental factors, is essential for realizing the full benefits of the chosen finish.

5. Food Safety

The intersection of food safety and butcher block finishing protocols is a critical consideration for surfaces intended for food preparation. The finish applied directly impacts the potential for bacterial growth, absorption of contaminants, and leaching of harmful substances into food. Improper finish selection or application can render a butcher block countertop a breeding ground for pathogens, posing significant health risks. For instance, a finish that cracks or peels provides crevices where bacteria can thrive, even with regular cleaning. Conversely, a properly applied and maintained food-safe finish creates a non-porous barrier, inhibiting bacterial growth and facilitating effective sanitation. The consequence of neglecting this aspect is direct exposure to foodborne illnesses, impacting public health and consumer safety.

Specific examples illustrate the practical importance of this connection. Mineral oil, often used as a butcher block finish, is food-safe but requires frequent reapplication to maintain its protective barrier. Specialized butcher block oils containing antimicrobial agents offer enhanced protection against bacterial growth. Alternatively, some conversion varnish products, while durable, are not food-safe unless fully cured and compliant with relevant regulations. The choice of finish, therefore, must align with the intended use of the countertop and adhere to established food safety standards. Furthermore, the process of how to finish butcher block counters should be well established.

In summary, achieving food safety on butcher block countertops necessitates a comprehensive understanding of finish properties, application techniques, and maintenance protocols. The challenge lies in balancing durability, aesthetics, and safety considerations. Failure to prioritize food safety not only compromises the intended functionality of the countertop but also poses potential health hazards, underscoring the indispensable role of informed decision-making in the finishing process. By selecting appropriate materials and implementing rigorous application procedures, individuals can ensure a safe and hygienic food preparation surface.

6. Maintenance

The long-term performance and aesthetic appeal of butcher block countertops are intrinsically linked to consistent and appropriate maintenance practices. The initial finishing process, while crucial, merely establishes a baseline level of protection. Subsequent maintenance determines the sustained resistance of the surface to moisture, stains, and microbial contamination, all of which impact the lifespan and food safety of the countertop. Neglecting maintenance renders the initial finishing efforts largely ineffective, leading to premature deterioration and potential health hazards. For example, a mineral oil finish, prized for its food safety, requires regular reapplication to replenish the protective barrier as it degrades through use and cleaning. Failure to do so results in a dry, porous surface susceptible to bacterial growth and staining. Therefore, understanding the interplay between finishing and maintenance is paramount for preserving the investment in a butcher block countertop.

Specific maintenance protocols vary depending on the type of finish applied. Oil-based finishes typically necessitate frequent reapplication of the oil, often monthly or quarterly, along with diligent wiping of spills to prevent absorption. Polyurethane or varnish finishes, offering greater durability, require less frequent reapplication but necessitate careful attention to avoid abrasive cleaners that can damage the surface. Regular cleaning with mild soap and water is generally recommended for all finish types. Sanding and refinishing may be required periodically to address deep scratches or worn areas, essentially restarting the finishing process. The frequency and intensity of maintenance directly correlate with the level of use and exposure to potentially damaging agents. For instance, a countertop used heavily for food preparation and frequently exposed to water will require more vigilant maintenance than one used primarily for light tasks.

In summary, maintenance is not a separate consideration but an integral and ongoing component of the process of how to finish butcher block counters. It bridges the gap between the initial application of a protective coating and the sustained functionality and longevity of the countertop. The effectiveness of any finishing procedure is ultimately determined by the commitment to consistent and appropriate maintenance, ensuring a durable, hygienic, and aesthetically pleasing surface for years to come. Ignoring maintenance undermines the initial finishing efforts and diminishes the value and usability of the butcher block countertop.

Frequently Asked Questions

This section addresses common queries and misconceptions regarding the proper methods and considerations for finishing butcher block countertops. These answers aim to provide clarity and ensure optimal results in achieving a durable and food-safe surface.

Question 1: Is mineral oil sufficient as a sole finish for butcher block countertops?

Mineral oil, while food-safe and easy to apply, provides limited long-term protection against moisture and staining. It necessitates frequent reapplication and may not be suitable for high-use areas. Consider supplemental finishes for enhanced durability.

Question 2: Can polyurethane be safely used on butcher block countertops intended for food preparation?

Standard polyurethane finishes are generally not recommended for direct food contact surfaces due to potential leaching of chemicals. Select a polyurethane explicitly formulated and certified as food-safe, ensuring full curing and compliance with relevant regulations.

Question 3: How often should mineral oil be reapplied to a butcher block countertop?

The frequency of mineral oil reapplication depends on usage. High-use countertops may require monthly applications, while less frequently used surfaces can be oiled quarterly. Observe the surface for dryness and water absorption as indicators.

Question 4: What is the recommended grit sequence for sanding butcher block prior to finishing?

A typical sanding sequence begins with 80-grit sandpaper to remove imperfections, followed by 120-grit to smooth the surface, and culminating with 220-grit for a fine finish. Consistent sanding ensures proper adhesion of the finish.

Question 5: How can water stains be removed from a butcher block countertop prior to refinishing?

Light water stains can often be removed with fine-grit sandpaper. Deeper stains may require bleaching or specialized wood stain removers. Ensure complete removal of residue before applying a new finish.

Question 6: What measures should be taken to prevent warping of butcher block countertops during the finishing process?

Ensure the butcher block is acclimatized to the environment prior to finishing. Apply finish evenly to all surfaces, including the underside, to minimize moisture absorption and prevent uneven expansion and contraction.

In conclusion, successful butcher block finishing requires a comprehensive understanding of material properties, application techniques, and long-term maintenance. Prioritizing food safety, durability, and appropriate preparation methods is essential for achieving optimal results.

The following section will address common mistakes to avoid when finishing butcher block countertops.

Concluding Remarks on How to Finish Butcher Block Counters

This exploration has provided a detailed overview of the essential steps and considerations involved in the appropriate finishing of butcher block countertops. Key aspects include surface preparation, finish selection, application method, curing time, food safety protocols, and ongoing maintenance. Adherence to these guidelines ensures a durable, aesthetically pleasing, and hygienic surface suitable for food preparation and other uses. The quality of the finished product directly reflects the attention to detail and the meticulous execution of each stage in the process.

The information presented herein serves as a practical guide for achieving professional-quality results. Individuals are encouraged to apply this knowledge diligently, prioritizing best practices to safeguard their investment and ensure the long-term functionality and safety of their butcher block countertops. A properly finished and maintained butcher block surface represents a commitment to quality, durability, and enduring aesthetic appeal.