The process of enhancing and protecting lumber through applied coatings is a critical step in woodworking. This treatment not only accentuates the natural beauty of the material but also provides a durable barrier against moisture, scratches, and other environmental factors. A properly executed application can transform a raw piece into a refined and lasting creation.

The selection and diligent application of a protective layer are fundamental to the longevity and aesthetic appeal of any wooden object. Historically, these methods were crucial for preserving wooden structures and tools. Today, the practice continues to be essential, ensuring that crafted items withstand the test of time while showcasing the inherent characteristics of the lumber. A well-protected surface resists wear and tear, maintaining its appearance and structural integrity for years to come.

Understanding the various types of coatings available, preparing the surface correctly, and applying the selected product meticulously are all essential elements. The subsequent sections will delve into these areas, providing a detailed guide to achieving a professional and lasting result. Focus will be placed on techniques for optimal surface preparation, selecting the appropriate protective substances, and mastering application methods for diverse project requirements.

Finishing Techniques

Achieving a professional result requires attention to detail and adherence to established best practices. The following guidance offers insights into optimizing the outcome.

Tip 1: Prioritize Surface Preparation: Before applying any coating, ensure the wood is smooth, clean, and free from imperfections. Sanding progressively through finer grits is crucial. Vacuum dust thoroughly after each sanding stage.

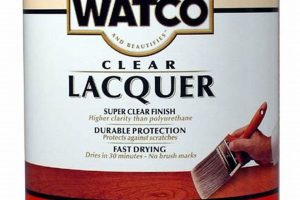

Tip 2: Select the Appropriate Coating: Different coatings offer varying levels of protection and aesthetic qualities. Consider the intended use of the item, the type of wood, and the desired appearance when making the selection. Options include varnish, lacquer, polyurethane, oil-based finishes, and water-based finishes.

Tip 3: Employ Proper Application Techniques: Follow the manufacturer’s instructions meticulously. Apply thin, even coats, allowing sufficient drying time between coats. Avoid applying coatings in excessively humid or dusty environments.

Tip 4: Utilize Sanding Between Coats: Lightly sanding between coats with fine-grit sandpaper (e.g., 320-grit or higher) can remove imperfections and create a smoother surface for subsequent coats to adhere to. Dust thoroughly after sanding.

Tip 5: Control Application Temperature: Temperature impacts the viscosity and drying time of coatings. Applying finishes within the recommended temperature range (typically specified by the manufacturer) is essential for optimal results.

Tip 6: Account for Wood Type: Different wood species react differently to finishes. Some woods may require a sealer to prevent blotching, while others may benefit from specific application techniques. Research the specific needs of the wood species being used.

Tip 7: Test the Finish: Before applying the finish to the entire project, test it on a scrap piece of the same wood. This will allow you to see how the finish looks and how it interacts with the wood, and to make any necessary adjustments.

Adhering to these principles will contribute significantly to a durable, attractive, and professional result. Consistent application of proven methodologies is key.

The subsequent section will present a detailed conclusion, summarizing the key elements for the project.

1. Surface Preparation

Surface preparation is a foundational stage. Ineffective or incomplete preparation undermines the integrity and aesthetic quality of the entire finishing process. This stage directly influences the coating’s ability to adhere correctly, creating a smooth, even, and durable final layer. For example, residual dust or oils on the lumber prevent coatings from bonding securely, leading to peeling, bubbling, or an uneven appearance. Failure to address imperfections, such as scratches or dents, prior to coating application results in these flaws being magnified by the finish, detracting from the overall visual appeal. Therefore, meticulous surface preparation is not merely a preliminary step, but rather a crucial determinant of the project’s long-term success.

Practical applications of appropriate surface preparation include thorough sanding, cleaning, and potentially the application of a wood conditioner or sealer. Sanding progresses through successively finer grits to remove imperfections and create a uniformly smooth surface. Cleaning eliminates dust, grease, and other contaminants that impede adhesion. Wood conditioners are used to even out porosity, particularly in woods prone to blotching, ensuring consistent stain absorption. Sealers can block the tannins or resins of wood from bleeding into the finish coat causing discoloration. In circumstances where projects will be exposed to moisture, these preparation methods are non-negotiable. Overlooking these steps has demonstrable impacts on the finish; for example, a table exposed to regular use will exhibit wear and tear quicker if the substrate was not sanded appropriately.

In summary, the intimate connection between surface preparation and the ultimate quality is undeniable. It impacts not only the immediate aesthetic outcome but also the coating’s capacity to provide long-term protection and resistance to wear. Challenges in surface preparation, such as dealing with uneven grain or difficult-to-reach areas, necessitate careful attention and often require specialized tools and techniques. Recognition of surface preparation as an indispensable component is vital.

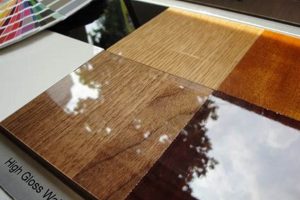

2. Coating Selection

Coating selection profoundly impacts the outcome of lumber surface treatment. It directly influences protection, aesthetics, and longevity. The appropriate coating provides a barrier against moisture, UV radiation, and physical damage. This selection is not merely a matter of preference; it is a crucial determination affecting the performance and durability. For example, using an interior varnish on exterior furniture inevitably leads to premature failure due to its lack of UV resistance, whereas an exterior spar varnish maintains its integrity under exposure to sun and weather. The relationship between the coating and the environment underscores the importance of informed selection.

The practical implications of coating choice extend to ease of application and maintenance. Some coatings, such as polyurethane, offer high durability and are relatively easy to apply, making them suitable for high-traffic surfaces like floors. Others, such as shellac, provide a classic look but require more careful application and offer less resistance to water and alcohol. Consider a wooden countertop where a penetrating oil might be chosen to protect the wood while maintaining a natural matte finish, contrasting with a glossier coating that creates a hard, reflective layer. The wrong selection would compromise the functionality. Factors such as the specific wood species, the object’s intended use, and the desired aesthetic all contribute to the decision-making process.

Challenges exist in navigating the array of available coatings and matching them correctly to specific projects. Misconceptions regarding product suitability can lead to unsatisfactory outcomes. Understanding the characteristics of each coating, its intended use, and its compatibility with the selected lumber, is essential for achieving the desired aesthetic effect and ensuring the long-term protection of the finished product. A carefully selected coating, properly applied, enhances and safeguards the lumber.

3. Application Method

The method by which a coating is applied is a critical determinant of the finish’s quality and longevity. Improper application can undermine even the highest-quality coating. The following facets highlight the significance of the application method in achieving a professional and durable result.

- Brush Application Techniques

The selection of the correct brush and employment of proper brushing techniques directly impact the smoothness and uniformity of the finish. Natural bristle brushes are often preferred for oil-based coatings, while synthetic brushes are better suited for water-based products. Applying the coating in smooth, even strokes, following the grain of the wood, minimizes brush marks. Failure to use the correct brush or employing improper techniques, such as applying excessive pressure, can lead to unsightly brush marks and uneven coverage. For example, when applying varnish, a high-quality brush ensures minimal shedding and a consistent film thickness, contributing to a glossier, more durable finish.

- Spray Application Techniques

Spray application, utilizing either compressed air or airless sprayers, offers the potential for a flawless, factory-like finish. However, success depends on careful adjustment of the sprayer, proper viscosity of the coating, and consistent spray technique. Overlapping passes are crucial to prevent thin spots and ensure uniform coverage. Environmental factors, such as temperature and humidity, also affect the application. For instance, in high humidity, some coatings may dry slowly and be prone to runs. Proper ventilation is essential to minimize overspray and ensure worker safety. Achieving optimal results necessitates experience and attention to detail.

- Wiping Application Techniques

Wiping application is often used for oils, stains, and some varnishes. This technique involves applying the coating liberally and then wiping off the excess, leaving a thin, even layer. This method is particularly suitable for accentuating the grain of the wood and achieving a natural, matte finish. The type of cloth used is important; lint-free cloths are essential to prevent fibers from being trapped in the finish. Multiple thin coats are generally preferred over a single thick coat. For example, applying a penetrating oil requires thorough wiping to prevent a sticky residue from forming on the surface.

- Considerations for Different Coating Types

The ideal application method varies depending on the coating’s characteristics. Water-based coatings often dry more quickly than oil-based coatings, requiring faster application techniques to prevent lap marks. Polyurethane coatings are prone to bubbling if applied too thickly, necessitating thin, even coats. Lacquer coatings require specialized spray equipment and excellent ventilation due to their rapid drying time and solvent content. Understanding the specific requirements of each coating type is essential for selecting the appropriate application method and achieving a successful outcome.

The selection and execution of the application method are integral to achieving a durable and aesthetically pleasing surface. Proper application enhances the protective qualities of the coating and showcases the wood’s natural beauty. Consistent technique, attention to detail, and understanding the specific requirements of the coating being used are critical for a successful outcome.

4. Durability Enhancement

Durability enhancement is intrinsically linked to the methods employed to protect lumber surfaces. The selected treatment not only imparts aesthetic qualities but also plays a fundamental role in safeguarding the substrate from environmental stressors, wear, and physical damage. The degree to which a coating can withstand these factors directly dictates the lifespan and functional integrity of the lumber. For example, a wooden deck treated with a UV-resistant sealant will resist fading, cracking, and water damage, whereas an untreated deck is susceptible to rapid degradation. The correct application is paramount in enhancing the longevity of objects.

Practical applications demonstrating the significance of durability enhancement include marine-grade varnishes on wooden boats, which protect against constant water exposure and saltwater corrosion. Similarly, catalyzed conversion varnishes used on kitchen cabinets offer exceptional resistance to abrasion, chemicals, and moisture, ensuring long-term performance in high-use environments. These examples illustrate how the selection and application of specific treatments are critical for creating surfaces that withstand demanding conditions. Factors such as the number of coats, surface preparation, and application technique contribute significantly to the final protective qualities of the treatment.

In summary, durability enhancement is an essential consideration. The investment in the correct surface protection methods translates directly into reduced maintenance costs, prolonged lifespans, and sustained aesthetic appeal. Challenges in achieving optimal durability often stem from selecting inappropriate products or failing to prepare surfaces adequately. However, the understanding and application of sound surface protection principles are indispensable for creating lumber surfaces that endure.

5. Routine Maintenance

Routine maintenance is integral to preserving the integrity and aesthetic appeal of lumber surfaces. Regardless of the initial quality of the finishing process, ongoing care is essential for maximizing the longevity and visual characteristics of treated lumber. Proper maintenance practices prevent premature wear, damage, and degradation, ensuring the surface continues to perform and appear as intended. The subsequent discussion will delve into facets of this crucial component.

- Regular Cleaning Practices

Consistent cleaning removes surface contaminants, such as dust, dirt, and spills, that can degrade the protective layer over time. The appropriate cleaning agents and methods depend on the type of surface treatment applied. For instance, a surface treated with polyurethane may be cleaned with a mild soap and water solution, whereas a waxed surface requires specialized cleaning products that won’t strip the wax. Ignoring regular cleaning results in the accumulation of grime, which can etch into the surface and necessitate more aggressive cleaning or refinishing. Proper cleaning extends the surface’s lifespan.

- Periodic Inspection and Repair

Regular inspections identify early signs of damage or wear, allowing for prompt intervention. Minor scratches or abrasions can be addressed with touch-up treatments before they escalate into more significant issues. Loose hardware or structural weaknesses should also be addressed during these inspections. For example, a wooden chair with a cracked varnish finish can be repaired with a small amount of varnish applied to the affected area, preventing further cracking and maintaining the surface’s integrity. Failure to address these problems allows them to compound and potentially necessitate complete refinishing.

- Environmental Control

Controlling the environment in which the treated lumber is situated plays a significant role in its preservation. Excessive humidity, direct sunlight, and extreme temperature fluctuations can all negatively impact the finish. For example, indoor furniture should be shielded from direct sunlight to prevent fading, and outdoor structures should be protected from prolonged exposure to rain and snow. Maintaining stable environmental conditions reduces the stress on the coating, thereby extending its lifespan and preserving its appearance.

- Reapplication of Protective Coatings

Over time, protective coatings may degrade or wear away, necessitating reapplication to maintain the desired level of protection. The frequency of reapplication depends on the type of coating, the level of use, and the environmental conditions. For instance, a wooden deck may require resealing every one to two years, while interior furniture may only need occasional polishing or waxing. Regularly reapplying protective coatings replenishes the barrier against moisture, UV radiation, and physical damage, ensuring the lumber remains protected and attractive.

These facets of routine maintenance collectively contribute to the long-term preservation and enhancement of the surface. By adhering to consistent cleaning schedules, performing regular inspections and repairs, managing environmental factors, and reapplying protective coatings as needed, the integrity of the original is prolonged, reducing the need for extensive and costly refinishing efforts. Routine care protects the investment in the object and the treatment process.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding surface treatments. These answers provide detailed explanations and practical advice for achieving optimal outcomes.

Question 1: What are the primary considerations when selecting a coating for outdoor wooden furniture?

Selecting a coating for outdoor furniture requires consideration of factors such as UV resistance, water repellency, and flexibility. Finishes should protect the wood from sunlight, moisture, and temperature fluctuations. Spar varnishes, marine-grade sealants, and penetrating oils formulated for exterior use are often recommended.

Question 2: What is the significance of sanding between coats of a coating?

Sanding between coats removes imperfections, such as dust particles and brush marks, creating a smoother surface for subsequent layers to adhere to. This process also enhances inter-coat adhesion, contributing to a more durable and uniform film. Fine-grit sandpaper (e.g., 320-grit or higher) is typically used for this purpose.

Question 3: How does wood species affect the selection and application of coatings?

Different wood species exhibit varying levels of porosity, density, and resin content, which can influence the absorption and adhesion of coatings. Softwoods, such as pine, may require a pre-treatment to prevent blotching, while hardwoods, such as oak, may require multiple coats due to their lower absorption rates. Coating recommendations should be tailored to the specific species.

Question 4: What are the potential consequences of applying a coating in excessively humid conditions?

Applying coatings in high humidity can lead to various problems, including prolonged drying times, clouding, and reduced adhesion. Excessive moisture can interfere with the curing process, resulting in a weak and compromised finish. Ideally, coatings should be applied in a controlled environment with moderate humidity levels.

Question 5: How frequently should surfaces be re-treated to maintain optimal protection?

The frequency of reapplication depends on several factors, including the type of coating, the level of exposure to environmental elements, and the degree of use. Exterior surfaces typically require more frequent re-treatment than interior surfaces. Regular inspections can help determine when reapplication is necessary.

Question 6: What are the key differences between oil-based and water-based coatings?

Oil-based coatings generally offer greater durability, penetration, and resistance to moisture. They tend to produce a richer, warmer tone but have longer drying times and emit stronger odors. Water-based coatings are typically lower in VOCs, dry more quickly, and are easier to clean up, but they may not provide the same level of durability or depth of color.

Proper lumber surface treatment is an ongoing process that requires attention to detail and adherence to best practices. By understanding and addressing common questions and concerns, individuals can achieve professional and lasting results.

The subsequent section will present concluding remarks, encapsulating the primary themes and insights from the preceding discussion.

How to Finish Wood

This exploration has underscored the comprehensive nature of how to finish wood, emphasizing surface preparation, coating selection, application techniques, durability enhancement, and routine maintenance. Each stage is interdependent, contributing to the protection and aesthetic enhancement of lumber. Adherence to established best practices remains paramount for achieving professional and lasting results.

The longevity and visual appeal of finished wood are directly correlated with the diligence applied throughout the entire process. Continued research and application of advanced techniques will undoubtedly refine future practices. A commitment to these principles ensures the preservation and enhancement of wood for generations to come. Understanding the process is key to any project.