The selection of suitable substances and surface treatments is a critical aspect of design and construction. This choice directly influences both the functional performance and aesthetic qualities of a product or structure. For example, selecting a corrosion-resistant alloy for outdoor applications ensures longevity, while applying a specific coating can achieve a desired visual appearance.

These considerations are paramount for durability, sustainability, and the overall value proposition. Historically, the availability and cost of resources heavily dictated choices. However, contemporary advancements in engineering and chemistry have broadened the scope of available options, empowering designers and engineers to optimize for various performance criteria. These criteria include lifespan, maintenance requirements, and environmental impact.

Subsequent sections will delve into the properties of diverse substances, examining their suitability for various applications. A detailed exploration of surface applications and their effect on characteristics like texture, color, and resistance to wear will also be provided. These topics are crucial for informed decision-making in design and engineering projects.

Considerations for Optimal Selection

The informed selection process requires careful evaluation. The following tips provide guidance for maximizing the performance and longevity of chosen elements.

Tip 1: Assess Environmental Exposure: Understand the conditions to which items will be exposed. This includes factors such as temperature fluctuations, humidity levels, and potential exposure to chemicals or UV radiation. Failure to consider these factors can result in premature degradation or failure.

Tip 2: Evaluate Performance Requirements: Identify the key functional requirements. Examples include load-bearing capacity, thermal conductivity, electrical insulation, or resistance to abrasion. Align selection with these critical performance metrics to ensure suitability.

Tip 3: Analyze Life-Cycle Costs: Consider the total cost of ownership, encompassing initial purchase price, installation costs, maintenance requirements, and eventual replacement. Opting for a lower-cost option may prove more expensive in the long run if it requires frequent repairs or replacement.

Tip 4: Investigate Compatibility: Confirm compatibility between disparate elements within a system. Galvanic corrosion can occur when dissimilar metals are in contact, leading to accelerated degradation. Ensure components are chemically compatible to avoid adverse reactions.

Tip 5: Review Industry Standards and Regulations: Adhere to relevant industry standards and building codes. These guidelines often specify minimum performance requirements and safety standards. Compliance ensures adherence to best practices and regulatory obligations.

Tip 6: Prioritize Sustainability: Consider the environmental impact of choices. Opt for options that are responsibly sourced, possess recycled content, or are readily recyclable at the end of their life cycle. Minimizing environmental footprint aligns with sustainable building practices.

Tip 7: Conduct Thorough Testing: Implement rigorous testing protocols to validate the performance and durability of chosen components. This proactive measure minimizes the risk of unexpected failures and ensures alignment with specified performance criteria.

Careful consideration of these factors enables informed decisions. This ensures optimal performance, longevity, and overall value in construction and manufacturing applications.

The subsequent sections will explore specific types of elements, providing a deeper understanding of their individual properties and applications. This knowledge will further enhance the decision-making process and promote successful project outcomes.

1. Durability

The longevity of any manufactured item or constructed edifice is fundamentally intertwined with the properties of its constituent substances and the protective treatments applied to their surfaces. The inherent resistance to degradation, wear, and environmental stressors directly dictates the effective lifespan of a product or structure. The selection process is therefore a crucial determinant of long-term performance and overall value. For example, the implementation of powder coatings on exposed metal components significantly enhances resistance to corrosion, thereby extending the operational life of outdoor equipment. Conversely, the utilization of inappropriate substances lacking requisite resistance to ultraviolet radiation or moisture will inevitably lead to premature failure, necessitating costly repairs or replacements.

Evaluating potential vulnerabilities under anticipated operating conditions is critical. This includes assessing resistance to abrasion, chemical exposure, temperature extremes, and mechanical stresses. The deployment of specialized polymers in high-traffic flooring applications, for instance, mitigates wear and maintains aesthetic appeal over prolonged periods. Similarly, the incorporation of UV-resistant additives in exterior coatings prevents color fading and substrate degradation, preserving the structural integrity of buildings. A failure to adequately consider these factors can result in accelerated deterioration, compromising both safety and functionality.

In summation, durability, inextricably linked to informed selection, constitutes a paramount consideration in engineering and design. Understanding the interplay between substance characteristics, environmental factors, and applied treatments is essential for ensuring long-term performance and minimizing life-cycle costs. The challenges in achieving optimal durability often involve balancing performance requirements with economic constraints and aesthetic considerations. Recognizing the critical importance of these factors contributes to sustainable design practices and the creation of resilient, long-lasting structures and products.

2. Sustainability

The selection of elemental components and surface treatments directly impacts the environmental footprint of a product or structure. Sustainability, in this context, encompasses the responsible sourcing, minimal processing, extended lifespan, and end-of-life management of resources. The conscious prioritization of environmentally benign alternatives reduces pollution, conserves natural resources, and minimizes waste generation throughout the entire lifecycle. For example, utilizing reclaimed timber in construction diverts material from landfills, reducing deforestation pressure and lowering the embodied energy associated with harvesting virgin wood. Similarly, opting for water-based coatings over solvent-based alternatives minimizes the emission of volatile organic compounds (VOCs), thereby mitigating air pollution and improving indoor air quality.

Further analysis reveals that the impact extends beyond the immediate selection. The energy required for extraction, manufacturing, transportation, and installation contributes significantly to the overall environmental burden. Choosing locally sourced items minimizes transportation distances and associated carbon emissions. Employing processes that reduce waste, such as precision cutting techniques in fabrication, further enhances resource efficiency. Consider the example of using bamboo, a rapidly renewable resource, as a substitute for traditional hardwoods in flooring. Its rapid growth rate, minimal processing requirements, and natural durability contribute to a significantly lower environmental impact compared to slower-growing, resource-intensive alternatives like oak.

In conclusion, the integration of sustainable practices within the realm of elemental components and surface treatments necessitates a holistic approach. Balancing performance requirements with environmental considerations is crucial. Challenges remain in establishing transparent supply chains and accurately quantifying the environmental impact of various options. However, a commitment to informed decision-making, coupled with technological advancements in material science, paves the way for a future where construction and manufacturing industries operate in harmony with the environment, promoting responsible resource stewardship and mitigating the adverse effects of human activities.

3. Aesthetics

Aesthetic considerations are inextricably linked to the selection of suitable elemental substances and their surface treatments. These choices are not merely functional but play a decisive role in shaping the visual appeal and perceived value of a product or structure. The correlation between these factors is not arbitrary; the inherent qualities of a substance texture, color, grain, and form directly influence the perceived aesthetics. For example, the application of a matte varnish to a wooden surface imparts a subtle, understated elegance, while a high-gloss finish on metal generates a modern, reflective aesthetic. This interplay determines how a design is perceived and experienced by the user.

The strategic deployment of contrasting elements creates visual interest and emphasizes specific design features. For instance, juxtaposing a rough-textured stone facade with smooth, polished metal accents enhances the perceived quality and sophistication of a building. Similarly, the deliberate selection of a color palette that complements the surrounding environment integrates a design harmoniously into its context. Practical application involves carefully balancing aesthetic goals with functional requirements. Achieving a desired visual effect may necessitate compromises in other areas, such as durability or cost. Therefore, a comprehensive understanding of substance properties, application techniques, and design principles is essential for successfully integrating aesthetic considerations into the design process.

In conclusion, the connection between aesthetics and the elements employed, along with their surface treatments, highlights the significance of a holistic approach to design. Aesthetics are not merely superficial embellishments but integral components that contribute to the overall value and functionality of a product or structure. While challenges exist in balancing aesthetic desires with practical constraints, a comprehensive understanding of this relationship enables designers and engineers to create visually appealing and functionally superior solutions that resonate with users and enhance the built environment. The selection and treatment of elements must be informed by an awareness of aesthetic impact, contributing to a more meaningful and impactful final product.

4. Functionality

The performance of any product or structure is intrinsically linked to the selection of its elemental substances and their subsequent surface treatments. Functionality, in this context, refers to the intended use and operational capabilities of the item, and the selection directly influences how well these requirements are met. Optimal choices ensure effective operation, durability, and user satisfaction.

- Load-Bearing Capacity

This aspect refers to the ability of a material to withstand static or dynamic loads without deformation or failure. The selection of structural steel with a high yield strength for bridge construction exemplifies this principle. Conversely, using a lightweight composite material for aircraft components prioritizes strength-to-weight ratio for enhanced fuel efficiency. The choice dictates the safety and performance limits of the structure.

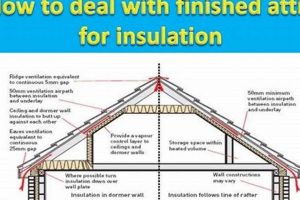

- Thermal Insulation

Controlling heat transfer is vital for energy efficiency and user comfort. Materials like fiberglass insulation or closed-cell foam are chosen for their low thermal conductivity in building envelopes. This reduces heat loss in cold climates and heat gain in warm climates, minimizing energy consumption. Similarly, specialized coatings on spacecraft protect against extreme temperature fluctuations during atmospheric re-entry.

- Chemical Resistance

Exposure to corrosive substances can degrade elemental substances, compromising functionality. The selection of stainless steel or specialized polymers in chemical processing plants ensures resistance to aggressive chemicals, preventing leaks and equipment failure. Likewise, marine coatings protect ship hulls from saltwater corrosion, maintaining structural integrity and preventing environmental contamination.

- Surface Friction

The frictional properties of a surface influence its interaction with other objects. High-friction surfaces, such as rubberized grips on tools, provide enhanced control and safety. Conversely, low-friction surfaces, such as polytetrafluoroethylene (PTFE) coatings on cookware, facilitate easy release and cleaning. Tailoring surface treatments to achieve desired frictional characteristics is crucial for optimal performance.

These interconnected aspects highlight the pivotal role of informed decisions in elemental composition and surface applications for achieving desired operational results. The selection impacts long-term performance, safety, and overall value. Careful consideration of functionality within the design process ensures the creation of efficient, durable, and user-friendly products and structures.

5. Cost-Effectiveness

The selection of appropriate elemental substances and their applied treatments inherently involves a careful evaluation of cost-effectiveness. This assessment considers the total financial implications throughout the product or structure’s lifecycle, balancing initial expenses with long-term performance, maintenance requirements, and potential replacement costs. A comprehensive understanding of cost-effectiveness is crucial for making informed decisions that optimize value and minimize financial burdens.

- Initial Material Cost vs. Lifespan

The initial expense of a substance is a primary consideration, yet it must be weighed against its anticipated lifespan. A lower-cost substance may require more frequent replacements, ultimately exceeding the total cost of a more durable, albeit initially more expensive, alternative. For instance, choosing a less expensive paint for an exterior surface might necessitate repainting every few years, while a high-quality, weather-resistant paint could last a decade or more. The long-term savings in labor and material costs associated with the higher-quality option can offset the initial investment. This necessitates a life-cycle cost analysis to accurately assess true cost-effectiveness.

- Maintenance and Repair Costs

Maintenance requirements and potential repair expenses contribute significantly to the overall cost-effectiveness evaluation. Substances that demand frequent maintenance or are prone to damage can impose substantial financial burdens over time. Consider the use of hardwood flooring versus laminate flooring in a high-traffic area. While hardwood offers a premium aesthetic, it requires regular refinishing and is susceptible to scratches and dents. Laminate flooring, though less visually appealing to some, is more resistant to wear and tear, requiring less maintenance and reducing repair costs. The long-term maintenance savings may outweigh the initial aesthetic advantage of hardwood.

- Installation Costs and Labor Requirements

Installation complexities and labor requirements also impact cost-effectiveness. Substances that are difficult to install or require specialized labor can significantly increase project expenses. For example, the installation of intricate stone veneer can be considerably more expensive than installing standard brick cladding due to the specialized skills and time required. Similarly, the use of pre-fabricated building components can reduce on-site labor costs and construction time, contributing to overall cost savings. The selection process should account for these installation-related expenses to accurately assess overall cost-effectiveness.

- Energy Efficiency and Operational Savings

The energy efficiency properties of elemental substances influence long-term operational costs. For instance, selecting highly insulated windows and doors reduces heat loss, lowering heating and cooling expenses. Similarly, utilizing reflective roofing materials minimizes solar heat gain, reducing air conditioning demands. These energy-saving features translate into significant cost reductions over the lifetime of the structure, justifying the initial investment in energy-efficient substances. A thorough analysis of energy performance is essential for evaluating cost-effectiveness in building applications.

In summary, cost-effectiveness is not simply about minimizing initial expenses; it necessitates a holistic assessment of lifecycle costs, including maintenance, repair, installation, and operational expenses. The interplay between elemental substances, surface treatments, and these cost factors emphasizes the importance of informed decision-making. A thorough cost-benefit analysis, considering both short-term and long-term implications, enables engineers and designers to optimize value and ensure the long-term financial viability of their projects.

Frequently Asked Questions Regarding Elements and Surface Applications

This section addresses common queries and misconceptions concerning the selection and application of elemental substances and their associated surface treatments. It aims to provide clarity and informative responses to promote better understanding and decision-making.

Question 1: What factors determine the optimal elemental components for a specific application?

Optimal selection hinges on a comprehensive evaluation of performance requirements, environmental conditions, and cost considerations. Critical factors include load-bearing capacity, resistance to corrosion, thermal conductivity, aesthetic preferences, and budgetary constraints. A thorough assessment of these variables is crucial for ensuring suitability and long-term performance.

Question 2: How do surface treatments affect the longevity and performance of elemental components?

Surface applications significantly influence the durability and operational characteristics of base elemental components. Protective coatings, such as paints, varnishes, and powder coatings, enhance resistance to environmental degradation, abrasion, and chemical exposure. Specialized treatments, such as anodizing and electroplating, can alter surface hardness, conductivity, and aesthetic appeal, thereby extending lifespan and improving functionality.

Question 3: What are the primary considerations for selecting sustainable elemental components and surface applications?

Sustainable choices prioritize responsible sourcing, minimal processing, extended product lifecycles, and end-of-life recyclability. Preference should be given to components with recycled content, low embodied energy, and minimal environmental impact during manufacturing and disposal. Water-based coatings and bio-based materials offer environmentally benign alternatives to conventional petroleum-based options.

Question 4: How does cost-effectiveness influence the selection process?

Cost-effectiveness involves a comprehensive assessment of lifecycle costs, encompassing initial purchase price, installation expenses, maintenance requirements, and potential replacement costs. While minimizing upfront expenses is a consideration, it is crucial to prioritize long-term value by selecting durable, low-maintenance components that offer superior performance and extended lifespans.

Question 5: What role do industry standards and regulations play in the selection process?

Adherence to relevant industry standards and building codes is essential for ensuring safety, performance, and regulatory compliance. These guidelines specify minimum performance requirements, testing protocols, and safety standards for various elemental components and surface applications. Compliance with these standards mitigates risks and ensures adherence to best practices.

Question 6: How can potential compatibility issues between dissimilar elements be addressed?

Compatibility issues, such as galvanic corrosion between dissimilar metals, can lead to accelerated degradation. To mitigate these risks, material compatibility charts should be consulted, and appropriate insulation techniques, such as dielectric barriers, should be employed. Careful selection and proper installation practices are crucial for preventing adverse reactions and ensuring long-term structural integrity.

In essence, the selection and implementation of elemental substances and their surface applications demands a comprehensive understanding of performance requirements, sustainability considerations, cost implications, and regulatory compliance. Informed decision-making, guided by sound engineering principles and industry best practices, ensures optimal outcomes and long-term value.

The subsequent sections will explore various case studies and practical examples, illustrating the application of these principles in real-world scenarios.

Conclusion

This exploration of materials and finishes underscores their critical influence on the performance, longevity, sustainability, aesthetics, functionality, and cost-effectiveness of any product or structure. A thorough understanding of these interdependent factors enables informed decision-making. It also ensures optimal results across diverse applications, from structural engineering to product design.

The discerning selection and application of materials and finishes remain paramount for achieving project goals. Continued advancement in material science, coupled with a commitment to sustainable practices, will shape the future of construction and manufacturing. This will ultimately enable the creation of more durable, efficient, and environmentally responsible solutions for generations to come. Further research and development in this area are essential for maximizing these benefits.