Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

This pneumatic or cordless electric tool, manufactured by Milwaukee Tool, drives finish nails into wood for trim and other fine woodworking applications. It is designed to provide a clean, countersunk nail head for a professional appearance. Examples of use include installing baseboards, crown molding, door casings, and window frames.

The significance of this type of tool lies in its ability to efficiently and precisely secure finish materials without splitting the wood or leaving unsightly marks. Its adoption has streamlined woodworking and carpentry processes, enabling quicker project completion and enhanced aesthetic results. Historically, finish work relied heavily on manual nail setting, a time-consuming and less accurate method.

The following sections will delve into the specific features, functionalities, maintenance requirements, and appropriate applications associated with this fastening implement, allowing for a more comprehensive understanding of its role in various construction and woodworking scenarios.

Operating Considerations

Effective utilization of this tool requires adherence to specific operational guidelines to ensure optimal performance and safety.

Tip 1: Material Compatibility: Select the appropriate nail gauge and length based on the density of the wood being fastened. Using an excessively large nail can cause splitting, while an insufficient nail may compromise holding strength. For example, when attaching delicate trim to softwood, a finer gauge and shorter nail length are advisable.

Tip 2: Depth Adjustment Calibration: Prior to commencing work, precisely adjust the depth setting to achieve consistent countersinking without damaging the surrounding material. Test the setting on a scrap piece of wood similar to the workpiece to verify the desired nail depth.

Tip 3: Air Pressure Regulation (for Pneumatic Models): Maintain the correct air pressure as specified by the manufacturer. Over-pressurization can result in tool damage or inconsistent nail placement, whereas under-pressurization may lead to incomplete nail driving.

Tip 4: Proper Tool Maintenance: Regularly clean and lubricate the tool according to the manufacturer’s recommendations. This includes inspecting the nail magazine, clearing any debris, and applying lubricant to the appropriate moving parts to ensure smooth and reliable operation.

Tip 5: Safety Precautions: Always wear appropriate personal protective equipment, including safety glasses, to protect against flying debris. Maintain a firm and stable grip on the tool and ensure the workpiece is securely supported to prevent movement during operation.

Tip 6: Sequential Actuation vs. Contact Actuation: Understand the difference between sequential and contact actuation modes and select the appropriate mode based on the specific task. Sequential actuation requires the nosepiece to be depressed before the trigger is pulled, enhancing safety, while contact actuation allows for rapid firing but requires greater caution.

Tip 7: Consistent Nail Placement: Practice consistent nail placement to achieve a uniform and professional finish. Avoid placing nails too close to the edge of the wood, as this can increase the risk of splitting. Staggered nail patterns can also provide increased holding strength.

Adherence to these operational guidelines contributes to enhanced efficiency, improved quality of work, and reduced risk of injury when employing this fastening solution.

The subsequent sections will explore specific applications and troubleshooting techniques related to this tool, further augmenting the user’s understanding and proficiency.

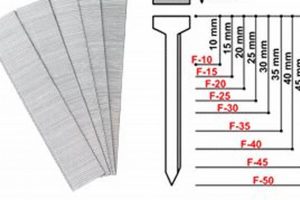

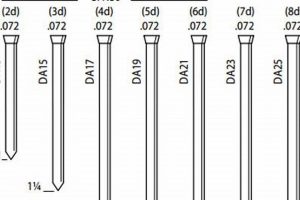

1. Nail Gauge Selection

Nail gauge selection is a critical parameter when utilizing a finish nailer from Milwaukee Tool. The gauge refers to the diameter of the nail shaft; a higher gauge number indicates a thinner nail. The tool’s performance and the integrity of the finished product depend on the correct match between the nail gauge and the work material. Using an inappropriate gauge can lead to splitting the wood or insufficient holding power. For instance, installing delicate trim on a softwood surface necessitates a higher gauge nail to prevent damage, while securing thicker hardwood might require a lower gauge for adequate fastening strength. The tool’s design anticipates specific gauge ranges, and exceeding those limits can cause malfunctions or damage.

Milwaukee Tool’s finish nailers are engineered to accommodate a range of nail gauges, typically between 15 and 18 gauge. The selection process considers the wood type, thickness, and the intended application. Using a heavier gauge nail in a delicate application, such as attaching thin molding, can result in unsightly nail holes and potential damage to the material. Conversely, using a lighter gauge nail for structural fastening can compromise the joint’s integrity, leading to premature failure. Specific models within the Milwaukee Tool product line may have narrower or wider gauge compatibility, reinforcing the importance of consulting the tool’s specifications before operation. For example, 16-gauge nails are commonly used for general-purpose trim work, striking a balance between holding power and minimizing visible nail holes. 18-gauge nails, often referred to as brad nails, are preferred for more delicate applications where minimal visibility is desired.

In summary, nail gauge selection is inextricably linked to the effective and proper use of a finish nailer manufactured by Milwaukee Tool. It directly influences the quality, appearance, and longevity of the finished product. Understanding the nuances of gauge selection, in combination with the tool’s capabilities, mitigates risks and optimizes performance in a variety of woodworking and construction scenarios. Improper gauge selection can lead to both cosmetic flaws and structural weakness, underscoring its importance.

2. Depth Adjustment Precision

Depth adjustment precision is a critical feature integrated into finish nailers manufactured by Milwaukee Tool. This capability directly impacts the quality of the finished product by controlling the degree to which nails are driven into the workpiece. Improper depth settings can result in nails protruding above the surface or being driven too deeply, damaging the surrounding material and necessitating remedial action.

- Consistent Nail Head Placement

Precise depth adjustment ensures consistent placement of the nail head flush with the surface or at a pre-determined depth. Inconsistent nail head placement compromises the aesthetic appeal of the finished product and can create uneven surfaces. For example, when installing baseboards, variations in nail depth are readily apparent and detract from the overall quality of the installation. This feature allows for repeatable results, crucial in high-volume applications.

- Material Integrity Preservation

Accurate depth control prevents overdriving nails, which can damage delicate materials like trim or molding. Overdriving compresses the wood fibers, creating unsightly dents or even splitting the material. Conversely, insufficient depth can leave nail heads exposed, creating a safety hazard and requiring manual setting. Milwaukee Tools finish nailers with precise adjustment mechanisms minimize these risks, preserving the integrity of the materials used.

- Ease of Use and Efficiency

Milwaukee Tools finish nailers often incorporate tool-free depth adjustment mechanisms, allowing for quick and easy modifications to nail depth without the need for additional tools. This feature enhances efficiency, especially when working with materials of varying densities or thicknesses. The user can quickly adapt the tool to the specific requirements of the task, minimizing downtime and maximizing productivity.

- Versatility Across Applications

Precise depth adjustment increases the versatility of the finish nailer, enabling its use in a wide range of applications. From installing delicate trim to securing thicker baseboards, the ability to fine-tune the nail depth allows the tool to adapt to different materials and fastening requirements. This versatility reduces the need for multiple tools and simplifies the workflow.

The depth adjustment precision found in Milwaukee Tools finish nailers is integral to achieving professional results in finish carpentry applications. The ability to consistently and accurately control nail depth enhances the quality of the finished product, preserves material integrity, and improves overall efficiency. This feature underscores the tool’s value in both professional and DIY settings, contributing to a more streamlined and effective workflow.

3. Power Source Efficiency

Power source efficiency is a significant factor in the performance and operational cost of finish nailers manufactured by Milwaukee Tool. The efficiency of the power source, whether pneumatic or cordless, directly impacts runtime, portability, and overall usability, influencing the tool’s suitability for various applications.

- Pneumatic Compressor Efficiency

Pneumatic finish nailers rely on compressed air, and the efficiency of the compressor supplying that air determines the tool’s operating cost and environmental impact. An inefficient compressor consumes more energy to maintain the required air pressure, leading to higher electricity bills and increased wear and tear on the compressor itself. The compressor’s capacity and recovery time are also critical; a slower recovery rate can limit the tool’s firing speed during continuous use. Milwaukee Tool’s pneumatic nailers are designed to operate within specific pressure ranges to optimize air consumption and firing consistency.

- Cordless Battery Technology

Cordless finish nailers utilize battery technology, and the efficiency of these batteries directly affects runtime and charging time. Advanced battery technologies, such as Lithium-Ion, offer improved energy density and reduced self-discharge rates compared to older battery types. Milwaukee Tool’s cordless nailers employ such technologies to maximize the number of nails driven per charge and minimize downtime associated with battery replacement. Furthermore, efficient battery management systems prevent overcharging and overheating, extending battery lifespan.

- Tool Design and Air Consumption (Pneumatic)

The internal design of pneumatic finish nailers impacts air consumption. Efficient designs minimize air leakage and optimize the transfer of energy to the nail driving mechanism. This translates to fewer compressor cycles and reduced energy expenditure. Milwaukee Tool engineers its pneumatic nailers to minimize internal friction and optimize valve timing, contributing to improved air consumption and overall efficiency. Regular maintenance, such as lubricating moving parts and checking for leaks, is essential to maintaining this efficiency.

- Brushless Motor Technology (Cordless)

Brushless motors, often incorporated into cordless finish nailers, offer significant advantages in terms of efficiency and durability compared to brushed motors. Brushless motors generate less friction and heat, resulting in increased power output and extended motor life. Milwaukee Tool utilizes brushless motor technology in its cordless nailers to optimize battery runtime and deliver consistent performance over extended periods. This technology contributes to a more reliable and efficient tool.

In summary, power source efficiency is a crucial consideration when evaluating finish nailers from Milwaukee Tool. Whether pneumatic or cordless, the efficiency of the power source directly impacts operating costs, runtime, and overall usability. Factors such as compressor efficiency, battery technology, tool design, and motor type contribute to the overall efficiency of the tool, making it a key factor in selecting the appropriate finish nailer for specific applications.

4. Ergonomic Design Attributes

Ergonomic design attributes are integral to the functionality and usability of any power tool, including finish nailers manufactured by Milwaukee Tool. These attributes directly influence user comfort, control, and overall productivity, mitigating the risk of fatigue and musculoskeletal disorders associated with prolonged tool use. The design elements are carefully considered to optimize the interaction between the tool and the operator.

- Grip Design and Material

The grip design and material are fundamental ergonomic considerations. Milwaukee Tool utilizes overmolded grips with textured surfaces to enhance grip security and reduce slippage, even in wet or sweaty conditions. The shape and diameter of the grip are carefully contoured to fit comfortably in the hand, minimizing strain on the fingers and wrist. For example, a pistol-grip design with a slight curve can reduce wrist extension and improve overall comfort. The material composition, often a durable elastomer, absorbs vibrations and provides a cushioned feel, further reducing fatigue during extended use.

- Weight Distribution and Balance

Weight distribution and balance significantly impact tool maneuverability and control. A well-balanced finish nailer reduces the amount of force required to hold and operate the tool, minimizing strain on the arm and shoulder. Milwaukee Tool engineers strive to distribute the weight evenly, placing heavier components closer to the center of gravity. This improves stability and reduces the tendency for the tool to tip or rotate during use, resulting in more accurate nail placement and reduced user fatigue. Cordless models often achieve optimal balance through strategic battery placement.

- Trigger Design and Actuation Force

The trigger design and actuation force influence the ease and precision with which the tool can be operated. Milwaukee Tool designs triggers with a smooth, consistent pull and minimal actuation force to reduce finger fatigue. The trigger’s size and shape are also optimized for comfortable finger placement and reduced strain. Some models incorporate adjustable trigger settings, allowing users to customize the trigger sensitivity to their preferences. This feature enhances control and reduces the risk of accidental firing.

- Noise and Vibration Reduction

Prolonged exposure to high levels of noise and vibration can contribute to hearing loss and musculoskeletal disorders. Milwaukee Tool incorporates noise and vibration reduction technologies into its finish nailers to minimize these risks. Dampening materials and vibration-isolated components reduce the transmission of vibrations to the user’s hand and arm. Noise reduction features, such as mufflers and optimized exhaust ports, minimize the sound level produced by the tool during operation. These measures contribute to a more comfortable and safer working environment.

The ergonomic design attributes integrated into Milwaukee Tool’s finish nailers are essential for maximizing user comfort, control, and productivity. These features contribute to a safer and more efficient working environment, reducing the risk of fatigue and musculoskeletal disorders. The careful consideration of grip design, weight distribution, trigger design, and noise/vibration reduction reflects Milwaukee Tool’s commitment to providing high-quality, user-friendly power tools that meet the demands of professional tradespeople and DIY enthusiasts alike. The combined effect of these attributes translates into improved accuracy, reduced fatigue, and increased overall efficiency in finish carpentry applications.

5. Maintenance Schedule Adherence

Adherence to a prescribed maintenance schedule is paramount for ensuring the optimal performance and longevity of a finish nailer manufactured by Milwaukee Tool. Regular maintenance directly mitigates the degradation of internal components, preventing premature failure and maintaining operational efficiency. Failure to adhere to the manufacturer’s recommended maintenance intervals can lead to diminished performance, increased repair costs, and potential safety hazards. For instance, neglecting lubrication of the internal mechanism can result in increased friction, leading to accelerated wear and tear on critical parts such as the driver blade and O-rings. Similarly, failure to regularly clean the nail magazine can result in nail jams, decreasing productivity and potentially damaging the tool. Therefore, consistent maintenance is not merely a suggestion but an essential component of responsible tool ownership.

Practical implications of neglecting the maintenance schedule are readily observable in real-world scenarios. A construction firm that routinely uses Milwaukee finish nailers for trim work, but fails to implement a consistent cleaning and lubrication protocol, will likely experience a higher incidence of tool malfunctions, requiring more frequent repairs or replacements. In contrast, a woodworking shop that diligently follows the manufacturer’s maintenance guidelines can expect their tools to operate reliably for a significantly longer period, resulting in lower overall operating costs and reduced downtime. Specific maintenance tasks often include cleaning the air filter (for pneumatic models), inspecting and replacing worn O-rings, lubricating moving parts with the appropriate lubricant, and ensuring the nail magazine is free from debris. These tasks, while seemingly minor, are crucial for maintaining peak performance and preventing costly repairs.

In summary, adherence to the maintenance schedule for a Milwaukee Tools finish nailer is not an optional consideration but a fundamental requirement for ensuring its reliability, performance, and longevity. Neglecting maintenance leads to increased repair costs, reduced productivity, and potential safety risks. The practical significance of this understanding lies in its direct impact on the tool’s operational lifespan and the overall efficiency of any woodworking or construction project. While challenges may arise in consistently implementing a maintenance schedule, the long-term benefits of reduced downtime and extended tool life far outweigh the initial investment of time and effort. Proactive maintenance is a strategic investment that ensures the tool remains a reliable asset for years to come.

Frequently Asked Questions About Milwaukee Tools Finish Nailers

This section addresses common inquiries regarding the proper use, maintenance, and troubleshooting of finish nailers manufactured by Milwaukee Tool.

Question 1: What is the recommended air pressure for operating a pneumatic finish nailer from Milwaukee Tool?

The recommended air pressure typically falls within the range of 70-120 PSI. Consult the tool’s manual for the specific pressure range appropriate for the model in question. Exceeding the maximum pressure can damage the tool, while insufficient pressure can result in incomplete nail driving.

Question 2: How frequently should a Milwaukee Tool finish nailer be lubricated?

Lubrication frequency depends on the intensity of use. For daily or heavy use, lubricating the tool before each use is advisable. For less frequent use, lubrication should occur at least monthly. Use only the lubricant recommended by Milwaukee Tool to avoid damaging internal components.

Question 3: What type of nails are compatible with a Milwaukee Tool finish nailer?

Compatibility is determined by the nail gauge and length specified for the particular model. Consult the tool’s manual to determine the acceptable nail range. Using nails outside of this range can cause jams or damage the tool.

Question 4: What are the common causes of a Milwaukee Tool finish nailer failing to drive nails completely?

Incomplete nail driving can result from several factors, including insufficient air pressure (for pneumatic models), an incorrect depth adjustment setting, or a worn driver blade. Verify the air pressure, adjust the depth setting, and inspect the driver blade for damage.

Question 5: How should nail jams be cleared from a Milwaukee Tool finish nailer?

Disconnect the power source (air hose or battery) before attempting to clear a nail jam. Use pliers or a similar tool to carefully remove the jammed nail, taking care not to damage the nail magazine or driver mechanism. Consult the tool’s manual for specific jam clearing instructions.

Question 6: What safety precautions should be observed when using a Milwaukee Tool finish nailer?

Always wear safety glasses to protect against flying debris. Keep hands and fingers clear of the nail discharge area. Disconnect the power source when performing maintenance or clearing jams. Never point the tool at oneself or others. Follow all safety guidelines outlined in the tool’s manual.

Adherence to these recommendations will contribute to the safe and efficient operation of finish nailers from Milwaukee Tool.

The following section provides specific troubleshooting tips for resolving common operational issues.

Concluding Remarks

This exploration has illuminated the multifaceted nature of the fastening implement, covering operational considerations, design attributes, maintenance requirements, and common issues. This tool is a vital asset in construction and woodworking, facilitating precision and efficiency in finish applications.

Understanding the intricacies of this device is essential for maximizing its potential and ensuring its safe and prolonged operation. Proper application and maintenance are critical investments, safeguarding against costly repairs and promoting consistent, professional-grade results. Continued adherence to best practices will ensure its enduring value in the pursuit of quality craftsmanship.