Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

The tool in question is a pneumatic fastening device designed for driving finish nails into wood. These tools are commonly employed in woodworking and construction applications requiring a refined, nearly invisible, method of joining materials. As an example, it might be used to attach decorative molding or secure trim around windows and doors.

Its significance lies in providing a fast and efficient alternative to hand-nailing, significantly reducing the time required for projects while ensuring a consistent and professional finish. Historically, air-powered nailers of this type revolutionized the speed and quality of finish carpentry, enabling carpenters to achieve finer details and tighter joints with greater ease.

The subsequent sections will delve into the specific features, applications, maintenance, and selection criteria relevant to this type of fastening tool. It will also examine various factors influencing its performance and longevity.

Operational Tips

Maximizing the tool’s performance and lifespan involves adherence to specific operational guidelines. These tips address safety, efficiency, and maintenance considerations crucial for optimal results.

Tip 1: Regulate Air Pressure: Consistent air pressure, typically between 70-100 PSI, is vital. Consult the tool’s manual for the recommended range. Over-pressurization can damage the internal components and compromise the fastening quality.

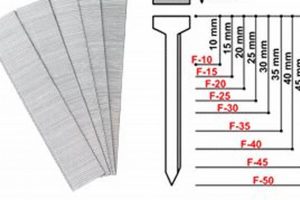

Tip 2: Utilize Appropriate Fasteners: Employ only finish nails of the specified gauge and length compatible with the tool’s magazine. Using incorrect fasteners can cause jamming or damage to the driving mechanism.

Tip 3: Maintain a Clean Air Supply: Install an air filter and regularly drain the air compressor tank to eliminate moisture and debris from the air supply. Contaminants in the air line can degrade the tool’s performance and reduce its lifespan.

Tip 4: Adjust Depth of Drive: Before commencing a project, test the depth of drive on a scrap piece of material. Adjust the depth setting to ensure nails are flush with the surface without damaging the surrounding material.

Tip 5: Lubricate Regularly: Apply a few drops of pneumatic tool oil into the air inlet before each use. This lubrication maintains the tool’s internal seals and reduces wear on moving parts.

Tip 6: Store Properly: When not in use, disconnect the tool from the air supply, empty the nail magazine, and store it in a dry, protected environment. This prevents corrosion and damage to the internal components.

Tip 7: Employ Safety Precautions: Always wear safety glasses to protect eyes from flying debris. Keep hands and other body parts away from the tool’s discharge area during operation.

Adhering to these tips enhances the tools operational efficiency, extends its service life, and promotes a safer working environment, ultimately leading to improved project outcomes.

The concluding section will address common troubleshooting scenarios and provide guidance on repairing minor malfunctions to ensure continued operational readiness.

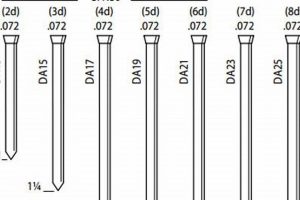

1. Gauge compatibility

Gauge compatibility represents a fundamental specification governing the performance of fastening tools. Its influence manifests as the primary determinant of nail size acceptance within the apparatus. Specifically, the gauge rating delineates the thickness of the nails that can be loaded into the magazine and effectively driven by the tool’s piston mechanism. Incorrect gauge compatibility, therefore, precipitates operational failures. For instance, a 16-gauge tool will malfunction if loaded with 18-gauge nails; the thinner nails will not properly align with the driver, leading to jams and potential damage. Conversely, attempting to load thicker, 15-gauge nails into a 16-gauge rated tool is physically impossible due to magazine size constraints. This restriction prevents forceful attempts that could damage the loading mechanism.

Real-world applications vividly underscore the practical significance of understanding gauge compatibility. Cabinet makers, for example, routinely employ 18-gauge fastening tools for delicate trim work where minimal nail visibility is desired. These tools, designed for finer nails, are unsuitable for framing tasks requiring the robust holding power of heavier-gauge fasteners. Similarly, carpenters installing baseboards often opt for 15- or 16-gauge tools to ensure secure attachment to wall studs, even though the resulting nail holes may require filling and painting. The selection of the correct gauge is thus critical for achieving both the desired aesthetic outcome and structural integrity of the finished product.

In summary, gauge compatibility is an immutable characteristic defining the tool’s functionality. Its understanding and correct application constitute a foundational element of safe and effective operation. Neglecting this principle leads to functional impairment, potential safety hazards, and suboptimal outcomes. The selection of appropriate nail gauge is, therefore, not merely a detail, but a prerequisite for successful project completion, aligning with the inherent capabilities and limitations of the specific tool in use.

2. Depth adjustment

Depth adjustment is an integral feature of pneumatic fastening tools, directly influencing the quality and integrity of finished work. Within the context of a finish nailer, this adjustment governs the extent to which a nail is driven into a material. The mechanism allows the user to modify the driving force, preventing nails from either protruding above the surface or being driven too deeply, which can compromise the structural integrity of the workpiece or leave unsightly marks.

The effect of improper depth adjustment is visually evident in numerous scenarios. For instance, failing to properly adjust the setting when working with softwoods can lead to nails being countersunk, necessitating filling and patching to achieve a smooth finish. Conversely, attempting to fasten hardwood trim without sufficient driving depth results in nail heads remaining proud of the surface, detracting from the overall aesthetic and potentially posing a safety hazard. The importance of this feature is further underscored by its ability to accommodate varying densities of materials and nail lengths, offering versatility across a range of finishing applications, from delicate cabinet assembly to robust trim installation.

In conclusion, depth adjustment is not merely a supplementary function but a core component enabling precise and professional outcomes. The ability to control nail penetration depth mitigates the risk of damage to the workpiece, ensures consistent fastening results, and enhances the overall quality of finished projects. Understanding and utilizing this feature effectively is paramount for any operator aiming to achieve optimal performance and maintain the aesthetic value of their work.

3. Air pressure regulation

Air pressure regulation is a critical operational parameter for pneumatic fastening tools, including the tool in question. Proper regulation ensures consistent and controlled driving force, directly impacting the quality of fastening. Insufficient air pressure results in incomplete nail penetration, leaving nail heads protruding from the material surface. Conversely, excessive air pressure can cause nails to be driven too deeply, potentially damaging the workpiece or causing the tool to recoil excessively, thereby presenting a safety hazard. A properly regulated air supply facilitates consistent and repeatable results, essential for professional-grade finishing work.

The tool’s internal mechanism relies on a precise balance of air pressure to cycle the piston and drive the nail. Fluctuations in air pressure, stemming from an improperly regulated compressor or leaks in the air line, can disrupt this process, leading to erratic performance and potential damage to internal components. For example, a carpenter installing crown molding relies on consistent nail placement to achieve a seamless finish; variations caused by pressure inconsistencies necessitate rework and compromise the final aesthetic. Similarly, in cabinetmaking, precise nail depth is critical to avoid splitting delicate wood, a task directly affected by stable air pressure.

In summary, air pressure regulation constitutes an indispensable element of pneumatic tool operation. The impact of this factor extends beyond mere functional performance, significantly influencing the safety, precision, and ultimately, the quality of the finished product. Consistent monitoring and adjustment of air pressure are thus imperative for operators seeking optimal results and prolonged tool lifespan. The ability to maintain a stable air supply is not simply a matter of convenience, but a critical determinant of success in any application requiring the use of a pneumatic fastening device.

4. Maintenance schedule

A systematic maintenance schedule is not merely advisable, but essential for preserving the operational integrity and extending the service life of a pneumatic finish nailer. Consistent adherence to a prescribed maintenance routine mitigates the risk of component failure, ensures optimal performance, and upholds user safety. The following facets outline key elements of such a schedule.

- Daily Lubrication

Daily lubrication of the tool’s internal mechanisms is paramount. Pneumatic tools rely on a constant supply of oil to maintain seals and reduce friction between moving parts. Introduce a few drops of pneumatic tool oil into the air inlet before each use. Failure to lubricate adequately leads to premature wear, reduced driving power, and eventual component failure. Imagine a carpenter utilizing a nailer for an entire workday without lubrication; the resulting friction would compromise the tool’s efficiency and substantially shorten its lifespan.

- Air Filter Maintenance

Regular cleaning or replacement of the air filter is critical for preventing contaminants from entering the tool. Airborne particles, moisture, and other debris can degrade internal seals, clog air passages, and impede proper operation. Check and clean the air filter at least weekly, or more frequently in dusty environments. An obstructed air filter reduces air flow, diminishing the tool’s power and increasing the risk of internal damage. Consider a situation on a construction site where excessive dust and grime accumulate; the air filter requires more frequent attention to sustain the nailer’s efficiency.

- Fastener Magazine Inspection

The fastener magazine should be inspected periodically for damage, debris, and proper alignment. Bent or damaged magazine components can cause nail jams, misfires, and inconsistent fastener placement. Regularly clean the magazine and ensure that the spring mechanism operates smoothly. A jammed magazine can interrupt workflow and create a potentially hazardous situation. Consider a scenario where a deformed magazine causes constant nail jams, impeding the completion of a project and leading to frustration.

- Hose and Fitting Inspection

Inspect air hoses and fittings for leaks, cracks, and proper connections. Air leaks reduce air pressure, diminishing the tool’s power and efficiency. Loose or damaged fittings present a safety hazard. Regularly check hoses for wear and tear, and ensure that all connections are secure. An undetected air leak can gradually reduce the nailer’s driving force and increase the workload on the air compressor. A contractor relying on a nailer for framing, if unaware of hose deterioration, may experience decreased fastening performance that affects the structural integrity.

These maintenance facets, when diligently followed, contribute significantly to the longevity and reliability of pneumatic fastening tools. Consistent adherence to the maintenance schedule is not merely a procedural matter, but a proactive investment in preserving the tool’s performance, ensuring user safety, and maximizing its return on investment. This holistic approach transforms a potentially short-lived tool into a dependable asset, essential for consistent performance.

5. Safety mechanisms

The integration of safety mechanisms within pneumatic finish nailers is not merely a regulatory compliance matter, but a critical design consideration that directly mitigates the risk of unintended nail discharge and potential injuries. These features, implemented to prevent accidental actuation, fundamentally shape the operational profile of the tool, influencing both its usability and inherent safety.

- Contact-Trip Mechanism (Sequential Actuation)

The contact-trip mechanism, often termed sequential actuation, necessitates a specific sequence of actions for the nailer to operate. The tool’s nosepiece must be pressed firmly against the workpiece before the trigger is activated. This dual-action requirement minimizes the possibility of unintended firing, such as when the tool is dropped or inadvertently handled. An example of its effectiveness is seen on construction sites, where carpenters moving between tasks may unintentionally bump the tool against themselves or equipment; the contact-trip prevents accidental nail discharge in such scenarios, reducing the risk of injury.

- Lockout Switch

A lockout switch serves as an additional layer of safety, effectively disabling the firing mechanism when the tool is not in active use or during maintenance procedures. This switch physically prevents the trigger from engaging the nail-driving piston, rendering the tool inert. In a workshop setting, where multiple workers may be present, the lockout switch prevents unauthorized or accidental use of the finish nailer, minimizing the risk of unintentional nail discharge and potential harm.

- Adjustable Exhaust Deflector

While not directly preventing nail discharge, an adjustable exhaust deflector redirects the expelled air away from the operator’s face and body, reducing the risk of eye irritation or disturbance from airborne debris. By directing the exhaust flow, the operator’s visibility remains unobstructed, and the potential for inhaling fine particles generated during operation is minimized. This seemingly minor feature enhances the overall safety and comfort of the user, particularly during prolonged periods of operation.

- Protective Guards and Shields

Many finish nailers incorporate physical guards and shields around the nosepiece to protect the operator’s hands and fingers from accidental contact with the firing mechanism or flying debris. These barriers create a physical separation between the user and the point of operation, minimizing the risk of direct contact with the moving parts of the tool. In situations where the operator’s grip may shift during operation, these guards provide a critical margin of safety, preventing accidental contact and potential injury.

The cumulative effect of these safety mechanisms is to substantially reduce the likelihood of unintended nail discharge and associated injuries. Their presence not only reflects a commitment to operator safety but also underscores the importance of responsible tool design and engineering. The proper functioning and diligent use of these features are paramount to ensuring a safe and productive working environment when employing pneumatic finish nailers.

6. Fastener capacity

Fastener capacity, referring to the maximum number of fasteners a pneumatic finish nailer can hold in its magazine, represents a pivotal factor influencing operational efficiency and workflow continuity. This capacity directly dictates the frequency of reloading, impacting the overall time required to complete a given task. Understanding this aspect is crucial for optimizing productivity in applications involving finish carpentry and trim work.

- Magazine Design and Capacity

Magazine design directly correlates with fastener capacity. Linear magazines, common in many finish nailers, typically accommodate a single strip of nails. Coiled magazines, while less prevalent in finish nailers, offer substantially higher capacities but at the expense of increased tool weight and bulk. The design dictates the upper limit of fastener capacity; for example, a linear magazine might hold 100 nails, whereas a coiled magazine could accommodate several hundred. The choice of magazine design is often a trade-off between capacity and maneuverability.

- Gauge and Nail Length Considerations

Fastener capacity is also affected by the gauge and length of the nails being used. Thicker-gauge nails, due to their larger diameter, will reduce the total number of nails that can fit within the magazine. Similarly, longer nails occupy more space, limiting the magazine’s capacity. A nailer rated for 16-gauge nails might hold more nails than the same model loaded with 15-gauge nails. Users must consider the nail dimensions relative to the magazine’s specifications to avoid overfilling or causing jams.

- Impact on Project Efficiency

High fastener capacity directly translates to fewer interruptions for reloading, thereby enhancing project efficiency. In large-scale trim work, such as installing baseboards in multiple rooms, a nailer with a greater capacity reduces downtime, allowing for continuous operation. Conversely, a smaller capacity necessitates more frequent reloading, potentially slowing down the overall progress of the project. The scale of the project should inform the selection of a nailer with adequate fastener capacity to minimize disruptions.

- Balance Between Capacity and Tool Weight

While a larger fastener capacity offers benefits in terms of reduced reloading, it often comes at the cost of increased tool weight and bulk. A heavier nailer can cause fatigue during extended use, potentially impacting precision and safety. A balance must be struck between the desired capacity and the user’s ability to comfortably handle the tool. Ergonomics and user comfort are critical considerations when selecting a finish nailer, particularly for projects requiring prolonged use.

The fastener capacity of a finish nailer, therefore, is not an isolated specification but an interconnected factor that influences efficiency, usability, and overall project outcomes. Choosing a nailer with an appropriate fastener capacity requires careful consideration of the project’s scale, the type of fasteners being used, and the user’s physical capabilities. These considerations ensure that the tool aligns with the demands of the task and promotes optimal productivity.

7. Material application

The term “material application,” in the context of a pneumatic finish nailer, defines the range of materials upon which the tool can be effectively and safely employed. This aspect is a critical determinant of the tool’s versatility and suitability for specific projects. Selecting a finish nailer without considering the material properties can lead to compromised fastening, damaged workpieces, or even hazardous operating conditions. A finish nailer designed for softwoods may prove inadequate for hardwoods, resulting in nails that do not fully penetrate or that bend upon impact. Conversely, a tool calibrated for hardwoods can easily overdrive nails into softer materials, leaving unsightly marks and weakening the joint. Examples include using a standard finish nailer on delicate trim, which may split the wood, or attempting to use the same tool on engineered lumber, where the density may require a specialized fastener and driving force.

Understanding material application extends beyond simply knowing whether a tool can drive a nail into a given substance. It also entails recognizing the optimal nail type, size, and driving depth for each material. For instance, fastening oak trim requires heavier-gauge nails and a greater driving force than securing pine molding. The choice of nail should also consider the material’s grain and susceptibility to splitting. Moreover, specialized applications, such as fastening materials to concrete or metal studs, necessitate specific finish nailers equipped with the appropriate driving power and nail types. Failure to adhere to these considerations can result in unstable or aesthetically unacceptable outcomes. The selection of a finish nailer should align closely with the predominant materials used in its intended applications. A carpenter primarily working with hardwoods would prioritize a different tool than one specializing in softwood trim.

In summary, material application constitutes a fundamental parameter governing the effective use of a finish nailer. Consideration of material properties, nail selection, and driving depth is essential for achieving secure and aesthetically pleasing results. Neglecting this aspect can compromise both the structural integrity and appearance of the finished product. Therefore, thorough assessment of material compatibility should precede any application of a finish nailer, ensuring that the selected tool is appropriately matched to the intended materials and fastening requirements. This alignment promotes safety, efficiency, and professional-grade outcomes.

Frequently Asked Questions

The following addresses common inquiries regarding the operation, maintenance, and selection of pneumatic finish nailers. These questions aim to clarify essential aspects of the tool, promoting safe and effective usage.

Question 1: What is the optimal air pressure for operating a finish nailer?

Recommended air pressure generally falls within the range of 70 to 100 PSI. However, consultation of the manufacturer’s specifications is crucial to determine the precise pressure range for a given model. Operating outside this range can result in either incomplete nail penetration or damage to the tool.

Question 2: How frequently should a pneumatic finish nailer be lubricated?

Daily lubrication is recommended for consistent performance and to prolong the lifespan of the tool. Introduce a few drops of pneumatic tool oil into the air inlet before each use. More frequent lubrication may be necessary in environments with high humidity or prolonged use.

Question 3: What types of nails are compatible with a typical finish nailer?

Finish nailers typically accept 15- or 16-gauge finish nails. The precise length of nail will vary depending on the tool’s specifications and the application. Always consult the tool’s manual for recommended nail sizes to prevent jamming or damage.

Question 4: What safety precautions should be observed when using a finish nailer?

Eye protection is mandatory to prevent injury from flying debris. Hands should be kept clear of the discharge area during operation. Disconnecting the air supply before performing maintenance or adjustments is also essential.

Question 5: What are common causes of a finish nailer malfunctioning?

Common causes include insufficient air pressure, incorrect nail size, a clogged air filter, and inadequate lubrication. Addressing these factors often resolves the issue; however, complex repairs may require professional assistance.

Question 6: How can nail depth be adjusted on a finish nailer?

Most finish nailers feature an adjustable depth-of-drive mechanism, typically a dial or knob located near the nosepiece. This allows for precise control over nail penetration, preventing overdriving or underdriving. Testing on scrap material before beginning a project is recommended to ensure proper adjustment.

Adherence to these guidelines enhances the efficiency, safety, and longevity of pneumatic finish nailers. Understanding these principles contributes to improved performance and professional-grade results.

The subsequent section will delve into specific troubleshooting techniques for common issues encountered with this type of tool.

Conclusion

The preceding examination of the porter cable finish nailer has underscored its operational intricacies, maintenance requirements, and safety considerations. From gauge compatibility to depth adjustment and proper air pressure regulation, a comprehensive understanding of these elements is critical for effective and safe utilization. Ignoring these aspects jeopardizes the tool’s performance, shortens its lifespan, and potentially compromises the safety of the operator.

The responsibility for proper tool handling rests ultimately with the user. Diligent adherence to established safety protocols and proactive maintenance practices is paramount. Neglecting these factors diminishes the tool’s value and invites potentially serious consequences. Therefore, a commitment to informed and responsible operation is not merely advisable, but essential for maximizing the benefits and minimizing the risks associated with this type of power tool. The informed and responsible operation of pneumatic tools is paramount for those engaged in professional work that needs quality and safety.