Surface roughness average measurement, often presented in a graphical format, quantifies the texture of a machined or manufactured surface. It represents the arithmetic mean of the absolute values of the deviations of the roughness profile from the mean line. As an example, a lower numerical value on this chart signifies a smoother surface, often achieved through processes like polishing, while a higher value indicates a rougher texture, potentially from processes like sandblasting.

This method of surface evaluation is critical for ensuring functional performance, aesthetics, and longevity of components. Its use facilitates standardized communication across engineering disciplines and manufacturing processes, ensuring that surface texture requirements are consistently met. The historical context involves the evolution of measurement techniques from tactile methods to advanced non-contact technologies, providing increasingly accurate and efficient data collection.

The subsequent sections will detail various surface finishing techniques, explore different measurement methodologies employed to generate these representations, and discuss the application of these charts across diverse industries. These will also include a discussion of the impact of surface texture on product functionality and performance.

Surface Roughness Average Measurement Chart Application Tips

The following guidelines offer crucial insights for effectively utilizing surface roughness average data across various engineering and manufacturing applications.

Tip 1: Establish Clear Surface Texture Requirements: Define the permissible range of surface roughness values for each component based on its intended function and operating environment. Refer to relevant industry standards to ensure compliance.

Tip 2: Select the Appropriate Measurement Technique: Employ measurement methods suited to the material and surface geometry. Contact stylus profilometry is useful for many surfaces, but optical techniques are preferable for delicate or easily damaged materials.

Tip 3: Ensure Proper Calibration of Measurement Equipment: Regularly calibrate equipment to maintain accurate readings. Use calibration standards traceable to national metrology institutes to minimize measurement errors.

Tip 4: Interpret Data in Conjunction with Process Knowledge: Understand the relationship between manufacturing processes and surface texture. The chart provides a numerical value, but process knowledge will aid in diagnosing the root cause of unacceptable roughness.

Tip 5: Utilize Statistical Process Control: Implement statistical process control charts to monitor surface roughness during production. This proactive approach helps to identify deviations from the target range and prevent the production of non-conforming parts.

Tip 6: Consider Surface Functionality Beyond Aesthetic Appearance: The surface characteristics affects friction, wear, adhesion, and corrosion resistance. Design the surface for its functional requirements, not merely its appearance.

Tip 7: Document Measurement Procedures and Results: Maintain detailed records of measurement procedures, equipment used, and results. This documentation is essential for traceability, quality control, and failure analysis.

Consistent application of these tips enables a more controlled manufacturing environment, leading to improved product performance and reduced instances of premature failure. By considering the nuances of surface roughness and incorporating these guidelines, professionals can enhance the quality and reliability of their products.

The next section will delve into the interpretation of these charts and how it contributes to design and manufacturing decisions.

1. Surface texture quantification.

Surface texture quantification provides the numerical and graphical representation of a surface’s micro-geometric features. This process is intrinsically linked to the analysis of these charts because the chart visually displays the quantified surface roughness values. Surface texture quantification gives the values the chart displays. An example can be a surface designed for low friction applications; its surface texture would be quantified to ensure it meets a specific numerical target to minimize friction, a target reflected on a chart.

The information derived from surface texture quantification are visually represented and are fundamental for quality control and process optimization. Without accurate quantification, the information on this representation would be meaningless. For instance, if a bearing surface exhibits excessive roughness when the average is outside of acceptable limit, this issue can be identified based on this measurement and represented on a chart; and the manufacturing process can be adjusted to achieve the desired value.

In summary, surface texture quantification provides the foundational data upon which chart analysis and interpretation are based. It presents actionable metrics that contribute to better manufacturing processes, product quality, and performance. Challenges remain in accurately capturing complex surface geometries, but continuous advancements in measurement techniques are addressing these limitations. The data provided on these charts is a direct visualization of surface characteristics.

2. Material Removal Processes and Surface Roughness

Material removal processes fundamentally determine the surface characteristics of manufactured components, directly impacting the resultant surface roughness measurements. The chart is, therefore, a direct representation of the efficacy and precision of these processes.

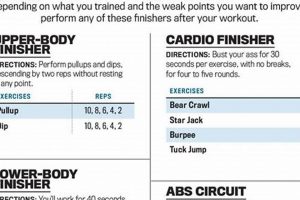

- Grinding and Honing

Grinding and honing, as abrasive machining processes, yield surfaces with controlled roughness suitable for functional applications. The resulting graphical representation shows the degree of uniformity and the presence of any surface defects introduced during the material removal. For example, precision grinding can achieve roughness average values of 0.025-0.4 m, ideal for bearing surfaces, and this is clearly visible as a ‘smoother’ result on the chart.

- Milling and Turning

Milling and turning operations, characterized by single-point or multi-point cutting tools, create distinct surface textures defined by the toolpath and feed rate. A higher feed rate typically results in a rougher surface with a larger roughness average, which is reflected by higher numerical values. These higher values can be identified on the chart.

- Electrical Discharge Machining (EDM)

EDM utilizes electrical discharges to remove material, resulting in a recast layer and a unique surface texture characterized by craters. The graphical representation of an EDM surface typically reveals a relatively high roughness average compared to traditional machining methods. This is due to the stochastic nature of the material removal, even with fine settings, the chart will reflect this.

- Polishing and Lapping

Polishing and lapping processes are employed to reduce surface roughness and enhance the surface finish. These processes utilize fine abrasive particles to remove minute amounts of material, significantly reducing the roughness average value. The chart will show the lower roughness that can be achieved by polishing. For instance, optical components often require roughness average values below 0.01 m achieved through these processes, with low, desirable values on the resulting chart.

Ultimately, material removal processes are the genesis of surface texture, and the graphical representation is a concise indicator of their effectiveness in achieving desired surface characteristics. This relationship underscores the importance of carefully selecting and controlling these processes to meet specific surface finish requirements. The data presented serves as a critical feedback mechanism, enabling engineers to optimize machining parameters and maintain consistent product quality.

3. Functional Performance Impact

The functional performance of a component is intrinsically linked to its surface roughness, which is quantified and visualized on a chart. Surface roughness significantly influences tribological properties, such as friction and wear, adhesive bonding strength, sealing capabilities, and fatigue life. For instance, a component designed to operate under high-speed sliding conditions requires a specific roughness to minimize friction and prevent premature wear. An inadequate finish, displayed as an inappropriate value, can lead to increased energy consumption, heat generation, and ultimately, component failure. Similarly, a rough surface might compromise the integrity of a seal, leading to leakage and system malfunction.

Conversely, surface roughness can be intentionally designed to enhance performance. In adhesive bonding applications, a controlled level of roughness increases the surface area available for adhesion, promoting stronger and more durable bonds. The adhesive is bonded, and the bond is improved. Moreover, in certain biomedical implants, a specific roughness promotes osseointegration, facilitating better integration of the implant with the surrounding bone tissue. The roughness average required for optimal osseointegration can be specified and verified using surface roughness analysis.

In summary, surface texture is not merely an aesthetic consideration; it is a critical determinant of functional performance. The chart provides a standardized means to specify, measure, and control surface roughness, ensuring that components meet performance requirements. Without adequate control over surface texture, the reliability and longevity of engineered systems may be compromised. Understanding and controlling surface finish through techniques is therefore essential for design optimization and performance assurance.

4. Standardization and Compliance

The utilization of surface roughness average measurement relies heavily on adherence to recognized standards, thereby ensuring compliance with established engineering practices and regulatory requirements. These standards provide a common language and methodology for quantifying and specifying surface texture, leading to consistent communication between designers, manufacturers, and quality control personnel. Without standardized practices, the interpretation of values becomes subjective, leading to potential miscommunication, manufacturing errors, and ultimately, compromised product performance. For example, ISO 25178 provides a comprehensive framework for surface texture measurement, specifying parameters, filtering techniques, and reporting formats. Compliance with this standard enables global interoperability and facilitates the exchange of technical information across international boundaries. A component manufactured in one country can be accurately assessed and integrated into a system produced in another, provided both adhere to the same standards.

Compliance with surface roughness standards is often mandated by industry-specific regulations, particularly in sectors such as aerospace, automotive, and medical device manufacturing. For instance, medical implants must meet stringent surface finish requirements to ensure biocompatibility and promote osseointegration. Regulatory bodies, such as the FDA, require manufacturers to demonstrate compliance with these standards through rigorous testing and documentation. Failure to meet these requirements can result in product recalls, legal liabilities, and damage to reputation. Furthermore, adherence to standards facilitates the development of robust quality control procedures, enabling manufacturers to monitor and control surface finish during production. Statistical process control charts, based on standardized measurement methodologies, provide real-time feedback on surface roughness trends, allowing for proactive intervention and prevention of non-conforming products.

In conclusion, standardization and compliance are integral to the accurate and reliable application of surface roughness measurement. Adherence to recognized standards ensures consistent communication, facilitates regulatory compliance, and promotes robust quality control practices. While challenges remain in harmonizing standards across different regions and industries, the ongoing efforts to improve standardization will continue to enhance the integrity and reliability of manufacturing processes. Accurate measurements and standardized practices provide the basis for making informed decisions about component design, material selection, and manufacturing process control.

5. Measurement Technique Selection

The accuracy and reliability of surface roughness average values are directly contingent upon the appropriate selection of a measurement technique. Different techniques operate on distinct principles and possess varying capabilities in resolving surface features, which profoundly affects the resulting roughness values presented on surface roughness average charts. Choosing an inadequate technique can lead to erroneous data, misinterpretation of surface characteristics, and ultimately, flawed decisions in manufacturing processes and quality control. For instance, tactile profilometry, which involves dragging a stylus across the surface, may be suitable for robust materials but can damage soft or delicate surfaces, leading to inaccurate readings. Conversely, optical techniques, such as confocal microscopy or interferometry, offer non-contact measurements that preserve the integrity of sensitive surfaces but might struggle with highly reflective or transparent materials.

The selection of a measurement technique should also consider the specific features of interest on the surface. If the primary concern is the overall average roughness, a technique that provides a large sampling area might be preferred. However, if the focus is on identifying and quantifying specific defects, such as scratches or pits, a technique with higher spatial resolution becomes essential. Examples include the use of atomic force microscopy (AFM) for characterizing nanoscale surface features or the application of focus variation microscopy for measuring the roughness of complex 3D geometries. Furthermore, the environmental conditions under which the measurement is performed can influence the choice of technique. Vibration, temperature variations, and ambient light can all affect the accuracy of certain measurement methods, necessitating careful consideration of these factors during technique selection.

In summary, appropriate measurement technique selection is a critical determinant of the validity and utility of values displayed on the chart. Considering the material properties, surface features of interest, environmental conditions, and measurement objectives is essential for obtaining reliable and representative surface roughness data. While advancements in measurement technology offer a wide range of options, careful evaluation and validation are necessary to ensure that the selected technique is fit for purpose, thereby enabling informed decision-making and effective control of surface finish in manufacturing. The ultimate goal is to use the best technique to accurately determine the values, enabling better decisions regarding manufacturing processes.

Frequently Asked Questions about Surface Roughness Average Charts

This section addresses common queries and misconceptions regarding surface roughness average measurements, providing clarity on the interpretation and application of these values in engineering and manufacturing contexts.

Question 1: What is the significance of surface roughness average (Ra) in manufacturing?

Surface roughness average serves as a key indicator of surface texture, influencing tribological properties, adhesion characteristics, and aesthetic appearance. Precise control of surface roughness ensures optimal performance and reliability of manufactured components.

Question 2: How does the surface roughness average differ from other surface texture parameters, such as Rz or Rq?

Surface roughness average (Ra) represents the arithmetic mean of the absolute values of the roughness profile deviations from the mean line. Rz, conversely, quantifies the average maximum height of the profile, while Rq denotes the root mean square roughness. These parameters provide complementary information about surface texture.

Question 3: What factors influence the selection of a suitable surface roughness average value for a given application?

The selection of an appropriate roughness value depends on the functional requirements, material properties, and operating environment of the component. Considerations include friction, wear resistance, sealing requirements, and aesthetic considerations.

Question 4: How is surface roughness average typically measured and what are the common measurement techniques?

Surface roughness average is commonly measured using tactile profilometry, where a stylus traverses the surface, or optical techniques, such as confocal microscopy and interferometry. The choice of technique depends on the material, surface geometry, and required resolution.

Question 5: Can surface roughness average values be directly correlated to component performance and longevity?

Yes, surface roughness directly influences tribological properties like friction and wear, which impacts performance and longevity. A rough surface can increase friction, accelerating wear, while a smoother surface can reduce friction and wear.

Question 6: What are the consequences of specifying an inappropriate surface roughness average value?

Specifying an inappropriate surface roughness average can lead to premature component failure, reduced performance, compromised sealing capabilities, and aesthetic deficiencies. Proper specification is essential for ensuring optimal product quality and reliability.

The information presented here offers a deeper comprehension of the importance of surface roughness average measurements, enabling informed decision-making in engineering and manufacturing.

The succeeding section will explore case studies showcasing the application of surface roughness analysis in diverse industries.

Surface Roughness Average Finish Charts

This exploration has detailed the significance of surface roughness average charts across various facets of engineering and manufacturing. From the definition of surface texture to the influence of material removal processes, and the critical role of standardization, the analysis underscores its function as a fundamental tool. These charts offer a concise, standardized visual representation of surface characteristics, enabling engineers and manufacturers to communicate effectively, optimize processes, and ensure product quality.

Therefore, a diligent application of the principles discussed herein is crucial for ensuring the reliability, performance, and longevity of engineered components. Further research and development in surface metrology are essential to address existing limitations and enhance the accuracy and efficiency of surface roughness measurement. The continuing advancement of surface metrology techniques will enable more precise surface characterization, contributing to innovation and progress across numerous industries, where careful considerations will lead to better designed and longer lasting products.