A pneumatic or cordless tool, this device is engineered to drive finish nails into wood for detailed carpentry and trim work. Often utilized in applications demanding a refined appearance, this type of tool ensures minimal surface damage while providing a secure fastening. For instance, it is frequently employed when installing baseboards, crown molding, or door casings, requiring a clean, almost invisible nail application.

This category of tool offers efficiency and precision compared to manual nailing methods. Its use reduces the likelihood of splitting wood and minimizes visible nail holes, contributing to a professional finish. Historically, such tools have evolved from simpler nail guns to more sophisticated, lightweight models with adjustable depth settings and enhanced safety features. The adoption of these tools has significantly streamlined carpentry and woodworking processes, improving both speed and quality.

The following sections will delve into the specific features, operational considerations, maintenance procedures, and appropriate applications for this tool category, offering a practical guide for both novice and experienced users. Further discussion will cover choosing the right model, troubleshooting common issues, and ensuring safe and effective operation in various project settings.

Operational Tips

The following are actionable recommendations to optimize the performance and longevity of the tool, ensuring projects are completed efficiently and with a professional standard.

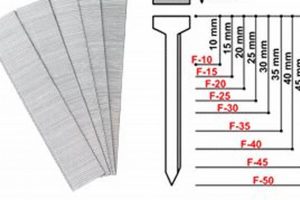

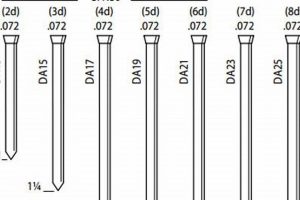

Tip 1: Nail Selection: Always use collated finish nails recommended by the manufacturer. Incorrect nail gauges or lengths can lead to jamming, misfires, or damage to the tool itself. Consult the owner’s manual for approved specifications.

Tip 2: Pressure Adjustment: Regulate the air pressure (for pneumatic models) according to the wood’s density. Softer woods require lower pressure to prevent over-driving, while hardwoods may necessitate higher pressure for proper nail penetration. Testing on scrap material is advisable.

Tip 3: Consistent Positioning: Maintain a consistent angle and firm pressure against the work surface during operation. This minimizes nail head protrusion and ensures uniform setting. Erratic positioning can result in angled nail entry and compromised aesthetics.

Tip 4: Regular Cleaning: After each use, disconnect the tool from the power source and clean the nail chamber to remove debris. A clean tool operates more efficiently and reduces the risk of malfunction. Compressed air can be used for this purpose.

Tip 5: Proper Storage: When not in use, store the tool in a clean, dry environment to prevent rust and corrosion. Applying a light coat of oil to internal components can further protect against environmental damage.

Tip 6: Depth Adjustment Calibration: Utilize the tool’s depth adjustment feature to fine-tune nail penetration. Calibrating the depth ensures the nail heads are flush with the surface without marring the surrounding material. Periodic recalibration may be necessary.

Tip 7: Battery Maintenance (Cordless Models): For cordless units, follow the manufacturer’s recommendations for battery charging and storage. Fully discharging batteries before storage or using incompatible chargers can reduce battery lifespan and performance. Regularly inspect battery contacts for corrosion.

Implementing these suggestions will improve operational efficiency, extend the tool’s lifespan, and result in higher-quality finished projects.

The subsequent section will provide a troubleshooting guide for addressing common issues encountered during operation, further enhancing the tool’s usability and reliability.

1. Precision

In the context of finish carpentry, precision refers to the accuracy and consistency with which a tool drives nails into a workpiece. The consequences of imprecision range from aesthetically displeasing results to structural compromise. A finish nailer’s precision directly impacts the uniformity of nail depth, the alignment of nail heads, and the minimization of surface damage. Without adequate precision, finish work exhibits uneven nail penetration, potentially splitting wood or leaving nail heads visibly protruding. This affects the professional quality of the finished product, requiring additional corrective measures or even material replacement.

The nailer’s internal mechanisms, including the driver blade and depth adjustment settings, are critical components contributing to precision. Variations in these components or improper calibration can introduce errors in nail placement and depth. For example, if the driver blade is misaligned, the nail may enter the wood at an angle, resulting in a skewed finish. Similarly, inconsistent depth settings can cause some nails to be overdriven, creating unsightly holes, while others remain insufficiently embedded. Such imprecision necessitates manual correction, increasing project time and labor costs.

Therefore, precision is not merely a desirable attribute but a functional requirement for a finish nailer. Achieving a professional-grade finish necessitates a tool engineered for accurate and repeatable nail delivery. Investing in a tool with demonstrable precision minimizes errors, reduces rework, and ultimately contributes to superior project outcomes. Understanding the causal relationship between tool precision and finished product quality empowers informed decision-making and optimizes the efficiency of finish carpentry projects.

2. Power Source

The operational functionality of a finish nailer is fundamentally linked to its power source. This dictates portability, sustained usage capacity, and overall application suitability. Options primarily consist of pneumatic and cordless (battery-powered) systems. Pneumatic models require an external air compressor, offering consistent power delivery for extended periods, suitable for high-volume tasks such as large-scale trim installation. The dependency on an air compressor, however, limits mobility, restricting the tool’s use to locations accessible to compressed air infrastructure. A practical example is a professional trim carpenter primarily working in a workshop setting where an air compressor is readily available.

Cordless models, conversely, provide enhanced portability, eliminating the need for hoses and compressors. These tools operate on rechargeable batteries, offering freedom of movement and applicability in remote locations or areas lacking compressed air access. However, battery runtime becomes a limiting factor, necessitating battery swaps or recharging during extended use. This is particularly relevant for contractors performing on-site repairs or installations where access to power outlets is restricted. Furthermore, the power output of cordless models can sometimes be lower than pneumatic counterparts, potentially affecting their ability to consistently drive nails into harder materials. Choosing a Ryobi finish nailer with a 18V ONE+ battery system can provide sufficient power and interchangeability with other tools within the same ecosystem.

Therefore, the selection of a power source is a critical decision, contingent upon project requirements and operational environment. Pneumatic systems prioritize consistent power and are well-suited for stationary applications, while cordless systems emphasize mobility and versatility. Understanding the trade-offs between these power sources enables informed decisions, ensuring the selected tool aligns with the demands of the specific task at hand. Misalignment of power source and application can lead to reduced efficiency, increased downtime, and compromised project quality.

3. Nail Capacity

Nail capacity, in relation to a finish nailer, directly influences operational efficiency and project workflow. It defines the number of nails a tool can hold within its magazine, impacting the frequency of reloading and subsequent interruptions during task execution. An adequate nail capacity is crucial for maintaining productivity, especially on large-scale projects.

- Magazine Design and Loading Mechanism

The magazine design determines the type and quantity of nails the nailer can accommodate. Some Ryobi finish nailer models employ a straight magazine, while others utilize an angled design to increase capacity or improve maneuverability in tight spaces. The loading mechanism, whether top-loading, side-loading, or rear-loading, affects the speed and ease of reloading. A well-designed magazine and loading system minimize downtime and reduce the risk of nail jams.

- Nail Strip Compatibility and Gauge

Finish nailers utilize collated nails, typically joined in strips or coils. The nail capacity is also determined by the gauge and length of the nails used. Ryobi finish nailers are commonly designed to accept 16-gauge or 18-gauge finish nails, with varying lengths depending on the model. Compatibility with standard nail strip sizes ensures consistent feeding and reduces the likelihood of misfires. Using the correct gauge and length for the specific application is critical for optimal performance.

- Impact on Project Completion Time

A higher nail capacity translates to fewer interruptions for reloading, especially on extensive projects. This reduction in downtime can significantly decrease overall project completion time. For instance, installing baseboards in a large room with a nailer having a low nail capacity requires frequent reloading, increasing labor costs and extending the project timeline. A larger capacity streamlines the process, allowing for more continuous work and faster results.

- Considerations for Different Applications

The ideal nail capacity varies depending on the specific application. For smaller, more intricate projects like cabinet trim, a lower nail capacity may suffice. However, for larger-scale projects such as installing crown molding or wainscoting, a higher nail capacity is preferable. Evaluating the typical project scope and nail consumption rate helps determine the appropriate nail capacity to maximize efficiency and minimize disruptions.

The nail capacity is a vital feature to evaluate. Choosing a Ryobi finish nailer with an adequate nail capacity for the anticipated workload optimizes efficiency and reduces the frustration associated with frequent reloading. The design of the magazine, nail compatibility, and impact on project completion time are key considerations when selecting a suitable model. Balancing these factors ensures the tool aligns with project requirements and enhances overall productivity.

4. Depth Control

Depth control is a critical feature on a finish nailer, and its effective management directly influences the quality of the finished product. The ability to precisely adjust the depth to which a nail is driven into a workpiece is vital for achieving a flush and aesthetically pleasing surface. Without effective depth control, nails may be overdriven, resulting in unsightly holes and damage to the material, or underdriven, causing nail heads to protrude, compromising both appearance and structural integrity. A Ryobi finish nailer equipped with accurate depth control allows the user to calibrate the tool for various wood densities and nail lengths, ensuring consistent and professional results.

The mechanisms enabling depth control vary across different models, typically involving a dial or adjustment screw that modifies the driver’s striking force. Adjusting the depth setting requires careful consideration of the material’s hardness. Softwoods, such as pine, require shallower nail penetration, while hardwoods, such as oak, necessitate greater force. Incorrect depth settings can lead to material splitting or inadequate fastening. Practical applications, such as installing delicate trim or molding, demand precise depth adjustments to prevent damage and maintain the material’s integrity. A nail driven too deep can mar the surface, while one driven too shallow can leave a sharp edge that catches clothing or skin.

In summary, depth control is an essential component of a finish nailer. Its correct application directly contributes to the quality and durability of the finished product. By understanding the principles of depth adjustment and carefully calibrating the tool for specific materials and applications, users can achieve professional results while minimizing the risk of damage and ensuring secure fastening. Mastery of this feature is key to realizing the full potential of the tool and achieving superior workmanship.

5. Ergonomics

Ergonomics, the science of designing tools and workspaces to fit the user, is paramount in the effective and safe operation of a finish nailer. Its relevance is directly tied to user comfort, reduced fatigue, and enhanced productivity. A well-designed finish nailer minimizes strain on the user’s body, allowing for extended periods of use without compromising accuracy or safety.

- Grip Design and Material

The grip design dictates the user’s ability to maintain a secure and comfortable hold on the tool. Ergonomic grips are typically contoured to fit the natural shape of the hand, reducing stress on the fingers and wrist. Material choice further contributes to grip comfort; over-molded rubber or similar materials provide a non-slip surface and dampen vibrations. For instance, a Ryobi finish nailer with an ergonomic grip allows for precise nail placement, even when working at awkward angles or for extended periods.

- Weight and Balance

The weight and balance of a finish nailer significantly impact user fatigue and maneuverability. A lightweight and well-balanced tool reduces strain on the arm and shoulder, enabling more precise control and minimizing the risk of repetitive strain injuries. Examples include cordless models where battery placement affects balance, and pneumatic models where hose weight can contribute to fatigue. A properly balanced tool allows for smoother operation and reduces the likelihood of errors, especially during intricate trim work.

- Trigger Mechanism and Activation Force

The trigger mechanism and activation force influence the user’s ability to control nail firing. A smooth trigger action with a moderate activation force reduces strain on the trigger finger and enhances accuracy. A trigger that requires excessive force can lead to fatigue and inconsistent nail placement. An ideally designed trigger allows for quick and precise firing, crucial for tasks requiring rapid nail placement without compromising accuracy.

- Vibration Dampening

Vibration dampening minimizes the transmission of vibrations from the tool to the user’s hand and arm, reducing the risk of hand-arm vibration syndrome (HAVS). Effective vibration dampening systems utilize materials and design features to absorb and dissipate vibrations generated during nail firing. The implementation of vibration dampening contributes to a more comfortable and safer working environment, allowing for prolonged use without adverse health effects.

These ergonomic considerations, from grip design to vibration dampening, are essential in the effective operation of a Ryobi finish nailer. Addressing these aspects results in improved user comfort, reduced fatigue, and enhanced productivity, ultimately leading to higher-quality finished projects and a safer working environment. The integration of ergonomic principles into the design of a finish nailer demonstrates a commitment to user well-being and the optimization of tool performance.

6. Applications

The utility of a finish nailer is defined by the scope of applications for which it is suited. These applications encompass a range of carpentry tasks requiring precision and a refined finish. Evaluating the diverse application scenarios provides insight into the tool’s versatility and its suitability for specific project requirements.

- Trim and Molding Installation

Finish nailers are commonly employed for installing trim and molding, including baseboards, crown molding, door casings, and window casings. These applications demand precise nail placement and minimal surface damage. A finish nailer ensures that the trim is securely fastened without leaving prominent nail holes, contributing to a professional appearance. For example, installing crown molding in a residential setting requires a finish nailer to create a seamless transition between the wall and ceiling.

- Cabinetry and Furniture Assembly

Cabinet and furniture assembly necessitates discreet fasteners that do not detract from the overall aesthetic. Finish nailers provide an effective means of joining cabinet components and attaching decorative elements. In furniture construction, finish nails can secure drawer fronts, backs, and sides, creating strong and visually appealing joints. The tool’s capacity for precise nail depth adjustment prevents splitting or marring of the wood surface, ensuring a high-quality finished product.

- Paneling and Wainscoting

Attaching paneling and wainscoting to walls requires a fastening method that is both secure and unobtrusive. Finish nailers are ideal for this purpose, providing the necessary holding power while leaving minimal evidence of the attachment. For instance, installing wainscoting in a dining room involves affixing panels to the wall studs, using a finish nailer to create a smooth and uniform surface. The tool’s ease of use and precision make it well-suited for this type of application.

- Staircase Construction

Building and renovating staircases often involves intricate trim work and precise fastening. Finish nailers are used to attach stair treads, risers, and decorative elements. Accurate nail placement is critical for ensuring the structural integrity and aesthetic appeal of the staircase. Examples include securing stair treads to stringers and attaching decorative molding to the handrail. The finish nailer’s ability to drive nails at consistent depths prevents damage to the wood and ensures a secure and professional finish.

These examples illustrate the broad applicability of finish nailers in carpentry and woodworking projects. The Ryobi finish nailer, in particular, offers a versatile solution for tasks demanding precision and a refined finish. Its design and features make it suitable for a wide range of applications, from basic trim work to more complex furniture and staircase construction. Understanding the diverse application scenarios allows users to select the appropriate tool for their specific needs, optimizing project outcomes and ensuring professional-quality results.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the use, maintenance, and selection of a Ryobi finish nailer. These questions aim to provide clarity and ensure optimal tool performance.

Question 1: What is the appropriate air pressure for a pneumatic Ryobi finish nailer?

The recommended air pressure typically ranges from 70 to 120 PSI, contingent upon the wood density and nail length. Consult the tool’s manual for precise specifications to prevent overdriving or underdriving nails.

Question 2: Can a Ryobi finish nailer be used with different nail gauges?

Ryobi finish nailers are designed for specific nail gauges, typically 16 or 18 gauge. Using an incorrect nail gauge can lead to jamming and damage to the tool. Always refer to the product specifications for compatible nail sizes.

Question 3: How frequently should a Ryobi finish nailer be cleaned?

Regular cleaning is recommended after each use to remove debris and prevent jams. Disconnecting the air supply (for pneumatic models) or removing the battery (for cordless models) prior to cleaning is essential for safety.

Question 4: What is the lifespan of a battery in a cordless Ryobi finish nailer?

Battery lifespan varies based on usage intensity and battery type. Ryobi’s ONE+ batteries generally provide adequate runtime for most projects; however, carrying a spare battery is advisable for prolonged use. Proper charging and storage practices extend battery longevity.

Question 5: How does one troubleshoot a Ryobi finish nailer that is misfiring or jamming?

Misfires and jams often result from incorrect nail loading or debris accumulation. Ensure the nail magazine is correctly loaded and free of obstructions. Inspect the driver blade for damage. Consult the troubleshooting section of the owner’s manual for detailed guidance.

Question 6: Are Ryobi finish nailers suitable for both professional and DIY use?

Ryobi finish nailers offer a balance of performance and affordability, making them suitable for both DIY enthusiasts and professional contractors. However, professional users may require more robust models for high-volume applications.

Understanding these frequently asked questions provides a solid foundation for effectively utilizing and maintaining a Ryobi finish nailer. Addressing these concerns proactively enhances tool performance and longevity.

The following section will provide a comparative analysis of different Ryobi finish nailer models, highlighting their unique features and suitability for various applications.

Conclusion

This exploration of the Ryobi finish nailer has detailed its applications, operational considerations, and critical features such as precision, power source, nail capacity, depth control, and ergonomics. These elements contribute to the tool’s overall utility and effectiveness in various carpentry tasks. Regular maintenance, proper nail selection, and adherence to safety guidelines are crucial for optimal performance and longevity.

Careful consideration of project requirements and user needs should inform the selection of a specific model. Further research and comparison of available options are recommended to ensure the chosen Ryobi finish nailer aligns with individual demands and promotes efficient, professional-quality results. Investing in a well-suited tool is an investment in project success and long-term productivity.