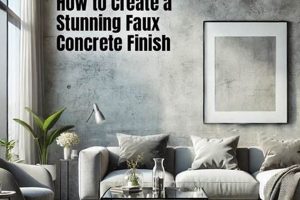

A refined cement surface presents a level, even plane, free from significant imperfections or aggregate exposure. This surface is often achieved through specialized techniques during the concrete pouring and finishing process, resulting in a sleek, modern aesthetic. Examples include polished floors in commercial spaces or walls in contemporary architectural designs.

The implementation of such surfaces provides several advantages, including enhanced durability and ease of maintenance. Its non-porous nature resists staining and simplifies cleaning. Throughout history, achieving this level of refinement has been a hallmark of skilled craftsmanship, evolving from rudimentary hand-tooling methods to advanced mechanical processes.

The remainder of this article will delve into specific methodologies used to create this type of surface, the tools and materials involved, and the factors influencing the final outcome. Further discussion will cover application considerations and the long-term performance characteristics associated with this specific treatment.

Achieving a Superior Cement Surface

The following guidelines are intended to provide practical advice for achieving a high-quality result during cement application and refinement processes.

Tip 1: Substrate Preparation is Paramount: Ensure the underlying foundation is clean, stable, and properly prepared. Remove any debris, oil, or existing coatings that could compromise adhesion. A properly prepared base is crucial for a uniform and durable outcome.

Tip 2: Precise Mixture Control: Adhere strictly to the manufacturer’s recommended water-to-cement ratio. Deviations can lead to inconsistencies in the final product, affecting strength and surface integrity. Use calibrated measuring devices for accuracy.

Tip 3: Consolidation Techniques: Employ vibration techniques during the placement process to eliminate air pockets and ensure proper density. This step minimizes voids that can weaken the surface and detract from the aesthetic appearance.

Tip 4: Timely Finishing Operations: Begin the finishing process when the surface has reached the appropriate level of plasticity. Delaying this step can lead to cracking and difficulty in achieving the desired texture and evenness. Use a bull float or darby to establish a level plane.

Tip 5: Multiple Floating Passes: Multiple passes with a float, using progressively finer blades, are essential to close the surface pores and create a dense, level plane. Allow sufficient time between passes for the material to set slightly.

Tip 6: Curing is Crucial: Implement proper curing procedures immediately after finishing to prevent rapid moisture loss. This can involve covering the surface with plastic sheeting, applying a curing compound, or regularly misting with water. Proper hydration is essential for strength development and minimizing cracking.

Tip 7: Protect the Surface: Safeguard the newly finished plane from damage during subsequent construction activities. Cover with protective materials to prevent scratches, stains, and other imperfections.

Implementing these recommendations will contribute significantly to achieving a professional result. Prioritizing preparation, precise execution, and proper curing protocols are essential for a durable, aesthetically pleasing, and long-lasting cement plane.

The next section will delve into common challenges encountered during cement application and provide troubleshooting strategies for addressing these issues effectively.

1. Preparation is key

The attainment of a refined cement plane is fundamentally reliant on thorough preliminary work. The condition of the substrate directly influences the adhesion, uniformity, and longevity of the finished surface. Inadequate preparation can manifest as surface imperfections, cracking, or premature failure, effectively negating the benefits of subsequent application techniques. For instance, applying cement over a substrate contaminated with oil or debris inhibits proper bonding, leading to delamination. Similarly, an uneven or unstable base will telegraph imperfections through the applied layer, compromising the desired level and evenness.

The significance of substrate preparation extends beyond mere cleanliness. Profiling, which involves creating a mechanical bond through roughening the existing surface, is often necessary to ensure optimal adhesion. This may involve methods such as scarifying, grinding, or shot blasting, depending on the substrate material and the desired surface profile. In cases where existing cement surfaces are being overlaid, proper repair of cracks and spalls is crucial to prevent these defects from propagating into the new plane. Furthermore, ensuring the substrate is properly wetted, but not saturated, prior to application aids in controlling the absorption rate of the cement mixture and prevents premature drying, which can lead to cracking.

In summary, meticulous substrate preparation constitutes a non-negotiable prerequisite for achieving a desirable cement surface. The investment in time and resources dedicated to this stage yields significant returns in terms of enhanced durability, improved aesthetic outcomes, and reduced long-term maintenance costs. Neglecting this foundational step introduces inherent risks that compromise the overall integrity and performance of the applied plane, ultimately hindering the realization of the intended result.

2. Mixture Consistency

The attainment of a refined cement surface is inextricably linked to the uniformity of the mixture. Deviations in consistency directly impact the workability, placement, and ultimate surface characteristics of the finished product. A mixture that is too dry, for instance, exhibits reduced plasticity, hindering its ability to flow and consolidate properly. This results in increased air entrapment, surface voids, and a higher propensity for cracking. Conversely, an excessively wet mixture leads to segregation, where the cement paste separates from the aggregate, resulting in a weakened surface with increased shrinkage and potential for dusting. A consistent mixture, on the other hand, allows for optimal consolidation, reducing air pockets and ensuring a dense, homogenous surface. This density directly translates into improved durability, reduced permeability, and enhanced resistance to abrasion. Consider, for example, the application of self-leveling cement toppings used to achieve extremely flat floors. The inherent fluidity of these materials is directly related to their precise mixture consistency, allowing them to spread evenly and eliminate imperfections.

The control of mixture consistency is achieved through careful measurement and monitoring of the water-to-cement ratio. This ratio is a critical parameter that directly influences the hydration process, strength development, and overall performance. Modern cement mixes often incorporate admixtures, such as water reducers or plasticizers, to enhance workability without increasing the water content. These admixtures allow for the creation of highly workable mixes that exhibit excellent surface characteristics. Furthermore, the type and gradation of aggregates used in the mix also contribute to consistency. Well-graded aggregates, which contain a balanced distribution of particle sizes, promote better packing and reduce the amount of cement paste required to fill the voids, resulting in a stronger and more durable product. For instance, when creating precast cement elements requiring exceptionally precise dimensions and surface quality, strict control over the mixture consistency is vital to prevent warping, cracking, and surface defects during the curing process.

In conclusion, maintaining mixture consistency is not merely a procedural detail, but a fundamental requirement for achieving a refined cement surface. The effects of inconsistencies manifest in numerous ways, from compromised structural integrity to aesthetic defects. Through precise control of the water-to-cement ratio, the utilization of appropriate admixtures, and the selection of well-graded aggregates, professionals can ensure optimal workability, consolidation, and surface characteristics. Addressing the challenges related to mixture consistency through diligent monitoring and quality control measures is essential to achieving a surface that meets both functional and aesthetic requirements, contributing to the long-term performance and visual appeal of the structure.

3. Consolidation matters

Effective cement consolidation is integral to realizing a high-quality, refined surface. Proper consolidation techniques directly influence the density, durability, and aesthetic appearance of the final product. The presence of voids and air pockets, resulting from inadequate consolidation, compromises surface integrity and diminishes the achievable level of refinement.

- Air Void Reduction

Consolidation processes, such as vibration, remove entrapped air within the cement mixture. These air voids weaken the cement matrix and create pathways for moisture penetration, leading to premature deterioration. A properly consolidated mass, with minimal air voids, yields a denser, more impermeable surface, less susceptible to damage from freeze-thaw cycles or chemical attack. Examples include bridge decks, where effective consolidation is essential for long-term durability in harsh environments.

- Aggregate Distribution

Consolidation facilitates the uniform distribution of aggregate particles within the cement matrix. This uniform distribution ensures that the load-bearing capacity is evenly dispersed across the surface. Improper consolidation can lead to segregation, where larger aggregate particles settle to the bottom, leaving a weak, paste-rich surface susceptible to abrasion and wear. Industrial floors, subjected to heavy machinery and traffic, require proper consolidation to ensure a durable surface capable of withstanding sustained use.

- Bond Enhancement

Effective consolidation improves the bond between the cement and any reinforcing steel present. This bond is crucial for transferring stresses and ensuring the structural integrity of the element. Inadequate consolidation can result in voids around the reinforcing steel, compromising its effectiveness and increasing the risk of corrosion. Applications in high-rise buildings, where steel reinforcement is critical, demonstrate the importance of consolidation for overall structural performance.

- Surface Finish Improvement

Proper consolidation reduces surface defects and improves the overall finish. By eliminating air voids and ensuring a dense, homogenous mixture, consolidation facilitates the creation of a level, even plane, free from imperfections. This enhanced surface quality simplifies subsequent finishing operations, such as polishing or coating, and enhances the aesthetic appeal. Architectural elements, such as exposed cement walls, benefit from effective consolidation, resulting in a visually appealing and durable surface.

The multifaceted benefits of effective cement consolidation underscore its importance in achieving a surface of superior quality. Addressing consolidation deficiencies through appropriate techniques and equipment is essential for maximizing the potential of cement and realizing the desired aesthetic and functional characteristics. The selection of appropriate consolidation methods and equipment should be based on project-specific considerations, including cement mix design, placement conditions, and structural requirements. Careful attention to consolidation results in cement products that are more robust, durable, and visually pleasing, contributing to the long-term performance of constructed infrastructure and buildings.

4. Timing crucial

The attainment of a refined cement surface is critically dependent on precise timing throughout the placement and finishing processes. Deviations from established timelines can significantly compromise the achievable level of smoothness and overall surface quality. The window of opportunity for effective finishing is finite, influenced by factors such as temperature, humidity, and cement mix design.

- Initial Setting and Floating Operations

The timing of initial floating operations is paramount in establishing a level plane and removing surface imperfections. Commencing floating too early, when the cement is overly plastic, can result in tearing and displacement of the surface layer. Conversely, delaying floating until the cement has hardened excessively makes it difficult to achieve the desired levelness and close surface pores. Experienced finishers assess the surface conditions meticulously to determine the optimal time for initiating these operations. Examples include observing the disappearance of surface water sheen and assessing the cement’s resistance to indentation. Precise timing ensures that the surface can be effectively manipulated to achieve the desired degree of flatness and eliminate surface irregularities.

- Bleed Water Management

The emergence of bleed water, the excess water rising to the surface after placement, necessitates careful management. Prematurely sealing the surface before bleed water has fully evaporated can trap moisture, leading to blistering and weakening of the surface layer. Allowing the bleed water to evaporate completely before commencing finishing operations ensures that the cement paste is sufficiently consolidated and that the surface is free from excess moisture. In large cement pours, such as slabs on grade, bleed water management is crucial to prevent localized variations in surface quality and ensure uniform strength development.

- Curing Commencement

The timing of curing commencement is critical in preventing rapid moisture loss and promoting proper hydration. Delaying curing can lead to surface cracking, reduced strength, and increased permeability. Initiating curing as soon as the finishing operations are complete helps to retain moisture, facilitating the continuous hydration of cement particles and strengthening the cement matrix. Various curing methods, such as the application of curing compounds, plastic sheeting, or continuous misting, can be employed. Selecting the appropriate curing method and initiating it promptly contributes to the overall durability and longevity of the refined surface.

- Joint Cutting and Contraction Management

The timing of joint cutting dictates its effectiveness in controlling cracking due to the cement shrinkage. Premature cutting is harmful to the cement, so it is better to cut at the right time. Early-entry saws are very good at controlling the timing of cutting joints and contraction management.

The interplay of these timing-dependent factors underscores the necessity for a skilled and experienced workforce. Effective management of each stage in relation to environmental conditions and cement properties is essential to achieve the desired surface properties and prevent common defects that compromise long-term performance. The success of achieving and maintaining a desirable level, flat cement finish depends on a keen awareness of these time constraints and an ability to adapt techniques to suit the prevailing conditions.

5. Proper floating

The creation of a refined cement surface is intrinsically linked to the execution of proper floating techniques. This process, performed after screeding and initial leveling, involves using specialized tools to further consolidate the surface, embed larger aggregate particles, and eliminate minor imperfections. Proper execution directly contributes to surface uniformity, density, and flatness, all critical attributes of a refined final product. For instance, improper floating can result in surface undulations, exposed aggregate, or a weakened surface paste, all detrimental to the desired aesthetic and functional characteristics. In large industrial floors, where flatness is paramount for efficient operation of equipment, skilled floating is essential for achieving the required tolerances.

Effective floating involves multiple passes with appropriate tools, such as bull floats, darbies, or hand floats, each serving a specific purpose. The selection of the correct tool and the timing of its use are critical factors. Early floating aims to level the surface and embed coarse aggregate, while subsequent passes with finer floats work to close surface pores and create a dense, homogenous finish. The angle and pressure applied during floating also influence the outcome. Excessive pressure can cause surface tearing or segregation, while insufficient pressure may not effectively consolidate the cement paste. Experienced finishers possess the skill and judgment to adapt their techniques to suit the specific cement mix, environmental conditions, and desired surface characteristics. Consider the crafting of architectural precast panels, where the visual quality of the surface directly impacts the aesthetic appeal. Precise floating operations are vital in creating a smooth, uniform surface suitable for subsequent finishing treatments or direct exposure.

In summary, proper floating constitutes a critical element in the creation of a refined cement surface. The technique addresses surface imperfections, enhances density, and promotes uniformity, each contributing to the overall quality and performance of the finished product. Mastering the art of floating requires a combination of technical knowledge, practical skill, and an understanding of the cement’s behavior under varying conditions. The investment in skilled labor and appropriate tools for floating yields significant dividends in terms of improved durability, enhanced aesthetic appeal, and reduced long-term maintenance costs, making it an indispensable step in achieving a superior result.

6. Curing protects

Adequate cement curing practices play a pivotal role in safeguarding and enhancing the characteristics of a smooth cement surface. Proper curing mitigates potential surface defects and contributes significantly to the material’s long-term durability and aesthetic appeal.

- Hydration Enhancement

Curing provides the necessary moisture for the continuous hydration of cement particles. This hydration process is essential for the development of strength and durability. Without adequate moisture, the hydration process ceases prematurely, leading to a weaker surface susceptible to cracking and abrasion. For instance, in arid climates, rapid moisture loss can severely impair surface strength and longevity.

- Cracking Mitigation

Proper curing practices minimize the risk of shrinkage cracking, a common defect in cement surfaces. Controlled hydration reduces internal stresses caused by rapid moisture loss, preventing the formation of surface cracks. The application of curing compounds or wet coverings maintains consistent moisture levels, mitigating the potential for cracking, particularly in large, exposed surfaces such as pavements.

- Dusting Reduction

Adequate curing reduces the likelihood of surface dusting, a phenomenon characterized by the release of fine cement particles from the surface. Proper hydration strengthens the cement paste, preventing the formation of a weak, friable surface prone to dusting. In industrial settings, where abrasion resistance is critical, proper curing is essential for minimizing dusting and maintaining surface integrity.

- Surface Density Improvement

Curing promotes increased surface density, reducing permeability and enhancing resistance to staining and chemical attack. A well-cured surface is less porous, preventing the ingress of liquids and contaminants that can degrade the cement matrix. This is particularly important in surfaces exposed to harsh environmental conditions or aggressive chemicals, such as laboratory benchtops or wastewater treatment facilities.

The benefits of proper curing extend beyond immediate visual improvements. By promoting hydration, mitigating cracking, reducing dusting, and improving surface density, curing safeguards the integrity and longevity of the refined cement area, contributing to its overall performance and minimizing long-term maintenance requirements. The selection of appropriate curing methods and their diligent application are therefore paramount in realizing the full potential of a smooth cement result.

Frequently Asked Questions

The following questions and answers address common concerns and misconceptions regarding the creation and maintenance of a specific, even cement surface.

Question 1: What defines a cement surface as being considered refined?

A refined cement surface is characterized by its level, even plane, absence of significant imperfections such as cracking or pitting, and a consistent texture. The surface typically exhibits a closed pore structure and minimal aggregate exposure.

Question 2: What is the single most crucial factor in achieving a refined cement plane?

While multiple factors contribute, meticulous substrate preparation is of paramount importance. A clean, stable, and properly profiled base is essential for ensuring adequate adhesion and preventing surface defects.

Question 3: How does the water-to-cement ratio influence the quality of a refined cement application?

Maintaining a precise water-to-cement ratio is critical. Excessive water weakens the surface, leading to dusting and cracking, while insufficient water reduces workability and impedes proper consolidation.

Question 4: What role does consolidation play in the development of a durable surface?

Consolidation removes entrapped air within the cement mixture, increasing density and reducing permeability. This results in improved resistance to freeze-thaw damage, chemical attack, and abrasion.

Question 5: Why is the timing of finishing operations considered crucial?

Initiating floating and troweling operations at the appropriate stage of cement hardening is essential for achieving a level plane and closing surface pores. Premature or delayed finishing can lead to surface imperfections and reduced durability.

Question 6: How does proper curing contribute to the long-term performance of a refined cement application?

Curing provides the necessary moisture for continuous cement hydration, enhancing strength, reducing cracking, and improving surface density. Adequate curing is essential for maximizing the durability and longevity of the surface.

Proper planning and execution are paramount to achieving the desired outcome.

The next section will detail case studies of project failures and effective implementations.

Smooth Concrete Finish

This exploration has underscored that achieving a smooth concrete finish is not merely the outcome of a single technique, but rather the culmination of meticulous planning, precise execution, and consistent quality control throughout the entire construction process. From initial substrate preparation to final curing procedures, each step significantly influences the surface’s aesthetic appeal, durability, and long-term performance. The importance of consistent mixture control, proper consolidation, and timely finishing operations cannot be overstated.

The pursuit of a smooth concrete finish demands a commitment to excellence and a thorough understanding of the material’s properties and behavior. Continuous advancements in concrete technology and finishing techniques offer new opportunities for achieving increasingly refined surfaces. A dedication to best practices and a focus on innovation will ensure that smooth concrete finish continues to be a hallmark of quality construction for years to come.