A treatment applied to wooden surfaces imparts a specific color and sheen reminiscent of the heartwood of Juglans, a genus of trees valued for their dark, fine-grained lumber. This application is commonly utilized to enhance the aesthetic appeal of furniture, cabinetry, and architectural details, offering a rich, warm tone. An example would be a dining table meticulously crafted from a less expensive material, then treated to simulate the deep, lustrous appearance associated with the premium hardwood.

This particular surface application holds significant value due to its ability to evoke a sense of luxury and sophistication without the cost associated with solid hardwood construction. It provides a durable layer of protection against daily wear and tear, extending the lifespan of the underlying material. Historically, the color has been favored for its classic elegance and versatility, seamlessly complementing a wide range of interior design styles, from traditional to contemporary.

The following discussion will delve into the various application methods of this treatment, explore the range of available color variations, and outline best practices for maintaining its beauty and integrity over time. The advantages and disadvantages of this method compared to using genuine lumber will also be addressed, providing a complete overview for consumers and professionals alike.

Application and Maintenance Guidelines

The following guidelines provide essential information for the successful application and long-term preservation of surfaces treated to resemble Juglans lumber.

Tip 1: Surface Preparation is Paramount: Prior to application, ensure the substrate is clean, dry, and free from dust, grease, or existing coatings. Proper preparation directly impacts adhesion and the final appearance of the treated surface. Light sanding is often recommended.

Tip 2: Select a Compatible Application Method: Options include brushing, spraying, or wiping. Each technique yields a different result; spraying provides the most even coverage, while brushing allows for greater control on intricate details. Consider the surface area and desired effect when choosing an application method.

Tip 3: Apply Thin, Even Coats: Multiple thin coats are preferable to a single thick coat. This minimizes runs, drips, and uneven drying, resulting in a smoother, more consistent finish. Allow each coat to dry completely before applying the next, adhering to the manufacturer’s recommended drying times.

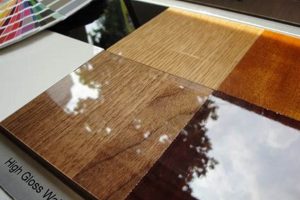

Tip 4: Consider the Sheen Level: Treatments are available in various sheen levels, from matte to high-gloss. Select a sheen that complements the style of the piece and the surrounding decor. Lower sheens tend to conceal imperfections, while higher sheens emphasize the wood grain.

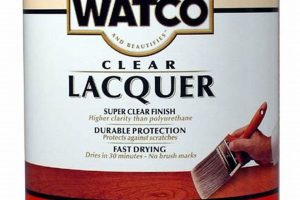

Tip 5: Utilize a Topcoat for Protection: After the application has fully cured, consider applying a clear topcoat for added protection against scratches, moisture, and UV damage. This topcoat will extend the lifespan and preserve the appearance of the treated surface.

Tip 6: Regular Cleaning is Essential: Clean surfaces regularly with a soft, damp cloth and mild soap. Avoid harsh chemicals or abrasive cleaners, which can damage the finish. Wipe dry to prevent water spots.

Tip 7: Periodic Maintenance: Over time, the finish may show signs of wear. Re-application may be necessary to restore its original luster and protective properties. Consult the product manufacturer’s guidelines for specific maintenance recommendations.

Adhering to these guidelines will ensure a professional-looking result and maximize the longevity of the treated surfaces, preserving their beauty for years to come.

The subsequent sections will explore common problems encountered during application and offer solutions for achieving optimal results.

1. Color Variation

Color variation is a defining characteristic when discussing treatments intended to replicate the appearance of Juglans lumber. This variation, inherent in the natural wood itself, is a key factor considered during formulation and application, aiming to capture the authentic aesthetic.

- Heartwood vs. Sapwood Mimicry

The heartwood of Juglans species typically presents a richer, darker hue compared to the sapwood, which is lighter in color. Treatments strive to replicate this natural contrast, sometimes employing techniques to simulate the subtle gradations between the two. Failure to address this distinction results in an artificial or flat appearance, detracting from the realism.

- Pigment Formulation and Blending

Achieving accurate color replication requires a complex blend of pigments. Manufacturers utilize precise ratios of browns, reds, and sometimes yellows to match the specific undertones found in different varieties of Juglans. Inaccurate pigment blending leads to hues that are either too warm or too cool, ultimately failing to capture the authentic color profile.

- UV Light Exposure and Color Shift

Like natural wood, treatments are susceptible to color changes over time due to ultraviolet light exposure. Some formulations incorporate UV inhibitors to minimize fading or yellowing. Understanding the potential for color shift is crucial when selecting a treatment for surfaces exposed to direct sunlight.

- Application Technique and Layering Effects

The method of application influences the final color appearance. Layering techniques, such as applying multiple thin coats, allow for greater control over the depth and richness of the color. Uneven application or the application of a single, thick coat often results in inconsistent color distribution and an undesirable blotchy appearance.

Understanding and accurately replicating these color variations is essential for achieving a realistic and aesthetically pleasing imitation. Disregard for these nuances diminishes the perceived value and authenticity, highlighting the importance of careful formulation and application techniques to emulate the natural beauty of Juglans lumber.

2. Grain Enhancement

Grain enhancement plays a pivotal role in the successful replication of Juglans lumber’s distinctive character. The treatment not only imparts color but also accentuates the inherent patterns and textures within the wood, contributing significantly to the perceived quality and aesthetic value.

- Highlighting Natural Figure

The figure, or pattern, present in lumber varies significantly. Treatments designed to replicate Juglans often employ techniques to emphasize these patterns, such as burl, curl, or crotch figures. Select stains and application methods are chosen to draw attention to these features, creating visual interest. For instance, a cathedral grain pattern may be accentuated with a stain that settles into the darker areas, increasing the contrast. Failure to properly highlight the existing figure can result in a flat, uninspired surface.

- Creating Depth and Dimension

Strategic use of shading and glazing techniques enhances the perception of depth and dimension within the wood grain. This involves applying varying tones of the application to create highlights and shadows, mimicking the natural play of light on textured surfaces. Improper shading can flatten the grain, making the surface appear artificial.

- Pore Filling and Surface Texture

The size and distribution of pores on the wood surface influence the overall texture and appearance. Some processes involve filling the pores to create a smooth, even surface, while others leave the pores open to enhance the natural texture. The choice depends on the desired aesthetic; a smooth finish typically conveys a more formal appearance, while an open-pore finish evokes a rustic or natural feel.

- Enhancing Medullary Rays

Medullary rays, visible as flecks or lines perpendicular to the grain, are particularly prominent in certain cuts of lumber. Treatments may emphasize these rays to add visual interest and authenticity. Proper enhancement can create a shimmering effect, particularly under specific lighting conditions. Conversely, obscuring the medullary rays can result in a less convincing imitation.

These interconnected facets of grain enhancement are crucial for achieving a convincing and aesthetically pleasing replication. By carefully considering and manipulating these elements, skilled artisans and manufacturers can transform ordinary surfaces into compelling imitations that capture the beauty and character of Juglans lumber.

3. Protective Coating

A protective coating is integral to the longevity and aesthetic preservation of surfaces treated to resemble Juglans lumber. It acts as a barrier against environmental factors and physical wear, safeguarding the underlying surface and maintaining the desired appearance.

- Scratch and Abrasion Resistance

Coatings formulated for wood surfaces provide a degree of resistance against scratches and abrasions encountered during normal use. For instance, a polyurethane coating on a table treated with a Juglans finish minimizes the visibility of superficial damage from everyday objects. Without such protection, the underlying treatment is more vulnerable to damage, leading to premature wear and requiring more frequent refinishing.

- UV Light Protection

Prolonged exposure to ultraviolet (UV) light can cause fading and discoloration in both natural wood and simulated surfaces. Protective coatings often incorporate UV inhibitors that absorb or reflect harmful rays, slowing down the degradation process. Consider a cabinet exposed to direct sunlight; a coating with UV protection will help maintain the richness of the color for a longer period than one without.

- Moisture Resistance

Moisture can cause warping, swelling, and staining of wood products. Protective coatings, particularly those formulated with water-resistant resins, create a barrier against moisture penetration. Countertops and furniture in humid environments benefit significantly from this protection, preventing water rings and other forms of moisture damage.

- Chemical Resistance

Household chemicals, such as cleaning solutions and solvents, can damage or dissolve the application if unprotected. Protective coatings offer a level of resistance to these chemicals, preventing staining, etching, and other forms of chemical damage. A kitchen table finished with a Juglans stain and a chemical-resistant coating is less likely to be marred by spills.

These protective attributes collectively contribute to the long-term viability and aesthetic appeal of surfaces treated with applications. By mitigating the effects of physical wear, UV exposure, moisture, and chemical exposure, protective coatings ensure that the desired color and finish are preserved, extending the lifespan of the treated item. The choice of coating should align with the intended use of the item and the environmental conditions to which it will be exposed.

4. Application Method

The selection and execution of the application method profoundly impact the final appearance and durability of surfaces treated to resemble Juglans lumber. Different techniques yield distinct visual and tactile outcomes, influencing color uniformity, grain definition, and overall protective qualities.

- Brushing Techniques and Surface Texture

Brushing is a manual application method that allows for precise control, particularly on intricate details and contoured surfaces. The bristles of the brush leave subtle striations, enhancing the texture and creating a hand-applied aesthetic. However, improper brushing can result in uneven coverage, brush marks, and an inconsistent color profile. For instance, a cabinet door with raised panels benefits from the controlled application afforded by brushing, allowing the applicator to reach corners and crevices effectively. The resulting texture adds depth and character, reminiscent of artisanal craftsmanship. In contrast, a large, flat surface may exhibit noticeable brush strokes if this method is not executed with care and expertise.

- Spraying Methods and Uniformity of Color

Spraying, whether utilizing compressed air or airless systems, provides a more uniform application, minimizing visible brush marks and ensuring consistent color distribution. This technique is well-suited for large, flat surfaces where a smooth, flawless finish is desired. However, spraying requires careful masking to protect surrounding areas from overspray, and proper ventilation is essential to mitigate health hazards. Automotive refinishing, for example, employs spraying techniques to achieve a uniform and durable coating. Similarly, spraying techniques applied to furniture enhance visual depth, adding to a product’s value.

- Wiping Stains and Grain Definition

Wiping stains are applied liberally and then wiped away with a cloth, allowing the stain to penetrate the wood pores and accentuate the grain pattern. This technique enhances the contrast between the light and dark areas of the wood, highlighting its natural figure. The type of cloth used and the wiping pressure affect the amount of stain that remains on the surface, influencing the overall color intensity. A mahogany table, when treated with a wiping stain, will exhibit a greater depth of grain as the stain settles into the open pores, resulting in a more pronounced and aesthetically pleasing grain pattern. Wiping application creates a surface pleasing to the eye.

- Application of Protective Clear Coats

Following the treatment process, the application of a protective clear coat is applied to the surface to add durability. Different application methods are used depending on the type of material and desired look. Spraying the material to create a uniform, smooth finish, brushing for intricate work, or rolling the material for larger surfaces are the primary options. A table will need to be durable against potential spills so multiple coats of clear protective coating will need to be applied to protect the wood underneath. The quality of the finish and application will determine how resistant it is to potential damage.

In summary, the selection of an application method is not merely a matter of convenience but a critical determinant of the aesthetic quality and longevity of surfaces finished to emulate Juglans. Each technique offers distinct advantages and disadvantages, influencing color uniformity, grain definition, and overall durability. The choice must align with the characteristics of the wood substrate, the desired aesthetic, and the skill level of the applicator to achieve a result that convincingly captures the beauty and character of genuine Juglans lumber.

5. Durability Level

The durability level of surfaces finished to emulate Juglans lumber is a critical consideration, influencing the longevity, maintenance requirements, and overall value of the treated article. The intrinsic properties of the application, combined with the application method, directly affect its resistance to wear, environmental factors, and chemical exposure. The subsequent examination details key facets of durability.

- Abrasion Resistance and Surface Integrity

Abrasion resistance dictates the treated surface’s ability to withstand rubbing, scratching, and other forms of mechanical wear. A higher abrasion resistance rating indicates a greater capacity to maintain surface integrity over time. For example, a tabletop treated with a Juglans stain and a durable polyurethane clear coat exhibits superior scratch resistance compared to a surface treated with only the stain and no protective topcoat. The absence of adequate abrasion resistance leads to premature wear, necessitating frequent refinishing or replacement.

- Chemical Resistance and Stain Prevention

The resistance to chemical exposure determines the treated surface’s ability to withstand contact with common household chemicals, solvents, and cleaning agents. A chemically resistant application prevents staining, etching, and other forms of chemical damage. Kitchen cabinetry finished to resemble Juglans benefits from a chemically resistant coating, protecting it from spills and splashes of acidic or alkaline substances. Surfaces lacking chemical resistance are vulnerable to irreversible damage, compromising their aesthetic appeal and functional utility.

- Moisture Resistance and Dimensional Stability

Moisture resistance refers to the ability of the treated surface to repel water and prevent moisture absorption. High moisture resistance is essential to maintain dimensional stability, preventing warping, swelling, and delamination of the underlying substrate. Bathroom vanities finished with a Juglans-colored treatment require a moisture-resistant coating to withstand high humidity and prevent water damage. Inadequate moisture resistance leads to structural instability and aesthetic degradation.

- UV Resistance and Color Retention

Ultraviolet (UV) resistance measures the treated surface’s ability to withstand prolonged exposure to sunlight without fading, discoloration, or degradation. Applications with UV inhibitors prevent the breakdown of pigments and resins, preserving the original color and finish. Exterior doors finished to resemble Juglans necessitate a UV-resistant clear coat to maintain their aesthetic appeal over time. Without UV protection, the treated surface is prone to fading and yellowing, diminishing its visual appeal.

These durability factors are interdependent and collectively determine the long-term performance of surfaces finished to emulate Juglans lumber. A comprehensive understanding of these facets enables informed selection of treatment materials and application methods, optimizing the durability and ensuring the lasting aesthetic appeal of the treated article. The selection of a “walnut wood finish” with a higher durability level ensures the long-term protection and attractiveness of furniture or other items.

6. Aesthetic Appeal

The allure of Juglans lumber, particularly its warm, dark tones and distinctive grain patterns, drives the widespread adoption of treatments designed to mimic its appearance. Aesthetic appeal is, therefore, not merely a desirable attribute but a foundational element of applications emulating this wood. The effectiveness of any such treatment is directly correlated with its ability to replicate the visual characteristics that define this highly prized material. Failure to capture the richness of color, the depth of grain, or the subtle variations inherent in Juglans lumber diminishes the perceived value and renders the treatment less desirable. For instance, consider furniture constructed from a less expensive wood, subsequently stained to resemble Juglans. The stain’s success hinges on its ability to convincingly convey the sought-after aesthetic, transforming a utilitarian piece into an object of visual interest and perceived higher quality. This highlights the importance of faithful replication in enhancing consumer appeal and perceived value.

The importance of aesthetic appeal extends beyond simple visual gratification. It plays a crucial role in influencing purchasing decisions, shaping perceptions of quality, and creating desired ambiances in interior spaces. Designers often select materials based on their ability to evoke specific emotions or complement existing design elements. A space designed with dark “walnut wood finish” can create an aura of timeless sophistication. Correct color and grain imitation create a sense of luxury and calm. The success or failure of the overall design depends heavily on the aesthetic qualities of the materials employed, including those imitating Juglans lumber. The more closely the imitation reflects the genuine article, the more successfully it contributes to the intended design aesthetic. Consequently, manufacturers invest significant resources in developing treatments that accurately replicate the visual attributes of this valued hardwood.

In summary, aesthetic appeal is an inseparable and vital component of applications designed to simulate Juglans lumber. Its influence extends from consumer perception and purchasing decisions to the overall success of design projects. Challenges remain in achieving perfect replication, particularly concerning variations in color, grain, and texture. Continual advancements in material science and application techniques strive to overcome these challenges, reflecting the enduring demand for the aesthetic qualities associated with prized hardwoods. Further investigation reveals the connection between aesthetic qualities and how to preserve and maintain them.

Frequently Asked Questions

This section addresses common inquiries regarding surfaces treated to resemble Juglans lumber. The following questions and answers provide clarification on various aspects, including maintenance, durability, and application.

Question 1: What is the expected lifespan of a Walnut Wood Finish on furniture exposed to moderate use?

The lifespan varies significantly depending on the quality of the finish, the application method, and the level of care provided. A well-applied, high-quality polyurethane coating on a table subjected to moderate use can last for several years, perhaps a decade or more, with proper maintenance. Surfaces subjected to heavy use or harsh conditions will naturally exhibit a shorter lifespan.

Question 2: How does Walnut Wood Finish react to common household cleaning products?

The reaction depends on the chemical composition of the cleaning product and the protective properties of the surface treatment. Harsh chemicals, abrasive cleaners, and solvents can damage or dissolve many protective coatings. It is advisable to use mild soap and water for routine cleaning. Consult the manufacturer’s recommendations for specific cleaning guidelines.

Question 3: Is Walnut Wood Finish susceptible to fading or discoloration when exposed to sunlight?

Yes, prolonged exposure to ultraviolet (UV) light can cause fading and discoloration. Finishes containing UV inhibitors offer greater protection against sunlight-induced degradation. Placing furniture away from direct sunlight or using window coverings can mitigate this effect.

Question 4: What are the primary differences between a Walnut Wood Finish and genuine Walnut lumber?

The primary differences lie in the material composition, cost, and inherent properties. A finish is an applied surface treatment, while genuine Juglans lumber is solid wood. Genuine lumber typically commands a higher price point and exhibits unique grain patterns and variations. Finishes can mimic the appearance of Juglans at a lower cost, but they do not possess the same structural integrity or tactile qualities.

Question 5: Can a damaged Walnut Wood Finish be repaired, or is complete refinishing required?

Minor scratches and blemishes can often be repaired with touch-up markers or repair kits designed for wood finishes. More extensive damage, such as deep scratches, water stains, or discoloration, may necessitate complete refinishing. The feasibility of repair depends on the severity and extent of the damage.

Question 6: What are the environmental considerations associated with Walnut Wood Finish applications?

Many traditional wood finishing products contain volatile organic compounds (VOCs), which can contribute to air pollution. Water-based finishes and low-VOC formulations are available as more environmentally responsible alternatives. Proper disposal of waste materials, such as used rags and containers, is essential to minimize environmental impact.

In summary, understanding the properties, maintenance requirements, and environmental considerations associated with this type of application is essential for ensuring its long-term performance and aesthetic appeal. Proper care and informed decision-making can maximize the benefits and minimize the drawbacks of this popular surface treatment.

The following section will provide a comparative analysis between various brands and formulations of “walnut wood finish,” offering insights into their respective strengths and weaknesses.

Conclusion

This exposition has detailed the multifaceted nature of a surface treatment intended to replicate the aesthetic qualities of Juglans lumber. Attention was given to color variations, grain enhancement techniques, protective coatings, application methods, and the overall durability achieved through various formulations and procedures. Careful consideration of these elements remains paramount in achieving a satisfactory and lasting result.

The decision to employ a “walnut wood finish” necessitates a comprehensive understanding of both its potential and its limitations. Ongoing advancements in materials science offer the prospect of increasingly realistic and durable imitations, yet informed evaluation and responsible application practices are essential to ensure the enduring beauty and functional integrity of treated surfaces. The pursuit of excellence in surface treatments requires a continued dedication to knowledge and skill.