These slender fasteners, commonly used in woodworking, measure one inch in length and are designed for applications requiring minimal visibility of the nail head. Their small head size allows for easy concealment with wood filler or paint, resulting in a smooth, professional finish. An example of their use would be attaching delicate trim to furniture or securing thin pieces of molding.

The benefit of utilizing such fasteners lies in their capacity to provide a strong hold without detracting from the aesthetic appeal of the finished product. They are frequently employed where visual appearance is paramount, such as in cabinet making, fine woodworking, and decorative trim installation. Historically, similar small nails have been used for centuries in crafts and construction where a less conspicuous fastener was desired.

The following sections will further explore the specific applications, appropriate tools, and best practices for using these fasteners effectively. Consideration will be given to material selection, proper driving techniques, and safety precautions to ensure optimal results and a long-lasting, visually pleasing outcome.

Usage Tips

The following tips provide guidance on the effective and safe employment of these fasteners for optimal results in various woodworking projects.

Tip 1: Select the Appropriate Gauge: Consider the thickness of the materials being joined. A thinner gauge prevents splitting in delicate wood, while a thicker gauge offers greater holding power in denser materials.

Tip 2: Use a Nail Set: Employ a nail set to countersink the nail head slightly below the surface of the wood. This allows for seamless filling and sanding, achieving a flawless finish.

Tip 3: Pre-Drill Pilot Holes in Hardwoods: When working with hardwoods, pre-drilling pilot holes prevents the wood from splitting and ensures the nail drives straight and true.

Tip 4: Orient the Wood Grain: Be mindful of the wood grain direction. Driving nails parallel to the grain increases the risk of splitting; drive at a slight angle for improved grip.

Tip 5: Consider Adhesive: For added strength, apply a small amount of wood glue to the joint before nailing. This enhances the bond and provides long-term stability.

Tip 6: Employ Consistent Spacing: Maintain consistent spacing between fasteners for a uniform appearance and even distribution of holding force.

Tip 7: Inspect for Bending: Regularly inspect the fasteners during installation. If a nail bends over, remove it and replace it with a fresh one to avoid compromising the joint’s integrity.

Adhering to these recommendations will promote successful outcomes, enhancing both the structural integrity and the aesthetic quality of woodworking projects.

The subsequent section will address common challenges and troubleshooting techniques related to the usage of these fasteners, further refining the understanding of their proper application.

1. Gauge Selection

Gauge selection, in the context of one-inch finishing nails, directly influences the fastener’s holding power and its potential to split the wood being joined. Choosing the correct gauge is vital for achieving a secure and aesthetically pleasing finish in woodworking projects.

- Impact on Holding Strength

A lower gauge number indicates a thicker nail, resulting in increased holding strength. However, using a thicker nail in delicate wood can lead to splitting. The one-inch length limits the total holding power regardless of gauge, making appropriate gauge selection crucial for the specific wood type. For example, a thicker gauge may be suitable for denser hardwoods, while a thinner gauge is necessary for softwoods.

- Risk of Splitting Wood

Overly thick nails can easily split wood, particularly when driven near the edge or end of a board. The slender profile of finishing nails is designed to minimize this risk, but proper gauge selection remains critical. One-inch finishing nails, due to their short length, offer less surface area for friction, making splitting a greater concern if an inappropriate gauge is used. Pre-drilling pilot holes can further mitigate this risk when using thicker gauges in hardwoods.

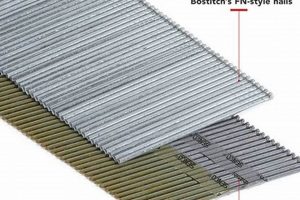

- Compatibility with Nail Guns

While typically hand-driven, some nail guns are designed to use finishing nails. Gauge compatibility is essential for proper function and to prevent damage to the tool or the workpiece. Using the incorrect gauge can cause jams, misfires, or even damage to the nail gun’s mechanism. Ensure the nail gun’s specifications align with the gauge of the one-inch finishing nails being used.

- Aesthetic Considerations

The gauge of the finishing nail affects the size of the hole left in the wood. While finishing nails are designed for minimal visibility, a larger gauge will create a more noticeable hole that requires more filler to conceal. In applications where aesthetics are paramount, selecting the thinnest gauge that provides adequate holding power is preferred. The one-inch length makes filling and sanding easier, but the initial hole size still influences the final appearance.

The judicious selection of gauge, therefore, is a balancing act between achieving sufficient holding power and minimizing the risk of splitting the wood, while also taking into account the compatibility with any tools being used and the desired aesthetic outcome. Understanding these interdependencies allows for the effective use of one-inch finishing nails in a variety of woodworking applications.

2. Concealment capability

Concealment capability is a defining characteristic of one-inch finishing nails, directly impacting their utility in applications where aesthetic considerations are paramount. The design of these fasteners, specifically the small head size, facilitates easy covering with wood filler or paint. This inherent feature allows for the creation of seamless, visually unobtrusive joints. The relatively short length of the nail further contributes to this characteristic, minimizing the potential for protrusion and facilitating easier countersinking.

The importance of this concealment capability is evident in a multitude of woodworking scenarios. For instance, when attaching delicate molding to furniture or installing trim around windows and doors, the ability to hide the fasteners becomes crucial for achieving a professional and polished appearance. Failing to adequately conceal the nails would detract from the overall aesthetic, rendering the finishing work subpar. In cabinet making, where clean lines and smooth surfaces are highly valued, these fasteners are chosen precisely for their ability to disappear beneath a layer of finish, leaving only the wood itself on display. The cause and effect is direct: small head size, proper countersinking, and appropriate finishing techniques lead to effective concealment, resulting in a visually superior finished product.

Understanding the interplay between one-inch finishing nails and concealment techniques provides a craftsman with a powerful tool for achieving high-quality results. While the nails provide the necessary holding power, the focus on concealment elevates the finished product from merely functional to aesthetically refined. Challenges arise when working with denser woods or attempting to hide imperfectly driven nails, requiring careful attention to detail and skillful application of wood filler. In summary, the marriage of these fasteners with proper finishing techniques provides the aesthetic appeal essential in many woodworking projects.

3. Material Compatibility

The selection of appropriate fasteners hinges critically on material compatibility, a principle that ensures the longevity and structural integrity of joined components. For one-inch finishing nails, understanding this compatibility is paramount to prevent issues like corrosion, staining, and joint failure.

- Wood Density and Splitting

The density of the wood dictates the gauge and alloy of the finishing nail required. Softwoods, like pine, necessitate thinner gauge nails to prevent splitting, while hardwoods, such as oak, may require thicker gauges or pre-drilling. An inappropriately sized nail for a given wood density can lead to structural weakness or aesthetic flaws. The one-inch length further emphasizes the need for correct gauge selection, as shorter nails have less surface area for grip.

- Corrosion and Environmental Factors

Environmental factors such as humidity and exposure to the elements necessitate careful consideration of the nail’s material. Standard steel nails are prone to rust, which can weaken the joint and cause unsightly staining of the surrounding wood. In damp environments or for outdoor use, stainless steel or galvanized nails provide superior corrosion resistance. The one-inch length doesnt negate the impact of corrosion, making material choice vital.

- Chemical Interactions

Certain wood species contain natural oils or acids that can react with specific metals. For instance, cedar can corrode standard steel nails more rapidly than other woods. Understanding these chemical interactions is crucial for selecting compatible nail materials. Silicon bronze nails are sometimes used in these situations to avoid the negative effects.

- Aesthetic Considerations and Finishing

The nail’s material also impacts the finishing process. Some metals may react differently to stains, paints, or other finishes, potentially leading to discoloration or adhesion issues. Consider the final aesthetic and ensure the nail material is compatible with the intended finish. Choosing materials that accept stains or paints evenly ensures a seamless and professional appearance.

The interplay of wood species, environmental conditions, potential chemical interactions, and aesthetic goals underscores the importance of material compatibility when employing one-inch finishing nails. Adherence to these principles ensures the creation of durable, visually appealing, and structurally sound woodworking projects.

4. Head design

The head design of a one-inch finishing nail is a critical element dictating its suitability for various woodworking applications. The head’s shape and size influence both the fastener’s holding power and its capacity for concealment, factors of paramount importance in achieving a professional and aesthetically pleasing result.

- Brad Head Profile

The brad head, characterized by its minimal size, is a common feature in one-inch finishing nails. Its small diameter allows for easy countersinking and subsequent concealment with wood filler or paint. This design is particularly advantageous in applications where visual obtrusiveness must be minimized, such as attaching delicate trim or molding. The trade-off for this near invisibility is a reduced holding power compared to nails with larger head profiles.

- Conical Head Variant

Some finishing nails incorporate a slightly conical head, offering a compromise between concealment and holding strength. This design allows for a deeper countersinking than a brad head while still providing a relatively unobtrusive appearance. The conical shape also aids in directing the nail straight during driving, reducing the likelihood of bending or buckling, particularly in denser woods. However, more filler may be required for complete concealment compared to a brad head.

- Collar Design Influence

Certain one-inch finishing nails feature a small collar or ring just beneath the head. This collar enhances the nail’s holding power by increasing friction against the wood fibers as the nail is driven. While effective in improving grip, this design can also increase the risk of splitting, particularly in thinner or more brittle materials. The presence of a collar also necessitates more precise countersinking to ensure complete concealment.

- Material and Coating Effects

The material of the head, along with any applied coating, also influences its functionality. Steel heads offer strength and durability, while brass or copper heads provide corrosion resistance and a decorative aesthetic. Coated heads, such as those with a polymer or adhesive layer, can further enhance holding power by creating a stronger bond with the surrounding wood. The color of the coating can also be selected to better match the wood finish, minimizing the visibility of the nail even before concealment.

The interplay between head design, material selection, and application technique ultimately determines the effectiveness of a one-inch finishing nail. Understanding these nuanced factors empowers woodworkers to select the appropriate fastener for a given task, ensuring both structural integrity and a visually appealing outcome. Consideration must always be given to the balance between holding power and ease of concealment to achieve optimal results.

5. Corrosion resistance

Corrosion resistance is a critical attribute governing the lifespan and performance of one-inch finishing nails, particularly in environments susceptible to moisture or chemical exposure. The absence of adequate corrosion resistance in these fasteners leads to premature degradation, compromising the structural integrity of the joined materials and potentially resulting in aesthetic flaws. The cause of this degradation is often electrochemical reactions between the nail material and the surrounding environment, causing rust formation and subsequent weakening of the nail.

The importance of corrosion resistance becomes evident in practical applications. For instance, when used in outdoor trim or furniture construction, standard steel finishing nails will rust over time, causing unsightly stains on the wood and potentially leading to joint failure. Conversely, using stainless steel or galvanized nails in similar applications provides a significantly longer service life, preserving both the structural integrity and visual appeal of the finished product. Similarly, in marine environments, where saltwater accelerates corrosion, specialized alloys are necessary to ensure longevity.

Understanding the implications of corrosion and selecting appropriate materials for one-inch finishing nails is essential for achieving durable and aesthetically pleasing results. While stainless steel and galvanized options provide superior protection, they often come at a higher cost. Therefore, careful consideration of the intended application and environmental conditions is crucial in determining the optimal balance between cost and performance. The challenge lies in assessing the long-term risks associated with corrosion and making informed decisions to mitigate those risks effectively.

Frequently Asked Questions

This section addresses common inquiries regarding the proper usage and selection of these fasteners in woodworking applications.

Question 1: What gauge of these fasteners is best suited for attaching delicate trim?

For delicate trim, a thinner gauge is recommended to minimize the risk of splitting. A higher gauge number (e.g., 18 gauge) offers sufficient holding power while reducing the likelihood of damage to the trim.

Question 2: How can the visibility of these fasteners be minimized?

Visibility can be minimized by employing a nail set to countersink the nail head slightly below the surface of the wood. Subsequent filling with wood filler and sanding creates a seamless finish.

Question 3: Are these fasteners appropriate for outdoor applications?

Standard steel finishing nails are not recommended for outdoor use due to their susceptibility to corrosion. Stainless steel or galvanized finishing nails offer superior corrosion resistance and are better suited for outdoor applications.

Question 4: When is pre-drilling necessary?

Pre-drilling is advisable when working with hardwoods or when driving nails near the edge or end of a board. This prevents splitting and ensures the nail drives straight.

Question 5: Can these fasteners be used with a nail gun?

Some nail guns are designed to accommodate finishing nails. Ensure compatibility between the nail gun and the nail gauge to prevent damage or malfunctions.

Question 6: What alternatives exist if increased holding power is required?

If greater holding power is needed, consider using a longer finishing nail, a thicker gauge nail, or supplementing with wood glue. Alternatives such as screws may also be considered, but they may compromise the desired aesthetic.

Selecting the correct gauge, material, and application technique is crucial for achieving both structural integrity and visual appeal when using these fasteners.

The subsequent section will delve into specific project applications showcasing the versatile utility of one-inch finishing nails.

Conclusion

The preceding exploration has detailed the multifaceted aspects of 1 inch finishing nails, encompassing their applications, optimal usage techniques, and material considerations. The significance of gauge selection, concealment methods, and material compatibility has been underscored, emphasizing the interplay between structural integrity and aesthetic outcomes. The importance of head design and corrosion resistance has also been examined, providing a comprehensive understanding of their functionality.

Effective utilization of 1 inch finishing nails requires a discerning approach, balancing the demands of secure fastening with the imperative of visual finesse. The informed application of these principles will ensure long-lasting and aesthetically pleasing results in diverse woodworking endeavors. Further investigation into specialized coatings and innovative designs will undoubtedly continue to refine the capabilities of these ubiquitous fasteners in the future.