A tool utilized in woodworking and construction, this device drives slender fasteners into materials. The gauge designation refers to the diameter of the nails it employs, indicating a finer fastener than those used in framing. These tools are commonly employed for applications where minimizing the visibility of the fastener is desired, such as installing trim, molding, and cabinetry.

Its significance lies in its ability to provide a secure hold while leaving a minimal hole, reducing the need for extensive filling and sanding. Historically, such tasks would have been completed manually with a hammer and nails, a process that is slower and less precise. The advent of pneumatic and cordless electric models has greatly improved efficiency and accuracy in finish carpentry.

The following sections will delve into the specific advantages of this type of tool, explore the various models available, discuss best practices for their use, and outline essential safety precautions. Understanding these aspects will enable informed decision-making and optimal utilization of this valuable asset in various woodworking and construction projects.

Operating Tips for Optimal Performance

Maximizing the effectiveness and lifespan of this tool requires adherence to certain operational guidelines. The following tips outline best practices for achieving professional results and ensuring safe operation.

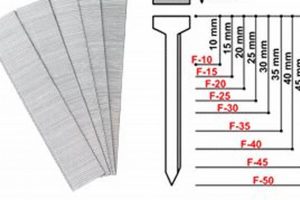

Tip 1: Select the Appropriate Nail Length: Choosing the correct nail length is crucial for secure fastening without excessive protrusion. Consider the thickness of the material being fastened and select a nail length that penetrates adequately into the substrate without passing entirely through.

Tip 2: Adjust the Depth Setting: Most models feature an adjustable depth setting. This allows for precise control over the nail’s penetration depth, ensuring a flush finish without damaging the surrounding material. Experiment with scrap material to determine the optimal setting before working on the final project.

Tip 3: Maintain Consistent Air Pressure: For pneumatic models, consistent air pressure is essential for uniform nail driving. Ensure the compressor is set to the manufacturer’s recommended pressure range. Fluctuations in air pressure can lead to inconsistent results and potential damage to the tool.

Tip 4: Employ Proper Nailing Technique: Hold the tool firmly and perpendicular to the work surface. Apply consistent pressure while actuating the trigger. Avoid angling the tool, as this can result in bent nails or compromised fastening.

Tip 5: Regularly Clean and Lubricate: Routine maintenance is vital for prolonging the tool’s lifespan. Regularly clean the nail magazine and driver blade to remove debris and prevent jams. Lubricate the tool according to the manufacturer’s instructions to ensure smooth operation.

Tip 6: Store the Tool Properly: When not in use, store the tool in a clean, dry environment. Disconnect the air hose or remove the battery to prevent accidental activation. Proper storage protects the tool from damage and ensures it is ready for the next project.

Adhering to these guidelines will enhance the performance and longevity of the equipment, resulting in professional-quality results and reduced downtime.

The following sections will address safety protocols and troubleshooting common issues to provide a comprehensive understanding of this specialized tool.

1. Fastener Gauge

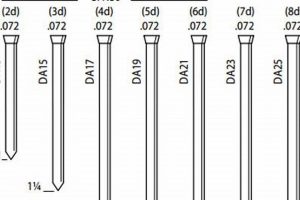

The term “16ga” directly relates to the fastener gauge, representing a crucial specification for this particular type of nailer. Gauge refers to the thickness of the nail shank; a higher gauge number indicates a thinner nail. Therefore, a 16ga finish nailer is designed specifically to drive 16-gauge nails. The selection of this gauge affects the tool’s application, providing a balance between holding power and minimal visibility. Using fasteners outside this gauge can damage the tool or lead to unsafe operation.

For example, a cabinet maker might choose a 16ga finish nailer over a framing nailer because the smaller diameter of the 16-gauge nail leaves a less noticeable hole, requiring less filling and sanding prior to finishing. Conversely, a thicker 15-gauge nail offers greater holding strength but leaves a larger, more visible mark. The choice of fastener gauge directly impacts the aesthetic outcome of the project. Similarly, forcing 15 gauge nails into a tool designed for 16 gauge can result in the equipment jamming or failing altogether.

In summary, fastener gauge is not merely a descriptive attribute, but a defining characteristic of the 16ga finish nailer. Understanding this connection informs proper tool selection, operation, and maintenance. Ignoring the gauge specification can lead to compromised results, equipment damage, and potential safety hazards, solidifying its importance in the comprehensive understanding of this tool. The ability to identify the gauge makes the tool have a balance between holding power and minimal visibility and is selected for that main reason to keep the nail tight and without a big hole.

2. Power Source

The operational functionality of a 16ga finish nailer hinges on its power source, dictating its portability, operational characteristics, and maintenance requirements. The two primary power sources employed are pneumatic (compressed air) and electric (corded or cordless). Each type presents distinct advantages and disadvantages affecting the user’s workflow and the tool’s suitability for specific applications. Without a compatible power source, the tool cannot operate, highlighting the crucial role power plays in its basic utility. For example, a pneumatic model relies on a consistent air supply from an air compressor. Insufficient air pressure results in incomplete nail driving, while excessive pressure risks damaging the tool or the workpiece. This cause-and-effect relationship underscores the need for precise control and understanding of the pneumatic power source.

Electric models, whether corded or cordless, eliminate the need for an external air compressor. Corded electric models offer consistent power but restrict mobility due to the tethered cord. Cordless models, powered by rechargeable batteries, provide enhanced portability, enabling work in locations lacking readily available power outlets. However, cordless models are limited by battery life and require periodic recharging, introducing potential workflow interruptions. A practical application of a cordless model involves trim installation in a newly constructed building without installed electricity. The cordless tool enables efficient work despite the absence of a conventional power source. In comparison, a pneumatic or corded electric model would require either an extension cord running from a distant power source or the use of a portable generator, adding complexity to the task.

In summary, the power source is an integral component of a 16ga finish nailer, fundamentally influencing its performance and application. Pneumatic models offer a balance of power and cost-effectiveness but require an air compressor. Electric models provide convenience and portability, though corded options limit mobility and cordless options necessitate battery management. Understanding the implications of each power source empowers users to select the appropriate tool for the task at hand, optimizing efficiency and ensuring successful project completion. The primary challenge resides in balancing the need for power, portability, and consistent operation, reflecting the broader theme of matching tool capabilities to specific project requirements.

3. Applications

The utility of a 16ga finish nailer is defined by its specific applications within woodworking and construction. Its design parameters nail gauge, power source, and adjustable features dictate the tasks for which it is best suited. Understanding these applications is crucial for selecting the appropriate tool for a given project and maximizing efficiency and precision.

- Trim and Molding Installation

The primary application lies in installing trim and molding. Its ability to drive thin fasteners with minimal surface disruption makes it ideal for securing delicate decorative elements. Examples include baseboards, crown molding, door casings, and window trim. The reduced hole size minimizes the need for filling and sanding, resulting in a cleaner, more professional finish. The holding power is sufficient for these lighter materials without causing splitting or damage.

- Cabinetry Assembly

Another significant application is in cabinetry assembly, particularly for joining face frames and attaching decorative panels. The 16ga nail provides adequate strength for these joints while remaining less conspicuous than larger fasteners. For instance, when assembling a kitchen cabinet, a finish nailer can be used to attach the face frame to the cabinet box, creating a strong and aesthetically pleasing connection. The ability to adjust the nail depth prevents over-penetration, which could mar the cabinet’s interior.

- Furniture Construction

In furniture construction, the device finds use in attaching decorative trim, securing drawer bottoms, and assembling smaller components. It is particularly useful for delicate furniture pieces where visible fasteners would detract from the overall aesthetic. When constructing a chair, for example, the equipment can be used to attach decorative molding to the chair back or legs, adding visual appeal without compromising structural integrity. The fine gauge minimizes the risk of splitting the wood, a critical consideration when working with hardwoods.

- Paneling and Siding (Interior)

While not typically used for exterior siding, the 16ga finish nailer can be effective for installing interior paneling, such as wainscoting or shiplap. The smaller nail size reduces the visibility of the fasteners, creating a smoother and more refined appearance. This is particularly important in areas where the paneling serves as a primary design element. Using the nailer, panels are secured evenly with minimized surface damage.

These applications showcase the versatility of the 16ga finish nailer in various woodworking and construction tasks. While larger framing nailers provide greater holding power for structural applications, the finish nailer excels in situations where aesthetics and minimal surface disruption are paramount. The tool’s suitability for these tasks makes it a valuable asset for carpenters, cabinet makers, and hobbyists alike.

4. Depth Adjustment

Depth adjustment is a critical feature found on most 16ga finish nailers, offering control over the nail’s penetration into the workpiece. This functionality allows users to achieve a flush or slightly recessed finish, essential for aesthetic quality and structural integrity. The ability to regulate nail depth prevents both cosmetic damage and potential weakening of the joint.

- Preventing “Nail Pops”

One primary role of depth adjustment is preventing “nail pops,” where the nail head protrudes above the surface of the material over time due to wood expansion and contraction. By setting the nailer to drive the nail slightly below the surface, the nail head is less likely to cause this unsightly issue. In furniture making, for example, nail pops can ruin the appearance of a finished piece, requiring costly repairs or rework. The depth adjustment helps mitigate this risk.

- Avoiding Over-Penetration

Conversely, over-penetration, where the nail is driven too deeply into the material, can weaken the joint and create an undesirable hole. Depth adjustment allows the user to avoid this problem, especially when working with thin or delicate materials. For instance, when attaching thin trim to a cabinet face frame, over-penetration could split the trim or damage the underlying cabinet material. Properly adjusted depth ensures a secure hold without causing structural damage.

- Material Density Compensation

Different materials exhibit varying densities, requiring adjustments to the driving force of the nailer. Depth adjustment allows for compensation for these differences. Softer woods, like pine, require less force than harder woods, like oak, to achieve the desired nail depth. Without this adjustment, the nailer would either under-drive in hardwood or over-drive in softwood. Accurate depth adjustment therefore enhances versatility.

- Achieving Consistent Results

The feature ensures consistent results across multiple fastening operations. Once the optimal depth setting is determined for a particular material and nail length, it can be replicated consistently throughout the project. This minimizes variations in finish quality and improves overall efficiency. Consider a large trim installation project; achieving a uniform nail depth across hundreds of feet of trim significantly improves the final appearance and reduces the amount of finishing work required.

These facets of depth adjustment underscore its importance in achieving professional results with a 16ga finish nailer. Proper use of this feature not only enhances the aesthetic appeal of the finished product but also contributes to its structural integrity and longevity. The depth adjustment allows the tool to be useful with various materials and thicknesses, but the user must be knowledgable to achieve perfection and avoid any form of damage.

5. Safety Mechanisms

Safety mechanisms are integral to the design and operation of any 16ga finish nailer, mitigating the inherent risks associated with high-speed fastener propulsion. These mechanisms serve as a primary defense against accidental nail discharge, protecting the operator and bystanders from potential injury. The absence or malfunction of these features can result in serious harm, underscoring their crucial role as a component of the tool. For example, a contact-trip mechanism prevents the nailer from firing unless the nosepiece is firmly pressed against the workpiece. This system reduces the likelihood of unintentional nail discharge if the trigger is accidentally engaged while the tool is not in direct contact with a surface. Failure of this mechanism could result in the tool firing a nail into thin air or, worse, into a person.

Another significant safety feature is the sequential actuation system, which requires the operator to depress the contact trip before pulling the trigger. This two-step process minimizes the risk of “bump firing,” where nails are discharged rapidly simply by bouncing the tool against the work surface while holding the trigger. Bump firing significantly increases the risk of misdirected nails and accidental injuries. Consider a scenario where a carpenter is installing baseboards. Without a functional sequential actuation system, a slight bump against the wall could cause the nailer to fire unexpectedly, potentially sending a nail through a hand or foot. Proper implementation and maintenance of these safety systems are therefore paramount.

In summary, safety mechanisms are not mere accessories but essential components of a 16ga finish nailer, directly influencing the tool’s safe and effective operation. Understanding the function and limitations of these mechanisms is crucial for preventing accidents and ensuring operator well-being. Regular inspection and maintenance are necessary to guarantee these features function as intended. Overriding or disabling safety mechanisms drastically increases the risk of injury and should never be attempted. The practical significance of adhering to safety protocols lies in preserving the health and safety of individuals working with this powerful tool. This principle remains fundamental for all users.

Frequently Asked Questions

The following section addresses common inquiries regarding the application, operation, and maintenance of this specialized tool. The information provided aims to clarify misconceptions and offer practical guidance.

Question 1: What distinguishes a 16ga finish nailer from other types of nailers?

The primary distinction lies in the gauge of nail utilized. A 16ga finish nailer is specifically designed to drive 16-gauge nails, which are thinner than those used in framing or roofing nailers. This results in a smaller entry hole, making it suitable for finish carpentry and trim work where aesthetics are important.

Question 2: Is a compressor necessary for all 16ga finish nailers?

Not all models require a compressor. Pneumatic models rely on compressed air for operation and thus necessitate an air compressor. However, electric models, both corded and cordless, operate without the need for an external compressor. Cordless models utilize batteries, while corded models plug directly into an electrical outlet.

Question 3: Can a 16ga finish nailer be used for structural applications?

Generally, it is not recommended for structural applications. The smaller gauge of the nails provides less holding power compared to larger framing nails. Using it for structural purposes could compromise the integrity of the structure. The tool is best suited for non-load-bearing applications.

Question 4: What safety precautions should be observed when operating a 16ga finish nailer?

Eye protection is mandatory, as is understanding the tool’s operating manual. Ensure the work area is clear of obstructions and bystanders. Never point the tool at oneself or others. Disconnect the air hose or battery when not in use. Regularly inspect the tool for damage and proper functioning.

Question 5: How often should a 16ga finish nailer be serviced?

Service intervals depend on the frequency and intensity of use. However, regular cleaning of the nail magazine and lubrication of moving parts are essential. Refer to the manufacturer’s recommendations for specific service schedules. Addressing minor issues promptly can prevent more significant problems and extend the tool’s lifespan.

Question 6: What causes a 16ga finish nailer to jam?

Jams can result from several factors, including using incorrect nail sizes, debris accumulation in the nail magazine, or insufficient air pressure (for pneumatic models). Bent or damaged nails can also cause jams. Clearing the jam according to the manufacturer’s instructions is crucial to prevent further damage.

Understanding these frequently asked questions contributes to the informed and safe operation of the tool. Adhering to best practices and addressing potential issues proactively will optimize performance and longevity.

The subsequent section will cover best-selling products and buying guides.

Conclusion

This exploration of the 16ga finish nailer has illuminated its defining characteristics, including its gauge specificity, power source options, and critical safety mechanisms. The examination of appropriate applications, such as trim work, cabinetry, and furniture construction, underscores its value in projects demanding precision and minimal surface disruption. The importance of depth adjustment for achieving consistent, professional results has also been emphasized, alongside practical advice for maintaining optimal performance and addressing common operational challenges.

The information presented serves as a foundation for making informed decisions regarding the selection, operation, and maintenance of this specialized tool. It remains incumbent upon the user to prioritize safety, adhere to manufacturer guidelines, and continuously seek to refine their understanding of its capabilities and limitations. The responsible and informed use of the 16ga finish nailer not only ensures project success but also contributes to a safer and more efficient working environment.