Achieving a superior coating application on surfaces, resulting in a smooth, durable, and aesthetically pleasing appearance, represents a high standard in the painting trade. This outcome reflects skill, precision, and the utilization of quality materials. For instance, a perfectly sprayed cabinet door, free from imperfections and exhibiting uniform sheen, exemplifies this superior outcome.

The significance of this high-caliber application extends beyond mere visual appeal. It contributes to the longevity and protection of the underlying surface. A meticulously applied coating resists wear, environmental damage, and corrosion, thereby reducing maintenance costs and extending the lifespan of the painted item. Historically, the pursuit of such a result has driven advancements in paint technology and application techniques.

The following discussion will delve into the critical factors contributing to achieving a superior painted outcome, encompassing surface preparation, product selection, application methods, and quality control procedures. Each of these elements plays a vital role in delivering a result that meets or exceeds expectations for both durability and visual appeal.

Achieving a Superior Painted Outcome

The attainment of a high-quality coating demands meticulous attention to detail and adherence to best practices. The following tips offer insights into key areas for improvement.

Tip 1: Surface Preparation is Paramount. A clean, sound, and properly prepared surface is essential for optimal adhesion and a flawless appearance. Remove any loose paint, dirt, grease, or rust. Consider sanding or abrading the surface to create a profile for better paint bonding. Priming may be necessary depending on the substrate and paint system.

Tip 2: Product Selection is Critical. Choose paints and coatings specifically designed for the intended surface and environment. Factors to consider include durability, resistance to weathering, chemical exposure, and intended use. Consult product data sheets and technical specifications to ensure compatibility and suitability.

Tip 3: Invest in Quality Application Tools. The use of high-quality brushes, rollers, and spray equipment contributes significantly to the final result. Select tools appropriate for the paint type and application method. Regularly maintain and clean application tools to ensure optimal performance.

Tip 4: Master Application Techniques. Proper application techniques are essential for achieving a uniform and defect-free finish. This may involve mastering brush strokes, roller techniques, or spray gun settings. Practice and experimentation are often required to achieve optimal results.

Tip 5: Maintain Consistent Environmental Conditions. Temperature, humidity, and ventilation can significantly impact paint drying and curing times. Ensure that environmental conditions are within the manufacturer’s recommended range. Avoid painting in direct sunlight or during periods of high humidity.

Tip 6: Apply Multiple Thin Coats. Multiple thin coats are generally preferable to a single thick coat. Thin coats dry and cure more evenly, reducing the risk of runs, sags, and other defects. Allow each coat to dry thoroughly before applying the next.

Tip 7: Inspect and Correct Imperfections. Regularly inspect the painted surface for imperfections, such as runs, sags, or blemishes. Address these issues promptly using appropriate touch-up techniques. Proper lighting is essential for identifying surface defects.

By implementing these strategies, practitioners can enhance the quality and durability of their coatings. The careful execution of each step is paramount in achieving the desired outcome.

The subsequent sections will address troubleshooting common issues and advanced techniques.

1. Smooth Surface Preparation

The correlation between meticulous surface preparation and a professional painted outcome is undeniable; smooth surface preparation acts as the cornerstone upon which the overall quality of the application rests. Without a properly prepared substrate, even the highest quality paints and most skilled application techniques will fail to deliver a truly superior finish. Imperfections, inconsistencies, and contaminants present on the surface directly translate into visible defects in the final coat. For example, painting over existing peeling paint will inevitably result in continued peeling, regardless of the new paint’s properties. Similarly, neglecting to sand rough areas will cause an uneven texture to be accentuated by the fresh coating.

Smooth surface preparation encompasses several critical steps, including cleaning, sanding, filling imperfections, and priming. Each step serves a specific purpose in creating an ideal surface for paint adhesion and optimal appearance. Cleaning removes dirt, grease, and other contaminants that can impede paint bonding. Sanding smooths out existing imperfections and creates a profile for better adhesion. Filling cracks and holes ensures a uniform surface, preventing visual distractions. Priming seals the surface, provides a uniform color base, and further enhances paint adhesion. The consequence of skipping or inadequately performing any of these steps is a compromised end result, falling short of the standards associated with a high-quality finish.

In summary, smooth surface preparation is not merely a preliminary step but an integral component of achieving a professional painted outcome. By dedicating the necessary time and effort to properly preparing the surface, practitioners lay the groundwork for a durable, aesthetically pleasing finish that reflects superior craftsmanship. The benefits of meticulous preparation extend beyond visual appeal, contributing to the longevity and overall performance of the painted surface. The failure to recognize and address this fundamental relationship inevitably leads to compromised results and diminished client satisfaction.

2. Quality Product Selection

The achievement of a coating, often referred to as a high standard within the painting profession, is inextricably linked to the selection of appropriate and superior-grade materials. Product selection is not merely a procurement task; it is a fundamental determinant of the final appearance, durability, and longevity of the application. A substandard coating can undermine even the most skilled application techniques, resulting in a finish that fails to meet professional standards. For example, using an interior-grade paint on an exterior surface will inevitably lead to premature degradation due to weather exposure, regardless of the applicator’s expertise. Similarly, selecting an incompatible primer and topcoat system can result in adhesion failures, causing peeling and blistering.

The influence of product selection extends beyond basic performance characteristics. Factors such as the paint’s sheen, color retention, and resistance to specific environmental conditions directly contribute to the aesthetic appeal and protective capabilities of the finished surface. A coating with poor color retention will fade and dull over time, diminishing the initial visual impact. A paint lacking resistance to mildew or chemicals will be susceptible to degradation in humid or industrial environments, compromising its protective function. Moreover, the ease of application and clean-up properties of a paint can significantly impact the efficiency and overall quality of the application process.

In conclusion, quality product selection is a non-negotiable aspect of achieving a desired outcome. By prioritizing the use of superior-grade paints, primers, and related materials, painting professionals ensure that their work meets the highest standards of quality and durability. This commitment to quality not only enhances the aesthetic appeal of the finished surface but also provides long-term protection and value for the client. Conversely, compromises in product selection can lead to premature failures, increased maintenance costs, and diminished client satisfaction, ultimately undermining the reputation and credibility of the painting professional.

3. Consistent Application Technique

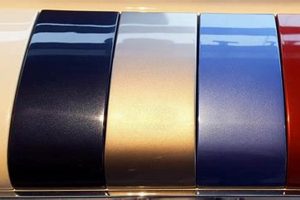

Consistent application technique is inextricably linked to the attainment of what painting professionals recognize as a superior coating. Variability in application directly correlates to visible inconsistencies in the final surface, undermining the intended aesthetic and functional qualities. This consistent technique impacts both visual appearance and coating performance.

The consequences of inconsistent application manifest in various forms. Uneven paint distribution leads to variations in sheen and color, creating a mottled or patchy appearance. Improper brush or roller techniques can leave visible brush strokes or stipple patterns, detracting from the desired smooth surface. Inconsistent spray patterns result in runs, sags, or orange peel texture, further compromising the quality of the outcome. For example, an inconsistent spray pattern during the application of automotive paint can lead to a highly undesirable outcome. This can result in the vehicle failing the customer and resulting in the loss of business.

Achieving consistent application requires training, practice, and attention to detail. Painters must develop a thorough understanding of the materials being used, the equipment employed, and the appropriate techniques for each application. Proper tool maintenance, controlled environmental conditions, and meticulous monitoring of the application process are all essential components. The pursuit of consistent application technique represents a commitment to quality and a recognition that the final result is directly dependent on the skill and diligence of the applicator. This understanding promotes not only the quality of the finished product but also creates the expectation for the same application of finish on all materials.

4. Proper Environmental Control

The relationship between environmental management and achieving a professionally applied coating is a critical factor. The external environment, encompassing temperature, humidity, and ventilation, exerts a tangible influence on the application, drying, and curing characteristics of paints and coatings. Failure to maintain suitable environmental conditions can lead to a spectrum of defects that compromise the quality and longevity of the finished surface. The understanding and implementation of proper environmental controls are therefore integral to achieving a superior standard for coating application.

The influence of temperature and humidity on paint viscosity and drying time provides a prime example. High temperatures can cause paint to dry too rapidly, resulting in brush marks, poor leveling, and reduced adhesion. Conversely, low temperatures can inhibit drying, leading to runs, sags, and prolonged curing times. Similarly, high humidity levels can interfere with the evaporation of solvents, resulting in a milky or cloudy finish and increasing the risk of blistering or peeling. Adequate ventilation is equally important, as it facilitates the removal of solvent vapors and prevents the build-up of harmful concentrations. In enclosed spaces, insufficient ventilation can lead to slow drying times, increased odor, and potential health hazards. For instance, when spraying solvent-based coatings indoors, a well-ventilated spray booth is essential to minimize exposure to toxic fumes and ensure proper curing.

Effective environmental management requires careful monitoring and adjustment of conditions to align with the paint manufacturer’s specifications. This may involve the use of temperature and humidity monitoring devices, climate control systems, and ventilation equipment. By diligently controlling the environment, painting professionals can mitigate the risk of defects and ensure that the finished surface meets the highest standards for appearance, durability, and performance. This control of the environment represents a distinct and definable characteristic of a professional coating and a core element in differentiating it from amateur or substandard work.

5. Meticulous detail orientation

Meticulous detail orientation is paramount in achieving a high standard for the outcome. This characteristic transcends basic competence and encompasses a profound commitment to precision and thoroughness throughout every stage of the painting process. The omission of even seemingly minor details can significantly detract from the final appearance and durability.

- Edge Definition and Crisp Lines

Precise masking and careful edging are essential for creating clean, sharp lines where painted surfaces meet adjacent materials or different colors. This requires steady hands, high-quality masking tape, and a keen eye for detail. Overlapping paint or uneven edges create a sloppy, unprofessional appearance, immediately detracting from the overall quality of the job. A lack of clear definition can result in light and reflection disparities, detracting from the desired aesthetic.

- Surface Imperfection Rectification

A thorough assessment of the surface is required to identify and address any minor imperfections, such as nail holes, cracks, or blemishes. These imperfections must be properly filled, sanded, and primed to ensure a smooth, uniform surface. Neglecting these details results in visible flaws in the final coat, diminishing the aesthetic appeal and potentially compromising the paint’s durability.

- Consistent Application Thickness

Maintaining a consistent paint thickness is crucial for achieving uniform color, sheen, and durability. Variations in thickness can lead to uneven drying, visible color variations, and premature wear. Proper application techniques, such as maintaining a consistent distance from the surface when spraying or using appropriate roller covers, are essential for achieving uniform thickness.

- Spotless Cleanup and Finishing Touches

A thorough cleanup of the work area and meticulous finishing touches are essential for creating a truly high-quality end product. Removing any paint splatters, cleaning brushes and equipment, and inspecting the finished surface for any minor imperfections are crucial steps. Attention to these details demonstrates a commitment to excellence and ensures complete client satisfaction.

The incorporation of meticulous detail orientation throughout every phase is a hallmark of professional workmanship. This dedication to precision translates into a superior outcome, characterized by flawless surfaces, crisp lines, and lasting durability. This degree of attentiveness separates a standard paint job from a true, professionally applied and executed finish, reinforcing the importance of meticulousness in the pursuit of excellence. Proper preparation and meticulous attention will minimize cost and material waste.

6. Durable protective coating

The integration of a durable protective coating is not merely an adjunct to professional-grade application; it represents a foundational element, intrinsically linked to achieving a long-lasting, aesthetically superior outcome. This protective layer safeguards the underlying surface from environmental degradation, physical wear, and chemical exposure, ensuring the longevity and visual appeal of the painted finish.

- Resistance to Environmental Factors

A durable protective coating shields the substrate from the damaging effects of ultraviolet radiation, moisture, temperature fluctuations, and airborne pollutants. For exterior applications, this resistance is paramount in preventing fading, cracking, peeling, and the growth of mold or mildew. For example, a marine-grade coating applied to a boat hull provides a barrier against saltwater corrosion and UV degradation, extending the life of the vessel’s finish. The absence of such protection can lead to premature deterioration, requiring costly repairs and reapplication.

- Protection Against Physical Wear and Tear

The inclusion of a durable coating enhances the surface’s resistance to abrasion, impact, and scratches. This is particularly important in high-traffic areas or on surfaces subject to frequent contact. For instance, a two-part epoxy coating applied to a garage floor provides a robust barrier against scuffing, staining, and chemical spills, maintaining a clean and presentable appearance even under heavy use. Without this protection, the underlying paint layer is susceptible to damage, leading to unsightly blemishes and reduced lifespan.

- Chemical Resistance and Stain Prevention

A durable coating can provide a barrier against chemical exposure, preventing staining, etching, and corrosion. This is particularly relevant in industrial environments or areas where surfaces are exposed to harsh chemicals or cleaning agents. For example, a chemical-resistant coating applied to laboratory countertops protects against spills and splashes of corrosive substances, maintaining the integrity of the surface and preventing costly damage. Choosing materials of this nature is highly important as well as a critical component of application.

- Enhanced Cleanability and Maintenance

Durable coatings often exhibit properties that facilitate easy cleaning and maintenance, reducing the effort required to maintain a pristine appearance. Smooth, non-porous surfaces are less susceptible to staining and can be easily wiped clean, simplifying routine maintenance. For example, a polyurethane coating applied to kitchen cabinets provides a durable, easy-to-clean surface that resists grease, spills, and fingerprints, maintaining a fresh and attractive appearance with minimal effort.

These facets illustrate how a durable protective coating serves as an essential component of a professional level coating system. By safeguarding the underlying paint layer from environmental degradation, physical wear, chemical exposure, and facilitating easy maintenance, a durable protective coating ensures the longevity and visual appeal of the finished surface. Integrating this protective element transforms a simple painting job into a professionally applied and meticulously executed outcome, demonstrating a commitment to quality, durability, and lasting value.

Frequently Asked Questions About Pro Finish Painting

The following questions address common inquiries regarding the characteristics and considerations associated with achieving a coating of the highest professional standard.

Question 1: What distinguishes a application from standard painting?

The most identifiable point includes meticulous surface preparation, the utilization of high-quality materials, consistent application techniques, precise environmental control, meticulous attention to detail, and the application of a durable protective coating. These elements combine to deliver a visually appealing and long-lasting result.

Question 2: How important is surface preparation in achieving a coating?

Surface preparation is paramount. Proper preparation, including cleaning, sanding, and priming, ensures optimal paint adhesion and a flawless final appearance. Inadequate surface preparation will inevitably lead to imperfections and reduced coating lifespan.

Question 3: What role does paint quality play in the final product?

Paint quality is a critical factor. High-quality paints offer superior durability, color retention, and resistance to environmental factors. Using substandard paints will compromise the coating’s longevity and aesthetic appeal, regardless of the application technique.

Question 4: How does environmental control affect the outcome?

Temperature, humidity, and ventilation significantly impact paint drying and curing. Maintaining proper environmental conditions is essential for preventing defects such as runs, sags, and blistering.

Question 5: What are the key components of a durable protective coating?

A durable protective coating provides resistance to environmental factors, physical wear, chemical exposure, and staining. This coating safeguards the underlying paint layer, extending the coating’s lifespan and maintaining its visual appeal.

Question 6: Is investment in achieving the finish justifiable?

Investment in the resources and quality necessary to achieve the finish is justifiable due to the long-term benefits of durability, aesthetic appeal, and reduced maintenance costs. A finish represents a long-term investment in the protection and enhancement of the coated surface.

In conclusion, several factors contribute to achieving the best outcome. Attention to each of these factors ensures a high-quality, durable, and aesthetically pleasing result.

The next section will explore techniques for problem-solving and troubleshooting of common painting issues.

Pro Finish Painting

This exploration has delineated the crucial elements contributing to a superior standard of surface coating. From the foundational importance of meticulous surface preparation to the selection of high-quality materials, consistent application techniques, controlled environmental conditions, meticulous detail orientation, and the application of a durable protective coating, each facet plays an indispensable role in achieving a truly exceptional result. The absence of attention to even a single one of these elements can compromise the entire undertaking, diminishing the overall quality and longevity of the finish.

The pursuit of application is not merely an aesthetic endeavor, but a commitment to enduring quality and long-term value. Investment in the necessary resources and expertise yields a surface that not only enhances visual appeal but also provides lasting protection against the ravages of time and environmental stressors. Practitioners are therefore encouraged to diligently adhere to these principles, recognizing that their dedication to excellence will be reflected in the enduring beauty and performance of their work.