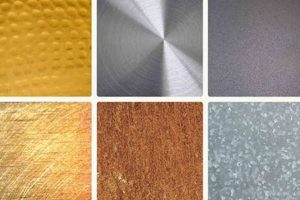

Surfaces on metallic components can be altered to introduce tactile qualities and visual interest beyond a smooth, reflective appearance. This process involves creating patterns, indentations, or raised features on the metal substrate. For example, a stainless steel appliance might feature a brushed surface to minimize fingerprints and enhance its aesthetic appeal.

This modification enhances durability, improves grip, and provides decorative options. Historically, techniques like hammering and etching were employed to create these effects. Modern applications span diverse industries, including architecture, automotive, and consumer electronics, improving both the functional and artistic aspects of manufactured goods.

The following sections will explore various methods of achieving these surface treatments, examine the range of materials suitable for texturing, and consider the factors influencing the selection process for a specific application. Furthermore, the discussion will extend to advancements in technology and future trends in this field.

Guidance on Specifying Textured Metallic Surfaces

The successful integration of altered surface attributes on metallic components necessitates a thorough understanding of available options and their respective implications for performance and aesthetics. The following considerations are crucial for informed decision-making.

Tip 1: Define Functional Requirements: Before selecting a specific approach, precisely identify the functional demands. Does the application require enhanced grip, improved wear resistance, or solely aesthetic enhancement? Understanding the primary purpose dictates the appropriateness of different methods and material choices. For example, a surface intended to reduce glare in an architectural application demands a different profile than one intended for tactile feedback on a control panel.

Tip 2: Consider Material Compatibility: Not all metals are equally amenable to texturing. The alloy’s hardness, ductility, and thermal properties impact the feasibility and outcome of various techniques. Aluminum, for instance, exhibits different behavior under laser etching than stainless steel. Consult material specifications and processing guidelines to ensure compatibility.

Tip 3: Evaluate Texture Depth and Pattern: The depth and pattern of the surface influence both the tactile feel and the optical properties. Deeper profiles provide a more pronounced tactile experience but may also increase the risk of debris accumulation. Finer patterns offer subtle visual effects and are easier to clean. Careful consideration should be given to the required balance between functionality and maintainability.

Tip 4: Specify Surface Treatment Method: A range of methods exists, including mechanical abrasion, chemical etching, laser engraving, and specialized coatings. Each method produces a unique visual and tactile result and offers varying levels of control over the texture parameters. Understanding the capabilities and limitations of each process is essential for achieving the desired outcome.

Tip 5: Address Corrosion Resistance: Introducing surface irregularities can potentially compromise the metal’s inherent resistance to corrosion. The selected method should not create stress concentrations or disrupt protective oxide layers. Post-processing treatments, such as passivation or coating, may be necessary to maintain or enhance corrosion protection.

Tip 6: Prototype and Test: Before committing to large-scale production, create prototypes with various surface treatments. Thoroughly test these prototypes under relevant operating conditions to evaluate their performance and suitability. This iterative process minimizes the risk of unforeseen issues and ensures that the final product meets the required standards.

By diligently adhering to these guidelines, engineers and designers can effectively leverage surface modifications to enhance the functionality, aesthetics, and durability of metallic components. A well-informed approach ensures that the selected method aligns with the application’s specific requirements and contributes to the overall success of the project.

In the next section, the discussion will transition to case studies illustrating successful implementations across diverse industries and highlighting the long-term performance of treated metal components.

1. Aesthetics

The aesthetic dimension of “textured metal finishes” is a critical factor influencing product appeal and perceived value. The selected surface treatment directly impacts the visual impression, affecting how consumers interact with and interpret the quality of the product. For instance, a brushed stainless steel appliance conveys a sense of sophistication and cleanliness, while a hammered texture might suggest robustness and handcrafted quality. Consequently, aesthetics is not merely an add-on but an integral component of the overall design strategy.

Different patterns and depths create varying optical effects. A matte surface diffuses light, minimizing glare and fingerprint visibility, which is particularly relevant in architectural applications and high-touch surfaces. Conversely, deeper, more irregular surfaces can create dynamic highlights and shadows, adding visual interest and depth. Consider the example of a textured aluminum panel used in building facades; the play of light across its surface changes throughout the day, providing a visually engaging element.

Ultimately, the aesthetic considerations in texturing metal surfaces extend beyond simple decoration. They reflect an understanding of how visual cues can influence consumer perception, brand identity, and the overall user experience. The careful selection of pattern, depth, and finish becomes a strategic decision that can significantly contribute to the success of a product or design. Ignoring this interplay risks undermining the intended impact, potentially leading to a disconnect between the product’s functional qualities and its perceived value.

2. Durability

The application of textured surface treatments can directly influence the lifespan and resilience of metallic components. While the primary intention might be aesthetic enhancement, the process and resulting surface topology have significant implications for resistance to wear, scratching, and environmental degradation. A key factor is the method employed to create the texture, as some techniques can introduce stress concentrations or micro-cracks that accelerate material fatigue. Conversely, certain texturing processes can enhance surface hardness and improve resistance to abrasion. For example, shot peening, a process that imparts a compressive stress layer, is frequently used to increase the fatigue life of aircraft components.

The durability impact is also contingent upon the material and the operating environment. For instance, a textured stainless steel surface used in a marine environment will exhibit different wear characteristics than a similar finish on aluminum used indoors. The chosen texture pattern and depth also play a role. Deeper textures can trap debris and moisture, potentially accelerating corrosion. In contrast, shallower, more uniform textures might offer better protection against surface scratching. The automotive industry provides a relevant example; textured dashboards are designed not only to reduce glare but also to resist scratching and fading caused by prolonged exposure to sunlight and temperature variations.

In summary, the relationship between texturing and durability is complex and multifaceted. While texturing can offer aesthetic advantages and improve certain performance characteristics, it is essential to carefully consider the potential trade-offs. The selection of the appropriate texturing method, material, and surface pattern must be informed by a thorough understanding of the operating environment and the desired performance requirements. Proper material selection is also important, such as using coatings and alloys to enhance durability. Ignoring these factors can lead to premature failure and compromise the long-term performance of the component.

3. Functionality

The implementation of “textured metal finishes” extends beyond mere aesthetics, significantly influencing the functional performance of various products and components. The selected surface treatment can enhance grip, reduce glare, improve acoustic properties, and influence thermal management, directly impacting usability and overall effectiveness.

- Enhanced Grip and Tactility

Surface texturing can dramatically improve grip and tactile feedback, particularly in applications involving hand tools, control panels, and medical devices. A textured surface provides increased friction, reducing the likelihood of slippage and improving control. For instance, knurled metal grips on precision instruments offer a secure hold, even in demanding environments. This improved tactile feedback also enhances user confidence and reduces the risk of errors.

- Glare Reduction and Optical Properties

Texturing can diffuse light and minimize glare, crucial for applications where visibility is paramount. A matte surface finish effectively scatters light, reducing reflections and improving visual clarity. Examples include textured instrument panels in vehicles, which prevent distracting reflections on the windshield, and architectural panels designed to minimize glare from sunlight. The choice of texture pattern and depth directly influences the degree of glare reduction.

- Acoustic Damping and Noise Reduction

Specific textures can improve acoustic damping and reduce noise transmission, particularly in industrial and transportation applications. Irregular surfaces disrupt sound waves, reducing resonance and minimizing noise levels. Textured metal panels are employed in aircraft interiors and machinery enclosures to mitigate noise pollution and enhance passenger comfort. The effectiveness of this application depends on the material properties and the specific texture design.

- Thermal Management and Heat Dissipation

Surface texturing can enhance heat transfer, facilitating thermal management in electronic devices and industrial equipment. A roughened surface increases the surface area, promoting convective heat transfer and improving cooling efficiency. Heat sinks with textured fins are commonly used in computers and power electronics to dissipate heat effectively. The geometry and spacing of the texture elements are critical for optimizing thermal performance.

The impact of texture on functionality highlights the need for a holistic approach in product design. Selecting an appropriate surface treatment requires careful consideration of both aesthetic and functional requirements. By understanding the specific performance objectives and the potential benefits of texturing, engineers and designers can optimize product performance and enhance user experience.

4. Manufacturing

The manufacturing process is inextricably linked to the feasibility, cost, and quality of textured metal finishes. The chosen manufacturing technique directly dictates the achievable texture patterns, the material limitations, and the consistency of the final product. For example, laser etching offers high precision and complex pattern generation but may be less suitable for large-scale production due to processing time and cost. Conversely, rolling processes are efficient for creating repetitive textures on sheet metal but are limited in pattern complexity. The selection of the manufacturing method is, therefore, a critical decision influencing the overall viability of a textured metal finish.

Moreover, the manufacturing process impacts the mechanical properties of the metal surface. Processes like shot peening induce compressive stresses that enhance fatigue resistance, while improper etching techniques can create stress concentrations leading to premature failure. The surface roughness introduced during manufacturing affects subsequent processes such as painting or coating. A poorly prepared surface can result in inadequate adhesion and reduced coating lifespan. In the automotive industry, for instance, careful control of surface roughness is crucial for achieving durable and aesthetically pleasing paint finishes on textured metal body panels.

In conclusion, a comprehensive understanding of manufacturing processes is essential for effectively utilizing textured metal finishes. The interplay between the desired texture, the material properties, and the manufacturing method determines the success of the application. Optimizing the manufacturing process to achieve the desired texture while maintaining material integrity and minimizing costs is a critical challenge in realizing the full potential of textured metal finishes in diverse industries.

5. Corrosion Resistance

The introduction of surface irregularities through textured metal finishes can profoundly affect a metal’s susceptibility to corrosion. While some texturing processes might inadvertently create microscopic crevices or stress concentrations that act as initiation sites for corrosion, others, when correctly implemented, can enhance resistance. The presence of sharp edges or corners in a textured surface, for example, can disrupt the protective oxide layer that naturally forms on certain metals, making these areas more vulnerable to localized corrosion such as pitting. Conversely, specific textures might promote better adhesion of protective coatings, thereby improving overall corrosion resistance. Marine environments, in particular, demonstrate the significance of this interplay, where textured metal surfaces on ships or offshore platforms are continuously exposed to corrosive saltwater.

The choice of texturing method and subsequent surface treatments is critical in mitigating potential corrosion risks. Techniques like laser texturing, if not properly controlled, can alter the metallurgical properties of the surface layer, creating galvanic couples that accelerate corrosion. In contrast, surface treatments like passivation or the application of corrosion-inhibiting coatings can be integrated into the texturing process to counteract these effects. For instance, a textured aluminum component used in aerospace applications would require meticulous surface preparation and coating to withstand the corrosive effects of atmospheric conditions and de-icing fluids.

Therefore, considering corrosion resistance as an integral component of textured metal finishes is paramount for ensuring long-term durability and performance. A thorough understanding of the electrochemical behavior of the metal, the environmental conditions, and the potential impact of the texturing process is essential for selecting appropriate materials and surface treatments. Failure to address corrosion concerns can lead to premature failure, increased maintenance costs, and potential safety hazards, underscoring the practical significance of a well-informed approach.

6. Cost

The cost associated with textured metal finishes is a multifaceted consideration encompassing material selection, manufacturing processes, and post-treatment requirements. The implementation of texturing invariably adds to the base cost of the metal component, the magnitude of which depends on the complexity of the texture, the chosen method, and the scale of production. For instance, a simple brushed finish applied to stainless steel using automated machinery will represent a relatively minor cost increase compared to a custom-etched pattern on titanium requiring manual intervention. Accurate cost estimation necessitates a detailed understanding of these factors and their interdependencies.

The selection of the texturing method plays a pivotal role in determining overall costs. Mechanical texturing techniques, such as rolling or embossing, are typically cost-effective for high-volume production runs but are limited in terms of pattern complexity and customization. Chemical etching and laser engraving offer greater design flexibility but involve higher per-unit costs and potentially require specialized equipment and expertise. The automotive industry provides a relevant example: textured interior trim components are often produced using injection molding with textured molds, balancing design requirements with cost efficiency for mass production. Ultimately, the cost-effectiveness of each technique hinges on the specific application, the desired texture characteristics, and the production volume.

In conclusion, cost is a critical driver in the decision-making process regarding textured metal finishes. A thorough cost analysis, encompassing material, manufacturing, and post-treatment considerations, is essential for making informed choices that align with budgetary constraints and performance requirements. Overlooking cost implications can lead to project overruns and compromise the overall value proposition. By carefully evaluating the trade-offs between design complexity, manufacturing efficiency, and material performance, it is possible to achieve aesthetically pleasing and functionally effective textured metal finishes within defined cost parameters.

Frequently Asked Questions

The following questions address common inquiries regarding textured metal surfaces, providing concise and authoritative answers to enhance understanding.

Question 1: What is the primary purpose of applying textured metal finishes?

Surface treatments serve multiple purposes, including aesthetic enhancement, improved grip, glare reduction, and increased durability. The specific objective dictates the choice of texturing method and pattern.

Question 2: Which metals are most suitable for texturing?

Aluminum, stainless steel, and titanium are frequently textured due to their workability and corrosion resistance. The suitability of a particular metal depends on its mechanical properties and the chosen texturing process.

Question 3: How does texturing affect the corrosion resistance of metal surfaces?

The impact on corrosion resistance varies depending on the texturing method and the presence of protective coatings. Some processes can create stress concentrations that accelerate corrosion, while others can enhance coating adhesion and improve overall protection.

Question 4: What are the primary manufacturing methods used to create textured metal finishes?

Common methods include mechanical abrasion, chemical etching, laser engraving, and rolling. The selection depends on the desired texture characteristics, production volume, and cost considerations.

Question 5: How does texturing influence the functionality of metal components?

Texturing can improve grip, reduce glare, enhance acoustic damping, and facilitate thermal management. The specific functional benefits depend on the selected texture pattern and depth.

Question 6: What are the cost considerations associated with textured metal finishes?

Costs vary depending on material selection, manufacturing processes, and post-treatment requirements. A comprehensive cost analysis is essential for making informed decisions that align with budgetary constraints and performance objectives.

In summary, the application of these surface treatments is a complex process with significant implications for aesthetics, functionality, and durability. A thorough understanding of the available options and their respective advantages and disadvantages is crucial for successful implementation.

The next article section will explore real-world case studies illustrating the diverse applications and benefits of enhanced metallic surfaces.

Conclusion

The preceding discussion has presented a comprehensive overview of textured metal finishes, encompassing their diverse applications, manufacturing methods, and performance characteristics. The inherent interplay between aesthetics, functionality, durability, and cost necessitates a holistic and informed approach to their specification and implementation. Considerations related to corrosion resistance and long-term performance are paramount, ensuring the suitability of these finishes for demanding operational environments.

As technology advances and design requirements evolve, further innovation in textured metal finishes is anticipated. Architects, engineers, and designers must remain cognizant of emerging techniques and material advancements to leverage the full potential of these surfaces. Continued research and development efforts are crucial for optimizing the performance and expanding the application of these finishes across various industries.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)