The application of a wood-like appearance to metal doors represents a design choice that combines the durability and security of metal with the aesthetic appeal of natural timber. This technique typically involves the use of specialized coatings or laminates that simulate the color, grain, and texture of wood on a metal substrate, often steel or aluminum. As an example, a commercial building might employ steel entryways treated to resemble oak, providing a visually welcoming entrance while maintaining a robust security profile.

The increasing popularity of simulating natural wood on metal surfaces stems from a desire for both visual warmth and enhanced performance characteristics. Metal doors offer superior resistance to warping, rotting, and insect damage compared to traditional wooden doors. Furthermore, the application of a simulated wood surface does not compromise the security or fire-resistance properties inherent in metal construction. Historically, achieving a natural wood appearance on metal often involved complex and costly processes, but advancements in coating technologies have made the process more efficient and affordable.

Understanding the methods for achieving this aesthetic, the durability and maintenance requirements, and the potential cost implications are critical for architects, contractors, and property owners considering this option. The subsequent sections will delve into the various application techniques, the selection of appropriate materials, and the long-term performance expectations associated with doors exhibiting this specific aesthetic.

Essential Considerations for Metal Door Wood Finish

Implementing a wood-like finish on metal doors requires careful planning and execution to ensure both aesthetic appeal and long-term durability. The following tips outline crucial aspects to consider during the selection, application, and maintenance phases.

Tip 1: Material Selection is Paramount: Choose metal substrates and finishing materials compatible with the intended environment. Exterior applications necessitate coatings formulated for UV resistance and protection against moisture and temperature fluctuations. Interior applications can utilize less robust, but potentially more cost-effective, options.

Tip 2: Surface Preparation is Critical: Proper surface preparation is fundamental for optimal coating adhesion and longevity. This includes thorough cleaning to remove grease, dirt, and rust, followed by appropriate priming to create a uniform and receptive surface for the simulated wood finish.

Tip 3: Application Technique Matters: Select an application method suitable for the chosen finishing material. Powder coating, for example, offers excellent durability and uniformity, while liquid coatings provide greater flexibility in color and texture selection. Ensure application adheres to the manufacturer’s specifications for optimal results.

Tip 4: Emphasize Grain Pattern Alignment: Pay close attention to grain pattern alignment, particularly when dealing with multiple door panels or adjacent surfaces. Consistent alignment contributes significantly to the realism and visual appeal of the simulated wood finish.

Tip 5: Prioritize Durable Clear Coats: Apply a durable, protective clear coat to safeguard the underlying finish from scratches, abrasion, and environmental damage. Select a clear coat formulated to resist yellowing and maintain its clarity over time.

Tip 6: Regular Maintenance is Essential: Implement a routine maintenance schedule to prolong the lifespan of the finish. This includes periodic cleaning with mild detergents and inspection for any signs of damage, such as chipping or peeling.

Tip 7: Consider Professional Installation: For complex projects or where a flawless finish is paramount, consider engaging experienced professionals specializing in the application of wood-like finishes to metal surfaces. Their expertise can minimize the risk of errors and ensure a high-quality outcome.

Adhering to these guidelines will facilitate the successful integration of doors emulating natural wood characteristics into a variety of architectural settings. By emphasizing careful material selection, meticulous surface preparation, and appropriate application techniques, one can achieve an aesthetically pleasing and durable solution.

The following sections will address the economic considerations, long-term performance expectations, and environmental impact of utilizing finishes that mimic the appearance of natural materials.

1. Appearance

The visual characteristics of metal doors with simulated wood surfaces constitute a primary factor in their selection and integration into architectural designs. The realism, color accuracy, and texture of the finish directly impact the overall aesthetic of the building and influence perceptions of quality and value.

- Grain Pattern Replication

The accurate replication of wood grain patterns is crucial for achieving a convincing resemblance to natural wood. Manufacturers employ various techniques, including photographic transfer and embossed texturing, to simulate the intricate details of different wood species. For example, a steel door treated with a photographic transfer process can effectively mimic the grain of cherry wood, enhancing the visual warmth of an entryway. Imperfect or unrealistic grain patterns detract from the overall aesthetic and undermine the intended effect.

- Color Matching and Consistency

Maintaining color consistency across different door panels and ensuring accurate color matching to specified wood species are essential for visual harmony. Variations in color, whether due to inconsistencies in the application process or fading over time, can create an undesirable appearance. Standardized color palettes and rigorous quality control measures are necessary to mitigate these issues. For example, in a commercial office building, all entry doors should exhibit a uniform color that complements the surrounding interior design elements.

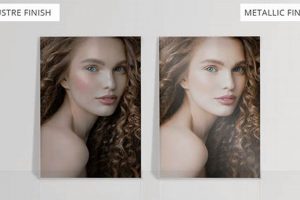

- Texture and Surface Finish

The texture and surface finish of the coating contribute significantly to the tactile and visual experience. A smooth, glossy finish may appear artificial, while a slightly textured or matte finish can enhance the realism of the simulated wood. The choice of texture should align with the intended aesthetic and the characteristics of the wood species being replicated. Consider, for instance, an aluminum door with a matte finish designed to emulate the texture of distressed wood, creating a rustic or aged appearance.

- Integration with Hardware and Surrounding Elements

The appearance of a metal door with a simulated wood surface is also influenced by its integration with hardware, such as handles, hinges, and frames, and its compatibility with surrounding architectural elements. Selecting hardware that complements the simulated wood finish and ensuring seamless transitions between the door and its surroundings can enhance the overall visual appeal. For example, using bronze hardware with a door that emulates walnut wood can create a cohesive and elegant design.

The interplay of these factorsgrain pattern replication, color matching, texture, and integration with surrounding elementscollectively determines the effectiveness of mimicking natural wood on metal doors. Thoughtful attention to these details is paramount for achieving a visually appealing and aesthetically successful application of this design technique.

2. Durability

The longevity and resistance to wear of surfaces emulating natural timber on metal doors represent a critical performance criterion. The durability of these finishes directly impacts maintenance requirements, lifecycle costs, and the sustained aesthetic appeal of the installation.

- Coating Adhesion and Resistance to Delamination

The ability of the applied coating to maintain a strong bond with the metal substrate is paramount. Poor adhesion leads to delamination, resulting in unsightly peeling and exposing the underlying metal to corrosion. Surface preparation, primer selection, and application technique significantly influence coating adhesion. For example, a powder-coated finish, properly applied to a pre-treated steel door, exhibits superior adhesion compared to a liquid coating applied to a poorly prepared surface. The consequences of delamination include increased maintenance costs and premature failure of the finish.

- Resistance to Abrasion and Impact

Metal doors in high-traffic areas are susceptible to abrasion and impact damage. The finish must withstand these stresses to prevent scratches, dents, and chipping. Coating hardness, flexibility, and thickness contribute to abrasion and impact resistance. A door in a retail environment, frequently subjected to contact with shopping carts and customer traffic, requires a more robust finish than a door in a low-traffic residential setting. Damage from abrasion and impact compromises the aesthetic appearance and can expose the metal substrate to environmental elements.

- UV Resistance and Colorfastness

Exterior applications of metal doors with simulated wood require finishes that are resistant to ultraviolet (UV) radiation. Prolonged exposure to sunlight can cause fading, discoloration, and degradation of the coating, resulting in a loss of aesthetic appeal. UV-resistant coatings incorporate specialized pigments and stabilizers that mitigate these effects. Consider a south-facing entrance door subjected to intense sunlight; a UV-resistant finish will maintain its color and vibrancy for a longer period compared to a standard coating. The lack of UV resistance leads to premature fading and necessitates more frequent refinishing.

- Resistance to Chemical Exposure and Environmental Factors

The finish must withstand exposure to various chemicals, such as cleaning agents, pollutants, and salts, as well as environmental factors like humidity, temperature fluctuations, and precipitation. Chemical exposure can cause discoloration, softening, or degradation of the coating. Formulations designed for specific environments should be selected accordingly. A door installed near a coastal region requires a finish that is resistant to salt spray, preventing corrosion and maintaining its appearance. Failure to consider chemical and environmental factors results in accelerated degradation and reduces the lifespan of the finish.

These facets of durability are interconnected and collectively determine the long-term performance of surfaces emulating natural wood on metal doors. Proper material selection, application techniques, and maintenance practices are essential for maximizing the lifespan and maintaining the aesthetic integrity of these finishes. The trade-off between initial cost and long-term durability should be carefully evaluated when selecting a finishing system for a metal door.

3. Application

The “Application” aspect is fundamentally linked to the success of a “metal door wood finish.” The method of applying the simulated wood surface directly influences its visual appeal, durability, and overall performance. Improper application techniques can negate the benefits of high-quality materials, leading to premature failure and aesthetic deficiencies. For instance, if a powder coating designed to replicate mahogany is not applied evenly, the resulting finish may exhibit inconsistencies in color and texture, detracting from the desired wood-like appearance. The application stage, therefore, acts as a critical control point in achieving a satisfactory outcome, affecting both the initial impression and the long-term value of the door.

Consider two contrasting examples. In one scenario, a metal door undergoes a multi-stage process involving thorough surface preparation, application of a primer, and precise application of a wood-grain film using specialized equipment. This careful application results in a realistic wood appearance with excellent adhesion and resistance to wear. Conversely, a metal door that receives a poorly applied, single-coat paint treatment intended to mimic wood may quickly exhibit chipping, peeling, and fading, revealing the underlying metal and compromising the door’s aesthetic and protective qualities. The selection of appropriate tools and the adherence to manufacturer’s specifications are thus essential to ensuring a quality application.

In summary, the manner in which a simulated wood finish is applied to a metal door dictates its ultimate effectiveness. Factors such as surface preparation, coating uniformity, and application precision are paramount. Achieving a durable and aesthetically pleasing “metal door wood finish” requires a meticulous approach to the application process, emphasizing proper techniques and adherence to best practices. Challenges in application can arise from environmental conditions, equipment limitations, or lack of skilled personnel, underscoring the need for careful planning and execution.

4. Maintenance

Sustaining the aesthetic appeal and functional integrity of metal doors with simulated wood finishes necessitates consistent and appropriate maintenance procedures. The longevity and visual quality of these installations are directly proportional to the adherence to recommended maintenance protocols. Failure to maintain these finishes adequately results in premature degradation and increased replacement costs.

- Regular Cleaning Regimen

The establishment of a routine cleaning schedule is fundamental to preventing the accumulation of dirt, grime, and environmental pollutants on the simulated wood surface. The frequency of cleaning should be tailored to the environmental conditions and the level of traffic exposure. For instance, doors located in industrial areas or coastal environments require more frequent cleaning compared to those in sheltered residential settings. Mild detergents and non-abrasive cleaning implements should be employed to avoid scratching or damaging the finish. Neglecting regular cleaning accelerates the deterioration of the coating, leading to discoloration and a diminished aesthetic appearance.

- Prompt Repair of Surface Damage

Addressing scratches, chips, or other forms of surface damage in a timely manner is crucial to preventing further deterioration. Minor imperfections can act as entry points for moisture and corrosive agents, leading to the delamination of the coating or the corrosion of the underlying metal substrate. Repair procedures should involve thorough cleaning of the affected area, followed by the application of a compatible touch-up paint or coating. Ignoring surface damage compromises the protective barrier and accelerates the degradation process.

- Periodic Inspection and Reapplication of Protective Coatings

Regular inspections should be conducted to identify any signs of wear, fading, or degradation of the simulated wood finish. Depending on the severity of the wear, a reapplication of a protective clear coat or sealant may be necessary to restore the original luster and enhance the durability of the finish. The frequency of these reapplications depends on the environmental conditions and the type of coating employed. Postponing the reapplication of protective coatings diminishes the protective barrier and increases the susceptibility to environmental damage.

- Appropriate Lubrication of Hardware Components

While not directly related to the simulated wood finish itself, the proper lubrication of hinges, handles, and locking mechanisms is essential for the smooth operation of the door and the prevention of unnecessary stress on the finish. Stiff or binding hardware can exert excessive force on the door surface, leading to scratches or dents. Regular lubrication with appropriate lubricants ensures smooth operation and minimizes the risk of damage to the finish.

These maintenance practices are interconnected and collectively contribute to the prolonged lifespan and sustained aesthetic quality of metal doors with surfaces emulating natural wood. A proactive approach to maintenance, incorporating regular cleaning, prompt repair of damage, periodic inspection, and appropriate hardware lubrication, is essential for maximizing the return on investment and preserving the value of these installations.

5. Cost

The economic implications of selecting metal doors with simulated wood finishes represent a critical consideration for architects, contractors, and property owners. The initial investment, long-term maintenance expenses, and potential life-cycle cost savings are all factors that must be carefully evaluated to determine the financial viability of this design choice.

- Initial Material and Manufacturing Expenses

The upfront cost of metal doors with wood-like finishes is influenced by several factors, including the type of metal substrate (steel vs. aluminum), the complexity of the simulated wood grain pattern, and the application method employed (powder coating, film lamination, or liquid coating). For instance, a custom-designed steel door with a multi-layered powder-coated finish replicating a rare wood species incurs significantly higher initial costs than a standard aluminum door with a simpler, pre-printed wood-grain laminate. These costs also encompass manufacturing processes, such as surface preparation and the application of specialized coatings, impacting the overall initial investment.

- Installation Labor and Complexity

Installation costs vary depending on the door size, weight, and the complexity of the frame and hardware integration. Larger, heavier metal doors typically require more specialized equipment and a larger installation crew, increasing labor expenses. The precise fitting and alignment of the door within the frame, along with the proper installation of handles, hinges, and locking mechanisms, also contribute to the overall installation cost. As an example, installing a double-leaf metal entrance door with an integrated access control system necessitates more skilled labor and time compared to installing a single-leaf interior door.

- Long-Term Maintenance and Repair Costs

While metal doors generally require less maintenance than traditional wooden doors, the longevity and appearance of the simulated wood finish depend on proper care and upkeep. Scratches, chips, or fading in the finish necessitate repairs or refinishing, incurring additional expenses. The frequency of maintenance and repair is influenced by factors such as the door’s exposure to sunlight, humidity, and physical abrasion. Choosing durable, UV-resistant finishes can reduce the need for frequent repairs, thereby minimizing long-term maintenance costs. As a case study, doors in high-traffic commercial settings may require more frequent refinishing than those in residential applications.

- Life Cycle Cost Analysis and Potential Savings

A comprehensive life cycle cost analysis considers the initial investment, maintenance expenses, repair costs, and the expected lifespan of the door. Metal doors with simulated wood finishes often exhibit lower life cycle costs compared to solid wood doors due to their greater durability and resistance to warping, rotting, and insect damage. Although the initial cost might be higher, the reduced maintenance and extended lifespan can result in long-term cost savings. For instance, a metal door designed to mimic oak might cost more initially, but its resistance to moisture and insects could eliminate the need for costly repairs or replacements associated with traditional wooden doors. This analysis informs decision-making, enabling a comparison of long-term economic benefits relative to initial costs.

In conclusion, the cost-effectiveness of metal doors with simulated wood finishes should be evaluated holistically, considering the interplay between initial expenses, installation costs, maintenance requirements, and long-term durability. A comprehensive life cycle cost analysis can provide a clear understanding of the economic advantages and disadvantages of this design choice, enabling informed decisions that align with budgetary constraints and performance expectations.

6. Sustainability

The integration of sustainability principles into the selection and application of metal doors with simulated wood finishes represents a growing concern within the construction industry. The environmental impact of material sourcing, manufacturing processes, and long-term performance are all critical factors in assessing the overall sustainability of these products. Understanding these considerations allows for more informed decisions that minimize environmental footprint and promote responsible resource utilization.

- Material Sourcing and Recycled Content

The selection of materials with high recycled content significantly reduces the environmental impact associated with metal door production. Utilizing recycled steel or aluminum decreases the demand for virgin materials and minimizes the energy required for extraction and processing. For example, specifying a metal door comprised of 80% recycled steel contributes to a reduction in greenhouse gas emissions and conserves natural resources. The sourcing of simulated wood finishes should also prioritize sustainable options, such as those derived from rapidly renewable resources or incorporating recycled content.

- Manufacturing Processes and Energy Consumption

The energy intensity of manufacturing processes used to create metal doors and apply simulated wood finishes represents a key sustainability consideration. Minimizing energy consumption during fabrication, coating application, and transportation reduces the carbon footprint of the product. Employing energy-efficient manufacturing techniques, such as optimized powder coating processes or the use of renewable energy sources in production facilities, contributes to a more sustainable outcome. For instance, a manufacturing plant powered by solar energy and utilizing closed-loop water recycling systems demonstrates a commitment to reducing environmental impact.

- Durability, Longevity, and Reduced Replacement Cycles

The extended lifespan and durability of metal doors with simulated wood finishes contribute to overall sustainability by minimizing the need for frequent replacements. Selecting materials and finishes that resist wear, corrosion, and fading reduces the demand for new products and conserves resources. For example, a properly maintained metal door with a UV-resistant simulated wood finish may last for several decades, significantly reducing the environmental burden associated with door replacement compared to less durable alternatives.

- End-of-Life Management and Recyclability

Designing metal doors for easy disassembly and recyclability facilitates the recovery of valuable materials at the end of their service life. Using readily recyclable metal components and avoiding the use of hazardous materials in finishes promotes closed-loop material flows and reduces waste sent to landfills. For example, a metal door designed with easily detachable hardware and a finish that does not impede metal recycling can be effectively processed at end-of-life, recovering valuable resources for future use.

These interconnected factors material sourcing, manufacturing processes, durability, and end-of-life management collectively influence the sustainability profile of metal doors with simulated wood finishes. A holistic approach that considers all stages of the product lifecycle is essential for maximizing environmental benefits and promoting responsible design and construction practices. The utilization of life cycle assessments (LCAs) provides a standardized methodology for quantifying the environmental impacts associated with different material and design choices, enabling more informed decision-making and driving continuous improvement in sustainability performance.

Frequently Asked Questions

This section addresses common inquiries concerning metal doors with surfaces simulating wood. The information provided aims to clarify misconceptions and offer objective insights.

Question 1: Does a finish that mimics wood on a metal door offer the same level of aesthetic appeal as a genuine wood door?

The aesthetic appeal is subjective and depends on the quality of the simulated wood finish. High-quality finishes, utilizing advanced printing or coating technologies, can closely resemble natural wood. However, subtle differences in texture and grain may be discernible upon close inspection.

Question 2: Are metal doors with a wood-like finish more durable than traditional wood doors?

Generally, yes. Metal doors offer superior resistance to warping, rotting, and insect damage compared to wood doors. The durability of the simulated wood finish itself depends on the type of coating and its application.

Question 3: Can a simulated wood finish be applied to any type of metal door?

The feasibility depends on the metal’s surface properties and the chosen finishing method. Steel and aluminum doors are commonly used. Proper surface preparation is crucial for ensuring adequate adhesion of the simulated wood finish.

Question 4: How does the cost of a metal door with a simulated wood finish compare to a solid wood door?

The cost varies depending on factors such as the type of metal, the quality of the finish, and the complexity of the design. In some cases, metal doors with simulated wood can be more cost-effective than solid wood, especially considering long-term maintenance.

Question 5: Is the simulated wood finish susceptible to fading or scratching?

The resistance to fading and scratching depends on the type of coating and its protective properties. UV-resistant coatings are essential for exterior applications to prevent fading. Durable clear coats enhance resistance to scratching and abrasion.

Question 6: Are there environmentally friendly options for metal doors with simulated wood finishes?

Yes. Options include using recycled metal content, employing low-VOC coatings, and selecting finishes that are durable and require less frequent replacement. Specifying products with environmental certifications can also ensure responsible sourcing and manufacturing practices.

In summary, metal doors with wood-like finishes offer a combination of aesthetic appeal and functional performance. Careful consideration of material selection, application techniques, and maintenance practices is essential for optimizing their long-term value.

The next section will provide a comprehensive guide to selecting the appropriate metal door with a surface that emulates the appearance of wood.

Conclusion

This exploration of metal doors with a wood finish has illuminated the diverse considerations involved in their selection, application, and maintenance. The key points emphasized encompass aesthetic realism, durability characteristics, application techniques, cost implications, and sustainable attributes. Careful evaluation of these aspects is crucial for informed decision-making.

The selection of an appropriate metal door wood finish should reflect a balance between aesthetic preferences, performance requirements, and budgetary constraints. The implementation of sustainable practices, throughout the lifecycle of the product is of paramount importance. Continued innovation in coating technologies and manufacturing processes will likely further enhance the visual fidelity, durability, and environmental performance of these doors, shaping their role in future architectural designs.