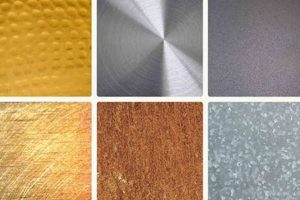

A surface treatment method achieves a lustrous, reflective appearance reminiscent of metal through the application of a specially formulated coating. This coating, often incorporating fine metallic particles suspended in a wax-based medium, imparts a distinctive shimmer and depth to the substrate. Examples include automotive body panels, furniture accents, and decorative items where a premium aesthetic is desired.

The value of this particular coating lies in its ability to enhance the visual appeal of products, increasing their market desirability and perceived value. Its protective qualities, while generally less robust than dedicated protective coatings, contribute to surface preservation. Historically, similar techniques have been employed across various cultures and industries to simulate the appearance of precious metals on more readily available materials.

The subsequent discussion will delve into the specific application techniques, material compositions, and maintenance procedures associated with achieving this desirable surface effect, along with considerations for its long-term durability and environmental impact.

Application and Maintenance Recommendations

Optimal results when utilizing this treatment necessitate careful preparation, application, and ongoing maintenance. Adherence to the following guidelines will maximize longevity and visual impact.

Tip 1: Surface Preparation is Paramount: Thoroughly clean and degrease the surface before application. Any residual contaminants will impede adhesion and compromise the final appearance. Use appropriate solvents and cleaning agents compatible with the substrate.

Tip 2: Apply in Thin, Even Coats: Multiple thin layers are preferable to a single thick application. This prevents streaking, ensures uniform coverage, and promotes proper drying or curing. Employ suitable application tools, such as soft cloths or specialized applicators.

Tip 3: Controlled Environment is Crucial: Apply the treatment in a dust-free environment with moderate temperature and humidity. Extremes in these conditions can negatively impact drying time and adhesion properties.

Tip 4: Buffing Technique Matters: Proper buffing is essential for achieving the desired sheen and removing excess material. Use clean, soft cloths and employ a gentle, circular motion. Avoid excessive pressure that could damage the underlying finish.

Tip 5: Regular Cleaning is Required: Clean the treated surface regularly with mild detergents and soft cloths. Avoid harsh chemicals or abrasive cleaners that could dull or damage the coating.

Tip 6: Wax Application Frequency: Reapplication of a compatible wax-based protectant at regular intervals will prolong the life and luster. The frequency depends on exposure to environmental factors; however, a quarterly application is generally advisable.

Effective execution of these processes extends the aesthetic appeal and protective value of the treatment. Diligent attention to preparation, application, and maintenance procedures optimizes the investment.

The concluding section will summarize the critical considerations for ensuring the long-term success of integrating this particular finish into various applications.

1. Appearance

The visual characteristics imparted by a wax metallic finish are central to its value and application. The reflective quality and perceived depth significantly influence the aesthetic appeal of the treated surface, directly impacting its marketability and perceived quality.

- Luster and Reflectivity

Luster refers to the way light interacts with the surface, creating a sheen or gloss. The presence of fine metallic particles within the wax matrix enhances reflectivity, producing a luminous effect. Automotive finishes utilize this aspect to create vibrant, eye-catching exteriors. Conversely, a dull or uneven luster can indicate improper application or degradation of the coating.

- Color Saturation and Depth

The metallic pigments contribute to the color saturation, providing a richer and more intense hue compared to standard coatings. The wax medium allows for a layered effect, creating a sense of depth and dimension. This characteristic is often exploited in furniture design to mimic the appearance of antique or precious metal inlays, adding visual interest and sophistication.

- Surface Smoothness and Uniformity

The application process influences the smoothness and uniformity of the finish. A well-executed application results in a seamless, even surface, free from streaks or imperfections. This level of smoothness is critical for achieving optimal light reflection and a consistent aesthetic. In contrast, poor application techniques lead to uneven surfaces, diminishing the overall visual impact and potentially impacting the perceived quality of the product.

- Metallic Particle Distribution

The distribution of metallic particles within the wax matrix dictates the overall visual texture and pattern. An even distribution creates a uniform shimmer, while variations in particle density can produce subtle visual textures or patterns. Luxury watch manufacturers leverage this facet to create unique and visually captivating dials that differentiate their products from competitors.

The interplay of luster, color saturation, surface smoothness, and particle distribution collectively defines the visual impact of a wax metallic finish. The skillful manipulation of these elements allows for a wide range of aesthetic effects, from subtle and elegant to bold and striking, making it a versatile choice for enhancing the appearance of various products and materials.

2. Protection

The protective qualities inherent in a wax metallic finish, while present, are generally considered secondary to its aesthetic contribution. The composition and application techniques dictate the degree of protection afforded to the underlying substrate.

- Resistance to Moisture and Oxidation

The wax component of the finish creates a barrier against moisture, reducing the potential for oxidation or corrosion of the underlying material, particularly metals. This is relevant in environments where exposure to humidity or water is common, such as outdoor furniture or certain automotive components. However, this barrier is not impervious and requires periodic maintenance to remain effective. An neglected surfaces may still suffer corrosion, despite the coating.

- Limited UV Resistance

Some formulations incorporate UV inhibitors, offering a degree of protection against ultraviolet radiation. This is particularly important for applications exposed to sunlight, where UV degradation can cause fading or discoloration of the finish. The level of UV protection varies depending on the specific additives used and the thickness of the coating. However, dedicated UV-resistant coatings offer significantly more effective protection.

- Abrasion Resistance

The wax layer provides a limited degree of abrasion resistance, protecting the underlying surface from minor scratches and scuffs. The hardness of the wax and the presence of metallic particles influence its ability to withstand abrasive forces. However, the coating is generally not as durable as specialized abrasion-resistant coatings and is susceptible to damage from more significant impacts or prolonged wear. Items subject to heavy use, such as countertops, may require additional protective measures.

- Chemical Resistance

The wax matrix offers some resistance to mild chemicals, such as household cleaners or spills. However, prolonged exposure to harsh chemicals, solvents, or acids can degrade the finish and damage the underlying material. The chemical resistance depends on the type of wax used and any additives incorporated into the formulation. Specialized chemical-resistant coatings are necessary for environments where exposure to aggressive chemicals is expected.

In summary, while a wax metallic finish offers a degree of protection against moisture, UV radiation, abrasion, and certain chemicals, its protective capabilities are limited compared to specialized coatings designed for these specific purposes. The primary value remains in its aesthetic enhancement, with protective qualities serving as a supplementary benefit. The longevity of this protection is directly related to the conditions to which it is exposed and the maintenance it receives.

3. Application

The successful realization of a wax metallic finish hinges critically on the application process. Improper application negates the inherent aesthetic and protective qualities of the materials, resulting in a substandard outcome. The technique employed directly influences the uniformity, smoothness, and overall durability of the final surface. For instance, automotive detailing utilizes specific application methods, including precise layering and buffing techniques, to achieve a flawless, reflective sheen. In contrast, incorrect application leads to streaking, uneven color distribution, and reduced longevity of the finish.

Consider the restoration of antique furniture, where the goal is to replicate an aged metallic appearance. Application methods such as dry brushing or controlled layering of the wax metallic finish are employed to simulate the natural wear and patina accumulated over time. These specialized techniques require a skilled artisan to execute properly. Conversely, applying a thick, uniform coat would result in an artificial and historically inaccurate appearance, diminishing the value and authenticity of the restored piece. Similarly, the application process impacts industrial coatings. Precision instruments benefit from wax metallic finishes, because the application contributes to the devices protective layer that protects the body from harsh environments.

In conclusion, the application phase is not merely a procedural step but an integral component in achieving the desired outcome with a wax metallic finish. Mastering appropriate techniques and understanding the nuanced interplay between the material and application method is paramount. The challenges in this process stem from the need for skilled labor and the sensitivity of the material to environmental conditions. However, a well-executed application yields a visually appealing and long-lasting surface, justifying the effort and expertise required.

4. Durability

Durability represents a critical performance metric for wax metallic finishes, influencing the longevity and sustained aesthetic appeal of treated surfaces. The resilience of the finish directly impacts its suitability for various applications, from decorative accents to functional components exposed to environmental stressors.

- Scratch and Abrasion Resistance

The inherent softness of wax, the primary binder in this type of finish, limits its resistance to scratching and abrasion. Daily wear and tear, even from gentle contact, can lead to visible surface damage, diminishing the reflective properties and overall appearance. High-traffic areas or surfaces subject to frequent handling require additional protective measures or alternative finishing systems with greater scratch resistance. Automotive clear coats applied over a wax metallic base are an example of a mitigation strategy.

- Environmental Degradation

Exposure to ultraviolet (UV) radiation, moisture, and temperature fluctuations accelerates the degradation of wax metallic finishes. UV light causes the wax to break down, leading to fading, discoloration, and a loss of luster. Moisture can penetrate the coating, promoting corrosion of the underlying substrate or causing the wax to swell and delaminate. These factors necessitate regular maintenance and reapplication of the finish, especially in outdoor environments. The longevity of outdoor furniture treated with such a finish will invariably be shorter than that of indoor items.

- Chemical Resistance

The composition of wax metallic finishes typically provides limited resistance to harsh chemicals, solvents, and cleaning agents. Contact with these substances can dissolve or damage the wax matrix, resulting in staining, etching, or complete removal of the finish. Careful selection of cleaning products and avoidance of harsh chemicals are essential to preserve the integrity and appearance of the treated surface. Spillage of common household chemicals on a kitchen appliance with such a finish can cause irreversible damage.

- Adhesion to Substrate

The long-term durability of a wax metallic finish depends on its ability to maintain a strong bond with the underlying substrate. Inadequate surface preparation or incompatible materials can compromise adhesion, leading to peeling, flaking, or blistering of the finish. Proper surface cleaning, priming, and the use of compatible waxes are crucial for ensuring optimal adhesion and preventing premature failure. Insufficient preparation of a metal surface prior to applying a wax metallic finish will lead to eventual detachment of the coating, regardless of the quality of the materials used.

In conclusion, while wax metallic finishes offer a unique aesthetic, their inherent limitations regarding durability must be carefully considered during material selection and application. Understanding the factors that contribute to degradation and implementing appropriate protective measures are essential for maximizing the lifespan and maintaining the visual appeal of surfaces treated with this type of finish. Alternative, more durable finishes should be considered when the application environment presents significant challenges to the long-term integrity of the coating.

5. Maintenance

The preservation of a wax metallic finish necessitates diligent maintenance practices due to its inherent vulnerability to environmental factors and physical wear. A direct cause-and-effect relationship exists between consistent maintenance and the longevity of the finish’s aesthetic appeal and protective qualities. Maintenance serves as a crucial component, mitigating the degradation processes that naturally occur over time. For instance, neglecting to regularly clean an automotive surface treated with this finish will lead to the accumulation of dirt and contaminants, dulling the metallic luster and potentially causing microscopic abrasions that compromise the wax layer.

Practical application of appropriate maintenance protocols includes routine washing with pH-neutral detergents to remove surface contaminants without damaging the wax. Periodic reapplication of a compatible wax product replenishes the protective layer and restores the original sheen. Specialized polishing techniques, executed with soft cloths, can address minor scratches and imperfections, further extending the finish’s lifespan. Failure to adhere to these practices accelerates the deterioration of the coating, resulting in costly repairs or the need for complete reapplication. Consider the difference between two furniture pieces, both treated with a wax metallic finish: one meticulously maintained, retaining its luster and depth, and the other, neglected, exhibiting a faded and worn appearance.

Understanding the critical role of maintenance is paramount for maximizing the return on investment in a wax metallic finish. Challenges arise from the time commitment and the need for specialized products and techniques. However, the alternativepremature degradation and the associated costs of repair or replacementunderscores the practical significance of proactive maintenance. Ultimately, consistent attention to detail and adherence to recommended procedures are essential for ensuring the long-term beauty and performance of surfaces treated with this finish.

6. Composition

The formulation of a wax metallic finish dictates its performance characteristics, aesthetic properties, and overall suitability for specific applications. The careful selection and combination of components are crucial for achieving the desired balance between visual appeal, durability, and ease of application. The composition, therefore, represents a fundamental aspect of this type of finish.

- Wax Matrix

The wax component serves as the primary binder, providing cohesion and film-forming properties. The type of wax usedwhether natural (e.g., beeswax, carnauba wax) or synthetic (e.g., polyethylene wax, microcrystalline wax)influences the hardness, melting point, and solvent resistance of the final finish. For example, carnauba wax, known for its high gloss and hardness, is often incorporated to enhance the durability and shine of automotive wax metallic finishes. The choice of wax also impacts the application process, affecting the ease of buffing and the resulting surface smoothness.

- Metallic Pigments

Metallic pigments impart the characteristic shimmering effect and contribute to the color and depth of the finish. These pigments typically consist of finely ground metal particles, such as aluminum, bronze, copper, or stainless steel, or metal-coated flakes. The size, shape, and concentration of the metallic particles influence the reflectivity and texture of the finish. Smaller particles create a smoother, more uniform shimmer, while larger particles produce a more textured, sparkling effect. The selection of metallic pigments must also consider their chemical compatibility with the wax matrix and their resistance to tarnishing or corrosion. Gold-colored pigments are more expensive so gold waxes are used only in premium products.

- Solvents and Additives

Solvents are incorporated to adjust the viscosity of the finish, facilitate application, and promote proper leveling and drying. The choice of solvent depends on the type of wax and metallic pigments used, as well as the desired application method. Additives, such as UV absorbers, antioxidants, and leveling agents, are included to enhance the durability, stability, and application properties of the finish. UV absorbers protect the wax and pigments from degradation caused by sunlight, while antioxidants prevent oxidation and discoloration. Leveling agents improve the flow and spread of the finish, resulting in a smoother, more uniform surface.

- Fillers and Extenders

In some formulations, fillers and extenders may be added to modify the properties of the wax metallic finish. These additives can adjust the texture, density, and cost of the product. Common fillers include talc, silica, and clay. The presence and type of filler affects scratch resistance, opacity, and the final sheen of the finish. Extenders can reduce the concentration of more expensive metallic pigments, balancing cost with the aesthetic goals of the formula.

The interplay between these compositional elements ultimately determines the performance and appearance of the wax metallic finish. Optimization of the formula requires a thorough understanding of the individual components and their interactions, as well as a clear definition of the desired performance characteristics and aesthetic goals. The success of a wax metallic finish depends on achieving the right balance of composition, application, and maintenance, as exemplified by the long-lasting shine of well-maintained waxed vehicles.

Frequently Asked Questions

This section addresses common inquiries regarding wax metallic finishes, providing concise and informative answers to clarify their properties, applications, and limitations.

Question 1: What distinguishes a wax metallic finish from other types of metallic coatings?

A wax metallic finish incorporates fine metallic particles within a wax-based medium, whereas other metallic coatings may utilize lacquer, enamel, or powder coating technologies. The wax base imparts a distinct sheen and tactile feel, offering a different aesthetic compared to harder, more durable coatings.

Question 2: How durable is a wax metallic finish compared to a traditional paint finish?

A wax metallic finish generally exhibits lower durability compared to traditional paint finishes, particularly in terms of scratch resistance and resistance to harsh chemicals. It requires more frequent maintenance and is best suited for applications where aesthetic appeal is prioritized over extreme durability.

Question 3: Can a wax metallic finish be applied to all surfaces?

A wax metallic finish is most effectively applied to smooth, non-porous surfaces such as metal, wood, or properly prepared plastic. Porous surfaces may absorb the wax unevenly, resulting in an inconsistent finish. Proper surface preparation is crucial for optimal adhesion and appearance.

Question 4: What are the recommended maintenance procedures for a wax metallic finish?

Maintenance includes regular cleaning with mild, pH-neutral detergents and soft cloths. Avoid abrasive cleaners or harsh chemicals. Periodic reapplication of a compatible wax product is recommended to replenish the protective layer and maintain the luster. Polishing with appropriate techniques can address minor imperfections.

Question 5: Is a wax metallic finish suitable for outdoor applications?

A wax metallic finish is generally not recommended for prolonged outdoor exposure due to its limited resistance to UV radiation, moisture, and temperature fluctuations. These environmental factors can accelerate degradation and diminish the finish’s appearance. Specialized formulations with UV inhibitors may offer some improvement, but dedicated outdoor coatings are generally preferable.

Question 6: What safety precautions should be observed when applying a wax metallic finish?

Adequate ventilation is essential during application to avoid inhalation of solvent vapors. Wear appropriate personal protective equipment, such as gloves and respirators, as specified by the product manufacturer. Follow all safety guidelines provided on the product label.

These responses provide a foundational understanding of wax metallic finishes. Further research and consultation with product specialists are recommended for specific applications.

The following section delves into real-world case studies and practical examples of wax metallic finish applications.

Wax Metallic Finish

This exploration has detailed the multifaceted nature of the wax metallic finish, encompassing its composition, application, durability, and maintenance requirements. The analysis has revealed a trade-off between aesthetic appeal and long-term resilience, highlighting the importance of informed decision-making when selecting this treatment. The distinctive visual properties, stemming from the interaction of wax and metallic pigments, provide a unique surface characteristic, albeit one that demands specific care protocols.

The effectiveness of a wax metallic finish hinges on a comprehensive understanding of its inherent limitations and a commitment to proper maintenance practices. Continued research into improved formulations and application techniques is warranted to enhance its durability and broaden its range of suitable applications. Careful consideration of these factors will determine the sustained value and visual impact of this particular finish.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)