An organization providing specialized services in surface treatment for metallic components is a key element in many manufacturing supply chains. These services enhance the durability, corrosion resistance, and aesthetic appeal of metal products, thereby extending their lifespan and improving their performance in various applications.

The significance of such an entity lies in its ability to add value to raw materials. By applying coatings, treatments, and finishes, it transforms standard metal parts into components with specific properties tailored to meet the demands of diverse industries. This process contributes to improved product quality, reduced maintenance costs, and enhanced overall performance, benefitting the end user.

The following sections will delve into specific metal finishing techniques, exploring their applications, advantages, and factors to consider when selecting a service provider in this specialized field. These techniques are crucial for industries requiring high-performance metal components.

Essential Considerations for Metal Finishing Projects

The successful completion of metal finishing projects hinges on a thorough understanding of the process and careful planning. Adherence to industry best practices is paramount for achieving desired results and ensuring long-term performance.

Tip 1: Material Selection is Critical: The substrate material directly impacts the choice of finishing process. Different metals react differently to various treatments. Selecting the appropriate metal alloy for the intended application is a crucial first step.

Tip 2: Define Performance Requirements Clearly: Understanding the end-use environment and performance requirements is essential. Factors such as corrosion resistance, hardness, and wear resistance should be precisely defined to select the optimal finishing technique.

Tip 3: Surface Preparation is Paramount: Proper surface preparation is fundamental to achieving a durable and adherent finish. Cleaning, degreasing, and etching are critical steps to remove contaminants and create a receptive surface for the coating.

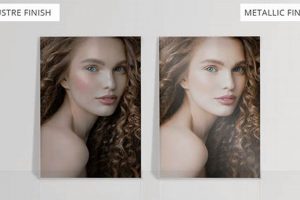

Tip 4: Coating Selection Aligns with Requirements: The choice of coating should directly address the identified performance needs. Consider factors such as coating thickness, hardness, corrosion resistance, and aesthetic appeal when making a selection.

Tip 5: Process Control is Essential: Maintaining strict control over the finishing process parameters is critical for ensuring consistent and repeatable results. Temperature, pressure, and dwell time should be closely monitored and adjusted as needed.

Tip 6: Quality Assurance and Testing: Implementation of a rigorous quality assurance program, including testing for adhesion, thickness, and corrosion resistance, is essential for verifying the integrity of the finished product.

Tip 7: Environmental Considerations Matter: Selection of finishing processes that minimize environmental impact and comply with relevant regulations is increasingly important. Sustainable practices should be prioritized.

By following these guidelines, stakeholders can increase the likelihood of a successful metal finishing project, resulting in components with enhanced durability, performance, and longevity.

The subsequent sections will examine specific applications and the advantages of various metal finishing technologies.

1. Service Portfolio

The service portfolio represents the comprehensive array of metal finishing treatments offered. This portfolio is a foundational element, directly influencing its capacity to meet diverse customer needs. A wide-ranging portfolio enables the organization to cater to various industries and application requirements, while a limited portfolio restricts its potential market and service offerings. The efficacy of the services within that portfolio ultimately determines the organization’s overall value proposition.

Consider, for example, a situation where a client requires both anodizing and powder coating for a single component. If the service portfolio includes both of these capabilities, then a single solution is viable. If, however, only one of these processes is available, the client may have to fragment their order across multiple service providers. This represents a practical consequence, potentially increasing logistical complexity, and affecting overall project timelines.

In summation, the nature and breadth of a metal finishing provider’s service portfolio is a direct determinant of its applicability for any given project. Companies should understand their distinct needs and make sure the providers service range is aligned to meet project needs.

2. Quality Assurance

Quality assurance (QA) forms a critical component of metal finishing operations. Its effective implementation directly influences the consistency, reliability, and longevity of finished products. A robust QA system within metal finishing processes is not merely a procedural requirement but a fundamental aspect of achieving desired performance characteristics, meeting stringent industry standards, and minimizing potential defects. A deficient QA system can lead to premature product failure, increased costs associated with rework or replacement, and potential reputational damage.

Effective QA typically involves a multi-faceted approach. This includes rigorous material testing, precise process control, and meticulous final inspection. For instance, coating thickness measurement is crucial for ensuring adequate protection against corrosion. Adhesion testing verifies the bond strength between the coating and the substrate material, preventing delamination and ensuring long-term durability. Salt spray testing evaluates the resistance of the finished product to corrosive environments, providing valuable insights into its expected service life. These examples illustrate how QA measures are integral to verifying that the finished product meets specified requirements and performance expectations. These processes and documentation provide reliability for the end customer and supplier.

The connection between stringent QA procedures and customer satisfaction in metal finishing is undeniable. Products that consistently meet or exceed expectations build trust and foster long-term relationships. While QA can represent a significant investment, the long-term benefits in terms of reduced warranty claims, improved product reliability, and enhanced customer loyalty far outweigh the initial costs. Continual QA helps both internal and external process improvement. The business should ensure resources and processes are maintained for ongoing improvement in this area.

3. Industry Expertise

Industry expertise is a critical factor determining the capability of a metal finishing organization. It extends beyond mere technical proficiency, encompassing a deep understanding of specific industry requirements, regulatory landscapes, and material science principles. This expertise is directly correlated with the ability to provide tailored solutions that meet the unique demands of various sectors, such as aerospace, automotive, medical device manufacturing, and electronics. Without a comprehensive grasp of the nuances within these industries, the organization risks applying inappropriate finishing techniques, resulting in compromised product performance and potential safety hazards.

Consider the medical device industry as an example. Components used in surgical instruments or implants require finishing processes that are biocompatible, resistant to sterilization procedures, and free from contaminants. Expertise in this area necessitates an understanding of specific regulations such as ISO 13485 and compliance with stringent cleanliness standards. Similarly, the aerospace sector demands finishing techniques that enhance corrosion resistance, improve wear performance, and meet rigorous quality control specifications outlined by organizations like the FAA. In these instances, general knowledge of metal finishing is insufficient; specialized industry knowledge is paramount for ensuring compliance and optimal product functionality. A company that understands the processes and regulatory needs of specific industry is able to more effectively meet their demands.

In conclusion, industry expertise is not a mere add-on but a core competency that dictates the level of value a metal finishing organization can provide. It enables the delivery of customized solutions, adherence to stringent regulations, and ultimately, the production of high-quality, reliable components that meet the demanding requirements of diverse industries. Organizations without this in-depth understanding face significant challenges in consistently delivering satisfactory results and maintaining a competitive edge. A customer would be prudent to evaluate this area before committing to a metal finishing solution.

4. Geographic Reach

Geographic reach defines the operating area and accessibility of “southwest metal finishing inc”, significantly impacting its customer base, logistical considerations, and market competitiveness. This aspect influences responsiveness, turnaround times, and the ability to serve clients across diverse industries.

- Proximity to Key Industries

The proximity to major manufacturing hubs and specific industries requiring metal finishing services dictates the organization’s ability to serve these sectors effectively. For example, locating near aerospace manufacturing centers can facilitate rapid prototyping and just-in-time delivery of finished components. Alternatively, a location near automotive plants enables close collaboration and responsiveness to production demands. The organization’s strategic location affects its capacity to capture market share within these key segments.

- Logistical Efficiency

Geographic reach directly influences logistical efficiency. Strategic placement near major transportation arteries, such as highways, rail lines, or ports, reduces transportation costs and shortens lead times. This is particularly crucial for businesses dealing with large volumes of parts or time-sensitive projects. Efficient logistics enhance competitiveness and improve the customer experience by ensuring timely delivery of finished products.

- Regional Market Competition

The competitive landscape within the geographic area impacts pricing strategies, service offerings, and overall market positioning. A highly competitive market necessitates differentiation through specialized services, superior quality, or competitive pricing. Conversely, a less competitive market may afford opportunities for premium pricing or expansion into underserved niches. Understanding the regional competitive environment is essential for developing effective business strategies.

- Service Area Limitations

Geographic reach imposes practical limitations on the service area. While modern logistics allow for serving customers across considerable distances, factors such as transportation costs, shipping times, and potential for damage during transit often restrict the economically viable service area. Organizations must carefully assess the geographic boundaries within which they can effectively and profitably operate.

These facets highlight the importance of geographic reach in determining the operational capabilities and market positioning of “southwest metal finishing inc”. Strategic location optimizes logistics, facilitates access to key industries, and shapes the competitive environment. Considering the company’s physical location is thus an essential component in assessing its overall value proposition for potential clients.

5. Client Partnerships

Client partnerships are a critical determinant of the long-term viability and success of a metal finishing enterprise. These relationships extend beyond transactional interactions, representing collaborative engagements focused on achieving mutual objectives. A well-developed client partnership strategy fosters trust, encourages open communication, and facilitates the co-creation of value.

- Collaborative Problem Solving

Metal finishing projects often present unique challenges related to material properties, performance requirements, and regulatory compliance. Effective client partnerships foster collaborative problem-solving, enabling the metal finishing provider and the client to work together to identify and implement optimal solutions. This may involve joint experimentation, design modifications, or process adjustments to achieve desired outcomes.

- Open Communication and Transparency

Honest and transparent communication is essential for building strong client partnerships. This includes providing regular updates on project progress, promptly addressing any issues or concerns, and sharing relevant technical information. Transparency builds trust and fosters a sense of shared ownership, leading to more collaborative and productive engagements.

- Customized Solutions and Service

A key benefit of strong client partnerships is the ability to deliver customized solutions and service offerings tailored to the specific needs of each client. This may involve developing unique finishing processes, providing specialized technical support, or offering flexible scheduling to accommodate production demands. A customer-centric approach fosters loyalty and strengthens the long-term relationship.

- Long-Term Value Creation

Client partnerships are ultimately about creating long-term value for both parties. This includes not only achieving immediate project objectives but also identifying opportunities for continuous improvement, innovation, and cost reduction. By working closely with clients, metal finishing organizations can gain valuable insights into their needs and challenges, enabling them to develop solutions that enhance their competitiveness and drive sustainable growth.

These aspects demonstrate the importance of cultivating client partnerships in the context of metal finishing. The resulting collaborations foster innovation, streamline processes, and ultimately contribute to the success of both the metal finishing organization and its clientele. An organization that prioritizes strong relationships is well-positioned for sustained growth and market leadership.

Frequently Asked Questions

The following section addresses common inquiries related to metal finishing processes and service considerations. Information provided intends to offer clear and concise answers to assist in informed decision-making.

Question 1: What factors determine the selection of a suitable metal finishing process?

The selection process hinges upon several key factors. These include the substrate material, desired performance characteristics (e.g., corrosion resistance, wear resistance, hardness), dimensional tolerances, aesthetic requirements, and budgetary constraints. Each factor should be carefully evaluated to ensure the chosen process aligns with the intended application.

Question 2: How is quality control maintained throughout the metal finishing process?

Quality control is maintained through a multi-stage approach encompassing incoming material inspection, in-process monitoring, and final inspection. Techniques such as coating thickness measurement, adhesion testing, and corrosion testing are employed to verify conformance to specified standards. Documentation and traceability are integral to maintaining quality assurance.

Question 3: What are the environmental considerations associated with metal finishing?

Metal finishing processes can generate waste materials, including spent chemicals and rinse water. Environmentally responsible practices involve minimizing waste generation, proper waste treatment and disposal, and compliance with relevant environmental regulations. Sustainable finishing technologies are increasingly being adopted to reduce environmental impact.

Question 4: How does surface preparation influence the effectiveness of metal finishing?

Surface preparation is critical for ensuring proper coating adhesion and performance. Contaminants such as oil, grease, and oxides must be removed to create a clean and receptive surface. Techniques such as cleaning, degreasing, etching, and blasting are employed to achieve the desired surface condition.

Question 5: What are the potential limitations of specific metal finishing processes?

Each finishing process has inherent limitations. For example, certain coatings may exhibit limited temperature resistance or may not be suitable for specific applications. Understanding these limitations is crucial for selecting the appropriate process and avoiding potential performance issues. Consulting with a metal finishing expert can help identify and mitigate such limitations.

Question 6: What information should be provided when requesting a quote for metal finishing services?

To obtain an accurate quote, it is essential to provide detailed information, including the quantity of parts, material specifications, desired finish, applicable standards, and delivery requirements. Engineering drawings or samples may also be necessary to facilitate accurate pricing and process selection.

This compilation provides a fundamental understanding of key considerations in metal finishing. Further consultation with specialized professionals is recommended for addressing specific project requirements.

The subsequent section will delve into case studies illustrating the application of metal finishing in diverse industrial sectors.

Conclusion

This exploration has highlighted critical facets of “southwest metal finishing inc,” emphasizing the importance of service portfolios, quality assurance protocols, industry expertise, geographic considerations, and client partnerships. These elements collectively define its operational capabilities and market position within the metal finishing sector. Rigorous adherence to industry standards and consistent delivery of tailored solutions are vital for sustained success in this demanding field.

Given the intricate demands of modern manufacturing and the increasing emphasis on material performance, the role of specialized metal finishing organizations remains crucial. Continued investment in technological advancements, workforce training, and environmental stewardship will be essential for companies seeking to meet the evolving needs of diverse industries. Stakeholders are encouraged to carefully evaluate all relevant factors when selecting a metal finishing partner to ensure optimal outcomes and long-term value.