The subject of this analysis is a corporation specializing in the treatment and coating of metallic components and products. This involves processes that enhance the aesthetic appeal, durability, and resistance to corrosion of metal surfaces. An example includes applying a protective layer to automotive parts to increase their lifespan.

Such businesses play a vital role in numerous industries, from aerospace and automotive to construction and electronics. Their services improve product quality, extend the functional life of materials, and reduce the need for frequent replacements, contributing to resource conservation. Historically, advancements in related technologies have been driven by the need for stronger, more resilient materials in demanding applications.

The following sections will delve into specific aspects of this type of operation, including the various techniques employed, the regulatory landscape, and the impact on environmental sustainability.

Essential Considerations for Metal Surface Treatment

Achieving optimal results in surface treatment requires careful attention to several key factors. The following tips offer guidance for ensuring quality and durability in the process.

Tip 1: Surface Preparation is Paramount. Thoroughly cleaning and preparing the metal substrate is critical. Contaminants such as oils, rust, or scale can impede adhesion and compromise the final finish. Methods like abrasive blasting or chemical etching may be necessary.

Tip 2: Select the Appropriate Coating Chemistry. The choice of coating material should align with the intended application and environmental conditions. Consider factors such as corrosion resistance, wear resistance, and operating temperature.

Tip 3: Precise Control of Process Parameters. Maintaining accurate control over parameters like temperature, current density, and immersion time is essential for consistent coating thickness and quality. Deviations can lead to defects and premature failure.

Tip 4: Regular Bath Analysis and Maintenance. Chemical solutions used in plating or coating processes require periodic analysis and adjustment to maintain optimal performance. Replenishing depleted components and removing contaminants ensures consistent results.

Tip 5: Adherence to Industry Standards. Compliance with relevant industry standards, such as those established by ASTM International or ISO, is vital for ensuring quality and meeting customer specifications. Certification can demonstrate a commitment to best practices.

Tip 6: Implement Rigorous Quality Control. Implementing a comprehensive quality control program, including visual inspection, thickness measurement, and adhesion testing, is essential for identifying and correcting defects early in the process.

These considerations are paramount for producing durable and aesthetically pleasing metal finishes that meet the demands of various applications. Careful attention to each of these areas will contribute significantly to the overall success of the finishing process.

The subsequent sections will explore advanced techniques and emerging trends in this field, further expanding on the principles outlined above.

1. Surface Preparation

Surface preparation is a foundational step within operations. Its effectiveness dictates the adherence and performance of subsequent coatings applied by the entity. Inadequate preparation, such as the presence of residual oils or scale, can directly lead to premature coating failure, compromising the intended protection and aesthetic qualities. For instance, in automotive component finishing, if the metal substrate is not properly cleaned before powder coating, corrosion resistance and paint adhesion are substantially reduced. This underscores the critical role of surface preparation as an integral initial process.

Different metals and alloys require specific surface preparation techniques. Aluminum, for example, might undergo anodizing for enhanced corrosion resistance, necessitating a specific chemical etching process. Steel components may require abrasive blasting to remove rust and create a profile for coating adhesion. The selection of an appropriate method is determined by the material properties, the type of coating being applied, and the desired performance characteristics of the finished product. Improper selection leads to suboptimal results. A common example is using an inappropriate abrasive material, resulting in surface contamination.

In conclusion, effective surface preparation is paramount for the successful execution of metal finishing operations and directly impacts the quality and longevity of the finished product. The selection of suitable techniques, rigorous process control, and adherence to industry best practices are crucial for achieving optimal results. Neglecting this critical step can lead to significant issues, undermining the overall value and effectiveness of the processes involved.

2. Coating Application

Coating application constitutes a core competency within operations. The specific methods employed by a company, for example, electroplating, powder coating, or painting, directly determine the performance characteristics of the finished product. The proper selection and precise execution of a coating application method are therefore fundamental to achieving desired outcomes, such as enhanced corrosion resistance, improved wear resistance, or specific aesthetic qualities. This aspect reflects directly on its capabilities, impacting both efficiency and product quality. When a company excels in this area, it can meet strict industry standards and customer demands.

Consider the case of aerospace components requiring exceptional resistance to extreme environmental conditions. The precise application of specialized coatings, such as thermal barrier coatings or chromium plating, becomes essential for maintaining structural integrity and functional performance. Similarly, in the automotive industry, electrodeposition of e-coat provides a durable, corrosion-resistant base layer for subsequent paint finishes, enhancing the lifespan and appearance of vehicle bodies. These are examples of the high impact of the coating in the product.

The expertise and resources dedicated to coating application directly influence the quality and competitiveness of the end product. Careful selection of materials and the proper execution of coating processes are paramount. These actions lead to enhanced durability, aesthetics, and overall customer satisfaction. The company’s capabilities in this area therefore define its position within the industry. Its success is ultimately dependent on mastery of these critical processes.

3. Material Selection

Material selection stands as a foundational element directly impacting the success and efficacy of operations. The properties of the base metal dictate the suitability of various finishing processes. For instance, aluminum alloys frequently undergo anodization to enhance corrosion resistance, whereas steel components might be subjected to galvanization or powder coating for similar protective benefits. Inappropriate selection of a finishing process for a given material can lead to compromised adhesion, reduced durability, and ultimately, product failure. The choice of coating chemistry and application method must be carefully aligned with the substrate materials characteristics to achieve desired performance criteria.

Consider a scenario where a high-strength steel component is inappropriately treated with a finishing process designed for softer metals. The resulting coating may lack the necessary hardness and abrasion resistance to withstand the intended operating conditions, leading to premature wear and potential structural failure. Conversely, applying a relatively aggressive finishing process to a more delicate material can result in surface damage or alteration of critical dimensions. An example of this would be the etching of magnesium alloys which can create hydrogen embrittlement, this would weaken the materials.

Therefore, a comprehensive understanding of material properties, including composition, hardness, thermal expansion coefficient, and surface energy, is essential for processes. Proper material selection, guided by thorough engineering analysis and informed decision-making, ensures that the selected finishing process will effectively enhance the material’s performance characteristics and extend its service life. This, in turn, leads to improved product reliability, reduced maintenance costs, and enhanced customer satisfaction.

4. Process Control

Process control is fundamental to the operations. It ensures consistent quality, minimizes defects, and optimizes resource utilization. Effective process control is not merely a procedural formality, but rather a strategic imperative directly affecting operational efficiency, profitability, and overall business reputation.

- Chemical Bath Monitoring and Adjustment

Maintaining precise chemical balance in plating or etching baths is paramount. Regular monitoring of pH, metal ion concentration, and additive levels is necessary. Deviations from optimal ranges can lead to inconsistent coating thickness, poor adhesion, and undesirable color variations. For instance, inadequate control of sulfuric acid concentration during anodization can result in a porous, non-protective oxide layer. The organization’s success depends on this.

- Temperature Regulation

Temperature control is crucial in many finishing processes. Elevated temperatures can accelerate reaction rates, potentially leading to uneven coatings or material degradation. Conversely, insufficient temperatures can slow down the process, reducing throughput and increasing energy consumption. Maintaining strict temperature control within defined tolerances is critical for achieving consistent results and minimizing waste. It involves using calibrated equipment and trained staff.

- Current Density Management

In electroplating and electrodeposition processes, current density directly impacts the deposition rate and coating uniformity. Excessive current density can result in burning or uneven plating, while insufficient current density can lead to slow deposition rates and incomplete coverage. Precise control of current density, often achieved through automated control systems, is essential for achieving optimal coating characteristics.

- Dwell Time Optimization

Dwell time, or the duration of immersion in a particular chemical solution, is a critical parameter in several finishing processes. Insufficient dwell time can result in incomplete surface treatment, whereas excessive dwell time can lead to over-etching or unwanted chemical reactions. Optimizing dwell time, based on material type, solution concentration, and temperature, is essential for achieving desired surface properties.

These interconnected aspects of process control highlight its essential role in metal finishing operations. By carefully monitoring and adjusting key parameters, such as chemical bath composition, temperature, current density, and dwell time, the organization can ensure consistent product quality, reduce waste, and optimize resource utilization, thus enhancing its competitive advantage in the marketplace. Process control is essential for business success.

5. Quality Assurance

In metal finishing, quality assurance is a systematic process designed to ensure that products and services meet predefined standards of quality and reliability. For operations such as the specified entity, robust quality assurance protocols are not merely beneficial, but essential for maintaining competitiveness, meeting stringent industry regulations, and satisfying customer expectations.

- Incoming Material Inspection

Thorough inspection of incoming raw materials is a critical first step. This involves verifying that the materials meet specified composition, purity, and dimensional tolerances. For instance, confirming that incoming steel batches possess the correct alloy composition prevents potential issues in subsequent finishing processes, reducing the risk of defects and ensuring the finished product meets performance requirements. This stage is important to reducing operational costs.

- In-Process Monitoring and Control

Continuous monitoring of process parameters, such as temperature, pH, and current density, is vital during coating or plating operations. Implementing statistical process control (SPC) techniques allows for real-time identification of deviations from established norms. As an example, monitoring bath chemistry in an electroplating line enables prompt adjustments, preventing inconsistencies in coating thickness and adhesion. This ensures consistent quality.

- Final Product Inspection and Testing

Rigorous final inspection and testing are conducted to verify that finished products conform to specified quality standards. This often involves non-destructive testing (NDT) methods, such as ultrasonic testing or radiographic inspection, to detect subsurface defects. For instance, assessing the corrosion resistance of a coated component through salt spray testing validates its ability to withstand harsh environmental conditions, ensuring long-term durability. The organization’s reputation depends on this.

- Documentation and Traceability

Maintaining detailed records of all quality assurance activities, including inspection results, test data, and corrective actions, is essential for traceability and accountability. Implementing a robust document control system ensures that all relevant information is readily accessible. For example, retaining batch-specific records of chemical analysis and coating parameters allows for swift identification of the root cause of any quality issues and facilitates effective corrective actions. This reduces future problems and customer complaints.

The implementation of comprehensive quality assurance measures is indispensable. By systematically monitoring processes and rigorously testing products, the company can ensure consistent delivery of high-quality finishes. This not only satisfies customer expectations but also contributes to enhanced operational efficiency, reduced costs associated with rework and scrap, and a strengthened reputation for excellence within the industry.

6. Environmental Compliance

Environmental compliance is a critical element of sustainable operations for any entity engaged in metal finishing. The activities inherent in this field, such as electroplating, etching, and coating, generate waste streams containing regulated pollutants including heavy metals, acids, and solvents. Non-compliance with environmental regulations can result in significant financial penalties, legal repercussions, and reputational damage. Therefore, adherence to environmental standards is not merely a legal obligation but an essential component of responsible business practice.

The specific regulations governing operations vary by jurisdiction but generally encompass wastewater discharge limits, air emissions controls, and hazardous waste management protocols. For example, the Clean Water Act in the United States establishes effluent limitations for various pollutants discharged by electroplating facilities. Similarly, the Resource Conservation and Recovery Act (RCRA) mandates strict requirements for the storage, treatment, and disposal of hazardous wastes generated during metal finishing processes. Effective compliance requires a comprehensive understanding of applicable regulations, implementation of appropriate pollution control technologies, and adherence to rigorous monitoring and reporting requirements. Failure to meet these requirements can lead to substantial fines, permit revocation, and even criminal prosecution.

In conclusion, environmental compliance constitutes an indispensable facet of responsible metal finishing operations. The implementation of robust environmental management systems, coupled with continuous monitoring and improvement efforts, is essential for mitigating environmental risks, ensuring regulatory compliance, and fostering a sustainable business model. Challenges include the evolving nature of environmental regulations and the need for ongoing investment in pollution control technologies. However, proactive engagement in environmental stewardship offers opportunities for cost savings through resource efficiency, enhanced brand reputation, and improved stakeholder relations.

Frequently Asked Questions

The following questions address common inquiries concerning the nature, processes, and compliance standards associated with metal finishing operations. The information provided is intended to offer clarity and understanding of critical aspects related to the field.

Question 1: What constitutes metal finishing?

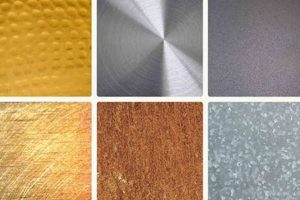

Metal finishing encompasses a range of processes aimed at altering the surface properties of metallic components. These processes may include cleaning, coating, plating, and other treatments designed to enhance corrosion resistance, improve wear resistance, or achieve specific aesthetic characteristics.

Question 2: Why is surface preparation essential prior to finishing?

Surface preparation is crucial for ensuring proper adhesion and performance of subsequent coatings or treatments. Contaminants such as oils, rust, or scale can impede the bonding process, leading to premature coating failure and compromised performance of the finished product.

Question 3: What are the principal environmental concerns associated with metal finishing?

Metal finishing processes often generate waste streams containing regulated pollutants, including heavy metals, acids, and solvents. The responsible management and disposal of these wastes are essential for minimizing environmental impact and ensuring compliance with applicable regulations.

Question 4: What are the most common methods used in metal finishing?

Common methods include electroplating, anodizing, powder coating, and various chemical conversion coatings. The selection of a particular method depends on the material being treated, the desired performance characteristics, and applicable regulatory requirements.

Question 5: How is the quality of the product ensured?

Quality assurance is maintained through rigorous monitoring of process parameters, thorough inspection of incoming materials, in-process controls, and final product testing. Statistical process control techniques are often employed to ensure consistency and identify potential deviations from established standards.

Question 6: What are the considerations when choosing the right coating material?

Selecting the right coating material involves careful consideration of factors such as the intended application, the operating environment, and the desired performance characteristics. Corrosion resistance, wear resistance, temperature stability, and aesthetic requirements all play a role in the decision-making process.

In summary, metal finishing is a multifaceted field requiring careful attention to process control, environmental compliance, and quality assurance. A comprehensive understanding of these aspects is essential for achieving optimal results and ensuring the long-term performance and reliability of finished products.

The subsequent section will explore emerging technologies and future trends in the field, offering insights into potential advancements and challenges that may shape the industry in the years to come.

Conclusion

The preceding analysis has presented a comprehensive overview of the considerations essential to responsible and effective metal finishing operations. Factors such as surface preparation, material selection, process control, quality assurance, and environmental compliance collectively determine the success and sustainability of any entity engaged in this field. A failure to address these elements adequately can compromise product integrity, regulatory adherence, and ultimately, business viability.

As industries increasingly demand durable, high-performance materials with minimal environmental impact, a commitment to excellence in metal finishing remains paramount. Continued innovation in processes, materials, and technologies will be crucial for organizations seeking to meet evolving market demands and maintain a competitive edge. Ongoing diligence and a proactive approach to operational improvements are essential for long-term success.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)