A surface treatment applied to freshly poured concrete, resulting in linear grooves or striations. This effect is achieved by dragging a specialized tool across the wet surface before it fully hardens, creating a textured pattern. This technique is often utilized in exterior applications like driveways, patios, and sidewalks.

This method provides enhanced traction, particularly beneficial in areas prone to wet or icy conditions. Furthermore, it offers an aesthetically pleasing visual element, adding depth and character to otherwise plain surfaces. Historically, such textured finishes were implemented to improve safety and conceal minor imperfections in the concrete.

The subsequent discussion will explore the specific techniques employed to achieve different variations of this treatment, the advantages and disadvantages associated with its use, and its suitability for various project types. This includes detailed information on the tools required and best practices for its application.

Application Tips for Surfaces with Linear Grooves

The following outlines best practices to ensure a successful and durable implementation of this textured concrete surface.

Tip 1: Preparation is Paramount: Ensure the concrete mix is appropriate for the intended use and environmental conditions. Proper subgrade compaction and formwork are crucial for a level and stable base.

Tip 2: Timing is Critical: The surface treatment must be applied when the concrete is plastic enough to be worked but firm enough to retain the pattern. Weather conditions significantly influence the setting time.

Tip 3: Tool Selection Matters: Choose the appropriate tool based on the desired groove depth and spacing. Metal or plastic rakes with varying tooth configurations are available.

Tip 4: Consistency in Application: Maintain a consistent speed and pressure when dragging the tool across the surface to achieve a uniform pattern. Overlapping passes may be necessary.

Tip 5: Edge Detailing: Pay close attention to the edges and corners of the slab. Use edging tools to create clean and professional-looking borders.

Tip 6: Curing is Essential: Proper curing is vital for the strength and durability of the concrete. Employ appropriate curing methods, such as wet curing or applying a curing compound, to prevent premature drying and cracking.

Tip 7: Consider Drainage: The grooved surface can aid in water runoff. Design the slab with a slight slope to facilitate drainage away from structures.

Adherence to these guidelines will result in a durable, aesthetically pleasing, and functionally effective surface.

The subsequent sections will address common problems encountered during the application process and strategies for their resolution.

1. Enhanced Traction

The incorporation of linear grooves into concrete surfaces represents a deliberate strategy to augment traction, mitigating the risk of slips and falls. This is particularly pertinent in environments susceptible to moisture or ice accumulation.

- Increased Friction Coefficient

The textured surface physically increases the friction coefficient between footwear and the concrete. The grooves provide edges that interlock with shoe soles, resisting slippage compared to smooth surfaces. This is especially beneficial for pedestrian walkways and areas with vehicular traffic.

- Water Displacement Mechanism

The channels created by the grooves facilitate the rapid displacement of water from the surface. This minimizes the formation of a thin film of water, which can drastically reduce friction and increase the likelihood of hydroplaning or slipping. This is critical for driveways and patios.

- Ice Disruption

In cold climates, the grooves disrupt the formation of a continuous sheet of ice. The increased surface area allows for faster melting due to exposure to sunlight and air. Furthermore, the texture provides edges for improved grip even when ice is present. This is applicable to sidewalks and entranceways.

- Reduced Polishing Effect

Over time, smooth concrete surfaces can become polished by foot traffic, further reducing their slip resistance. The textured finish inherently resists this polishing effect, maintaining a higher level of traction over an extended period. This contributes to long-term safety and reduced maintenance costs.

These facets highlight the multifaceted nature of enhanced traction achieved through textured concrete. By increasing the friction coefficient, facilitating water displacement, disrupting ice formation, and resisting polishing, this finish provides a durable and effective solution for improving safety in a variety of environments. Other textured finishes such as exposed aggregate provide similar benefits with different aesthetics.

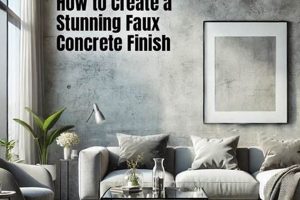

2. Surface Aesthetics

The visual appeal of concrete surfaces is significantly influenced by the chosen finishing technique. Linear grooving imparts a distinct aesthetic character that differentiates it from conventional smooth concrete. This surface treatment allows for intentional design elements that enhance overall architectural appeal.

- Directional Emphasis

The linear nature of the grooves introduces a sense of directionality. This can be strategically employed to guide the eye, delineate spaces, or complement the surrounding landscape. For instance, aligning the grooves with the long axis of a walkway can visually lengthen the path, while orienting them perpendicular to a building faade can accentuate its horizontal lines. These directional cues add a layer of visual interest and purposeful design.

- Shadow and Light Play

The textured surface creates subtle variations in shadow and light, adding depth and dimension. Sunlight interacts with the grooves, creating a dynamic interplay of light and dark that changes throughout the day. This tactile effect enhances the visual richness of the concrete, preventing it from appearing flat or monotonous. Such effects are particularly pronounced on large expanses of concrete.

- Customization Options

The spacing, depth, and pattern of the grooves can be customized to achieve different aesthetic outcomes. Narrow, closely spaced grooves create a subtle, refined texture, while wider, deeper grooves offer a bolder, more rustic appearance. The choice of tool and the application technique allow for significant design flexibility, enabling architects and designers to tailor the finish to specific project requirements.

- Material Contrast

Linear grooves can create a deliberate contrast with surrounding materials, enhancing the overall visual composition. For example, the textured concrete might be juxtaposed with smooth stone or polished metal to create a dynamic interplay of textures. This contrast can add visual interest and highlight the unique qualities of each material, contributing to a more sophisticated and visually appealing design.

These facets demonstrate how the surface treatment with linear grooves extends beyond mere functionality to encompass a significant aesthetic dimension. Through directional emphasis, shadow play, customization options, and material contrast, it offers a versatile tool for enhancing the visual appeal of concrete surfaces in a wide range of architectural contexts. Other finishes, such as stamped concrete, provide different aesthetic choices, but all options contribute to overall design intent.

3. Water Runoff

The incorporation of linear grooves into concrete surfaces significantly influences water runoff characteristics, establishing a direct correlation between this surface texture and efficient water management. The channels created by the raking process serve as conduits for water, directing it away from the surface and minimizing the potential for ponding. This functionality is particularly crucial in exterior applications such as driveways, patios, and walkways where exposure to precipitation is unavoidable. The angle and depth of the grooves directly impact the speed and volume of water displaced, therefore, careful consideration must be given to site-specific rainfall patterns and drainage requirements during the design phase.

In practical applications, the strategic orientation of grooves can maximize water removal efficiency. For instance, aligning the grooves perpendicular to a building foundation can prevent water from accumulating near the base, mitigating the risk of water damage or foundation instability. On sloped surfaces, the grooves can channel water towards designated drainage points, preventing erosion and maintaining the integrity of the surrounding landscape. Furthermore, the enhanced drainage provided by the surface reduces the likelihood of ice formation in colder climates, thereby increasing safety and reducing the need for de-icing measures. Examples of successful implementation can be observed in public spaces, residential areas, and industrial sites, highlighting the versatility and effectiveness of the approach.

In summary, surface texture with linear grooves promotes efficient water runoff by providing designated channels for water displacement. This improves safety, minimizes potential damage, and contributes to the long-term durability of the concrete surface. While factors such as groove depth and orientation require careful consideration to optimize performance, the principles of enhanced water management are consistently applicable across diverse project types. Overcoming challenges, such as uneven surfaces, and precise surface grooving creates durable and efficient water runoff.

4. Application Timing

The successful execution of a surface with linear grooves hinges critically on precise application timing. The state of the concrete mix dictates the feasibility and quality of the grooved pattern. If the concrete is too wet, the grooves will collapse, resulting in a blurred or non-existent texture. Conversely, if the concrete has begun to set prematurely, the raking tool will tear the surface, producing an uneven and aesthetically displeasing finish. The ideal window for application occurs when the concrete surface has lost its surface sheen, indicating that excess bleed water has evaporated, but the mix remains sufficiently plastic to accept the impression of the raking tool. This timing is affected by environmental factors, such as temperature, humidity, and wind speed, which necessitate constant monitoring and adjustment of application schedules.

In practical terms, experienced concrete finishers continuously assess the concrete’s workability by touch and visual inspection. A small test area is often created to determine the optimal moment for initiating the raking process. If the test pass demonstrates clean, well-defined grooves that hold their shape, the application can proceed. Consider a large concrete pour on a hot, windy day: the concrete will set much faster than on a cool, humid day. The finisher must be prepared to work quickly and efficiently, possibly using multiple teams to ensure that the entire surface is treated within the optimal timeframe. Failure to adapt to these changing conditions can lead to inconsistencies in the finished surface, requiring costly repairs or even complete replacement.

In conclusion, application timing is not merely a procedural step but an integral element of achieving a high-quality surface with linear grooves. Mastery of this timing requires a thorough understanding of concrete behavior, environmental influences, and the practical skills to assess concrete workability. By carefully managing the application window, concrete finishers can ensure a durable, aesthetically pleasing, and functionally effective surface. Ignoring this critical parameter invariably leads to compromised results and increased project costs.

5. Tool Selection

The execution of linear grooves in concrete is intrinsically linked to the selection of appropriate tools. The chosen instrument directly determines the groove’s depth, width, spacing, and overall pattern, thus dictating the final aesthetic and functional properties of the surface. Inadequate or inappropriate tool selection invariably results in a compromised finish, exhibiting inconsistent textures, insufficient traction, or premature wear. For instance, utilizing a rake with excessively wide tines on a small patio would produce an unrefined, coarse appearance, while a rake with dull or damaged tines would create irregular and poorly defined grooves. The relationship is causal; the tool is the direct agent responsible for imparting the desired texture.

The practical significance of tool selection is evident across various applications. A driveway designed for heavy vehicular traffic necessitates a robust rake capable of creating deep, wide grooves that provide optimal traction in wet conditions. In contrast, a decorative patio might benefit from a finer-toothed rake that produces shallower, more closely spaced grooves, enhancing the visual appeal without compromising walkability. Concrete finishing supply companies offer a diverse range of raking tools, each engineered for specific purposes. These include metal rakes for durability, plastic rakes for flexibility, and specialized tools designed to create unique patterns, such as those mimicking natural stone or wood grain. The investment in high-quality, specialized tools is often offset by the increased efficiency, precision, and longevity of the finished concrete surface.

In summary, tool selection is not a mere ancillary consideration but a critical component of the surface treatment process. A clear understanding of the relationship between tool characteristics and desired outcome is essential for achieving optimal results. The challenge lies in matching the appropriate tool to the specific project requirements, considering factors such as the intended use, aesthetic preferences, and environmental conditions. By carefully considering tool selection, concrete professionals can ensure the creation of durable, functional, and visually appealing surfaces.

6. Curing Method

The integrity and longevity of a surface bearing linear grooves are inextricably linked to the curing method employed. Curing, the process of maintaining adequate moisture and temperature in newly placed concrete to facilitate proper hydration of the cement, is critical for achieving the desired strength and durability. This importance is magnified when dealing with a textured surface because the increased surface area created by the grooves accelerates moisture loss, potentially leading to premature drying and subsequent cracking. Improper curing can negate the benefits of a carefully executed surface treatment, resulting in a structurally compromised and aesthetically flawed final product. A lack of proper hydration weakens the cement matrix, diminishing the concrete’s resistance to abrasion, freeze-thaw cycles, and chemical attack. In regions experiencing frequent temperature fluctuations, inadequate curing can lead to surface scaling and disintegration, particularly along the edges of the grooves.

Several curing methods are applicable to surfaces with linear grooves, each with its advantages and limitations. Wet curing, involving continuous application of water through ponding, spraying, or covering with saturated burlap, provides the most consistent and effective hydration. However, this method can be labor-intensive and impractical for large-scale projects or in arid environments. Membrane-forming curing compounds, applied as a liquid coating to the concrete surface, offer a more convenient alternative by sealing in moisture and preventing evaporation. Selecting an appropriate curing compound is essential; some compounds can discolor the concrete or react adversely with sealers or other surface treatments applied later. Another approach involves covering the concrete with plastic sheeting, which traps moisture and maintains a humid environment. Regardless of the chosen method, consistent and thorough application is paramount. Uneven curing can lead to differential shrinkage, creating stress concentrations that ultimately manifest as cracks. Real-world examples of curing failures can be observed in parking lots with extensive surface cracking or in residential patios where the decorative grooves exhibit premature deterioration.

In conclusion, the curing method is not merely an ancillary step in the construction process but a critical determinant of the long-term performance of surfaces with linear grooves. Implementing a rigorous curing regimen, tailored to the specific environmental conditions and project requirements, is essential for ensuring a durable, aesthetically pleasing, and structurally sound finished product. The challenges associated with maintaining adequate moisture and temperature require diligent monitoring, proper material selection, and skilled application techniques. Ignoring these considerations compromises the entire effort, diminishing the inherent benefits of texturing the concrete surface. The success of any such project resides in the consistent integration of suitable curing procedures.

Frequently Asked Questions About Surfaces with Linear Grooves

The following addresses common inquiries regarding the application, performance, and maintenance of concrete surfaces textured with linear grooves.

Question 1: Is surface treatment with linear grooves suitable for all climates?

While beneficial in many environments, extremely cold climates may experience issues with ice accumulation within the grooves. Evaluate local freeze-thaw cycles before specifying this finish.

Question 2: How does this finish affect the longevity of the concrete?

Properly executed, this surface treatment does not inherently compromise concrete longevity. However, inadequate curing or improper mix design can lead to premature deterioration, irrespective of the finish.

Question 3: Can these surfaces be sealed?

Yes, sealing is permissible and often recommended to enhance stain resistance and ease of cleaning. However, ensure compatibility between the sealer and the concrete mix.

Question 4: What is the typical cost compared to standard concrete finishes?

The cost is generally higher than a standard broom finish due to the additional labor and specialized tools required for application. Obtain localized quotes for accurate cost assessments.

Question 5: How does this finish perform in high-traffic areas?

The durability in high-traffic zones depends on the concrete mix, application quality, and maintenance practices. Proper reinforcement and a high-strength mix are crucial for extended performance.

Question 6: Is it possible to apply this finish to existing concrete slabs?

Generally, no. This finish is applied to freshly poured concrete. Applying it to existing slabs would require resurfacing with a concrete overlay.

These frequently asked questions provide a foundation for understanding this specialized surface. Consulting with experienced concrete professionals is recommended for project-specific guidance.

The subsequent section will delve into case studies illustrating the successful application of surfaces with linear grooves in various settings.

Conclusion

This exploration of raked finish concrete has illuminated the multifaceted aspects of this specialized surface treatment. From its functional benefits in enhancing traction and managing water runoff to its aesthetic contributions in adding visual interest and directional emphasis, the value proposition has been established. Crucially, the success of raked finish concrete hinges upon meticulous planning, proper material selection, and skilled execution, encompassing everything from optimal application timing to appropriate curing methods.

While the information herein serves as a comprehensive guide, practical experience and adherence to industry best practices remain paramount. Specifiers, contractors, and property owners are encouraged to consult with qualified concrete professionals to ensure the successful implementation of raked finish concrete in their respective projects. By carefully considering the principles outlined, raked finish concrete can provide a durable, safe, and aesthetically pleasing surface for years to come.