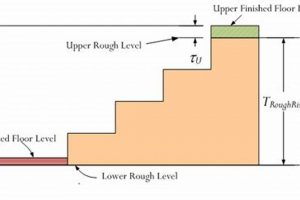

The phrase identifies the characteristics, qualities, or interpretations associated with materials applied as the uppermost layer of a flooring structure. These applications, which include sealants, coatings, and other treatments, serve to protect the underlying material, enhance its appearance, and modify its functional properties. Examples encompass polyurethane coatings applied to hardwood, epoxy resins used on concrete, and waxes applied to resilient flooring like linoleum.

Understanding the attributes inherent to these applications is crucial for making informed decisions regarding design, durability, and maintenance. This understanding impacts factors such as resistance to wear, ease of cleaning, aesthetic appeal, and overall lifespan of the floor. Historically, choices in this area were limited, but modern advancements offer a wider array of options tailored to diverse environments and performance requirements. This detailed knowledge enables the matching of specific product characteristics to the demands of various settings.

Subsequent sections will delve into the various types available, focusing on their specific properties, suitable applications, and installation considerations. Furthermore, this discussion will address the environmental impact of different choices and explore best practices for maintenance to ensure longevity and sustained performance. A comprehensive review of testing standards and performance metrics will also be provided to facilitate informed product selection.

Practical Guidance on Flooring Surfaces

The following points offer practical guidance to ensure optimal selection, installation, and maintenance regarding the surface treatment of flooring.

Tip 1: Material Compatibility: Thoroughly assess the compatibility of a chosen surface treatment with the underlying flooring material. Incompatible combinations can lead to adhesion failures, discoloration, or accelerated wear.

Tip 2: Environmental Considerations: Evaluate the environmental conditions to which the floor will be exposed. High-traffic areas, moisture-prone environments, or exposure to chemicals necessitate specific formulations designed for resilience.

Tip 3: Surface Preparation: Proper surface preparation is crucial for achieving optimal adhesion and performance. This includes cleaning, abrading, and priming the substrate according to the manufacturer’s recommendations.

Tip 4: Application Techniques: Adhere strictly to the manufacturer’s guidelines for application techniques, including mixing ratios, application rates, and drying times. Deviation from these instructions can compromise the integrity and durability of the finished surface.

Tip 5: Maintenance Protocols: Implement a regular maintenance schedule utilizing appropriate cleaning agents and techniques. Preventative measures, such as the use of mats in high-traffic areas, can significantly extend the lifespan of the surface.

Tip 6: Performance Testing: Consider independent performance testing data to validate the claims made by manufacturers. Third-party certifications can provide objective assessments of durability, slip resistance, and chemical resistance.

Tip 7: Ventilation During Application: Ensure adequate ventilation during application and curing to minimize exposure to volatile organic compounds (VOCs). Select low-VOC or VOC-free products to promote healthier indoor air quality.

Adhering to these guidelines will contribute to a more durable, aesthetically pleasing, and cost-effective flooring solution. Careful consideration of these factors minimizes potential problems and maximizes the return on investment.

The subsequent analysis will delve into specific product categories, offering detailed comparisons and considerations for specialized applications. This comprehensive evaluation will enable informed decision-making for any flooring project.

1. Protection and durability

The protective and durability aspects inherent to surface treatments are central to the interpretation of “floor finishes meaning.” These attributes determine the longevity and sustained performance of a flooring system under diverse operational conditions.

- Abrasion Resistance

Abrasion resistance denotes a material’s capacity to withstand wear from foot traffic, equipment movement, and other physical contact. Finishes like polyurethane and epoxy are frequently employed to enhance this resistance, particularly in commercial and industrial settings. The measure of abrasion resistance directly impacts the lifespan of the floor and the frequency of required maintenance. Failure to address abrasion can lead to surface degradation and eventual substrate damage.

- Chemical Resistance

Chemical resistance refers to the ability of a floor surface to withstand exposure to solvents, acids, alkalis, and other corrosive substances. Specific finishes, such as epoxy and certain specialized coatings, are formulated to resist chemical attack, making them essential in laboratories, manufacturing facilities, and healthcare environments. A lack of appropriate chemical resistance can result in staining, etching, and structural compromise of the flooring material.

- Moisture Resistance

Moisture resistance is the capacity of a surface to impede the penetration of water and other liquids. This is critical in environments prone to spills or high humidity, such as kitchens, bathrooms, and basements. Finishes like sealants and waterproof coatings prevent moisture from seeping into the underlying material, thereby preventing mold growth, swelling, and structural decay. Neglecting moisture resistance can lead to significant long-term damage and health hazards.

- Impact Resistance

Impact resistance measures the ability of a surface to withstand sudden forces or impacts without cracking, chipping, or denting. This is particularly important in areas subject to heavy objects, dropped tools, or other forms of physical stress. Finishes incorporating resilient polymers or reinforced compositions provide enhanced impact resistance, safeguarding the floor from damage and maintaining its structural integrity. Insufficient impact resistance can lead to unsightly damage and require costly repairs.

These facets of protection and durability are intrinsic to “floor finishes meaning.” The proper selection and application of appropriate treatments are fundamental to ensuring the long-term performance, safety, and aesthetic appeal of a flooring system. Failing to consider these aspects can result in premature failure, increased maintenance costs, and potential hazards within the environment.

2. Aesthetic enhancement

Aesthetic enhancement, in the context of surface applications, denotes the enhancement of visual appeal and design harmony achieved through strategic surface treatments. This aspect forms a significant dimension of “floor finishes meaning,” influencing the perceived value and environmental integration of a space.

- Color and Tone Modulation

Color and tone modulation involves the strategic use of dyes, stains, and pigmented coatings to alter the inherent color of the flooring material. This allows for seamless integration with existing design schemes or the creation of specific moods and atmospheres. Examples include staining hardwood floors to achieve a richer, darker tone or using colored epoxy coatings in commercial spaces to reinforce branding elements. The implications extend to influencing occupant perceptions and the overall visual coherence of an environment.

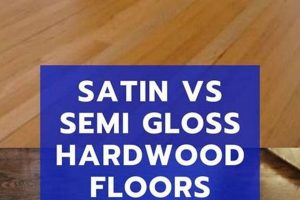

- Gloss and Sheen Variation

Gloss and sheen variation encompasses the selection of finishes that control the reflectivity and luster of the surface. This can range from matte finishes that minimize glare to high-gloss finishes that create a polished, reflective appearance. The selection impacts the perceived cleanliness and modernity of the space. For instance, matte finishes are often preferred in residential settings for their subtle elegance, while high-gloss finishes are common in retail environments to attract attention. The appropriate selection enhances visual interest and functionality.

- Texture and Pattern Integration

Texture and pattern integration refers to the incorporation of physical textures or applied patterns to enhance the tactile and visual experience. This may involve embossing, etching, or the application of patterned coatings. Examples include textured concrete surfaces for slip resistance and visual interest or decorative epoxy coatings with embedded patterns. The use of texture and pattern adds depth and complexity to the flooring surface, contributing to a more engaging and personalized environment.

- Material Simulation and Replication

Material simulation and replication involves the use of surface treatments to mimic the appearance of more expensive or rare materials. This includes techniques like staining concrete to resemble marble or using laminate flooring to replicate the look of hardwood. This provides a cost-effective alternative to natural materials, enabling the creation of luxurious and sophisticated environments within budgetary constraints. Material simulation allows for expanded design possibilities without compromising on aesthetic appeal.

These aesthetic elements, while seemingly superficial, contribute significantly to the comprehensive understanding of “floor finishes meaning.” By carefully considering color, gloss, texture, and material simulation, designers and specifiers can create flooring systems that enhance the visual appeal, functionality, and overall value of a space, ensuring a harmonious integration with the surrounding environment.

3. Functional properties alteration

Functional properties alteration, when considered within the framework of “floor finishes meaning,” signifies the modification of a flooring material’s inherent characteristics through the application of a surface treatment. This alteration aims to enhance specific performance attributes or to impart new functionalities that address particular operational demands. The relevance lies in tailoring the floor’s performance to meet the unique requirements of a given environment.

- Slip Resistance Enhancement

Slip resistance enhancement involves the application of coatings or treatments that increase the coefficient of friction of the flooring surface. This is particularly critical in environments prone to moisture or spills, such as kitchens, bathrooms, and entryways. Examples include the use of epoxy coatings with embedded aggregates or the application of anti-slip sealants. The implication is a reduction in the risk of slip-and-fall accidents, thereby improving safety and mitigating potential liability.

- Cleanability and Hygiene Improvement

Cleanability and hygiene improvement entails the use of finishes that create a smooth, non-porous surface, facilitating the removal of dirt, bacteria, and other contaminants. This is essential in healthcare facilities, food processing plants, and laboratories. Examples include the application of seamless epoxy or polyurethane coatings that eliminate grout lines and crevices where microorganisms can accumulate. The impact is a more hygienic environment, reduced maintenance costs, and enhanced infection control.

- Sound Dampening Augmentation

Sound dampening augmentation involves the application of resilient coatings or underlayments that reduce the transmission of impact noise and airborne sound. This is beneficial in multi-story buildings, classrooms, and office environments. Examples include the use of cork underlayments or specialized acoustic coatings that absorb sound waves. The consequence is a quieter, more comfortable environment, improved speech intelligibility, and reduced noise-related distractions.

- Thermal Conductivity Modification

Thermal conductivity modification refers to the alteration of a floor’s ability to conduct heat, either to enhance warmth or to provide cooling effects. This can be achieved through the application of insulating coatings or the incorporation of materials with specific thermal properties. Examples include radiant floor heating systems with thermally conductive overlays or the use of reflective coatings to reduce heat absorption in warm climates. The outcome is improved energy efficiency, enhanced thermal comfort, and reduced heating or cooling costs.

These modifications, viewed collectively, demonstrate that “floor finishes meaning” extends beyond mere aesthetic considerations. Functional properties alteration is a critical aspect of flooring design, enabling the creation of environments that are safer, more hygienic, more comfortable, and more energy-efficient. The strategic manipulation of these properties through carefully selected surface treatments is essential for optimizing the performance of a flooring system and aligning it with the specific needs of its intended use.

4. Material composition analysis

Material composition analysis, within the framework of “floor finishes meaning,” involves the systematic identification and quantification of the constituents comprising a surface treatment. This analytical process is fundamental because the material makeup directly dictates the performance characteristics, durability, and potential environmental impact of the finish. Understanding the precise components and their respective proportions allows for a predictive assessment of the finish’s resistance to abrasion, chemical exposure, UV degradation, and other forms of environmental stress. For example, a polyurethane finish with a high concentration of aliphatic isocyanates will exhibit superior UV resistance compared to one with aromatic isocyanates, influencing its suitability for outdoor applications. Similarly, the presence and concentration of volatile organic compounds (VOCs), determined through material composition analysis, directly impact indoor air quality and adherence to environmental regulations. Therefore, this analysis is a prerequisite for informed decision-making and responsible material selection.

Further analysis reveals the practical significance of material composition analysis in various scenarios. In healthcare settings, the presence of antimicrobial additives in epoxy finishes, verified through composition analysis, contributes to infection control by inhibiting microbial growth on the floor surface. In industrial environments, the identification of specific polymers and reinforcing agents in concrete sealers allows for targeted selection based on the anticipated chemical exposure, ensuring long-term protection of the concrete substrate. Moreover, this analysis is crucial for quality control in manufacturing, ensuring that each batch of finish meets predefined compositional specifications, thereby guaranteeing consistent performance and minimizing the risk of product failure. Without detailed compositional data, performance claims remain unsubstantiated, and the potential for unforeseen consequences increases substantially.

In conclusion, material composition analysis is an indispensable component of understanding “floor finishes meaning.” It provides the empirical foundation for predicting performance, ensuring compliance, and mitigating risks associated with the use of specific floor surface treatments. The analytical data derived from this process enable informed decision-making throughout the lifecycle of a flooring system, from initial selection to long-term maintenance. While challenges exist in accurately characterizing complex formulations, the insights gained from material composition analysis are paramount for achieving optimal performance, durability, and sustainability in flooring applications, linking technical specifications to real-world outcomes.

5. Application method variation

Application method variation is intrinsically linked to “floor finishes meaning,” dictating not only the aesthetic outcome but also influencing the protective qualities and longevity of the treatment. The chosen application technique profoundly impacts the uniformity, adhesion, and overall performance of the resulting surface.

- Spray Application Influence

Spray application, often employed for urethanes and epoxies, necessitates careful control of pressure, nozzle type, and environmental conditions. Inconsistent spray patterns can lead to uneven film thickness, resulting in variations in gloss, color, and protection levels. Proper technique ensures a uniform, pinhole-free surface, maximizing resistance to abrasion and chemical ingress. Improper spray application can manifest as “orange peel” texture or solvent popping, compromising both appearance and durability. The selection of spray equipment and operator skill are critical determinants of finish quality.

- Roller Application Considerations

Roller application, commonly used for paints, sealers, and some water-based finishes, demands specific attention to roller nap, overlap consistency, and pressure control. The selection of an inappropriate roller nap can result in uneven coating thickness or the introduction of air bubbles into the finish. Insufficient overlap leads to thin spots and potential adhesion failures. Consistent pressure ensures uniform distribution and proper penetration of the finish into the substrate. Ignoring these factors can result in visible roller marks and diminished protective properties.

- Brush Application Nuances

Brush application, often favored for intricate details and edges, requires expertise in brush loading, stroke direction, and feathering techniques. Overloading the brush leads to drips and runs, compromising the finish’s appearance. Improper stroke direction can create visible brush marks. Feathering ensures a smooth transition between applied areas, preventing noticeable lap lines. Skilled brushwork is essential for achieving a professional, seamless finish in complex areas, demonstrating how artisanal skill informs the realized “floor finishes meaning.”

- Trowel Application Specifications

Trowel application, typically used for self-leveling epoxies and cementitious overlays, necessitates precise control of material viscosity, trowel angle, and application speed. Inconsistent trowel pressure can result in uneven surface levels and variations in finish thickness. Improper trowel angle can lead to the formation of ridges or imperfections. Maintaining a consistent application speed is crucial for ensuring proper self-leveling and a smooth, uniform surface. Expertise in trowel application is essential for achieving a durable and aesthetically pleasing result with these specialized finishes.

These application method variations highlight the crucial role of technique in realizing the intended “floor finishes meaning.” The selection of an appropriate technique, combined with skilled execution, ensures that the finish achieves its optimal performance characteristics, enhances the aesthetic appeal of the floor, and provides long-lasting protection against wear and tear. Conversely, inadequate application can undermine the inherent qualities of the finish, leading to premature failure and compromised performance. These considerations underscore the importance of skilled labor and adherence to manufacturer specifications in the successful implementation of any flooring project.

6. Maintenance requirements

The term “maintenance requirements,” when viewed through the lens of “floor finishes meaning,” signifies the specific protocols and actions necessary to preserve the intended characteristics and extend the lifespan of a floor surface. These requirements are not arbitrary but are directly determined by the material composition and application method of the finish, establishing a critical connection between the initial choice of finish and its subsequent upkeep.

- Cleaning Regimen Specificity

The cleaning regimen is dictated by the finish’s susceptibility to staining, scratching, and chemical degradation. For instance, wax finishes on hardwood require regular waxing and polishing to maintain their sheen and protective qualities, while polyurethane finishes necessitate gentler cleaning agents to prevent dulling. Neglecting these specific cleaning protocols can lead to premature wear, discoloration, and a diminished aesthetic appeal, directly impacting the interpreted “floor finishes meaning.” A high-gloss acrylic finish requires different products than an oil-based penetrating sealer.

- Periodic Recoating or Refinishing

Many floor finishes, particularly those subjected to high traffic, require periodic recoating or refinishing to restore their protective barrier and aesthetic qualities. The frequency of this intervention depends on the durability of the finish and the intensity of use. For example, commercial floors with epoxy finishes may require annual recoating, while residential floors with polyurethane finishes may only need refinishing every few years. Failure to address these recoating needs results in progressive damage to the underlying flooring material, negating the initial protective intent of the finish.

- Environmental Control Measures

Environmental control measures, such as humidity regulation and UV protection, are often critical for maintaining the integrity of certain floor finishes. Excessive humidity can cause swelling and warping in wood floors with water-based finishes, while prolonged exposure to sunlight can lead to fading and discoloration in some synthetic finishes. Implementing environmental controls mitigates these risks and preserves the intended appearance and performance characteristics of the finish, thereby safeguarding the “floor finishes meaning” from external degradation.

- Repair and Restoration Protocols

Even with diligent maintenance, localized damage may occur, necessitating specific repair and restoration protocols. The nature of these protocols depends on the type of finish and the extent of the damage. For instance, scratches in wax finishes can often be buffed out, while deeper damage to polyurethane finishes may require spot repairs or complete refinishing. Prompt and appropriate repair actions prevent minor damage from escalating into more significant problems, ensuring the continued functionality and aesthetic appeal of the floor.

In conclusion, the maintenance requirements associated with a floor finish are not merely an afterthought but are an integral component of the overall “floor finishes meaning.” They represent the ongoing effort required to uphold the intended protective, aesthetic, and functional qualities of the surface, demonstrating a commitment to preserving the investment and realizing the full potential of the flooring system. The long-term success of any flooring project hinges on a comprehensive understanding and diligent execution of these essential maintenance practices.

Frequently Asked Questions

The following section addresses common inquiries regarding floor surface treatments, offering clarity on their purpose, application, and maintenance.

Question 1: What constitutes a “floor finish” in technical terms?

A floor finish denotes a material applied to the uppermost layer of a flooring system. Its function extends beyond mere aesthetics, encompassing protection, enhancement of functional properties, and increased durability of the underlying substrate.

Question 2: How does the selection of a floor finish impact the lifespan of a floor?

The chosen finish directly affects the floor’s resistance to abrasion, chemical exposure, moisture penetration, and impact damage. A properly selected finish can significantly extend the lifespan of a floor by mitigating these detrimental factors.

Question 3: Are there health considerations associated with certain floor finishes?

Some floor finishes contain volatile organic compounds (VOCs) that can impact indoor air quality. Selection of low-VOC or VOC-free options is recommended to minimize potential health risks.

Question 4: What role does surface preparation play in the application of a floor finish?

Proper surface preparation is critical for ensuring adequate adhesion and optimal performance of the finish. This typically involves cleaning, abrading, and priming the substrate in accordance with the manufacturer’s recommendations.

Question 5: How often should a floor finish be reapplied or refreshed?

The frequency of reapplication depends on the type of finish, the level of traffic, and the environmental conditions. Regular inspection and maintenance are essential for determining the need for reapplication.

Question 6: Does the application method influence the effectiveness of a floor finish?

The application method significantly impacts the uniformity, adhesion, and overall performance of the finish. Adherence to recommended application techniques is crucial for achieving optimal results.

A comprehensive understanding of these frequently asked questions facilitates informed decision-making regarding floor finish selection and maintenance.

The subsequent discussion will delve into specific product categories and their associated performance characteristics.

Floor Finishes Meaning

The exploration of “floor finishes meaning” has underscored the multifaceted nature of these surface treatments. It is evident that these applications are not mere aesthetic enhancements but integral components of a flooring system, impacting durability, functionality, and long-term performance. The choice of finish, the method of application, and the implementation of appropriate maintenance protocols are all critical determinants of a floor’s lifespan and sustained value. Neglecting these factors leads to premature degradation and compromised performance.

Therefore, a comprehensive understanding of “floor finishes meaning” is essential for informed decision-making. The industry must prioritize accurate performance data, rigorous testing standards, and clear communication of product characteristics to ensure that specifiers, installers, and end-users are equipped to make optimal choices. Future advancements should focus on developing more sustainable, durable, and versatile finishes that minimize environmental impact and enhance the overall performance of flooring systems. The integrity and longevity of our built environment depend on a continued commitment to the principles outlined herein.