These slender fasteners, typically employed in woodworking, are characterized by their fine diameter and headless or near-headless design. They are commonly used to attach trim, molding, and other delicate pieces where minimizing visible evidence of the fastener is crucial. For instance, these fasteners might secure crown molding to a cabinet without leaving a prominent mark.

The value of such a fastener lies in its ability to provide a strong, almost invisible hold. This is particularly important in finish carpentry, where aesthetics are paramount. Historically, similar fasteners were manually driven, but modern pneumatic and electric nailers significantly enhance speed and precision. This has contributed to increased efficiency in construction and renovation projects, while simultaneously preserving the quality of the finished product.

Therefore, understanding the appropriate applications, the correct driving techniques, and the various tool options available is essential for achieving optimal results in projects that require a subtle yet reliable method of joinery. Subsequent sections will delve into these specific aspects.

Tips for Optimal Use

Employing these fasteners effectively requires attention to detail and adherence to specific best practices. These guidelines will maximize performance and minimize potential issues.

Tip 1: Select the Appropriate Length: Choosing the correct length is crucial. The fastener should penetrate sufficiently into the substrate material for secure holding power, but it should not extend entirely through the material. A general guideline is to ensure penetration of at least twice the thickness of the material being fastened.

Tip 2: Adjust Air Pressure on Pneumatic Nailers: When using a pneumatic nailer, carefully adjust the air pressure. Insufficient pressure may result in incomplete setting, whereas excessive pressure can cause the fastener to drive too deeply and damage the surrounding material.

Tip 3: Use a Nail Set for Countersinking: For a truly seamless finish, employ a nail set to countersink the fastener slightly below the surface. This allows for filling the small indentation with wood filler or putty, creating an invisible repair.

Tip 4: Consider Wood Species: The density and hardness of the wood species influence the ease of driving the fastener. Hardwoods require more force; pre-drilling pilot holes may be necessary to prevent bending or splitting. Softer woods may require reduced air pressure to prevent excessive sinking.

Tip 5: Maintain Proper Nailer Angle: Maintain a consistent and appropriate angle when driving the fastener. Angling the nailer incorrectly can cause the fastener to bend, break, or protrude at an undesirable angle. A 90-degree angle to the surface is typically ideal.

Tip 6: Examine Fastener Quality: The quality of the fasteners themselves affects performance. Ensure the fasteners are free from rust, bending, or other defects before loading them into the nailer. Inferior fasteners are more prone to jamming and misfiring.

Effective implementation of these methods will result in cleaner, stronger, and more professional-looking finished projects. Proper application minimizes cosmetic defects and ensures long-term structural integrity.

The subsequent section will address common problems encountered and provide solutions to mitigate them.

1. Gauge Size

Gauge size is a critical attribute defining the diameter of a fastener. In the context of 18 gauge finishing nails, it directly influences the nail’s holding power, visibility, and suitability for various woodworking and finishing applications. Understanding its implications is vital for selecting the appropriate fastener.

- Diameter and Holding Power

The 18 gauge designation refers to a specific wire diameter. A smaller gauge number indicates a larger diameter, and vice versa. Consequently, an 18 gauge nail possesses a relatively small diameter, resulting in reduced holding power compared to larger gauge nails. This characteristic is advantageous in delicate applications where minimizing splitting or damage to the workpiece is paramount.

- Impact on Visibility

The narrow profile of an 18 gauge finishing nail contributes to its minimal visibility once installed. This is a key consideration in finish carpentry where the aesthetic outcome is crucial. The small entry point left by the nail allows for easier concealment with wood filler or putty, resulting in a cleaner, more professional appearance.

- Tool Compatibility

Gauge size dictates the type of nail gun or fastening tool required for proper installation. 18 gauge finishing nails are specifically designed for use with 18 gauge nailers, ensuring consistent and accurate driving. Using the incorrect nail gauge can lead to tool malfunctions, fastener damage, and unsafe operating conditions.

- Material Suitability

Due to their slender profile, 18 gauge finishing nails are best suited for use with softer woods and thinner materials. Attempting to use them in dense hardwoods may result in bending, breakage, or insufficient penetration. Choosing the correct gauge size based on the material being fastened is essential for achieving a secure and lasting connection.

The attributes related to gauge size collectively determine the application envelope of 18 gauge finishing nails. Their subtle profile is ideal for trim, molding, and delicate woodworking, providing a balance between adequate holding power and minimal visual impact. Selecting the appropriate gauge size necessitates a thorough assessment of project requirements and material characteristics.

2. Head Type

Head type is a defining characteristic of 18 gauge finishing nails that critically influences their application and aesthetic outcome. The head, or lack thereof, dictates the fastener’s visibility and the degree of finishing work required. Variations in head design offer specific advantages in different scenarios. The selection of an appropriate head type is not arbitrary; it directly impacts the final appearance and structural integrity of the project.

One prevalent head type is the “brad head,” characterized by its small, slightly rounded profile. This design allows the nail to be driven nearly flush with the surface, minimizing visibility. Another common type is the “headless” or “almost headless” pin nail. As the name suggests, these nails have extremely small heads, essentially rendering them invisible upon installation. These are particularly suited for delicate trim work where concealment is paramount. The functional consequence of these differing head designs is the variation in surface area available for holding power. Brad heads offer slightly more holding power due to the marginally larger head, but at the expense of increased visibility compared to pin nails. Conversely, the near invisibility of pin nails necessitates careful material selection and appropriate nail length to ensure adequate holding strength.

In summary, the head type of an 18 gauge finishing nail represents a crucial design element, demanding careful consideration based on the project’s specific requirements. Choosing the appropriate head type balances the need for holding power with the desired level of visual concealment. Understanding these trade-offs is essential for achieving professional-quality results in finish carpentry and related applications. The next section will explore shank styles and their relationship to overall performance.

3. Shank Style

The shank style of an 18 gauge finishing nail significantly influences its holding power and suitability for different materials. Variations in shank design provide enhanced grip and resistance to pull-out, impacting the overall performance of the fastener in woodworking and finishing applications.

- Smooth Shank

Smooth shank nails feature a plain, untextured shaft. They offer lower resistance during insertion, making them easier to drive into wood. However, their holding power relies primarily on friction, making them less suitable for applications requiring high pull-out resistance or for use with softer woods where friction is diminished.

- Barbed Shank

Barbed shank nails incorporate small, backward-facing barbs along the shaft. These barbs provide increased holding power by mechanically interlocking with the wood fibers. The barbs resist nail withdrawal, making them a better choice for applications where the fastener is subjected to tension or vibration.

- Twisted Shank

Twisted shank nails, also known as spiral shank nails, have a helical or screw-like thread along the shaft. Driving these nails into wood involves a twisting motion, which compresses the wood fibers and creates a tighter grip. Twisted shanks offer superior holding power compared to smooth shanks, particularly in dense materials or applications requiring resistance to racking forces.

- Ring Shank

Ring shank nails feature a series of annular rings along the shaft. Similar to barbed shanks, these rings mechanically interlock with the wood fibers, providing increased resistance to pull-out. Ring shanks are commonly used in applications where the fastener is subjected to cyclical loading or where long-term holding power is critical.

The choice of shank style for 18 gauge finishing nails should be carefully considered based on the specific requirements of the project. Factors such as the type of wood, the load on the joint, and the desired level of holding power will dictate the optimal shank style for achieving a secure and lasting connection. While smooth shanks offer ease of use, barbed, twisted, and ring shanks provide enhanced holding power for more demanding applications.

4. Material Composition

The material composition of 18 gauge finishing nails is a primary determinant of their performance, durability, and suitability for diverse applications. The selection of materials dictates resistance to corrosion, bending strength, and compatibility with various wood types and environmental conditions. The inherent properties of the constituent materials directly impact the fastener’s longevity and effectiveness.

- Steel Alloys

The predominant material in 18 gauge finishing nail manufacturing is steel. Variations in steel alloy composition dictate the nail’s tensile strength and flexibility. Higher carbon content increases hardness and strength but may also increase brittleness, making the nail more susceptible to breakage. Lower carbon content results in increased ductility but reduces the fastener’s ability to withstand bending forces. The precise alloy composition is therefore a trade-off tailored to balance strength and flexibility for efficient driving and secure holding.

- Stainless Steel

Stainless steel offers superior corrosion resistance compared to carbon steel alloys. This makes stainless steel 18 gauge finishing nails ideal for exterior applications, marine environments, or use with treated lumber containing corrosive chemicals. The chromium content in stainless steel forms a passive oxide layer that prevents rust formation. Although generally more expensive than carbon steel options, stainless steel provides long-term durability and prevents staining or degradation of the surrounding wood. Example: Use in boat building or outdoor furniture to withstand weather exposure.

- Coatings and Finishes

To enhance the performance and longevity of steel nails, various coatings are applied. Galvanization, involving a zinc coating, provides sacrificial corrosion protection. Polymer coatings offer a barrier against moisture and chemical attack. Resin coatings reduce friction during driving, minimizing wood splitting. The selection of coating is driven by the intended application and the anticipated environmental conditions. For example, a galvanized nail is suitable for general construction where moderate moisture exposure is expected, while a resin-coated nail is preferred to prevent splitting delicate trim.

- Copper

While less common, copper 18 gauge finishing nails offer excellent corrosion resistance and aesthetic appeal. Copper is naturally resistant to rust and develops a distinctive patina over time. These nails are often employed in historical restoration projects or high-end woodworking where the visual aspect is paramount. Copper nails provide a secure and durable fastening solution while complementing the natural beauty of the wood. For example, these might be used in antique furniture restoration or decorative woodwork where a touch of elegance is desired.

In summary, the material composition of 18 gauge finishing nails is a critical factor governing their performance and durability. Ranging from various steel alloys to stainless steel and copper, each material and coating provides specific advantages tailored to particular applications and environmental conditions. Selecting the appropriate material composition ensures a secure, lasting, and aesthetically pleasing fastening solution in woodworking and construction endeavors.

5. Point Type

Point type, an essential characteristic of 18 gauge finishing nails, significantly affects driving performance and the potential for wood splitting. The geometry of the nail point dictates the force required for penetration and the way in which wood fibers are displaced. A well-designed point minimizes damage to the surrounding material, contributing to a cleaner, more professional finish. Conversely, an improperly shaped point can lead to bending, jamming, or splitting, compromising the integrity of the joint.

Common point types include the chisel point, diamond point, and blunt point. The chisel point, characterized by its angled, blade-like shape, facilitates easier penetration with less force, reducing the risk of splitting in hardwoods. The diamond point, with its four-sided pyramidal shape, offers a balance between penetration force and holding power. The blunt point is primarily used in softer woods to minimize splitting, although it requires greater driving force. For instance, when attaching delicate trim to oak cabinets, a chisel-point nail minimizes the risk of splitting the oak, while a diamond-point nail may be preferable for attaching pine molding, balancing penetration and holding. In practical terms, understanding the relationship between point type and wood density enables efficient and precise fastening, minimizing waste and rework.

In conclusion, the selection of point type for 18 gauge finishing nails is a critical consideration influencing ease of application and quality of the final product. Mismatched combinations of nail point and material can lead to structural deficiencies and cosmetic imperfections. Recognizing the significance of this relationship is paramount for achieving optimal results in finish carpentry and woodworking applications, ensuring both aesthetic appeal and structural soundness.

6. Length Variety

Length variety represents a crucial consideration when selecting 18 gauge finishing nails, as it directly influences the fastener’s holding power, penetration depth, and suitability for diverse woodworking and finishing applications. Proper length selection ensures secure attachment without compromising the aesthetic appeal of the finished piece.

- Holding Power and Material Thickness

The length of the nail must correspond to the thickness of the materials being joined. Insufficient length results in inadequate penetration into the substrate, leading to weak holding power and potential joint failure. Conversely, excessive length can cause the nail to protrude through the back of the workpiece, creating an unsightly appearance and posing a safety hazard. For instance, when attaching 1/2-inch trim to a solid wood frame, a 1-inch nail may provide sufficient penetration, whereas a 1 1/4-inch nail might be more appropriate for thicker materials or when increased holding strength is required.

- Preventing Clinching and Splitting

Choosing the correct nail length minimizes the risk of clinching (bending over) or splitting the wood. Clinching occurs when the nail encounters resistance during driving and bends back upon itself. Splitting can occur when the nail forces the wood fibers apart, particularly near the edges of the workpiece. Selecting a shorter nail reduces the force required for driving and minimizes the potential for these issues. For example, using a shorter nail near the edge of a delicate piece of molding can prevent unsightly splits.

- Application-Specific Requirements

Different applications demand varying nail lengths to accommodate specific needs. When attaching thin veneer or delicate trim, shorter nails are preferred to minimize visibility and prevent damage to the underlying material. In contrast, when attaching heavier moldings or structural components, longer nails are necessary to provide adequate holding power. The specific requirements of the project dictate the optimal length range. For example, attaching picture frame backs requires shorter nails; installing baseboards calls for longer ones.

- Substrate Density and Nail Length

The density of the substrate material impacts the required nail length. Denser woods require longer nails to achieve adequate holding power, while softer woods may be adequately secured with shorter nails. Selecting the appropriate length based on the wood species ensures a secure and lasting connection. Using a longer nail for a hardwood vs. soft wood is important for long term hold.

The available length variety in 18 gauge finishing nails addresses the diverse requirements of woodworking and finishing projects. By carefully considering the factors outlined above, one can select the optimal nail length to ensure secure attachment, prevent damage, and achieve a professional-looking finished product. The relationship between nail length and substrate properties is crucial for long term stability and appearance.

7. Coating Options

Coating options significantly influence the performance and longevity of 18 gauge finishing nails, impacting their resistance to corrosion, ease of driving, and interaction with various wood types. Selection of the appropriate coating is essential for optimizing fastener performance in specific applications.

- Galvanization

Galvanization involves coating steel nails with a layer of zinc, providing sacrificial corrosion protection. The zinc corrodes preferentially to the steel, preventing rust formation. Galvanized nails are suitable for general construction and exterior applications where moderate moisture exposure is expected. Example: Use in attaching exterior trim where prolonged exposure to the elements is anticipated.

- Polymer Coatings

Polymer coatings offer a barrier against moisture, chemicals, and other corrosive agents. These coatings can be tailored to provide specific performance characteristics, such as increased lubricity or enhanced color matching. Example: Use in preservative-treated lumber to prevent chemical reactions between the wood treatment and the nail.

- Resin Coatings

Resin coatings reduce friction during nail driving, minimizing the potential for wood splitting, particularly in delicate trim or hardwoods. The resin acts as a lubricant, easing the nail’s passage through the wood fibers. Example: Application in attaching thin moldings to prevent splitting the wood during installation.

- Phosphate Coatings

Phosphate coatings provide a slightly textured surface that enhances paint adhesion. These coatings are often used on nails intended for applications where painting or finishing is required. The phosphate layer creates a mechanical bond with the paint, improving its durability and resistance to chipping. Example: Use in attaching trim that will be painted to match the surrounding walls or cabinetry.

The selection of coating options for 18 gauge finishing nails represents a critical decision impacting the fastener’s long-term performance and compatibility with specific applications. Careful consideration of environmental factors, wood type, and desired aesthetic outcome ensures optimal fastener performance and longevity. Understanding the properties of each coating type provides a framework for informed selection.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, application, and performance characteristics of 18 gauge finishing nails.

Question 1: What distinguishes 18 gauge finishing nails from other nail types?

18 gauge finishing nails are characterized by their small diameter, which minimizes visibility and reduces the risk of splitting delicate wood. This differs from larger gauge nails used for structural applications where holding power is prioritized over aesthetic considerations.

Question 2: In what applications are 18 gauge finishing nails most appropriate?

These nails are best suited for attaching trim, molding, and other lightweight materials where a subtle, near-invisible fastener is desired. They are commonly employed in finish carpentry, cabinet making, and picture framing.

Question 3: Can 18 gauge finishing nails be used in hardwoods?

While possible, usage in hardwoods requires caution. Pre-drilling pilot holes is recommended to prevent bending or breaking the nail. The holding power in hardwoods may be limited compared to larger gauge fasteners.

Question 4: What length of 18 gauge finishing nail should be selected for a given application?

The nail length should be approximately twice the thickness of the material being fastened. This ensures adequate penetration into the substrate for secure holding power without protruding through the back of the workpiece.

Question 5: Are there different types of 18 gauge finishing nails for interior and exterior applications?

Yes. Stainless steel or galvanized nails are recommended for exterior applications due to their superior corrosion resistance. Standard steel nails are suitable for interior use in dry environments.

Question 6: What are the common issues encountered when using 18 gauge finishing nails, and how can they be mitigated?

Common issues include bending, jamming, and insufficient holding power. Bending and jamming can be minimized by using a quality nailer, adjusting air pressure appropriately, and ensuring the nailer is held perpendicular to the work surface. Insufficient holding power can be addressed by selecting a longer nail or using a stronger adhesive in conjunction with the nails.

In summary, 18 gauge finishing nails are specialized fasteners designed for applications where aesthetics are paramount. Proper selection and application techniques are crucial for achieving optimal results.

The subsequent section will address best practices for maintenance and storage.

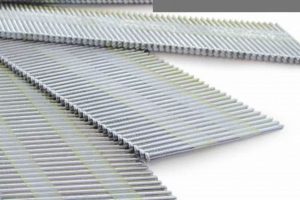

18 Gauge Finishing Nails

This exposition has detailed various attributes of 18 gauge finishing nails, from gauge size and head type to shank style, material composition, point configurations, length availability, and coating options. These elements collectively define the application envelope of this specialized fastener. Their slender profile offers minimal visibility, making them suitable for finish carpentry and delicate woodworking where aesthetics are paramount. The choice of material and coating further tailors their performance to specific environments and wood types, enhancing durability and preventing corrosion.

Therefore, a comprehensive understanding of these features is crucial for informed decision-making. It enables professionals and hobbyists alike to select the appropriate 18 gauge finishing nails for a given project, ensuring both a visually appealing outcome and a secure, long-lasting bond. Continued adherence to best practices in application and maintenance will maximize the value and extend the service life of this essential woodworking component.