This tool employs compressed air to drive slender fasteners into wood. These fasteners, typically 15 or 16 gauge, are designed to leave minimal surface disruption. An example of its application is securing delicate trim work where aesthetics are paramount.

Its significance lies in its ability to accomplish precise and consistent fastening. Advantages include increased efficiency and reduced risk of splitting the material being worked. Historically, this type of tool has evolved from purely manual methods, offering a significant improvement in speed and accuracy for detailed woodworking.

The subsequent sections will delve into the specific applications, maintenance procedures, and safety considerations associated with the use of such a tool.

Operational Tips

Optimal performance and longevity are contingent upon adherence to established operational guidelines. The following tips provide insights for maximizing utility and minimizing potential issues.

Tip 1: Regulate Air Pressure: The manufacturer’s recommended pressure should always be observed. Excessive pressure can lead to fastener over-driving, while insufficient pressure can result in incomplete setting.

Tip 2: Select Correct Fastener Length: Fastener length must be appropriate for the combined thickness of the materials being joined. Utilizing excessively long fasteners presents a risk of protrusion and potential injury.

Tip 3: Maintain a Consistent Angle: Ensure the tool is held perpendicular to the work surface unless a specific angled drive is required for the application. Inconsistent angles can compromise the integrity of the joint.

Tip 4: Regularly Lubricate: Consistent lubrication, using pneumatic tool oil, is crucial for internal component functionality and extended lifespan. Neglecting lubrication may result in premature wear and reduced performance.

Tip 5: Inspect the Air Hose and Fittings: Prior to each use, the air hose and fittings should be inspected for signs of damage, such as cracks or leaks. Defective components should be replaced immediately to prevent pressure loss and potential hazards.

Tip 6: Use Appropriate Safety Equipment: Eye protection and hearing protection are mandatory when operating this tool. Failure to use proper safety equipment may result in injury.

Tip 7: Store Properly: When not in use, disconnect the tool from the air supply and store it in a clean, dry environment. This helps to prevent corrosion and damage to internal components.

Consistent application of these tips contributes to safer, more efficient, and more durable operation, optimizing the return on investment. Correct employment will significantly improve quality.

The following sections will present additional aspects of its utilization, including maintenance procedures and specific safety protocols.

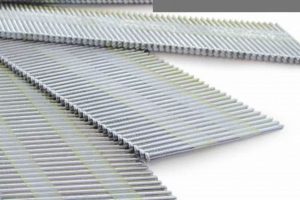

1. Fastener Gauge

Fastener gauge, in the context of a pneumatic finishing nailer, refers to the thickness of the nail or brad used by the tool. It is a critical factor affecting both the holding power of the fastener and the visibility of the entry point on the finished surface. A higher gauge number indicates a thinner fastener. For instance, an 18-gauge brad creates a significantly smaller hole than a 15-gauge finishing nail. The choice of gauge directly influences the suitability of the tool for a given application.

The selection of an appropriate gauge hinges on the materials being joined and the desired aesthetic outcome. In applications such as attaching delicate trim or molding where minimal surface disruption is paramount, a higher gauge fastener is preferred. Conversely, for securing heavier stock or when a stronger hold is needed, a lower gauge fastener is more appropriate. Failure to select the correct gauge may result in inadequate holding power or undesirable cosmetic effects. Common examples include using 18-gauge brads for lightweight picture frames and 15-gauge nails for securing baseboards.

Ultimately, understanding the relationship between fastener gauge and the tool’s intended use is essential for achieving professional-quality results. Choosing the appropriate gauge mitigates risks of material damage and ensures a secure, aesthetically pleasing finish. Limitations imposed by the nailer’s magazine capacity and the material’s susceptibility to splitting also impact gauge selection, thereby requiring careful consideration of these interrelated factors.

2. Air Pressure

Air pressure serves as the operational foundation for a pneumatic finishing nailer. Its precise regulation and consistent delivery are critical for achieving desired fastening results and preventing damage to both the workpiece and the tool itself. The following points detail key facets of air pressure’s role.

- Optimal Operating Range

Each pneumatic finishing nailer model specifies a recommended air pressure range, typically measured in pounds per square inch (PSI). Operating outside this range can lead to inconsistent nail depth, fastener misfires, or even internal tool damage. For example, a nailer rated for 70-100 PSI will likely experience issues if supplied with only 60 PSI or as much as 120 PSI.

- Impact on Fastener Depth

Air pressure directly governs the force with which the nailer drives fasteners. Higher pressure results in deeper nail penetration, while lower pressure results in shallower penetration. This relationship is crucial for ensuring fasteners are set flush with the material surface without overdriving and causing cosmetic damage. This makes the tool useless.

- Regulator Importance

An air pressure regulator, connected to the air compressor, allows for precise control over the pressure supplied to the nailer. This is essential for adapting to different materials and fastener sizes. Without a regulator, pressure fluctuations from the compressor can lead to inconsistent results. This is crucial to be aware of.

- Air Line Maintenance

The air line connecting the compressor to the nailer must be free of leaks and obstructions to maintain consistent pressure delivery. Leaks can cause pressure drops, resulting in under-driven fasteners. Routine inspection and replacement of worn air lines are necessary for reliable tool operation.

In summation, diligent monitoring and precise adjustment of air pressure are not merely recommended but are essential for the safe and effective operation of a pneumatic finishing nailer. Mastery of this parameter is crucial for achieving consistent, professional-quality results in various finishing applications.

3. Depth Adjustment

The depth adjustment mechanism on a pneumatic finishing nailer regulates the extent to which the fastener is driven into the material. This adjustment directly influences the finish quality and structural integrity of the fastened joint. A properly adjusted nailer sets the fastener flush with the surface, avoiding both protrusion (which poses a hazard and detracts from appearance) and over-driving (which damages the material and reduces holding power). The depth adjustment, therefore, is a critical component dictating the effectiveness and appropriateness of the tool for a given task.

Consider, for example, the task of attaching delicate trim to a cabinet. If the depth adjustment is set too high, the nailer will drive the fastener too deep, leaving an unsightly hole and potentially splitting the trim. Conversely, if the depth is set too low, the fastener will not be fully embedded, resulting in a weak or unstable joint. In both scenarios, the outcome is substandard. Another application involves securing baseboards to drywall. In this case, a depth adjustment ensuring the fastener penetrates the drywall and engages the framing behind it is essential for a secure, long-lasting attachment. The depth must be carefully calibrated to avoid damaging the drywall paper or weakening the joint.

In summary, the depth adjustment feature is indispensable for the versatility and utility of a pneumatic finishing nailer. Mastering this adjustment is essential for achieving professional-quality results across a range of applications. Improper adjustment leads to compromised aesthetics and diminished structural integrity. This fundamental control, therefore, represents a key indicator of proficient tool operation and skilled craftsmanship.

4. Safety Mechanisms

The inherent power of a pneumatic finishing nailer necessitates the incorporation of various safety mechanisms. These mechanisms are designed to mitigate risks associated with unintended nail discharge, recoil, and general tool handling, thereby protecting the operator and bystanders from potential injury.

- Contact Trip Mechanism

The contact trip, or nose piece, requires the tool to be pressed firmly against the work surface before a nail can be discharged. This prevents accidental firing when the trigger is pulled in open air or when the tool is inadvertently bumped. This is a standard feature in many nailers.

- Sequential Trigger System

Sequential trigger systems require the contact trip to be engaged before the trigger can be pulled. This two-step process further reduces the risk of accidental firing. Its presence provides an additional layer of protection.

- Adjustable Exhaust Port

The adjustable exhaust port allows the user to direct the expelled air and debris away from the face and body. By controlling the direction of the exhaust, the operator can minimize the risk of eye or respiratory irritation. Directing the exhaust away from the user enhances comfort and safety.

- Magazine Lockout

Some models feature a magazine lockout that prevents the tool from firing when the nail magazine is empty. This avoids dry firing, which can damage the tool and startle the user. This mechanism serves as a reminder to reload and prevents unnecessary wear.

The aforementioned safety mechanisms are essential components of a pneumatic finishing nailer, contributing to a safer working environment. Consistent adherence to manufacturer’s safety guidelines, combined with regular inspection and maintenance of these mechanisms, remains paramount for minimizing the potential for accidents during operation.

5. Tool Maintenance

The operational lifespan and reliability of a pneumatic finishing nailer are directly contingent upon diligent tool maintenance. Neglecting routine maintenance procedures precipitates a decline in performance, increased risk of malfunction, and ultimately, premature tool failure. The connection between maintenance and functionality is one of direct cause and effect; inadequate lubrication, for instance, leads to increased friction within the tool’s internal components, causing wear and diminished driving power. Similarly, the accumulation of debris and contaminants compromises the tool’s precision and responsiveness.

Consider the practical example of a contractor tasked with installing intricate crown molding. If the pneumatic finishing nailer employed for this task is not properly maintained, the likelihood of misfires and inconsistent nail depth increases significantly. This leads to damaged materials, increased labor costs due to rework, and potentially, a compromised reputation. Regular cleaning of the nailer’s nosepiece, lubrication of internal components with pneumatic tool oil, and inspection of the air hose and fittings are all essential maintenance procedures that mitigate these risks. Another relevant example is the potential for corrosion in humid environments. Without proper cleaning and storage practices, internal components can corrode, leading to a loss of air pressure and reduced driving force. A well-maintained tool ensures consistent, reliable performance, minimizing downtime and maximizing productivity.

In conclusion, tool maintenance is not merely a supplementary activity but an integral component of pneumatic finishing nailer ownership. The investment of time and resources in routine maintenance procedures yields significant returns in terms of extended tool life, consistent performance, and reduced operational costs. Disregarding maintenance protocols presents substantial risks, ultimately undermining the tool’s effectiveness and increasing the potential for costly repairs or replacements. Prioritizing proper care ensures the continued utility and reliability of this essential woodworking tool.

6. Material Compatibility

Material compatibility, in the context of pneumatic finishing nailers, denotes the suitability of a given material for fastening with the tool, considering both the properties of the material and the capabilities of the nailer. Understanding this relationship is essential for achieving secure, aesthetically pleasing, and structurally sound results.

- Wood Density

Wood density significantly impacts fastener penetration and holding power. Softer woods, such as pine or cedar, require lower air pressure settings and finer gauge fasteners to prevent over-driving and splitting. Conversely, harder woods, such as oak or maple, necessitate higher pressure and potentially coarser gauge fasteners to ensure adequate penetration and secure fastening. Failure to account for wood density results in either insufficient holding strength or material damage.

- Material Thickness

Material thickness dictates the appropriate fastener length. Using excessively long fasteners in thin materials presents a risk of protrusion and potential injury. Conversely, using fasteners that are too short in thicker materials results in inadequate holding power. The correct fastener length should penetrate at least two-thirds of the total material thickness to ensure a secure and durable joint.

- Pre-existing Conditions

Pre-existing conditions, such as knots, grain patterns, or moisture content, influence the ease and effectiveness of fastening. Knots can deflect fasteners, leading to misfires or weakened joints. Grain patterns can contribute to splitting, particularly when fasteners are driven parallel to the grain. High moisture content can cause wood to swell and contract, potentially loosening fasteners over time. Assessing these conditions prior to fastening allows for adjustments in technique or fastener selection to mitigate potential issues.

- Alternative Materials

While primarily designed for wood, pneumatic finishing nailers are occasionally employed with other materials such as MDF (Medium Density Fiberboard) or certain plastics. However, compatibility must be carefully considered. MDF is prone to crumbling if fasteners are over-driven, requiring precise depth adjustment and careful fastener selection. Plastics can be brittle and prone to cracking. Test fastenings should be performed on scrap material to assess compatibility before proceeding with the final application.

These facets underscore the importance of material compatibility in the context of pneumatic finishing nailers. Selecting appropriate settings, fasteners, and techniques, based on a thorough understanding of the material’s properties and pre-existing conditions, is essential for maximizing the tool’s effectiveness and achieving professional-quality results. A lack of consideration for material compatibility can result in compromised structural integrity, aesthetic imperfections, and potentially unsafe outcomes.

Frequently Asked Questions

This section addresses common inquiries regarding the operation, maintenance, and safety of pneumatic finishing nailers. The information provided aims to enhance user understanding and promote safe and effective tool utilization.

Question 1: What is the optimal air pressure range for operating a pneumatic finishing nailer?

The optimal air pressure range varies depending on the specific model and the material being fastened. Consult the manufacturer’s specifications for recommended pressure settings. Exceeding or falling below this range may result in improper fastener depth and potential tool damage.

Question 2: How frequently should a pneumatic finishing nailer be lubricated?

Lubrication frequency depends on the intensity of use. For regular use, lubrication with pneumatic tool oil is recommended daily or before each extended work session. Infrequent use necessitates lubrication before each operation to ensure optimal performance.

Question 3: What types of safety equipment are necessary when operating a pneumatic finishing nailer?

Eye protection, in the form of safety glasses or goggles, is mandatory to protect against flying debris. Hearing protection, such as earplugs or earmuffs, is recommended, particularly during prolonged use, to mitigate noise-induced hearing damage.

Question 4: What causes a pneumatic finishing nailer to misfire, and how can this be prevented?

Misfires can result from several factors, including insufficient air pressure, incorrect fastener selection, a dirty or damaged nosepiece, or a malfunctioning trigger mechanism. Prevention involves ensuring adequate air pressure, using the correct fasteners, regularly cleaning the nosepiece, and periodically inspecting the trigger mechanism.

Question 5: What is the purpose of the depth adjustment feature on a pneumatic finishing nailer?

The depth adjustment feature regulates the depth to which fasteners are driven into the material. This adjustment is critical for setting fasteners flush with the surface without overdriving and damaging the material or underdriving and compromising the joint’s integrity.

Question 6: How should a pneumatic finishing nailer be stored when not in use?

When not in use, the tool should be disconnected from the air supply, cleaned to remove any debris, and stored in a dry, secure location. This helps to prevent corrosion, damage to internal components, and unauthorized use.

Adherence to these guidelines promotes safety, enhances performance, and extends the lifespan of the pneumatic finishing nailer.

The subsequent section will discuss troubleshooting common issues that may arise during operation.

Conclusion

The preceding discussion has explored critical aspects of the pneumatic finishing nailer, encompassing operational techniques, safety protocols, maintenance procedures, and material compatibility. Understanding these elements is paramount for responsible and effective utilization of this powerful tool.

The consistent application of the knowledge presented herein serves as a foundation for both skilled craftsmanship and accident prevention. Continued diligence in these matters will ensure the pneumatic finishing nailer remains a valuable asset, delivering reliable performance and professional results while minimizing risks in the work environment.